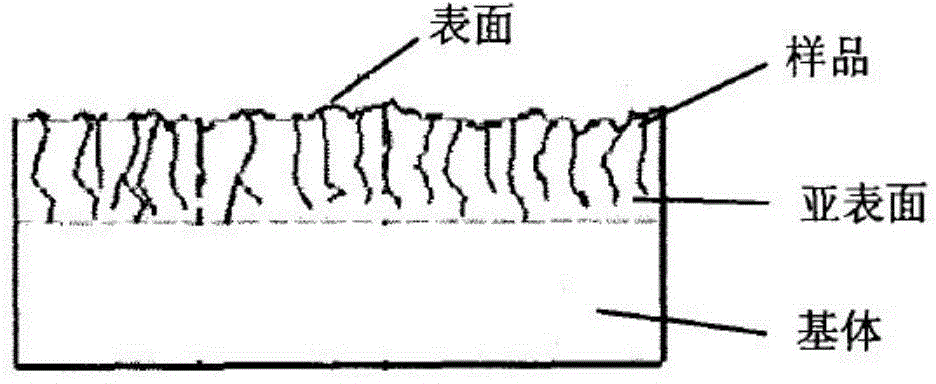

Method for evaluating material sub-surface machining damage layer thickness

A technology of subsurface damage and damage layer, which is applied in the evaluation field of material subsurface processing damage layer thickness, can solve the problem of non-damage detection difficulty of subsurface damage layer thickness, achieve wide applicability and reduce the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

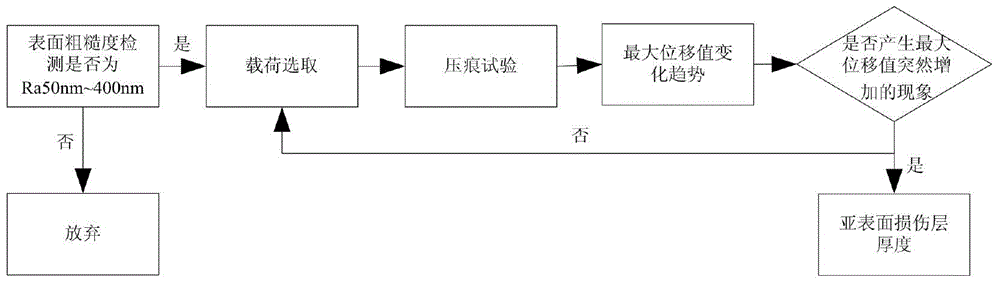

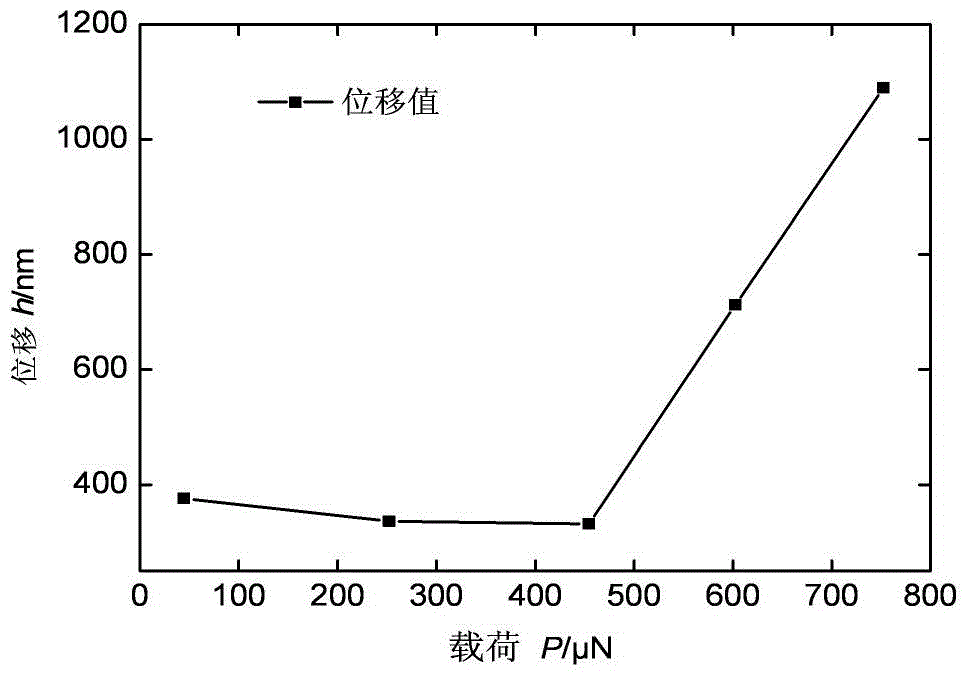

[0029] The evaluation method of the present invention first detects the surface roughness of the material sample: if the range of the surface roughness of the material sample is not within Ra50nm~400nm, the test is abandoned; if the range of the surface roughness of the material sample is Ra50nm~400nm; then the material sample is tested. Indentation test; the process is as follows: first set the load, with 45μN as the initial load and 50-200μN as the increment, set the load in turn, and the end load is 1500μN; the increment between every two adjacent set loads It can be the same or different; then carry out the indentation test on the material sample, carry out the loading-unloading test in order according to the set load from small to large and record the maximum displacement value of the indenter in each load loading-unloading test; when When the maximum displacement value produced by the selected load increases by more than 50% compared with the maximum displacement value pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com