Engineering glue spray curing device based on vortex tube

A vortex tube and glue technology, applied in chemical instruments and methods, cleaning methods using gas flow, coatings, etc., can solve the problem of high cost, achieve comprehensive functions, save construction period, and shorten construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

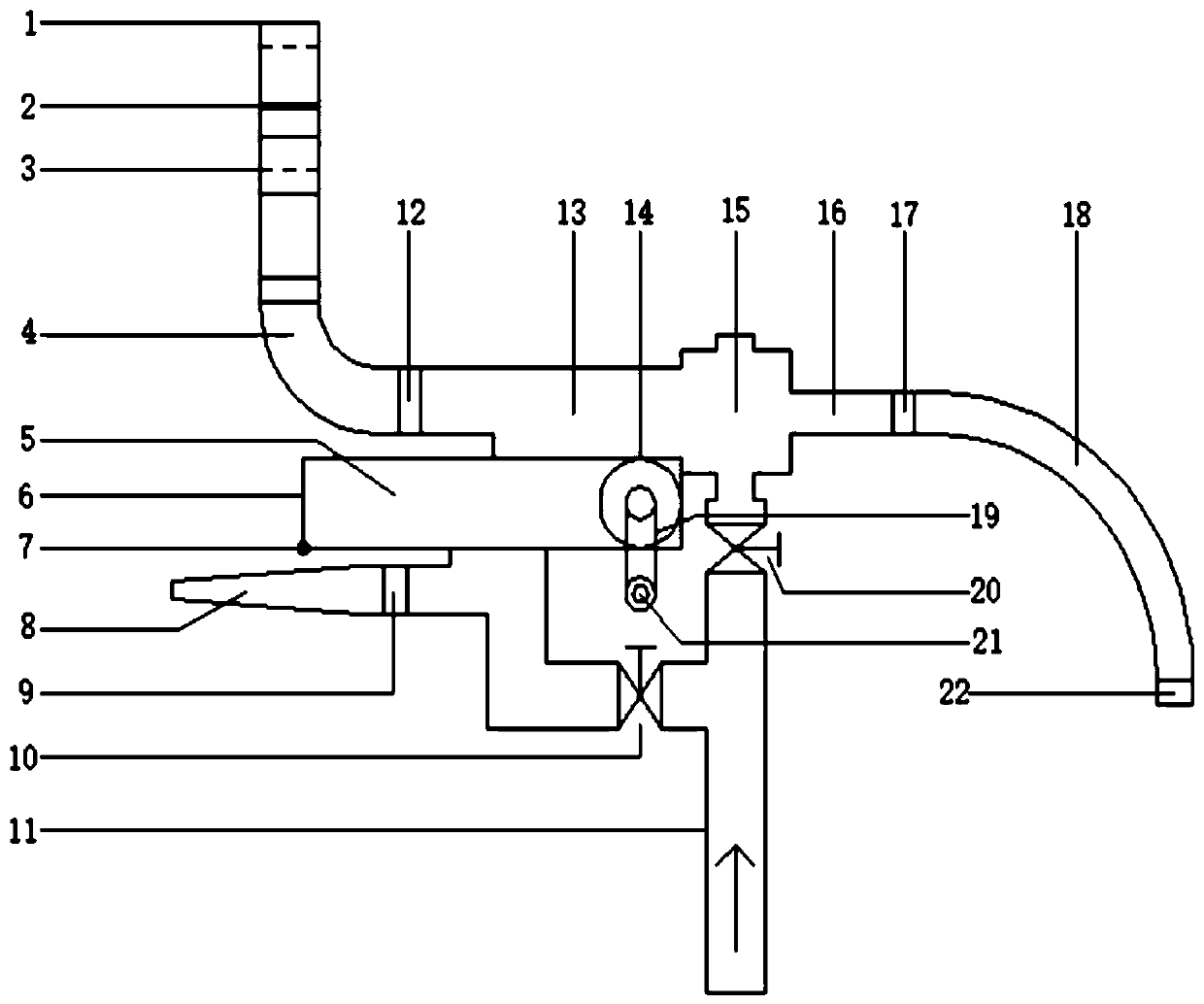

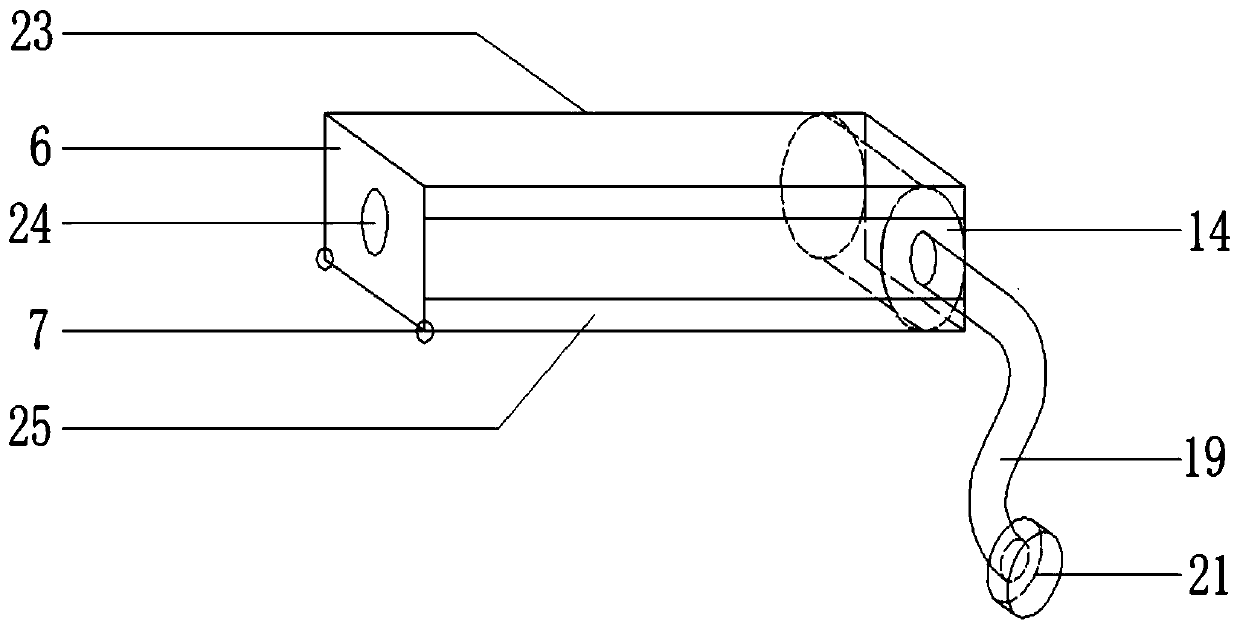

[0027] The specific technical solutions of the present invention are described in conjunction with the accompanying drawings.

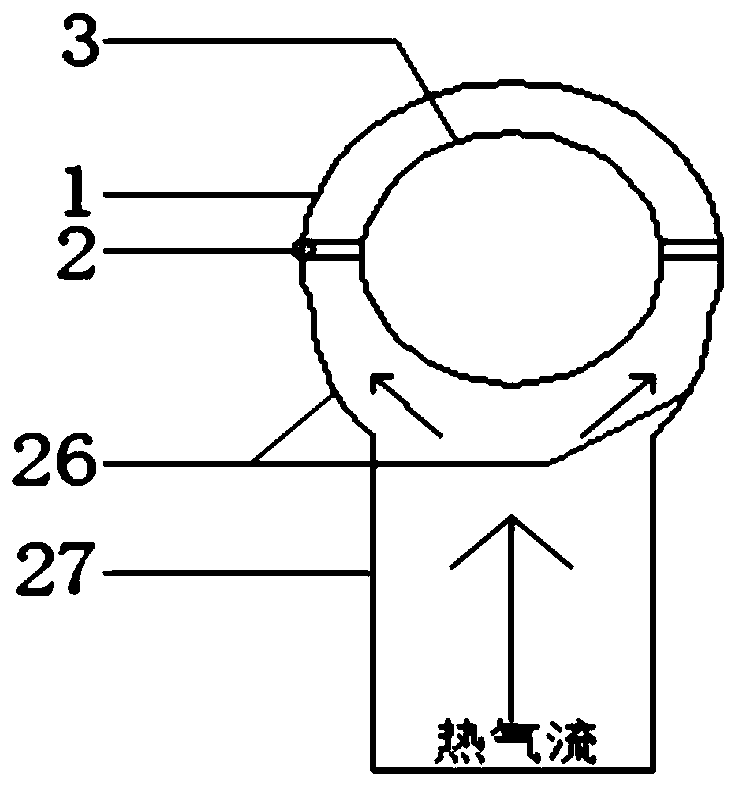

[0028] like figure 1 As shown, the engineering glue spraying curing device based on the vortex tube includes a horizontal cylindrical annular heating curing device, and the annular heating curing device includes an outer ring 1 and an inner ring 3 installed on the coaxial core line, A closed airflow channel is formed between the outer ring 1 and the inner ring 3, and the inner ring 3 is provided with a plurality of pores; the ring-shaped heating and curing device is divided into an upper part and a lower part, and one side of the upper part and the lower part is passed through a card The mouth shaft is connected by 2, and the other side is opened and closed; it is convenient for the heating and curing operation of the pipes to be cured with different pipe diameters, ensuring that they can be clamped during heating and curing, and the bayonet shafts ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com