Preparation method of high-hydrophobicity leather coating agent

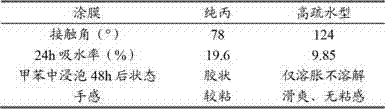

A leather finishing agent, high hydrophobic technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve water resistance and solvent resistance Poor resistance and other problems, to achieve the effect of improving water resistance and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) First heat the three-necked flask in a water bath to 45°C, and then add 22 parts of a deionized aqueous solution containing 0.6 parts of emulsifier and 0.1 part of sodium bicarbonate to the three-necked flask according to the mass parts. After the emulsification is uniform, add another 5 parts Mix monomer A, stir for 20 minutes, then add 3.5 parts of deionized aqueous solution with 0.06 part of ammonium persulfate dissolved, stir for 30 minutes, heat up to 75°C, react for 30 minutes to obtain a seed emulsion;

[0019] 2) Use a constant pressure funnel to simultaneously drop a core layer pre-emulsion composed of 0.1 parts of emulsifier, 2.5 parts of deionized water, 5.5 parts of mixed monomer A and 3 parts of 0.024 parts of initiator ammonium persulfate dissolved into the seed emulsion. Deionized water, after 2h dripping, the core layer emulsion is formed after the constant temperature reaction is completed;

[0020] 3) Then through a constant pressure funnel, add dropwise...

Embodiment 2

[0025] 1) First heat the three-necked flask in a water bath to 47°C, and then add 22 parts of a deionized aqueous solution containing 0.6 parts of emulsifier and 0.12 parts of sodium bicarbonate to the three-necked flask according to the mass parts. After the emulsification is uniform, add another 5 parts Mix monomer A, stir for 20 minutes, then add 3.5 parts of a deionized aqueous solution containing 0.08 parts of potassium persulfate, stir for 30 minutes, heat up to 77°C, and react for 30 minutes to obtain a seed emulsion;

[0026] 2) Use a constant pressure funnel to simultaneously drop a core layer pre-emulsion composed of 0.1 parts of emulsifier, 2.5 parts of deionized water, 5.5 parts of mixed monomer A and 3 parts of 0.030 parts of initiator potassium persulfate dissolved into the seed emulsion. Deionized water, after 2.5 hours of dripping, the core layer emulsion is formed after the constant temperature reaction is completed;

[0027] 3) Then through a constant pressure fun...

Embodiment 3

[0032] 1) First heat the three-necked flask in a water bath to 50°C, then add 22 parts of a deionized aqueous solution containing 0.6 parts of emulsifier and 0.14 parts of sodium bicarbonate to the three-necked flask according to mass parts, and add 5 parts after the emulsification is uniform Mix monomer A, stir for 20 minutes, then add 3.5 parts of deionized aqueous solution with 0.07 part of ammonium persulfate dissolved, stir for 30 minutes, heat up to 79°C, react for 30 minutes to obtain a seed emulsion;

[0033] 2) Use a constant pressure funnel to simultaneously drop a core layer pre-emulsion composed of 0.1 parts of emulsifier, 2.5 parts of deionized water, 5.5 parts of mixed monomer A and 3 parts of 0.028 parts of initiator ammonium persulfate dissolved into the seed emulsion. Deionized water, after 2h dripping, the core layer emulsion is formed after the constant temperature reaction is completed;

[0034] 3) Then through a constant pressure funnel, add dropwise a shell pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com