Inductor manufacturing method

A manufacturing method and technology of inductors, applied in the field of inductors, can solve the problems of poor electrical performance and poor heat dissipation effect of inductors, and achieve the effects of good thermal conductivity, good EMI effect and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

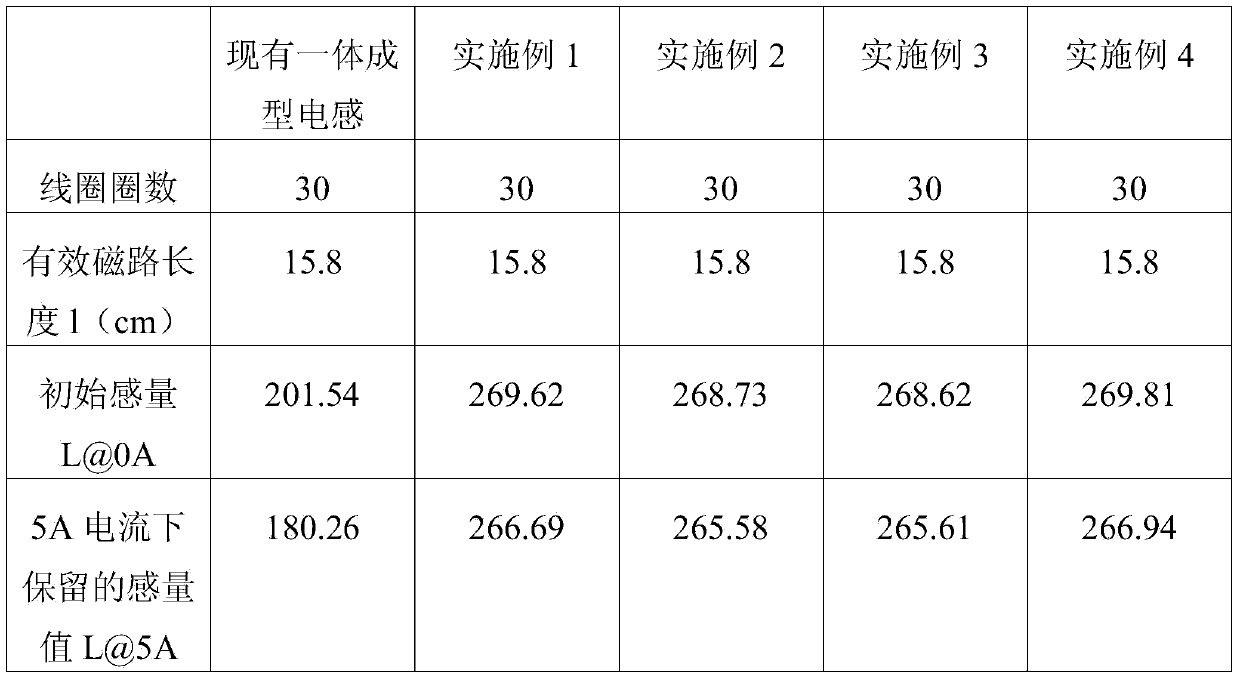

Embodiment 1

[0037] A method for manufacturing an inductor in this embodiment includes the following steps:

[0038] (1) Through the automatic winding machine, the enameled wire coil is wound into a spiral shape;

[0039] (2) compressing the first ferromagnetic powder into a magnetic core by a powder molding press;

[0040] (3) Put the magnetic core into the hollow cavity of the enameled wire coil;

[0041] (4) the enameled wire coil that magnetic core is housed is packed in the injection mould;

[0042] (5) uniformly stirring the second ferromagnetic powder with the high-temperature resin glue and the binder successively to obtain the feeding material of the mixed powder;

[0043] (6) The mixed powder is granulated and injected into the cavity of the injection mold for sintering to obtain the outer magnet, and the density of the outer magnet is ensured to be lower than the density of the magnetic core.

[0044] (7) Cooling and stripping to obtain a molded inductor.

[0045] (8) A heat...

Embodiment 2

[0049] In this embodiment, the difference from embodiment 1 is that the density of the outer magnet is 5.5g / cm 3 , the core density is 6.0g / cm 3 ; The radiator is made of pure copper material. Other steps in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0051] In this embodiment, the difference from Embodiment 1 is that the density of the external magnet is 5.0 g / cm 3 , the core density is 7.0g / cm 3 . Other steps in this embodiment are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com