Patents

Literature

40results about How to "Good EMI effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

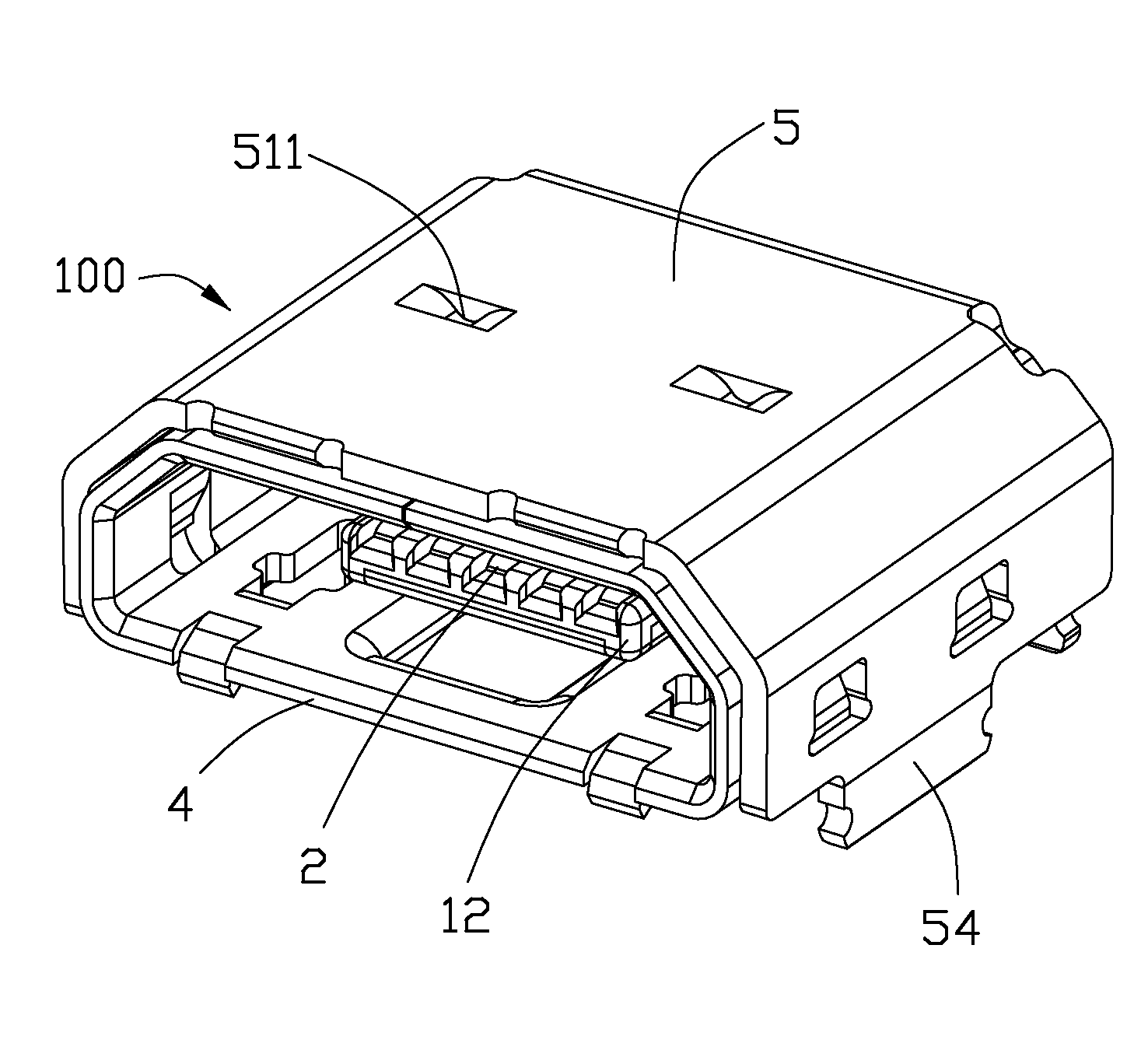

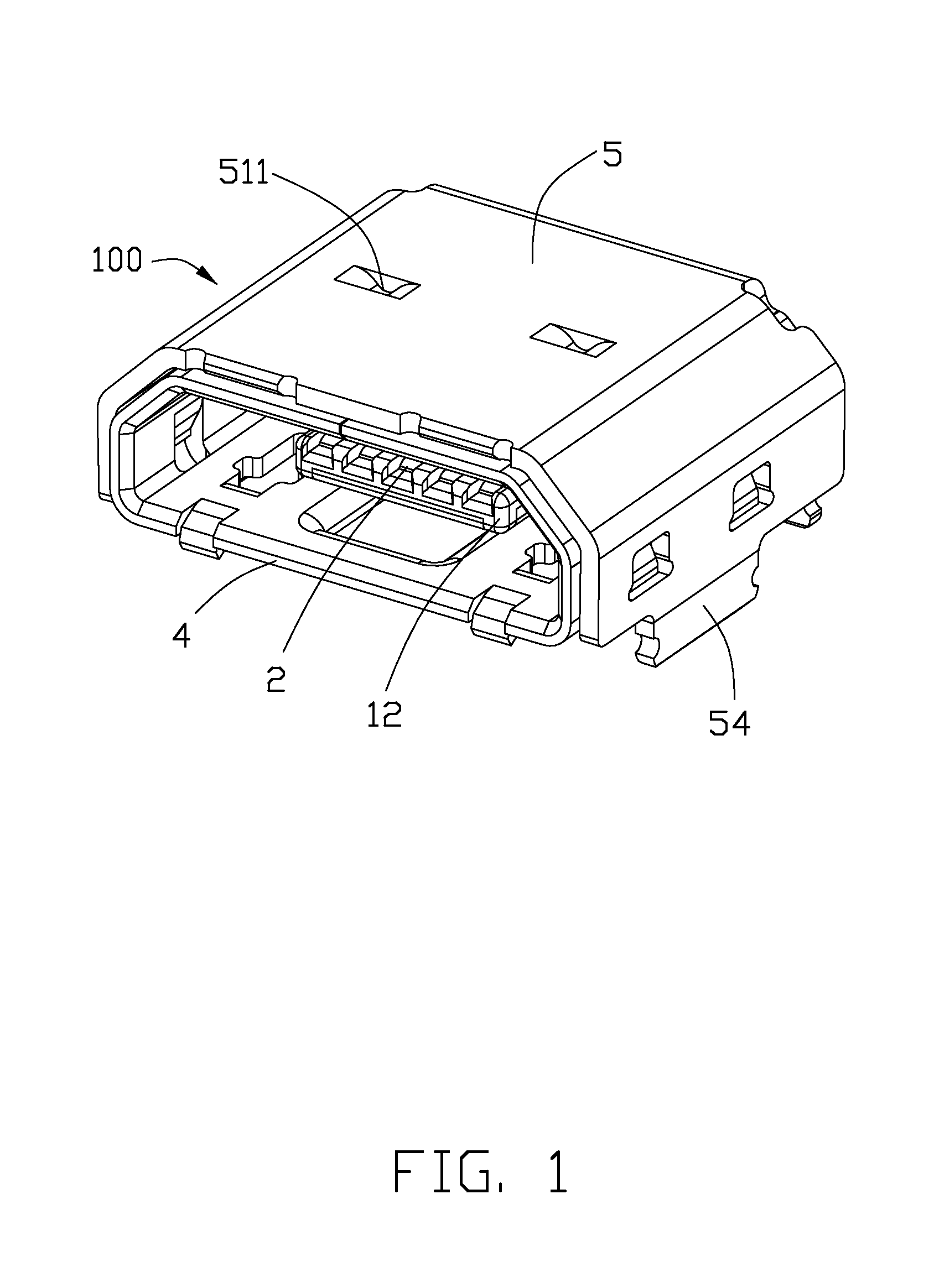

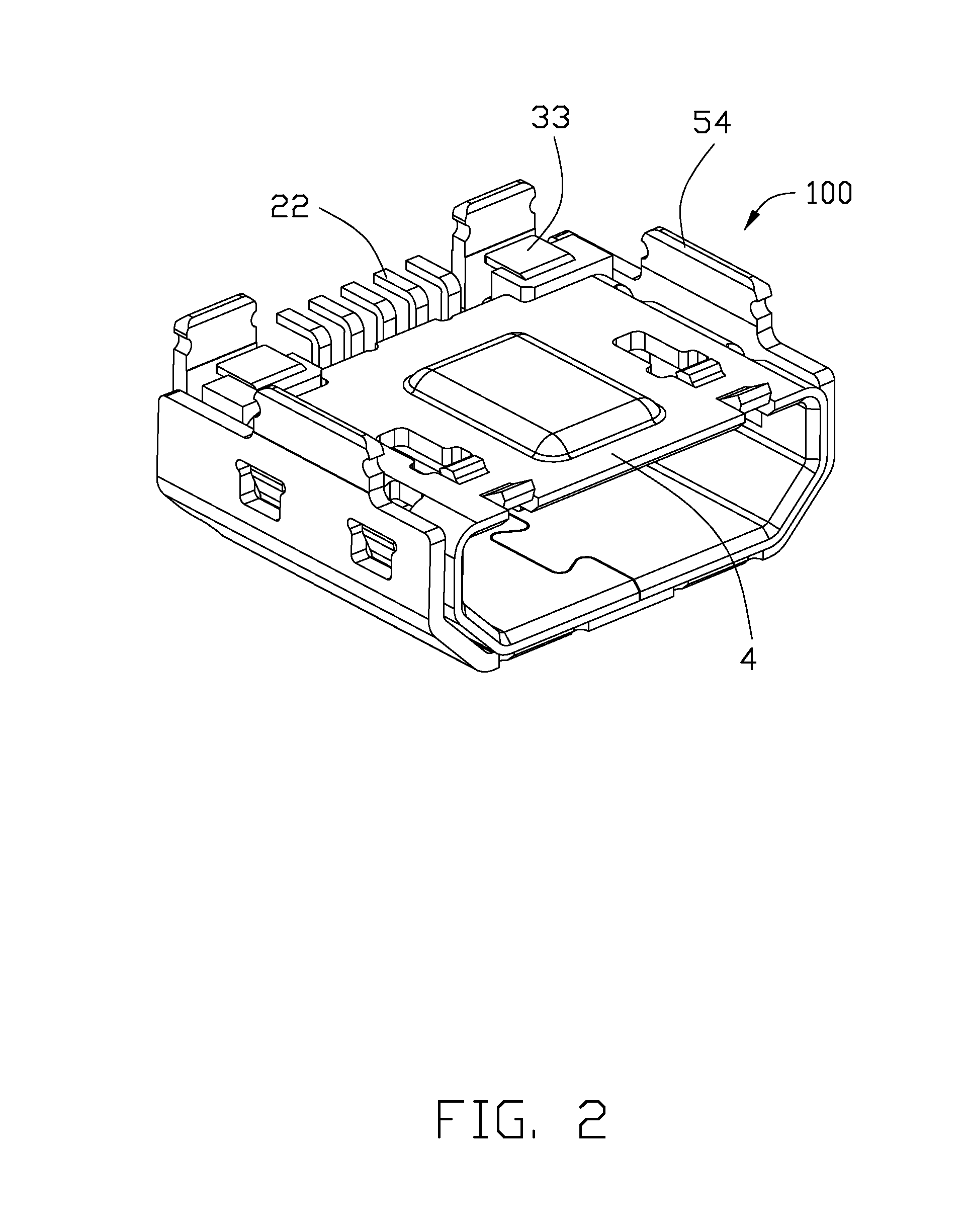

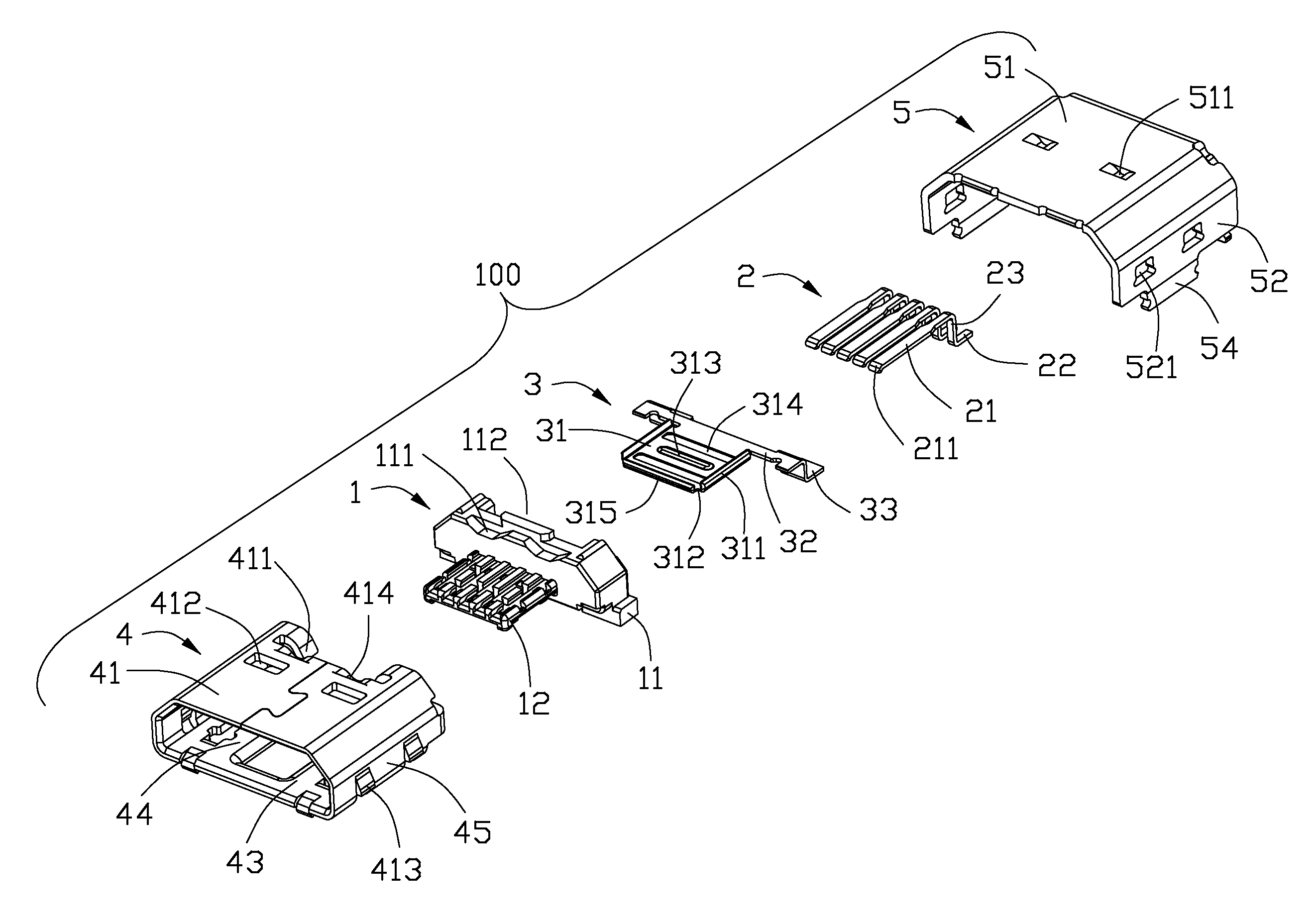

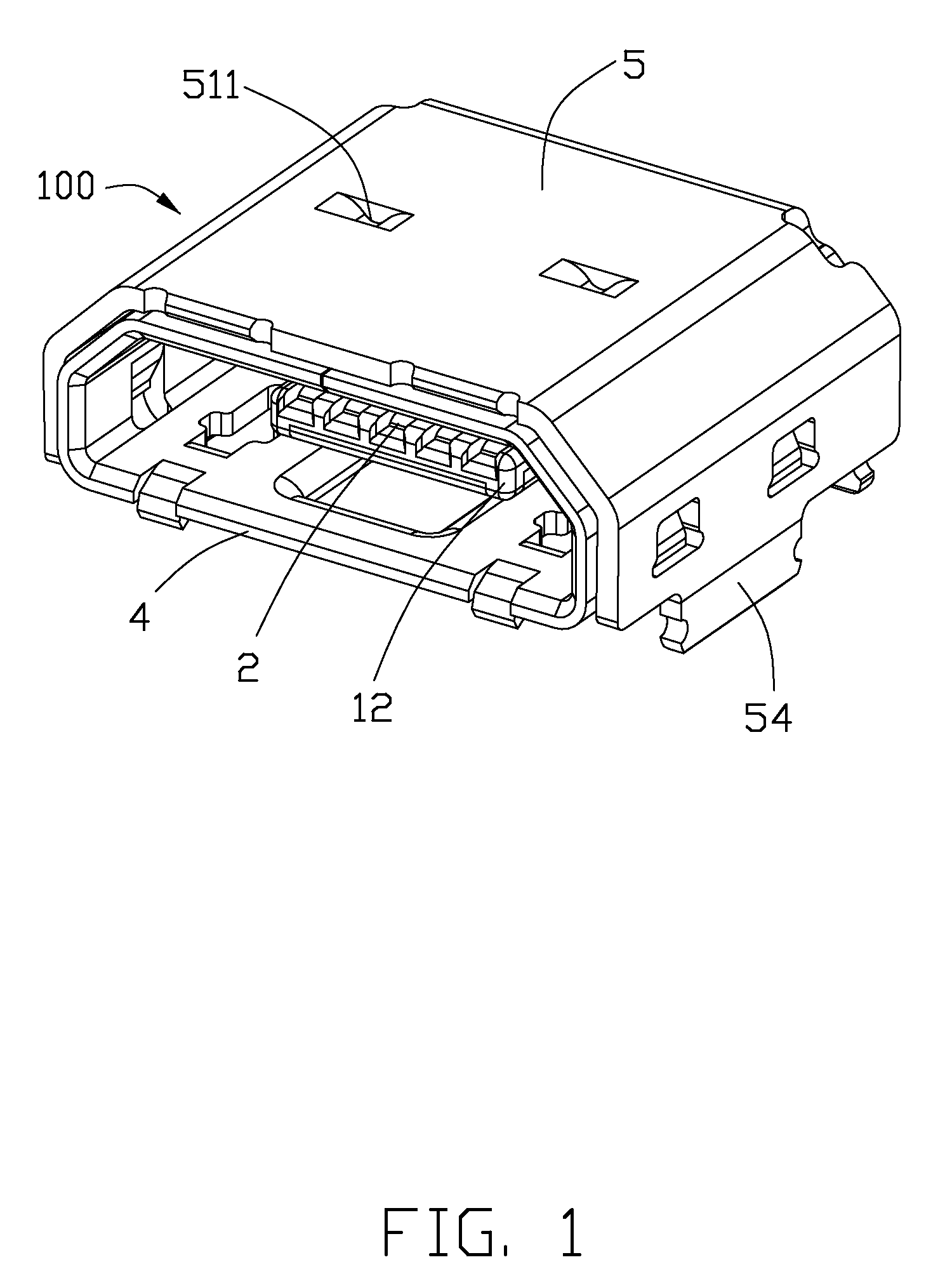

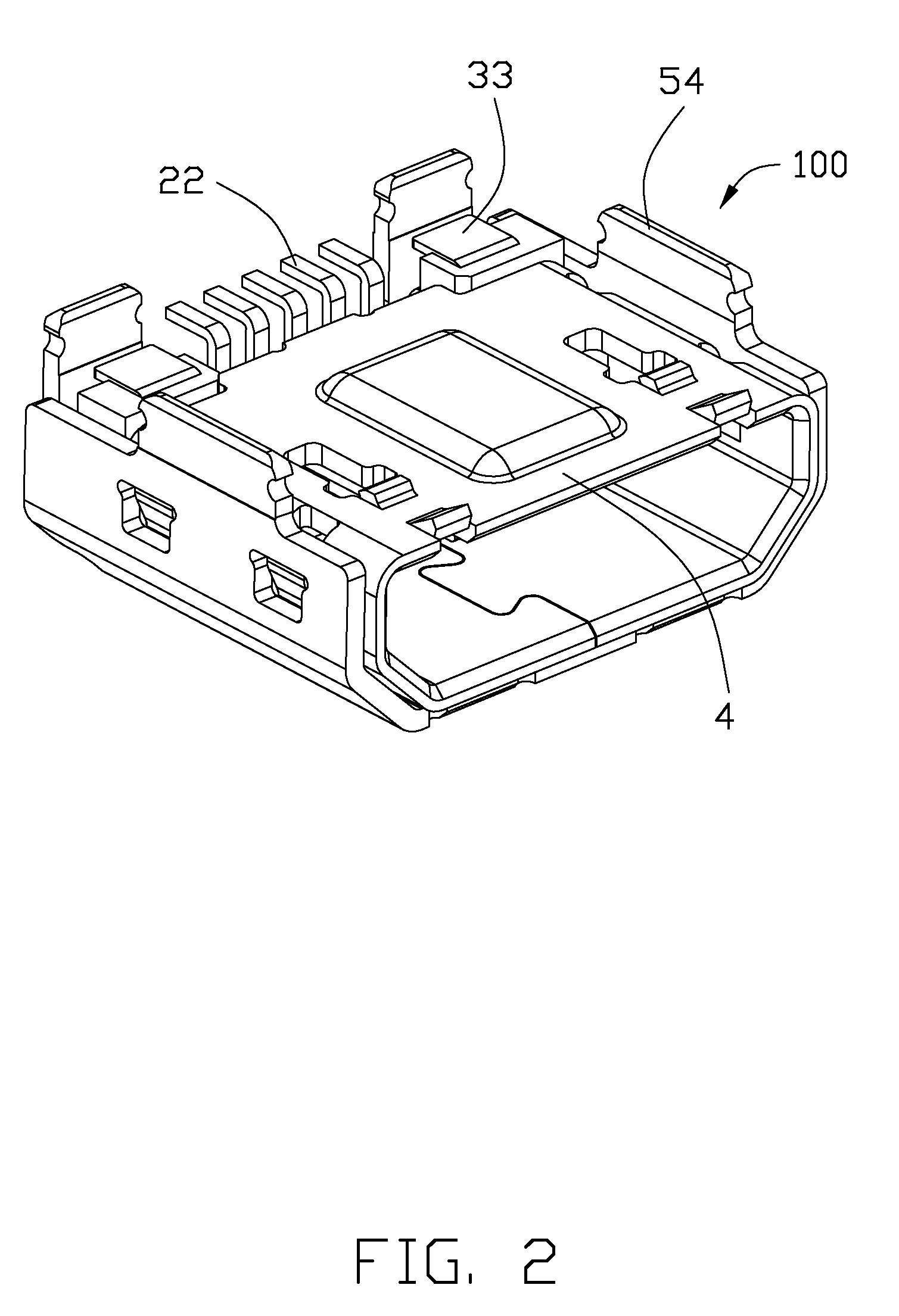

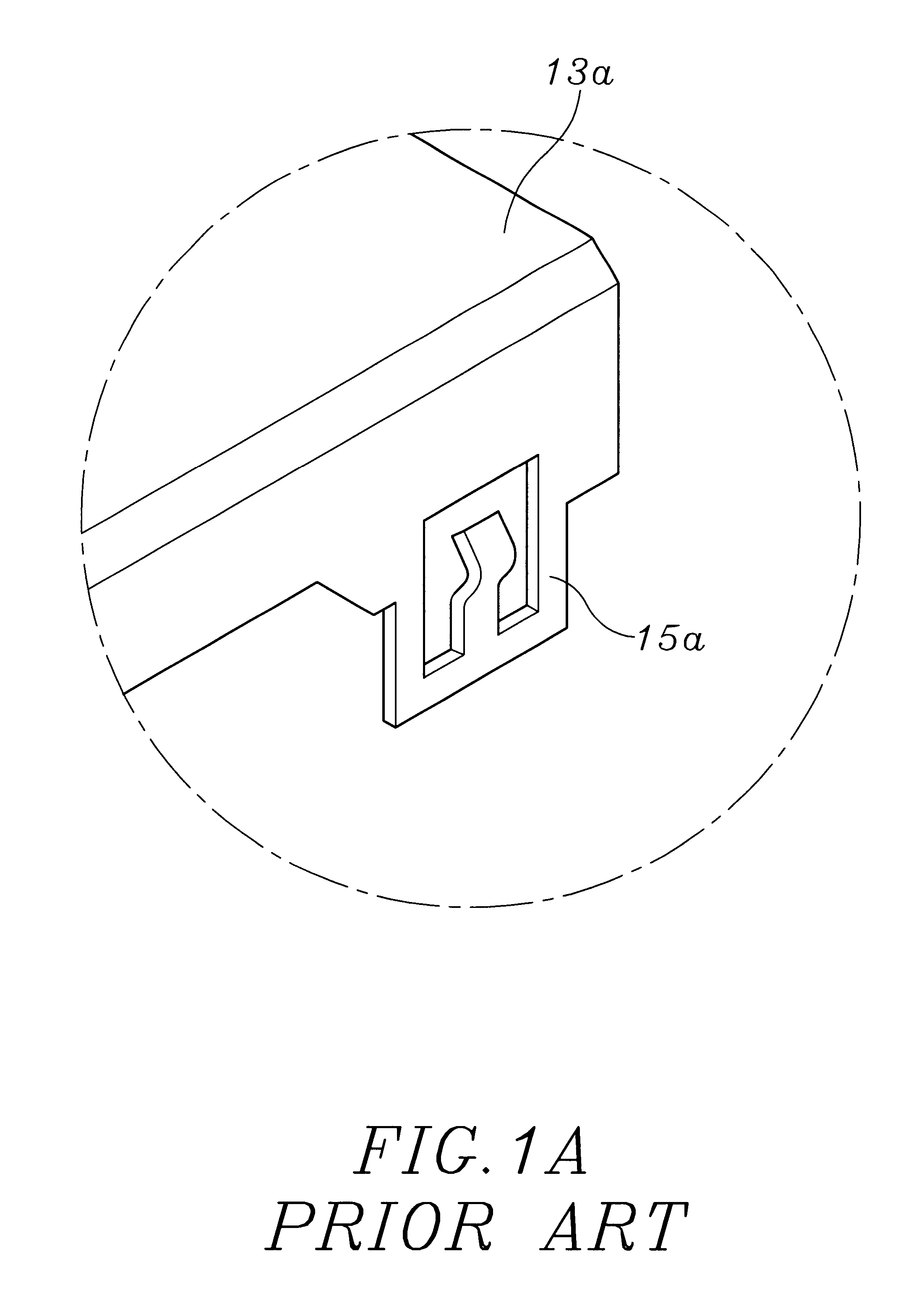

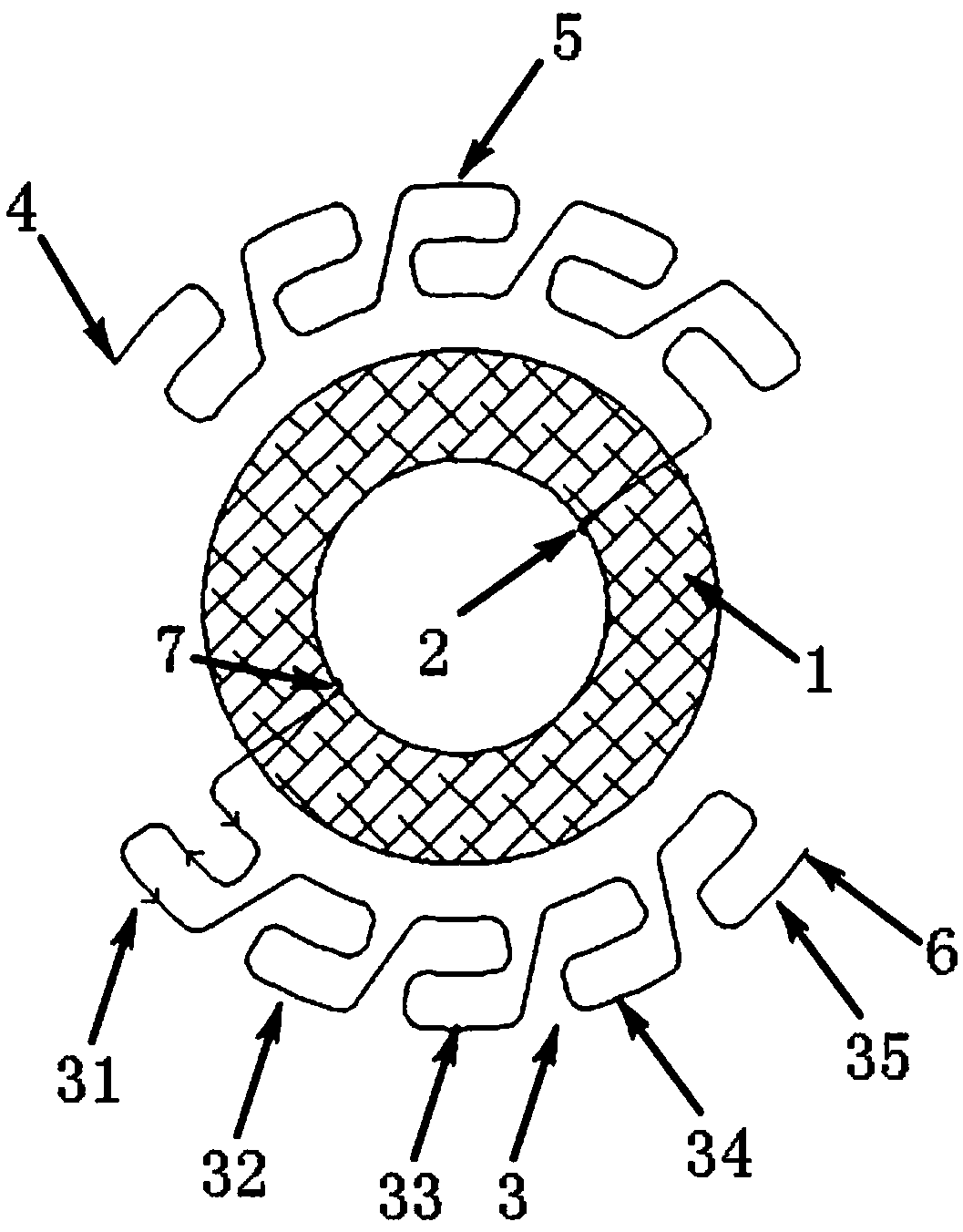

Electrical connector with a metal plate for preventing electromagnetic interference

ActiveUS20140073184A1Good EMI effectElectrically conductive connectionsCoupling protective earth/shielding arrangementsPrinted circuit boardElectromagnetic interference

An electrical connector (100) includes an insulative housing (1), a number of contact terminals (2), a metal plate (3), and a metallic shell (4) enclosing the insulative housing (1). The terminals and the metal plate (3) are retained in the insulative housing (1). The insulative housing (1) includes a base portion (11) and a tongue portion (12) extending forward from the base portion (11). The contact terminal includes a contacting portion (21), a tail (22), and a connecting portion (23) connecting the contacting portion (21) and the tail (22). The tails (22) are positioned out of the insulative housing (1). The metal plate (3) has a number of positioning end portions (33). The positioning end portions (33) are soldered on a printed circuit board for grounding. The electrical connector (100) has improved electromagnetic interference effect.

Owner:HON HAI PRECISION IND CO LTD

Electrical connector with a metal plate for preventing electromagnetic interference

ActiveUS9106024B2Good EMI effectElectrically conductive connectionsCoupling device detailsElectromagnetic interferenceEngineering

Owner:HON HAI PRECISION IND CO LTD

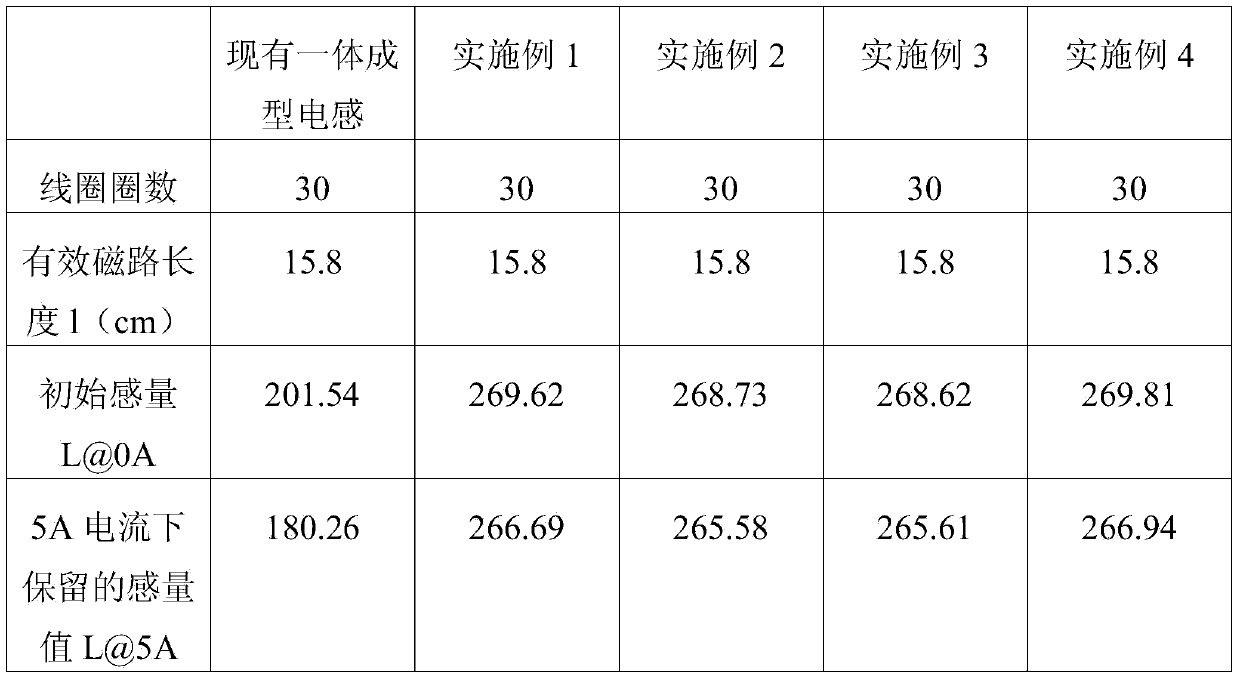

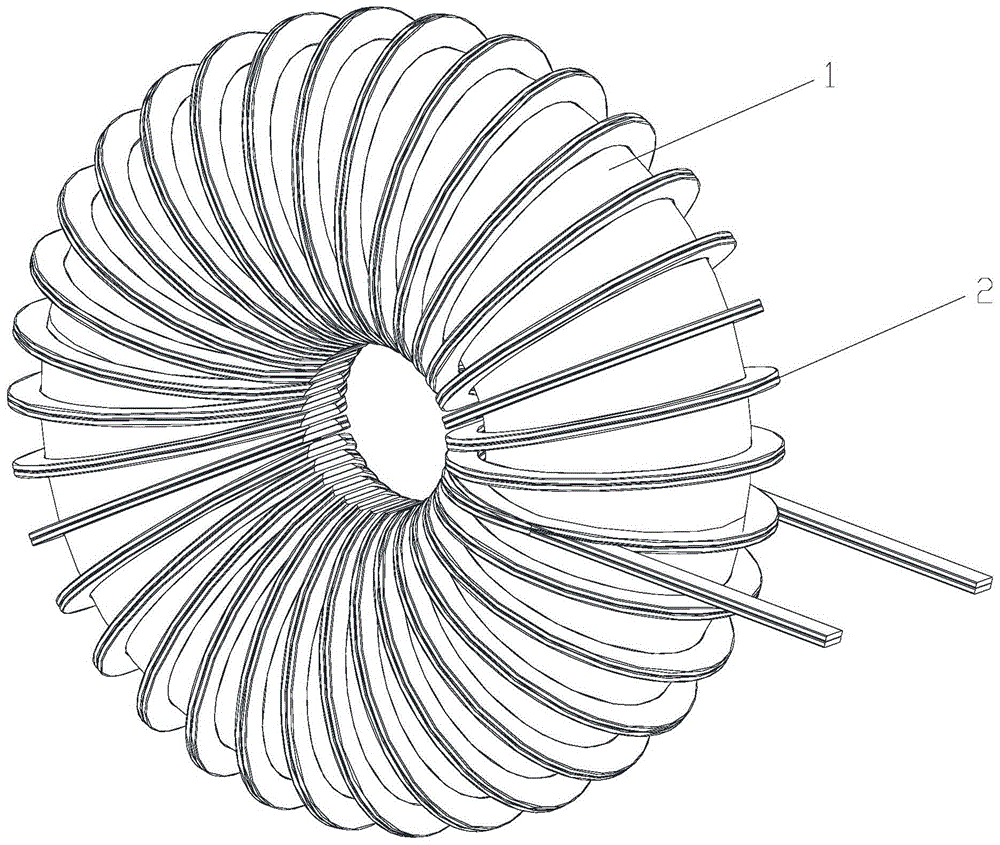

Inductor manufacturing method

InactiveCN104200981ASimple production processRealize automated manufacturingInductances/transformers/magnets manufactureInductance with magnetic coreInductorInductance

The invention provides an inductor manufacturing method. The method includes the following steps that first, an enameled wire coil is wound; second, first ferromagnetic powder is pressed into a magnetic core; third, the magnetic core is installed in a hollow cavity of the coil; fourth, the coil is installed in an injection mold; fifth, second ferromagnetic powder and high-temperature resin are evenly stirred and mixed power can be obtained; sixth, the mixed powder is injected into the injection mold and formed so that an outer magnet can be obtained, and it is guaranteed that the density of the outer magnet is smaller than that of the magnetic core; seventh, cooling and demolding are performed so that an inductor can be obtained. The inductor manufactured according to the scheme has the advantages that the inductor is good in thermal conductivity and long in service life; the density of the magnetic core is different from that of the outer magnet, a totally-sealed magnetic shielding structure is achieved as a whole, and the EMI effect of the inductor is better compared with that of an existing integrally formed inductor; the problem that a coil is damaged by mechanical stress in the original integrally formed inductor is solved, and in other words, the insulating capacity of the original coil is not weakened.

Owner:POCO HLDG CO LTD

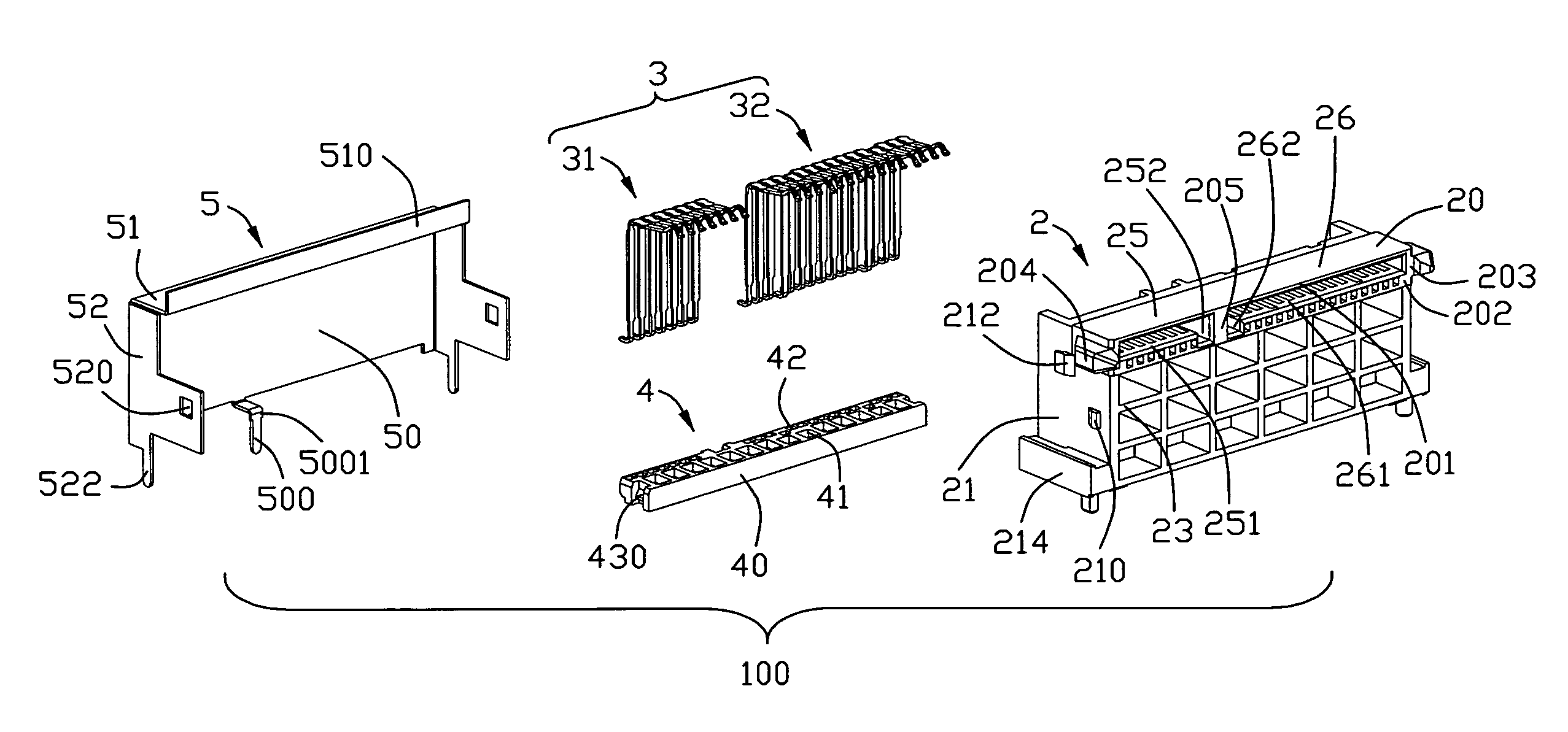

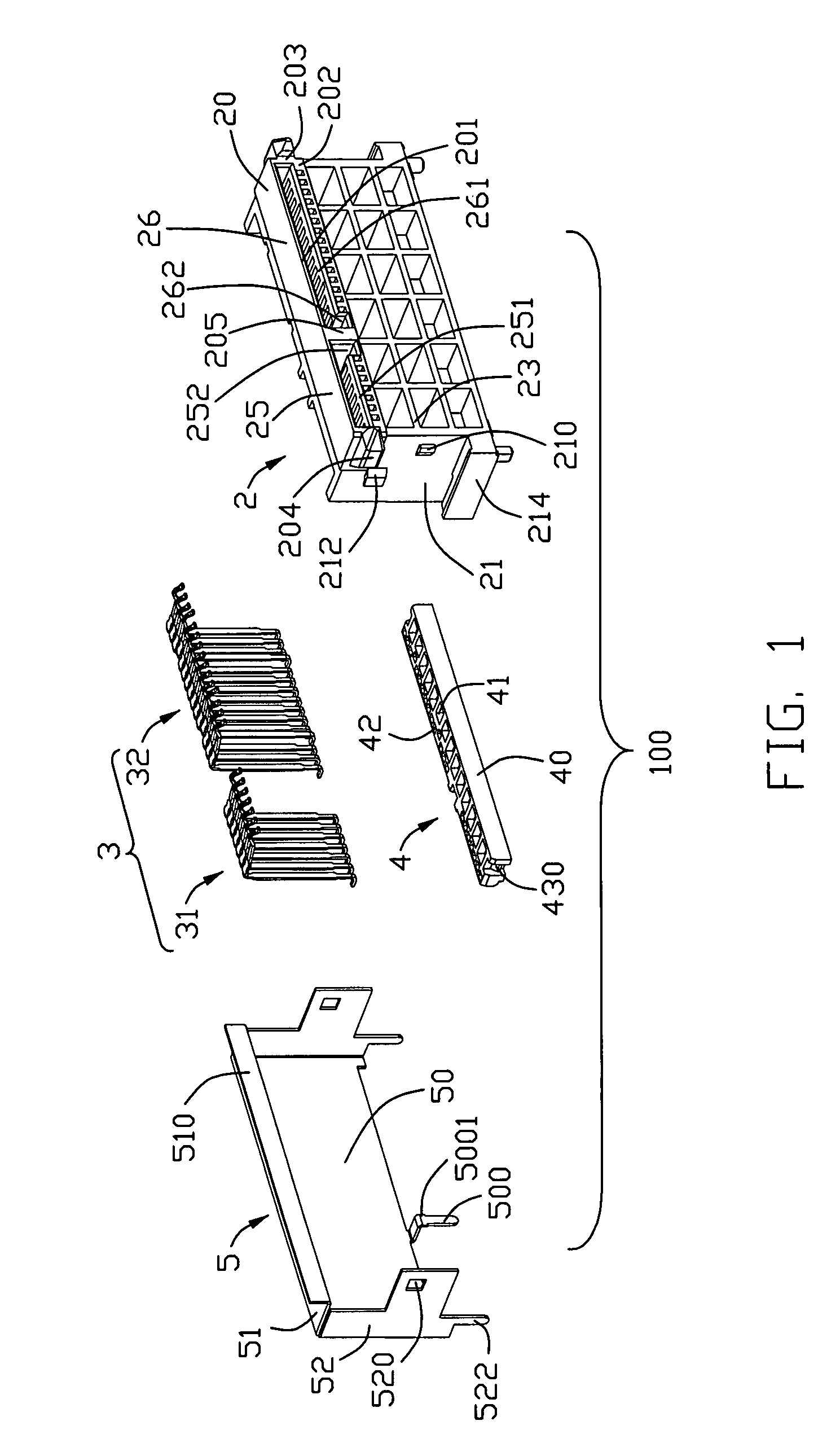

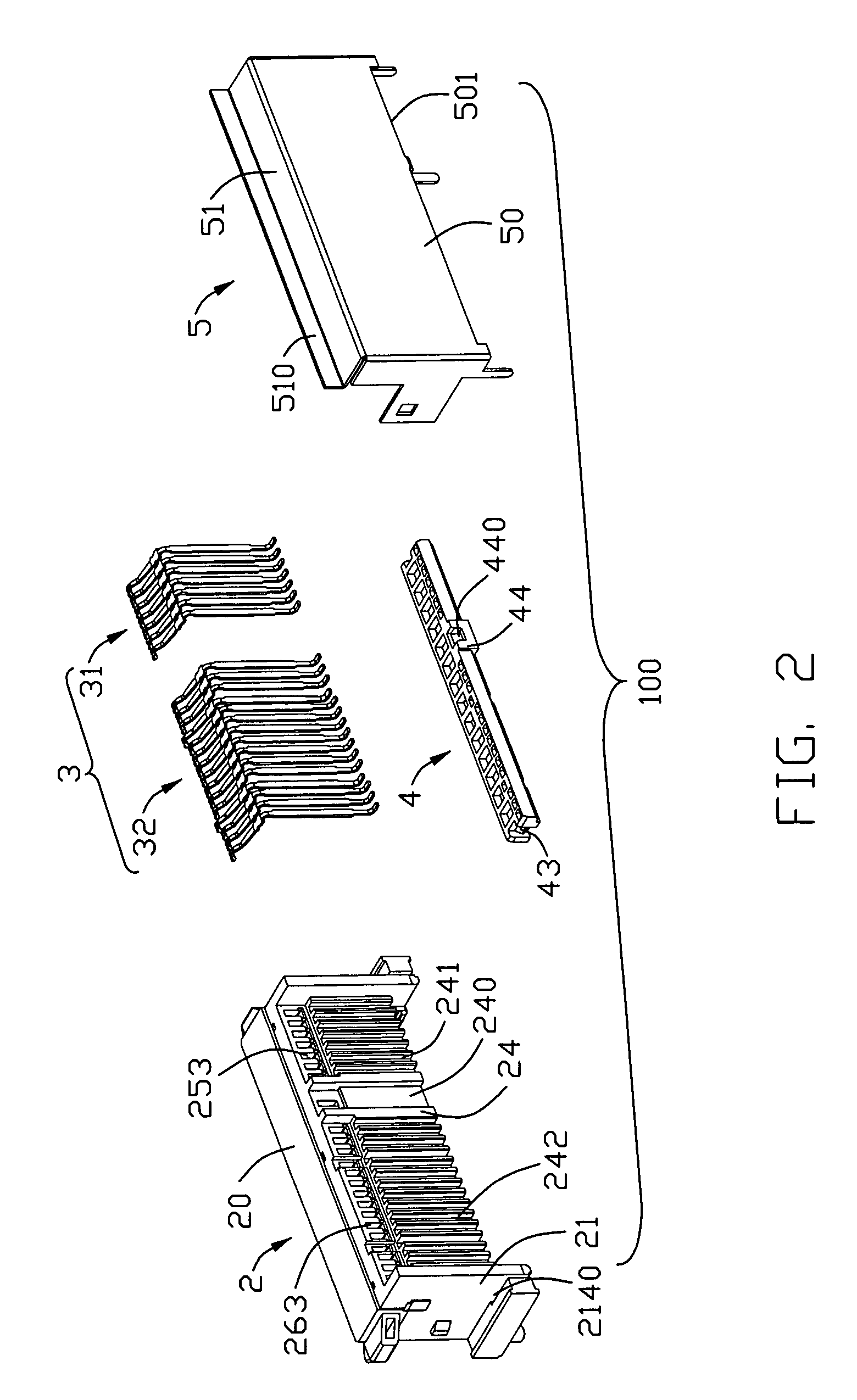

Electrical connector

InactiveUS7473133B1Improve EMI effectFacilitate conductionElectrically conductive connectionsPrinted circuitsEngineeringElectrical connector

An electrical connector (100) includes an insulative housing (2), a number of first and second contacts (31, 32) accommodated in the insulative housing and a conductive shell (5). The insulative housing includes first and second mating segments (25, 26) side by side arranged along a lateral direction perpendicular to a mating direction and divided by a partition wall (205), and a rear wall (24) extending downwardly from rear ends of the first and second mating segments and forming a division section to divide the rear wall into two parts corresponding to the first and second mating segments. The first and second contacts are received in the insulative housing with mating portions (30) thereof received in the first and second mating segments, and leg portions (34) bending downwardly to be located in the two parts of the rear wall. The conductive shell encloses the insulative housing and the contacts except the first and second mating segments and mating portions of the contacts. The conductive shell forms a solder foot (500) aligning with the division section of the rear wall of the insulative housing for being assembled to a printed circuit board.

Owner:HON HAI PRECISION IND CO LTD

Novel high-density magnetic composite material for inductor

ActiveCN104867640AEasy to produceReduce investmentInorganic material magnetismInitial permeabilityHigh density

The invention discloses a novel high-density magnetic composite material for an inductor. The novel high-density magnetic composite material for the inductor comprises, by weight, 6%-12% of high-temperature resin adhesive and 88%-94% of magnetic powder. When the magnetic composite material is used for manufacturing a magnetic core of the inductor, production is easy, no large pressing machine is needed, and equipment investment is saved; mold losses during pressing are reduced, and production cost is reduced; operation is easy, a magnet in a complicated shape can be produced, and a super-large magnet can also be produced; a closed loop is formed, and the EMI effect is good. According to the magnetic composite material, through the action of the special high-temperature resin glue, the density of the solidified magnet is high, it can be guaranteed that the density ranges from 5.5 g / cm<3> to 6.2 g / cm <3>, the induction quantity value of the manufactured inductor is high, and the initial permeability reaches over 14 microns; the magnetic composite material can bear high temperature and can work under the 180 DEG C environment; the magnetic composite material is high in utilization rate, waste is little, powder is little, and the requirement for environmental friendliness is met.

Owner:河源市铂科新材料有限公司

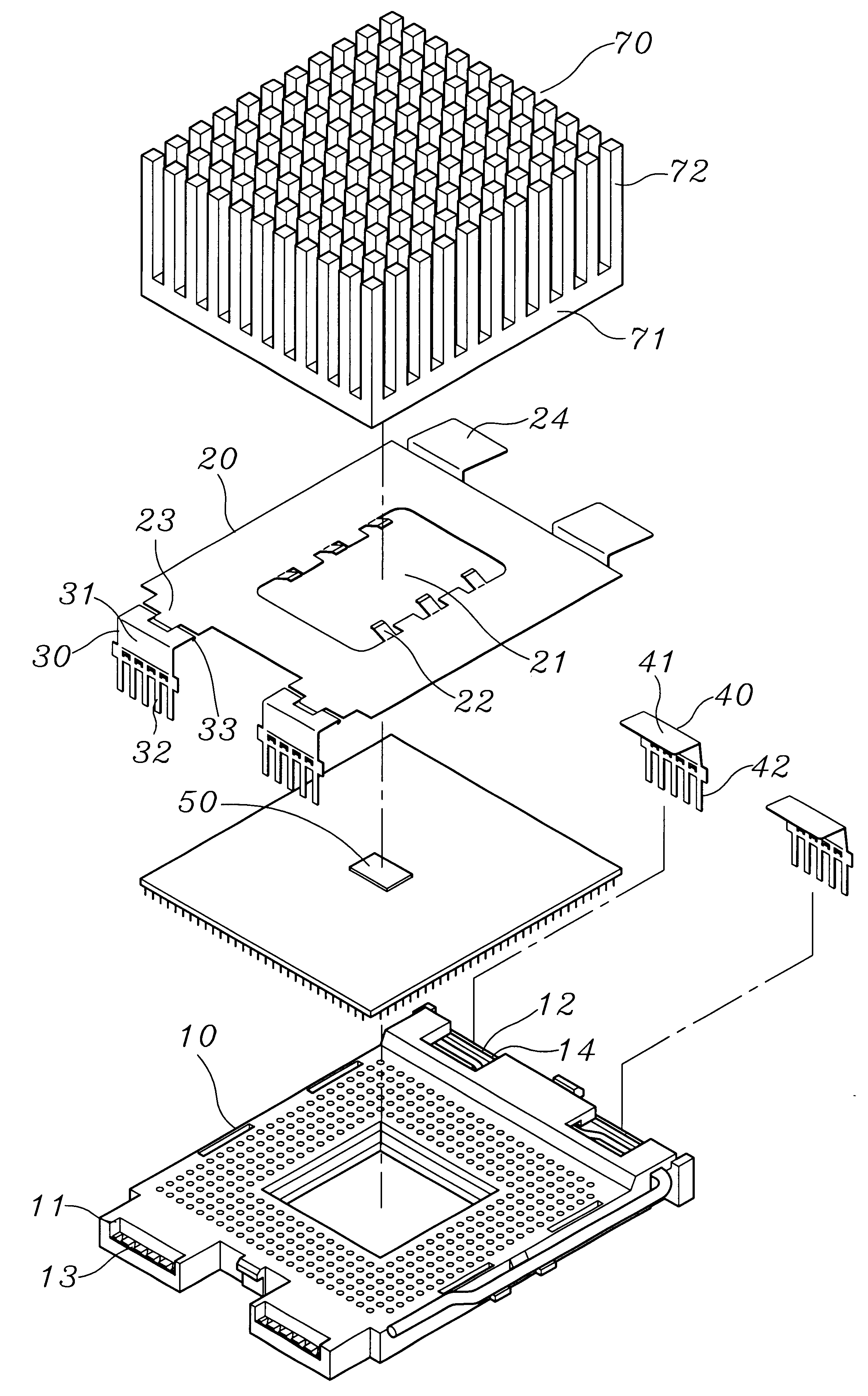

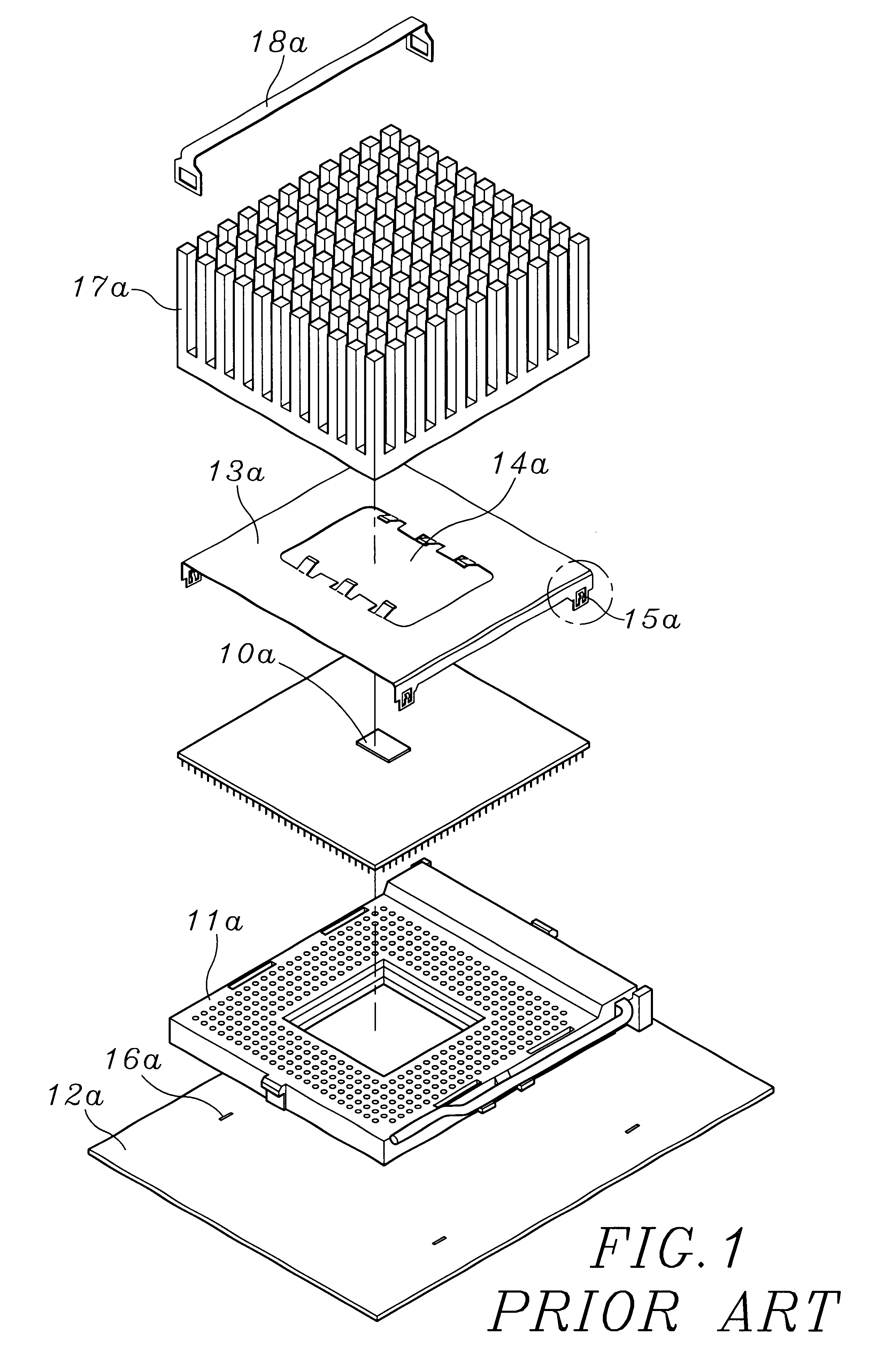

Modified structure for preventing electromagnetic interference of central processing unit

InactiveUS6296520B1Avoid electromagnetic interferenceGood EMI effectSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

The present invention proposes a modified structure for preventing EMI of a CPU. The proposed modified structure comprises a base, a shielding element, two first pins, and two second pins. A CPU can be mounted in the base. Two first pin sockets are installed at one side of the base, and two second pin sockets are installed at the other side of the base. Pin-receiving holes are disposed on each of the pin sockets. Pivot joints are installed at one side of the shielding element, and lapping parts are installed at the other side of the shielding element. Each first pin has a main body extending to form a plugging part. The plugging parts of the first pins are plugged in the pin-receiving holes of the first pin sockets of the base. Each second pin has a main body extending to form a plugging part. The plugging parts of the second pins are plugged in the pin-receiving holes of the second pin sockets of the base. The shielding element can be closed or unfolded. When the shielding element is closed, it can cover over the CPU with lapping parts at one side thereof lapping on the main body of the second pin. Through the contact of the first pins and the second pins with the motherboard to acquire electrically grounding function, the shielding element can provide good electromagnetic shielding effect. Better shielding effect of EMI for the CPU can thus be achieved. Moreover, the assembly of the shielding element is timesaving and laborsaving. Manpower can be greatly saved so that production cost can be effectively reduced. Additionally, the disassembly of the shielding element is a very simple operation.

Owner:HORNG CHIN FU

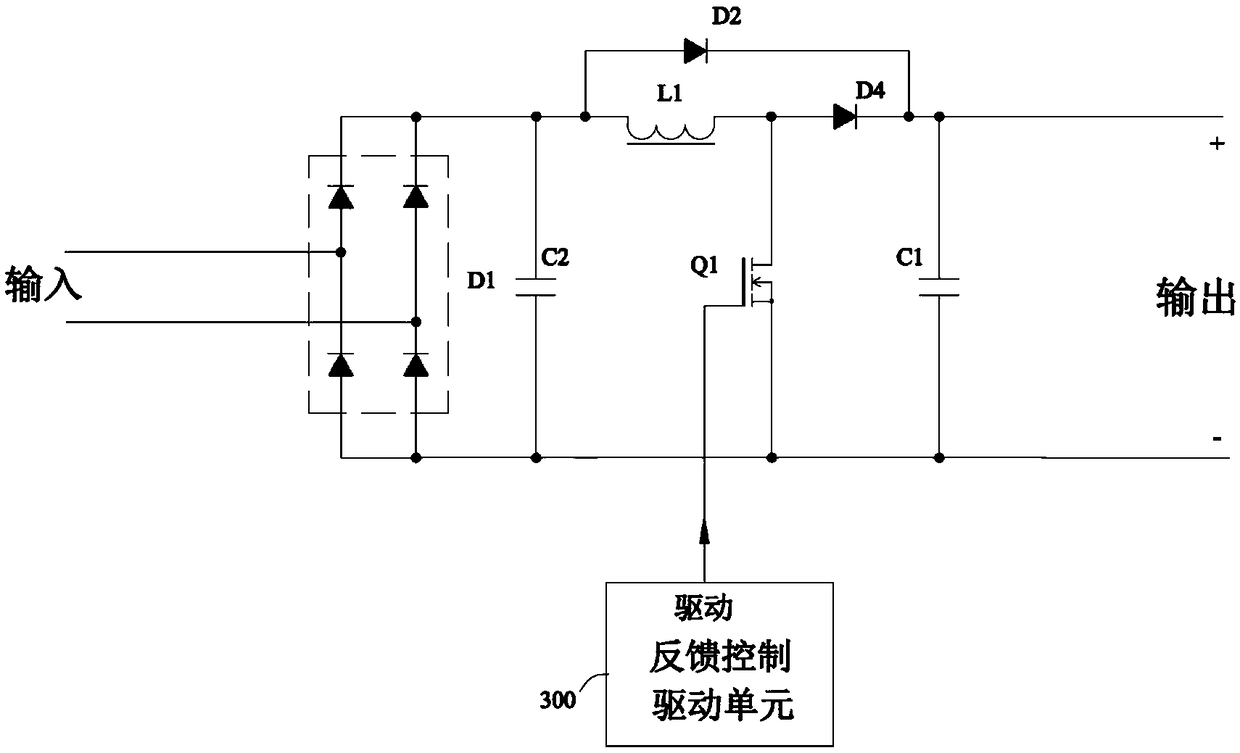

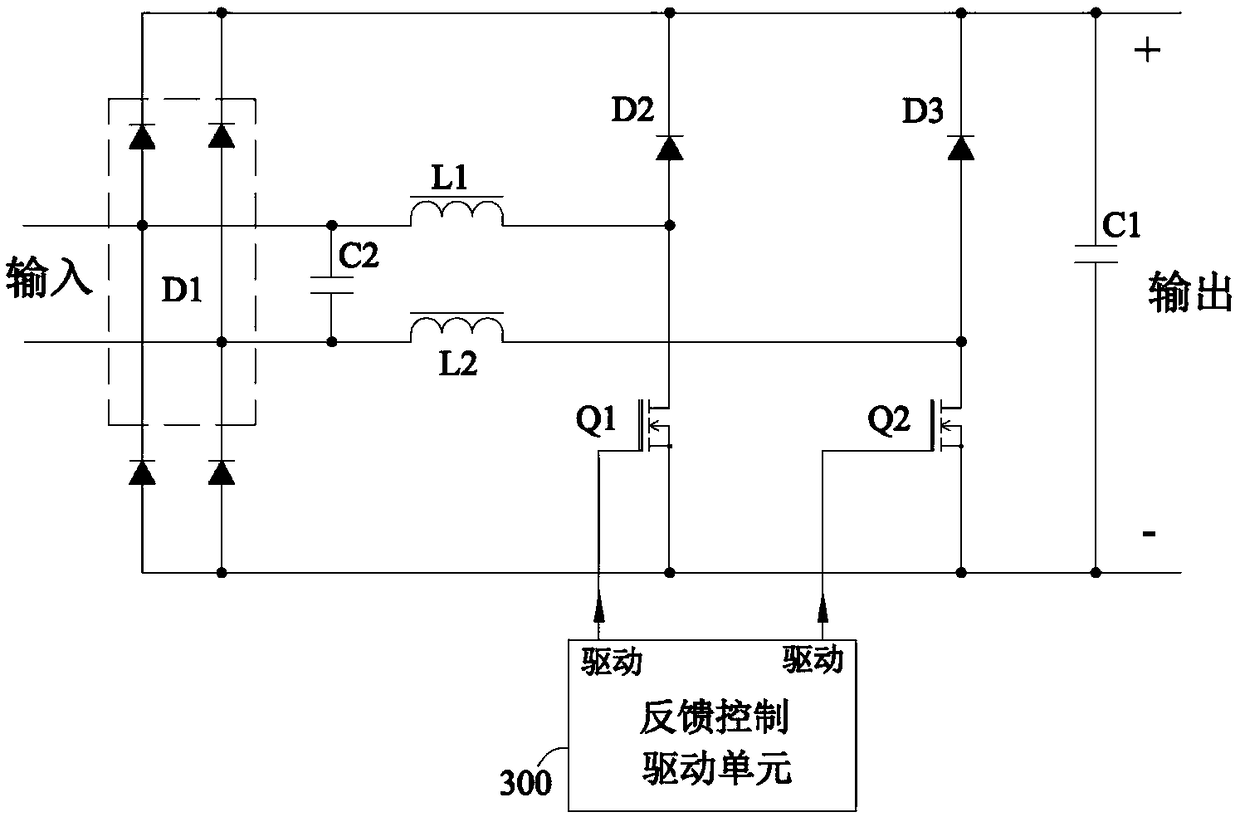

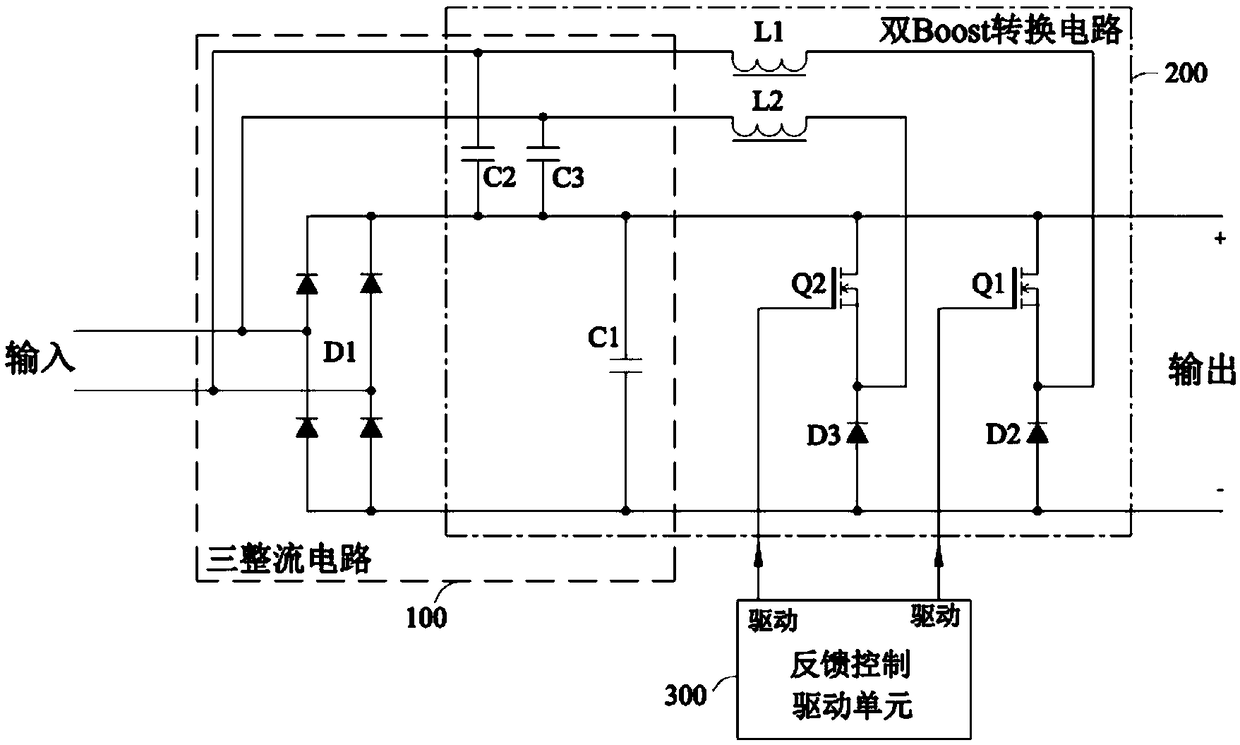

A bridgeless three-rectifier Boost power supply circuit

InactiveCN109039074AImprove efficiencyReduce noiseEfficient power electronics conversionAc-dc conversionCapacitanceEngineering

The invention discloses a bridgeless three-rectifier boost power supply circuit, includes three rectifying circuits, two Boost capacitors, energy storage capacitors, two Boost conversion circuits andfeedback control driving unit. The three rectifying circuits rectify and charge the energy storage capacitors, and charge the two Boost capacitors respectively when the input voltage is positive and negative. When the input voltage is positive or negative, the double Boost converter alternately charges the storage capacitor by superposing the voltage on the Boost inductor and the Boost capacitor,thus realizing the Boost boost conversion function. In the three-rectifier circuit, only one diode is used to charge the Boost capacitor, so the effect of bridge-less PFC is achieved. Rationally arrange the connection position of the input surge suppression circuit so that it has zero loss. As the invention follows the input structure of the traditional BoostPFC, the invention has better EMI effect than the traditional bridgeless PFC circuit.

Owner:SHANGHAI TUITUO TECH CO LTD

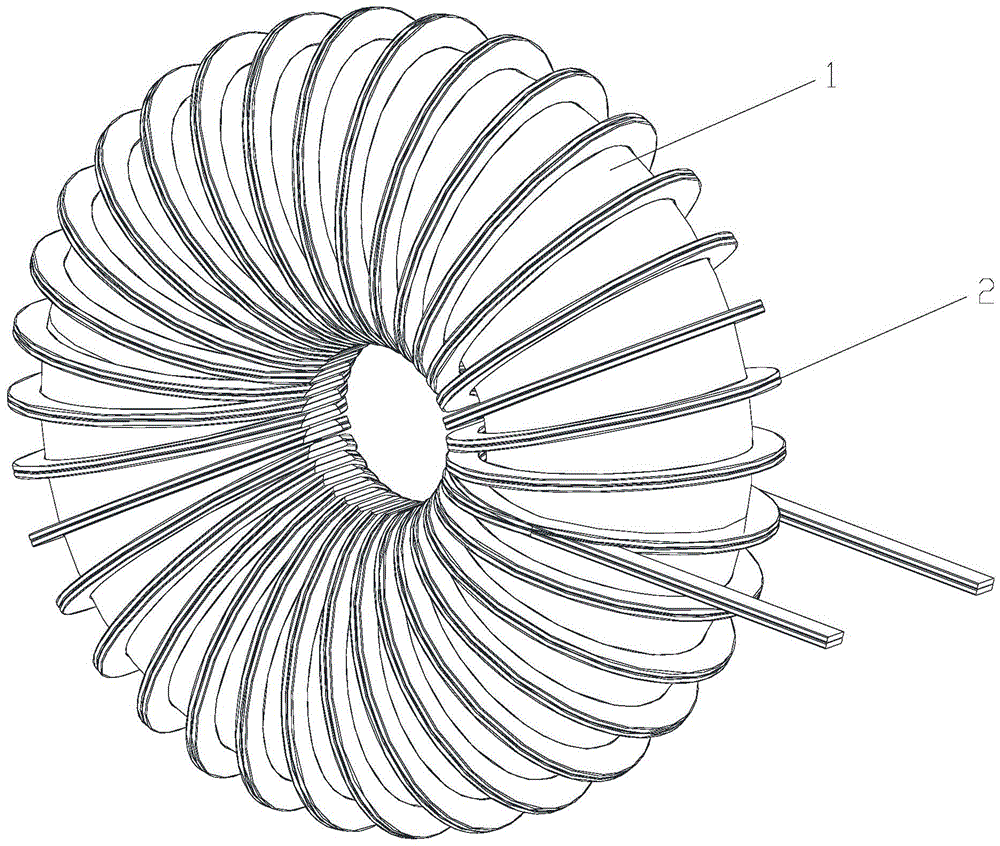

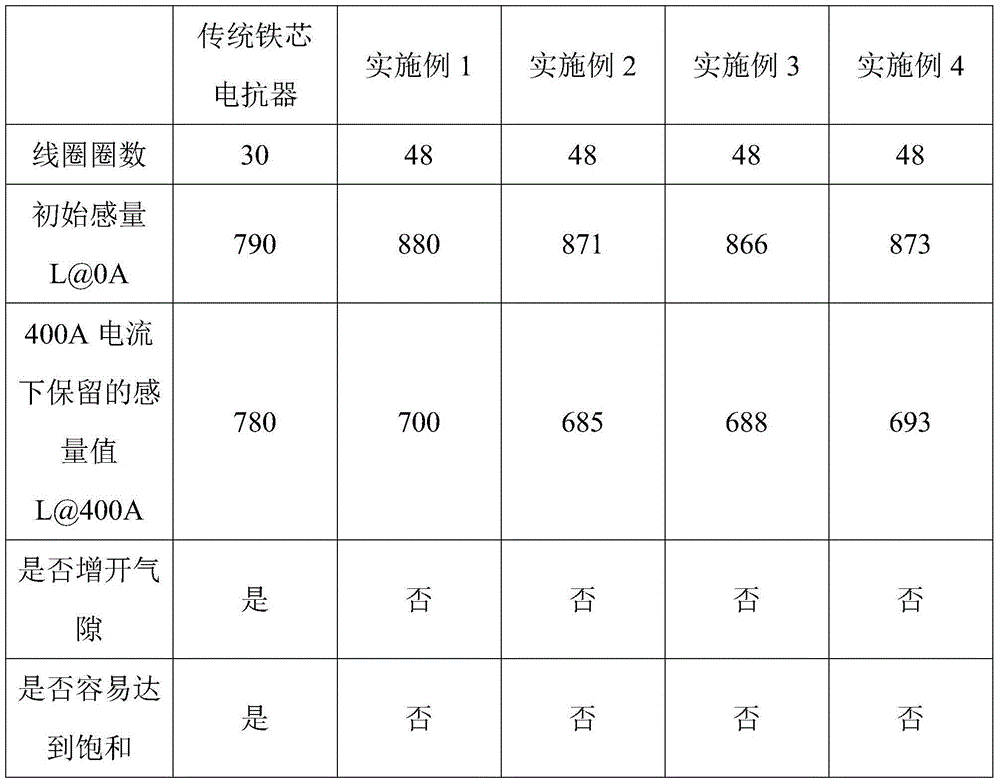

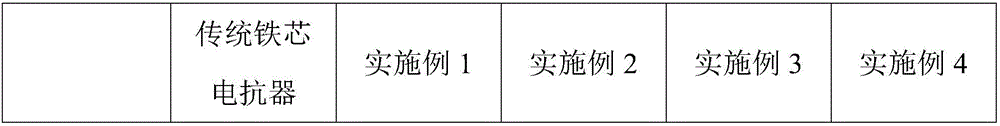

Novel circular-ring-shaped high-power electric reactor and manufacturing method thereof

ActiveCN104835616AReduce investmentSave materialTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEngineeringResin adhesive

The invention discloses a novel circular-ring-shaped high-power electric reactor. The electric reactor comprises a magnetic core and a coil. The magnetic core is a circular-ring-shaped magnetic core formed by two identical semicircular-ring-shaped magnetic core bodies in a combined mode, the diameter of the circular-ring-shaped magnetic core ranges from 7 inches-20 inches, and the magnet density of the circular-ring-shaped magnetic core ranges from 5.5 g / cm<3> to 6.2 g / cm<3>. The two semicircular-ring-shaped magnetic core bodies are sleeved with the coil which is a spiral varnished wire coil formed by a flat wire in a vertical winding mode. The semicircular-ring-shaped magnetic core bodies are formed by pouring a magnetic composite material composed of ferromagnetic powder and high-temperature resin adhesive through a semicircular-ring-shaped mould. The electric reactor is simple in structure, low in production cost, light in weight, low in noise, low in loss, good in surface heat dissipation and long in service life; the process is simple, and automatic operation is easy to achieve; the utilization rate of the magnetic core is high, magnetic leakage is small, and the EMI effect is good.

Owner:POCO HLDG CO LTD +2

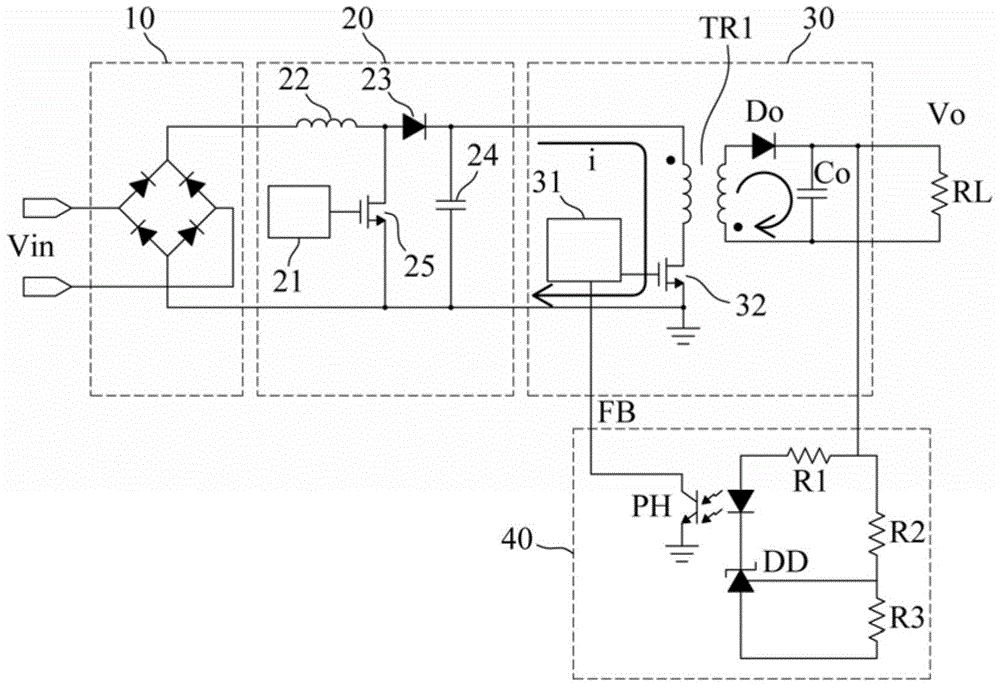

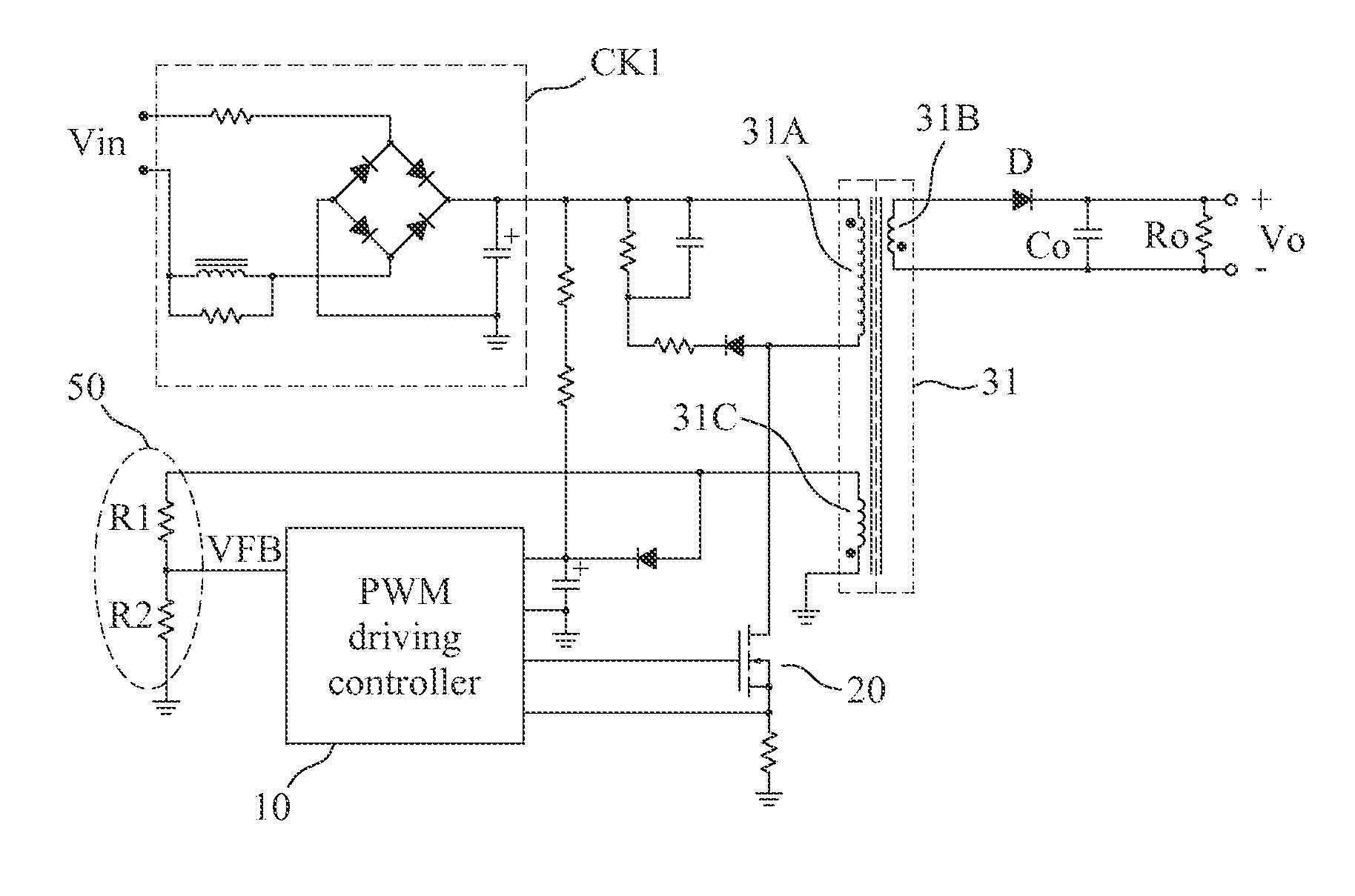

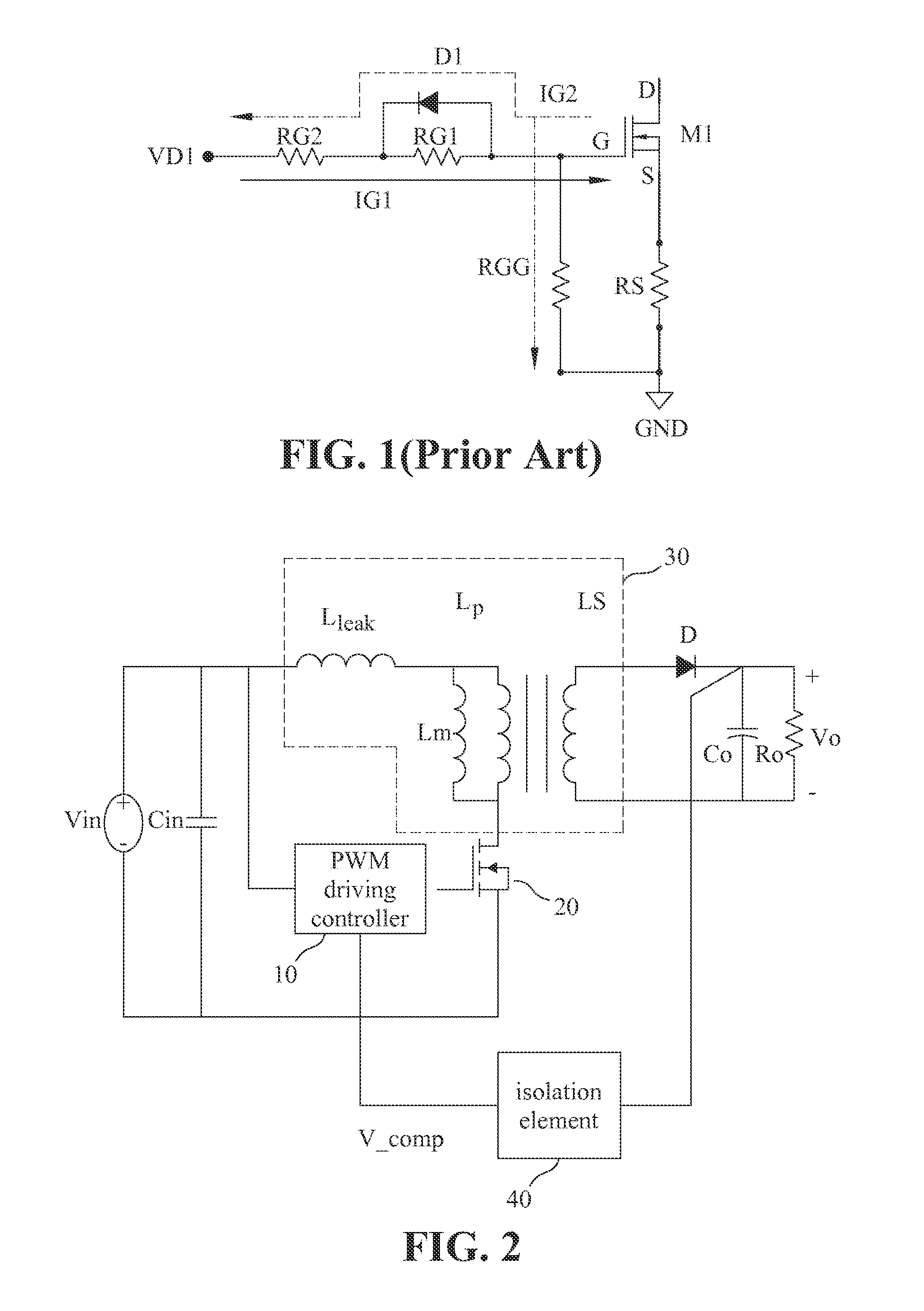

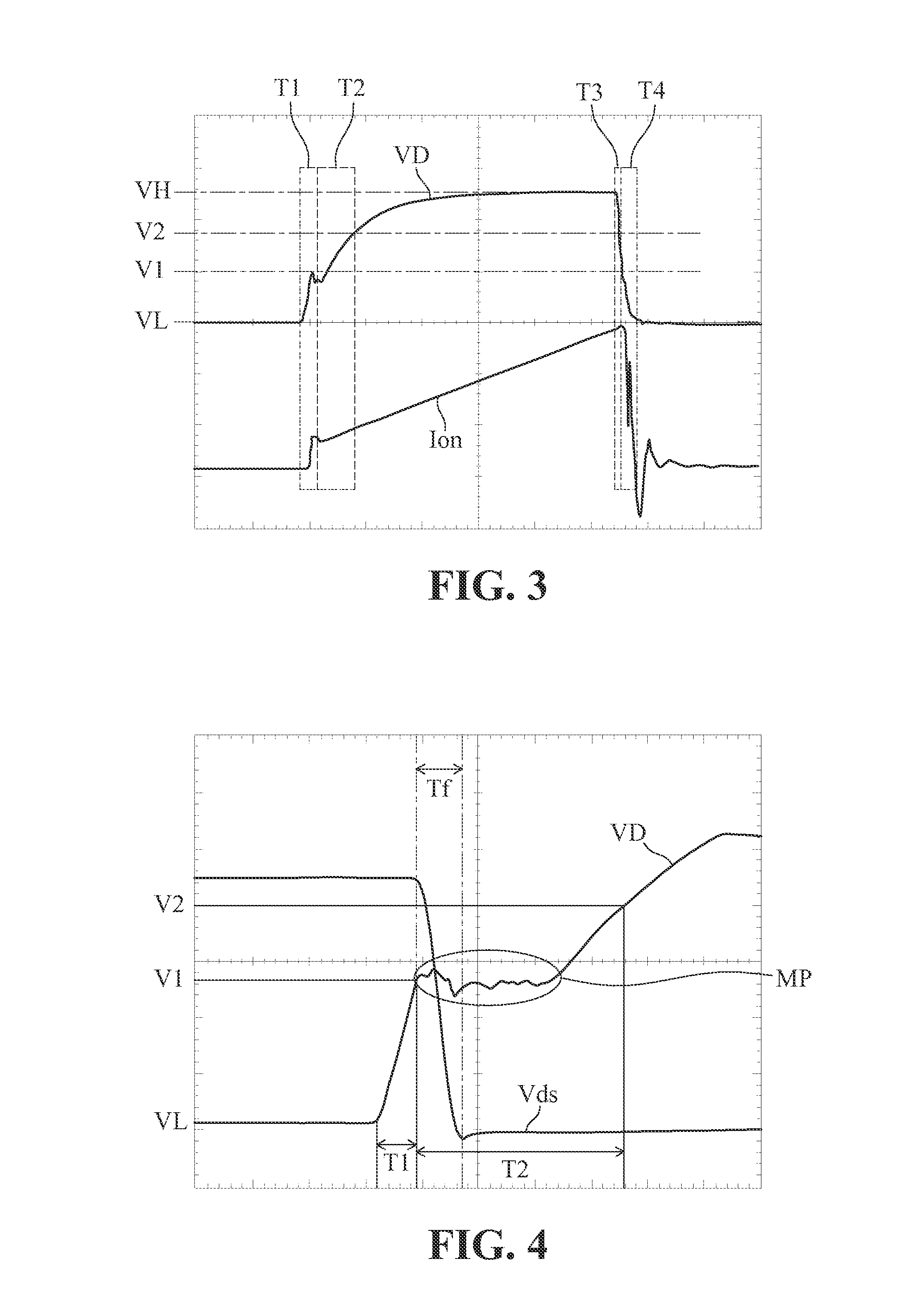

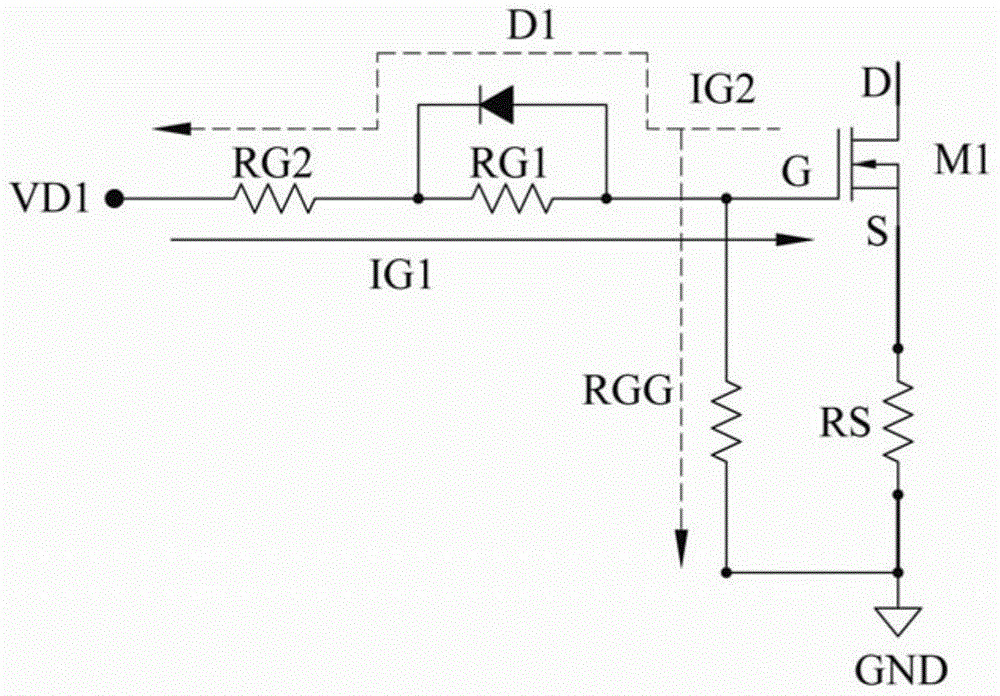

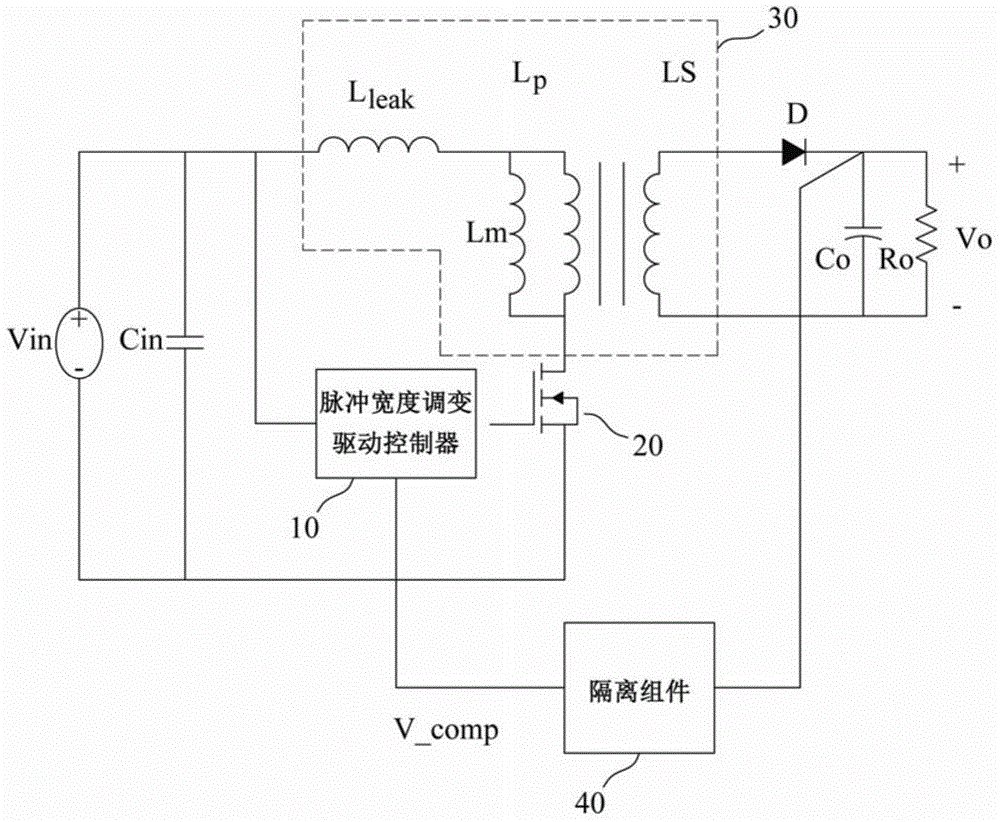

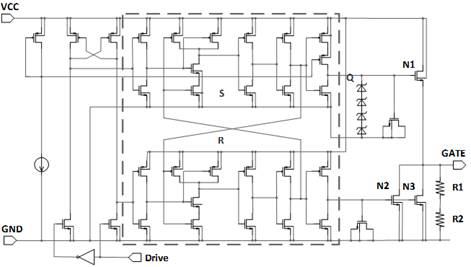

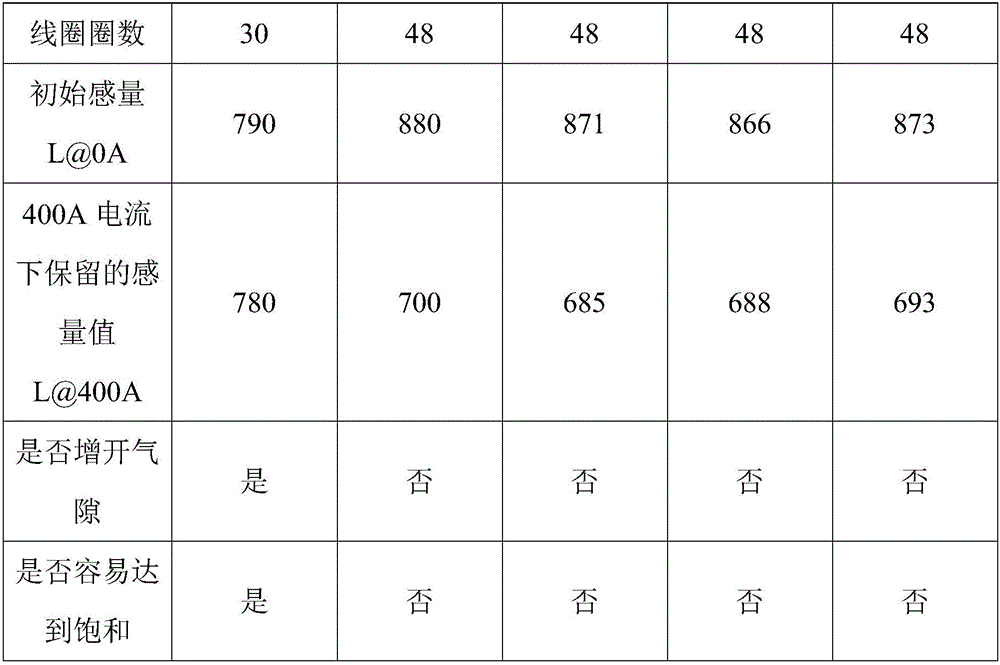

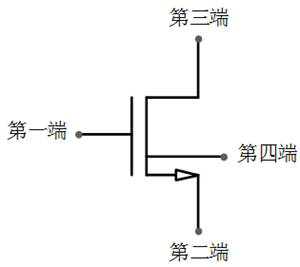

Power source control device capable of dynamically adjusting driving ability

InactiveCN105871232AImprove the efficiency of conversion operationsDynamically adjustable drive capabilityAc-dc conversionEnergy industryElectromagnetic interferenceEngineering

The invention relates to a power source control device capable of dynamically adjusting driving ability. The power source control device comprises a rectifying unit, a power factor correction unit, a power source conversion unit and a feedback unit; the rectifying unit receives an alternating current input power source, rectifies the alternating current input power source to obtain a direct current power source, and transmits the direct current power source to the power factor correction unit for performing power factor correction processing on the direct current power source; a generated power factor corrected power source is transmitted to the power source conversion unit; the feedback unit is electrically connected with the power source conversion unit, so that a control loop can be formed; and the pulse width modulation driving controller of the power source conversion unit carries out adjustment processing according to the feedback signals of the feedback unit so as to control a switching transistor, so that the power factor corrected power source can be converted into an output power source which is provided for an external load. With the power source control device of the invention adopted, the optimal on current of the switching transistor can be realized, and electromagnetic interference margin can be increased, and switching loss can be reduced.

Owner:产晶积体电路股份有限公司

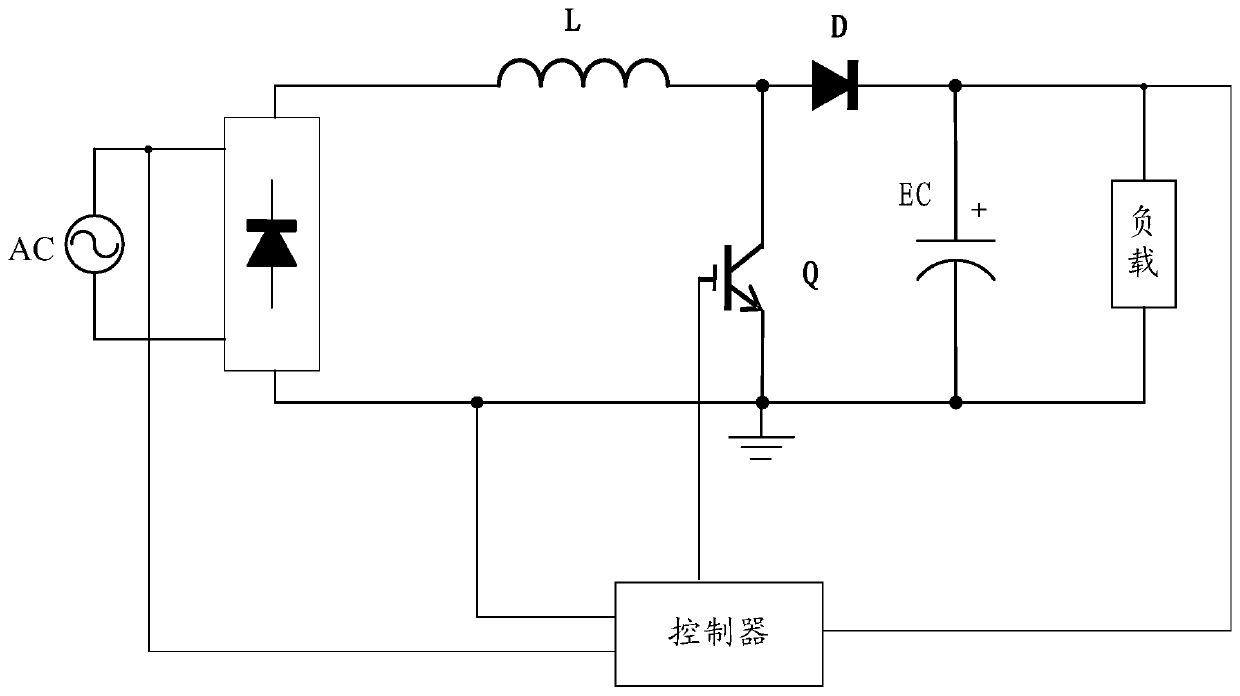

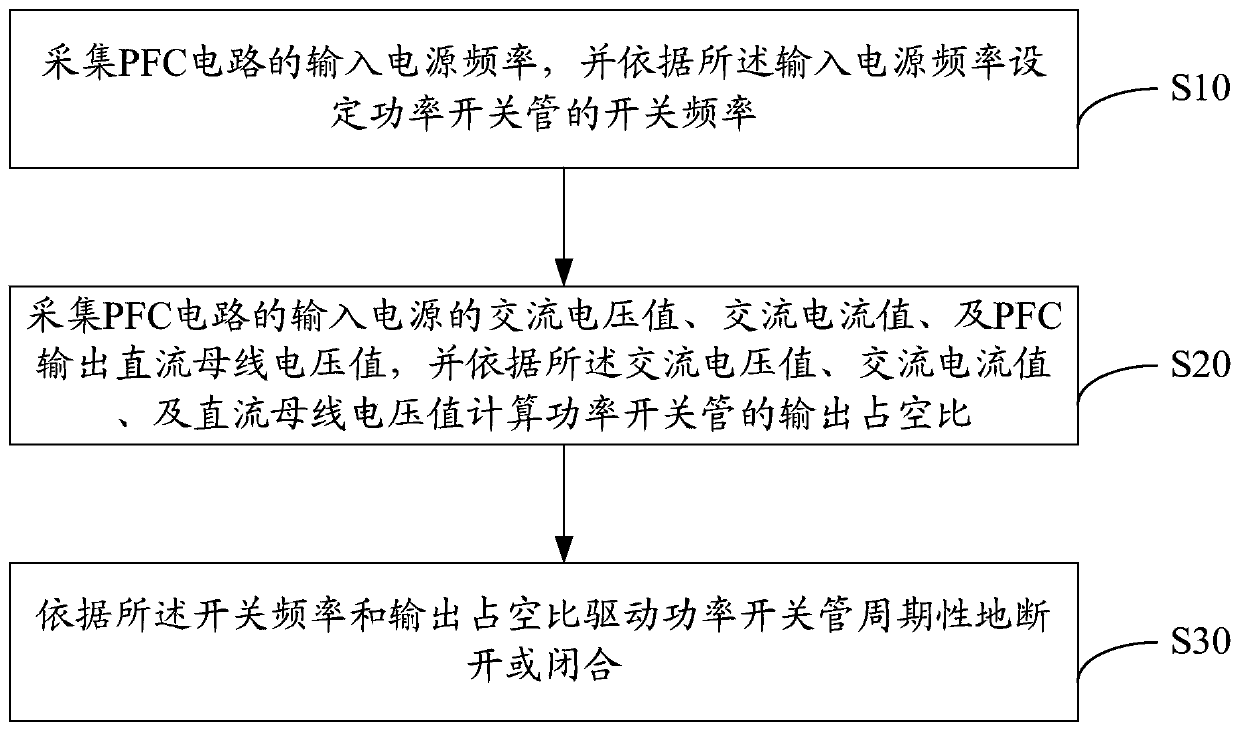

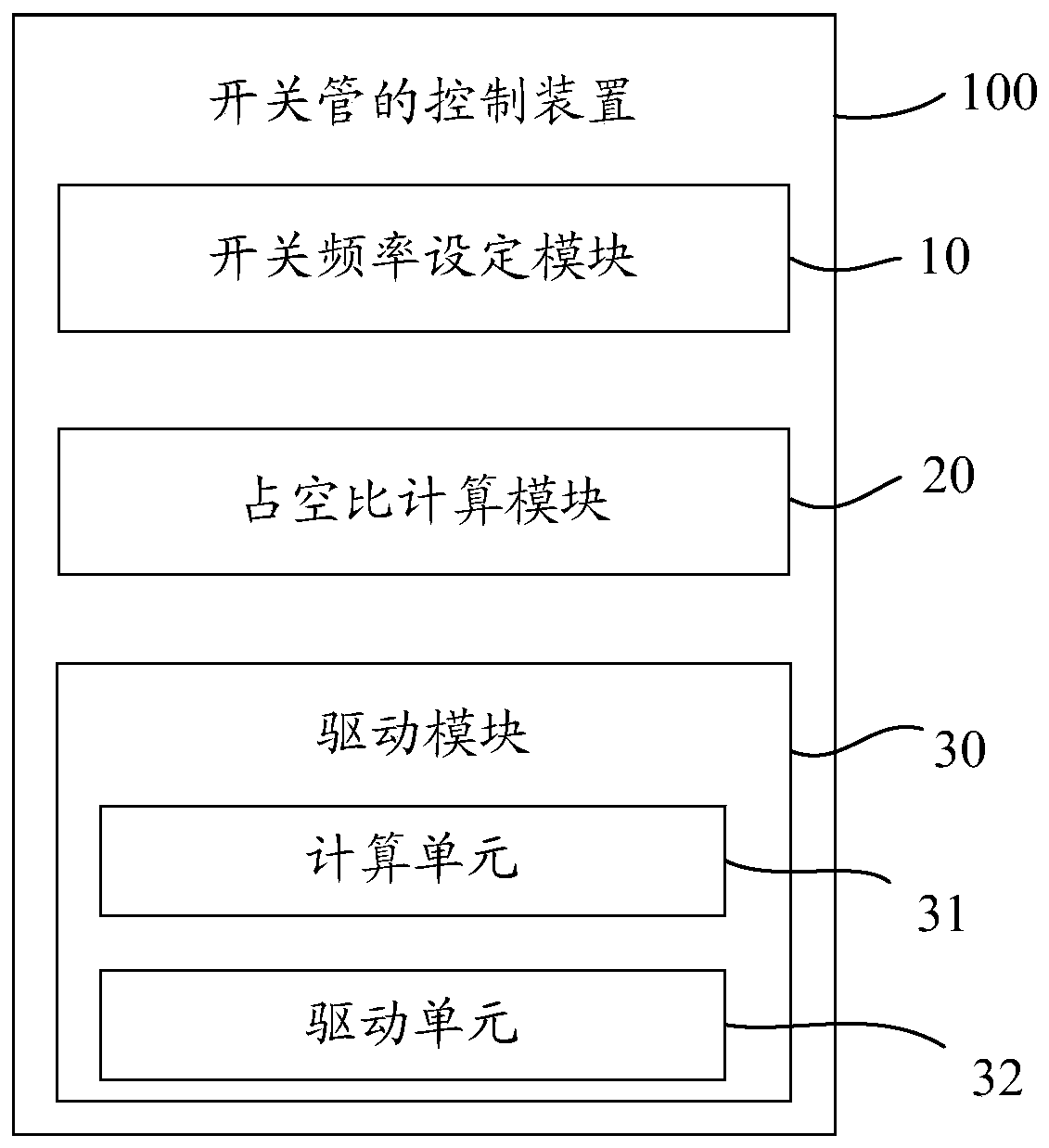

Control method and device of switch tube and air conditioner

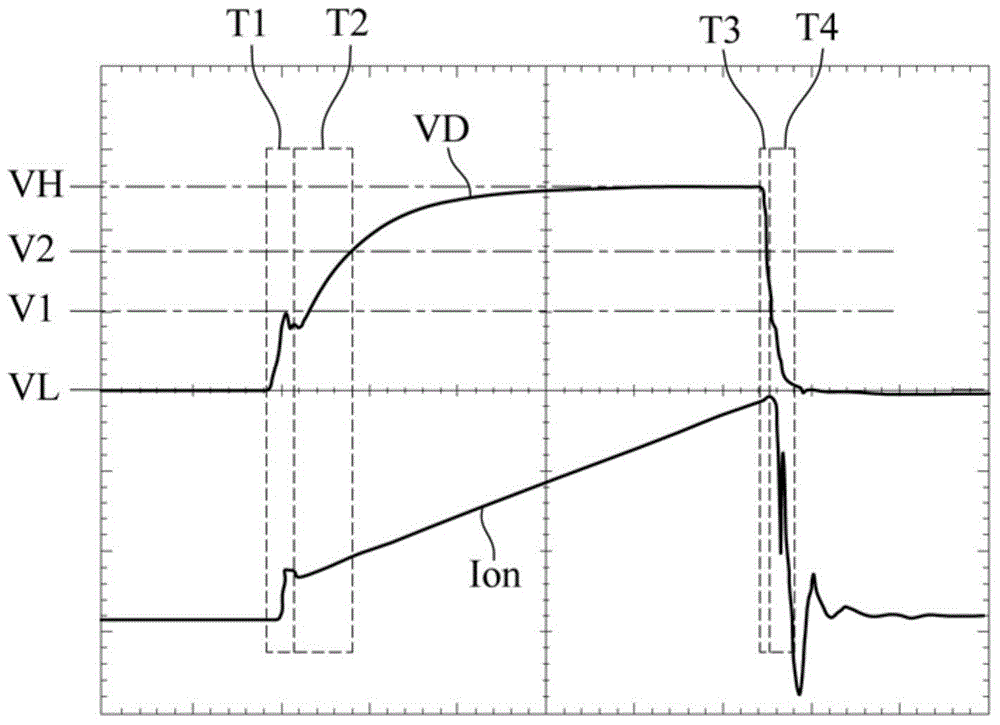

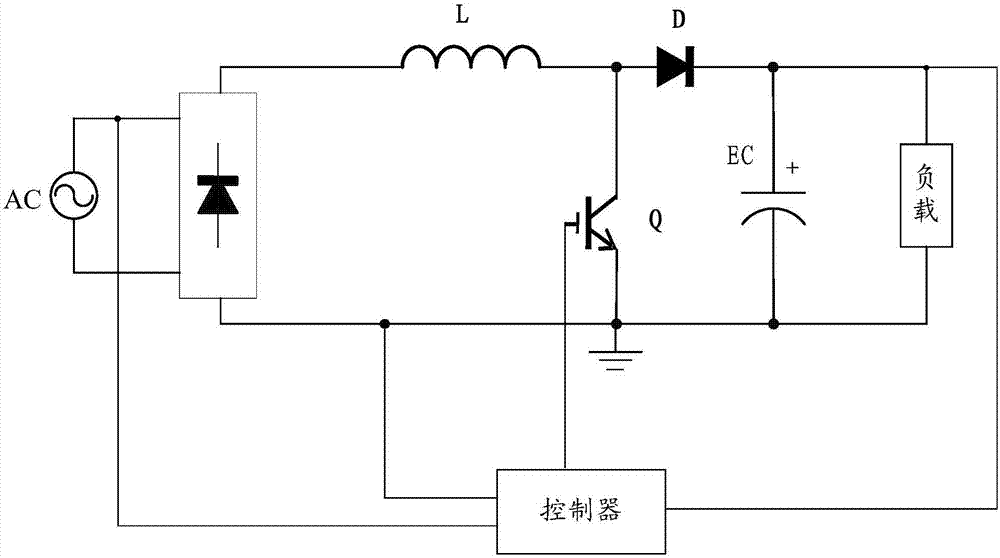

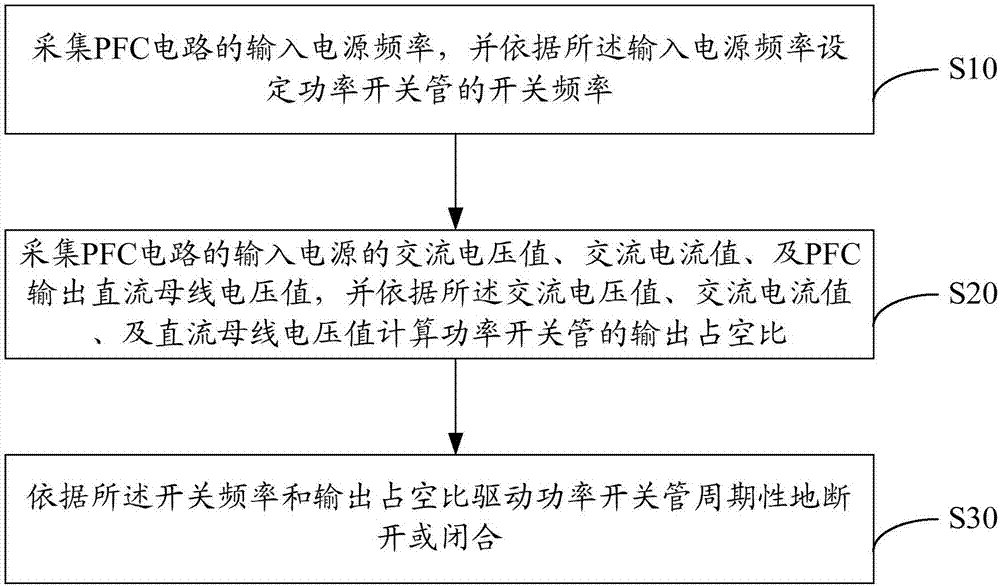

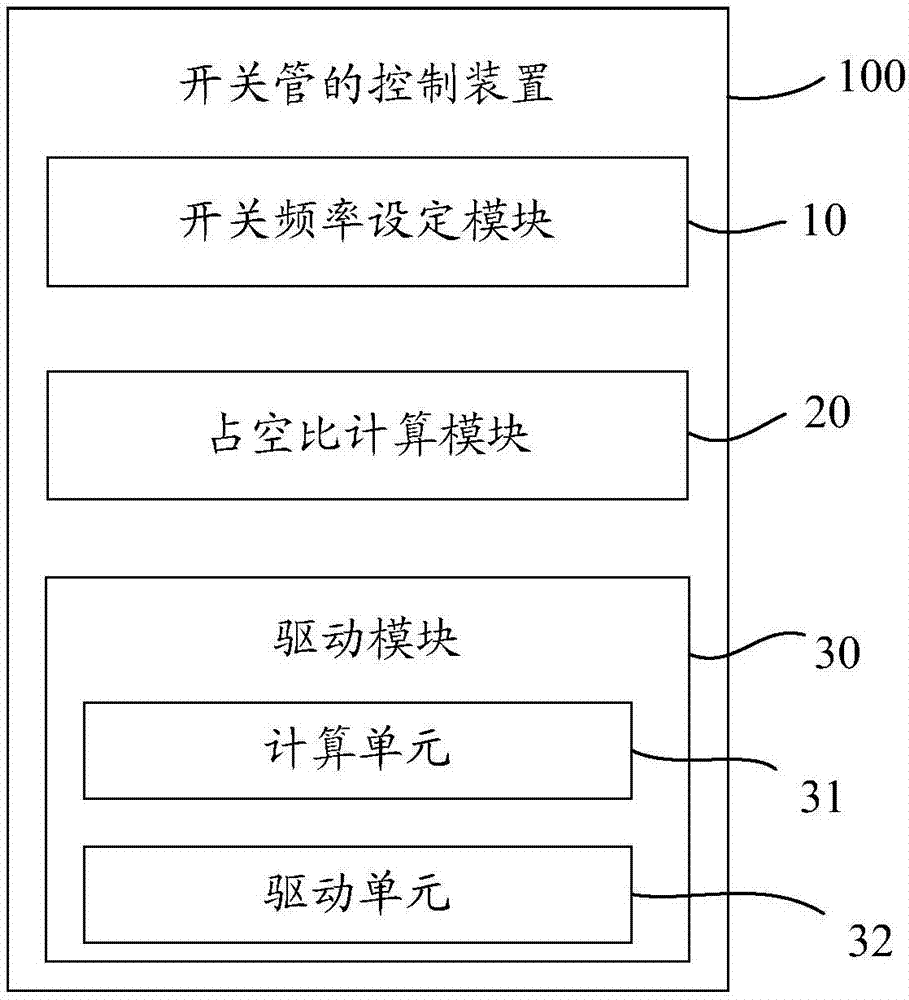

ActiveCN106998133AImprove power factorGood EMI effectEfficient power electronics conversionPower conversion systemsEngineeringPower factor

The invention discloses a control method and device of a switch tube and an air conditioner. When the control method is used, a frequency of an input power supply of a power factor correction (PFC) circuit is periodically acquired, a switch frequency of a power switch tube is set, an output duty ratio of the power switch tube is calculated according to an AC voltage value an AC current value, which are acquired, of the input power supply of the PFC circuit and an acquired DC bus voltage value, and the power switch tube is driven to be periodically switched off or switched on according to the switch frequency and the output duty ratio. By the control method, the switch-on and the switch-off of the power switch tube can be controlled according to different frequencies of the input power supply, the power factor of the PFC circuit is increased, so that the optimal electro magnetic interference (EMI) effect is achieved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

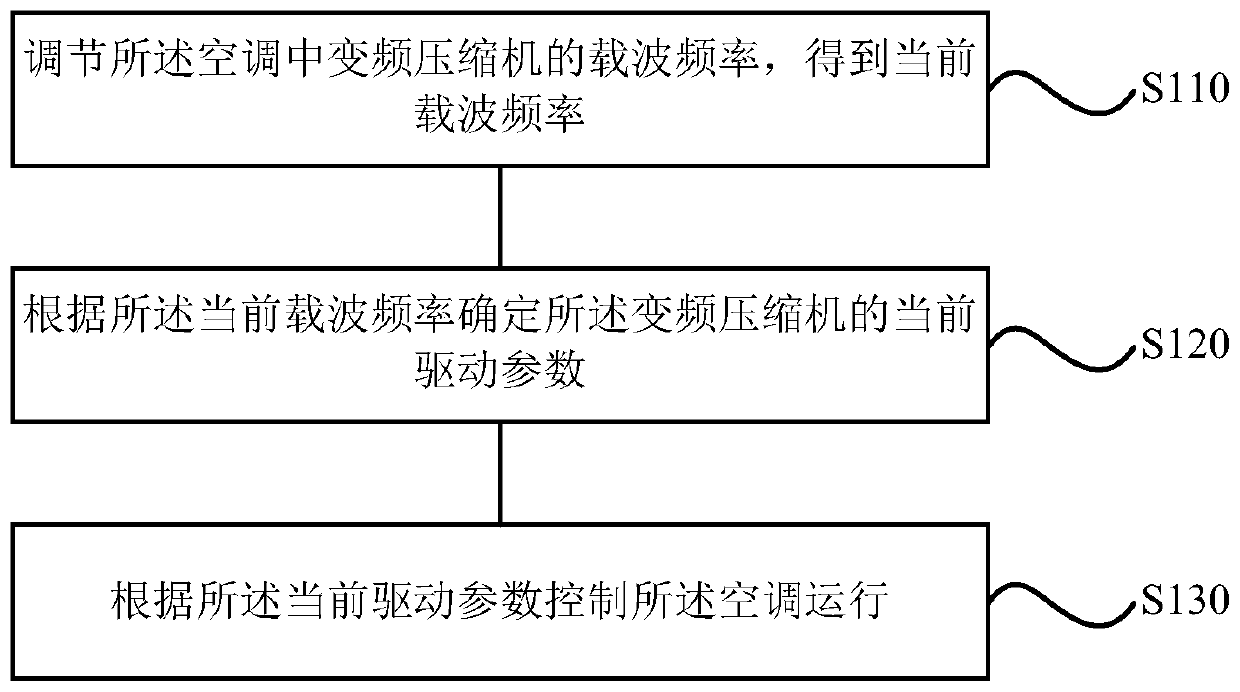

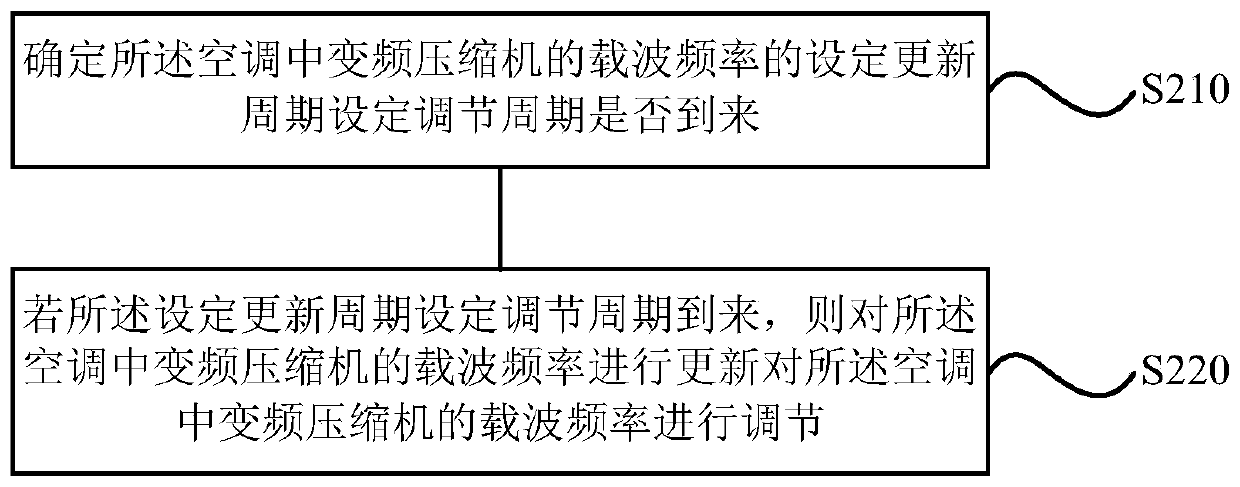

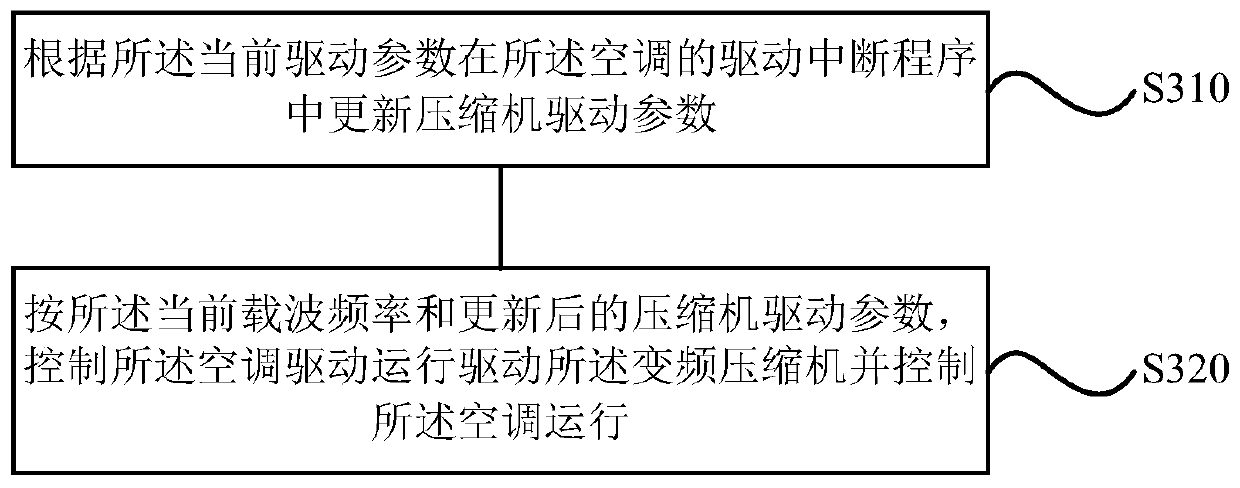

Control method and device for air conditioner, storage medium and air conditioner

ActiveCN109883020ASuppress electromagnetic noiseReduce electromagnetic interferenceMechanical apparatusSpace heating and ventilation safety systemsEngineeringParameter control

The invention discloses a control method and device for an air conditioner, a storage medium and the air conditioner. The method comprises the following steps: adjusting carrier frequency of an inverter compressor in the air conditioner so as to obtain current carrier frequency; determining current driving parameters of the inverter compressor according to the current carrier frequency; and controlling the air conditioner to run according to the current driving parameters. According to the scheme disclosed by the invention, the problem that an inverter air conditioner has high electromagneticnoises can be solved and the effect of reducing the electromagnetic noises is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

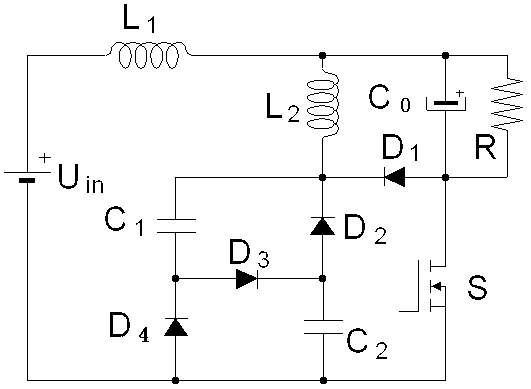

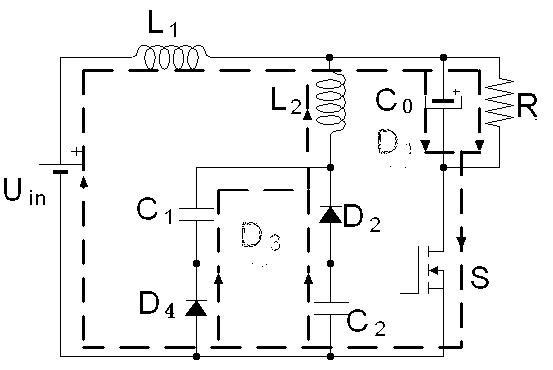

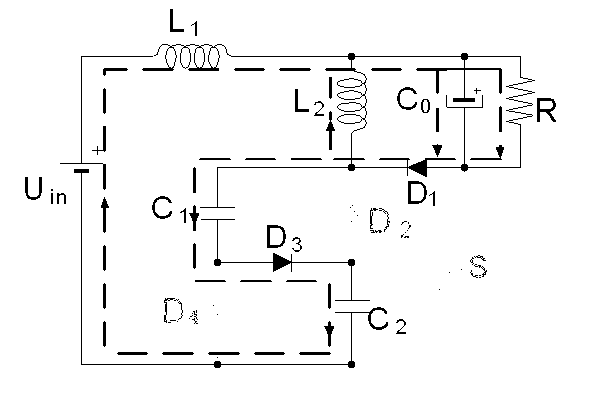

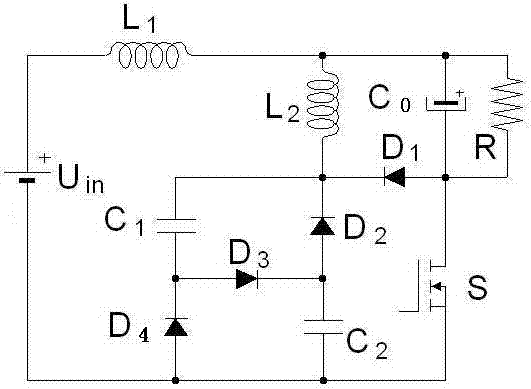

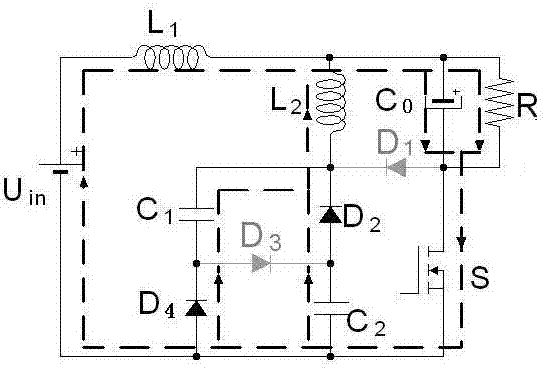

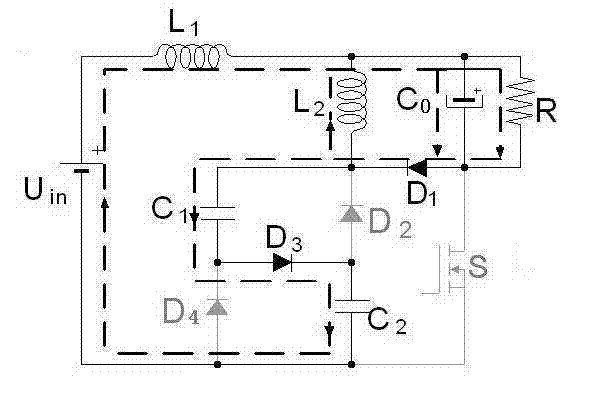

Voltage division step-down Cuk converter circuit

InactiveCN103023313AInput and output current continuousSmall pulsationApparatus without intermediate ac conversionElectric variable regulationCapacitancePower flow

The invention relates to a voltage division step-down Cuk converter circuit which comprises a power switch tube S, a diode D1, a diode D2, a diode D3, a diode D4, a capacitor C1, a capacitor C2, an output electrolytic capacitor Co, an inductor L1 and an inductor L2. The capacitor C1, the capacitor C2, the diode D2, the diode D3 and the diode D4 form a voltage division circuit structure, and a step-down range is widened. The voltage division step-down Cuk converter circuit can realize large step-down change, reasonable PWM (pulse width modulation) duty ratio control and floor control for a switch, and has the advantages of continuous input and output current, low pulse, high circuit conversion efficiency, fine EMI (electro-magnetic interference) effect, convenience in control and the like.

Owner:FUZHOU UNIV

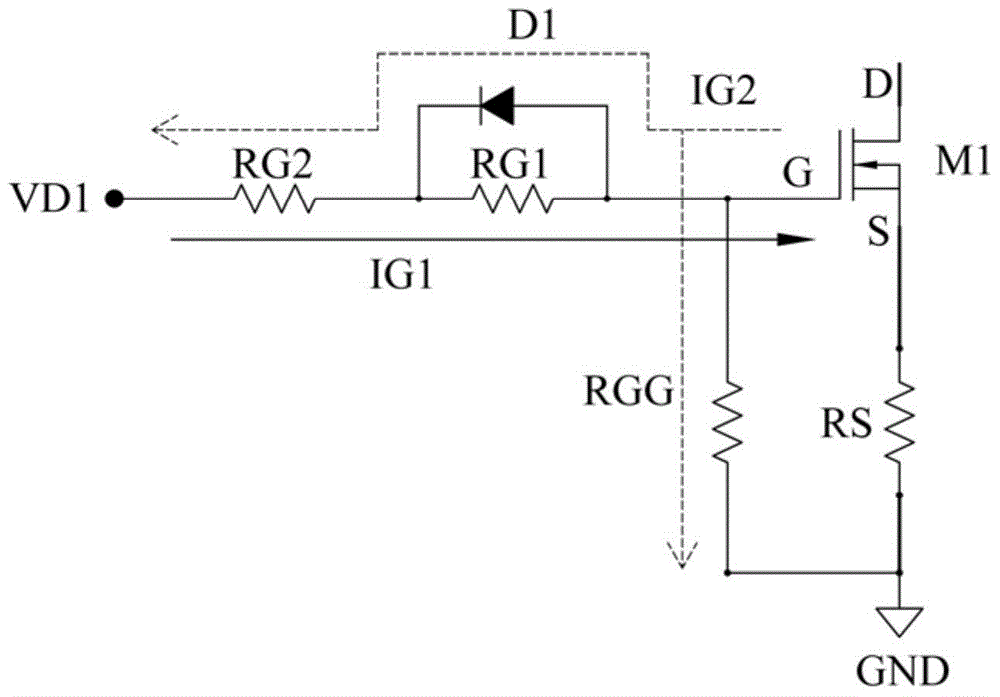

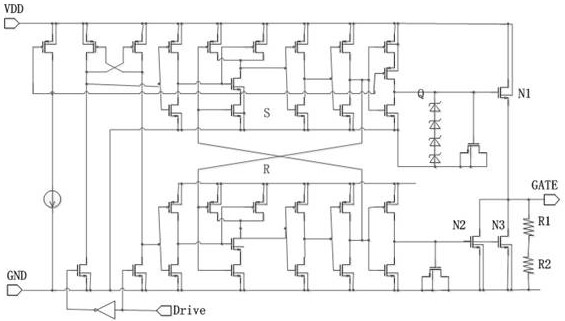

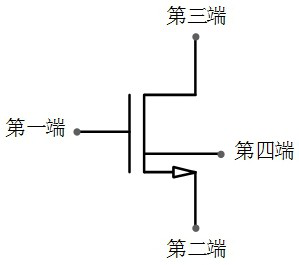

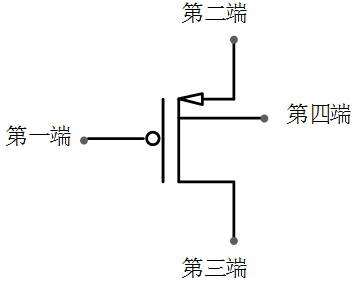

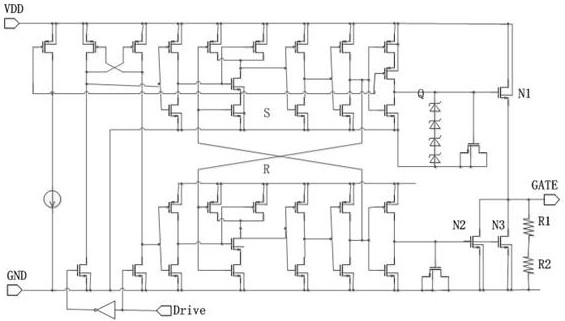

Driving circuit and related product

ActiveCN113676026ADrive voltage rises smoothlyImprove EMI effectEfficient power electronics conversionDc-dc conversionDriving currentHemt circuits

The invention provides a driving circuit and related products. The driving circuit comprises a first-section driving circuit and a second-section driving circuit. The first-section driving circuit is connected with the second-section driving circuit. The second-section driving circuit is used for driving an external power tube to realize a driving function. The driving current of the second-section driving circuit is E times of the driving current of the first-section driving circuit, and E is greater than 1. According to the embodiment of the invention, due to the fact that the first-section driving circuit adopts low-current driving and the second-section driving circuit adopts a high-current driving method, di / dt change can be reduced, the driving voltage of a power tube is enabled to rise smoothly, and the EMI effect of a chip is improved.

Owner:SHENZHEN INJOINIC TECH

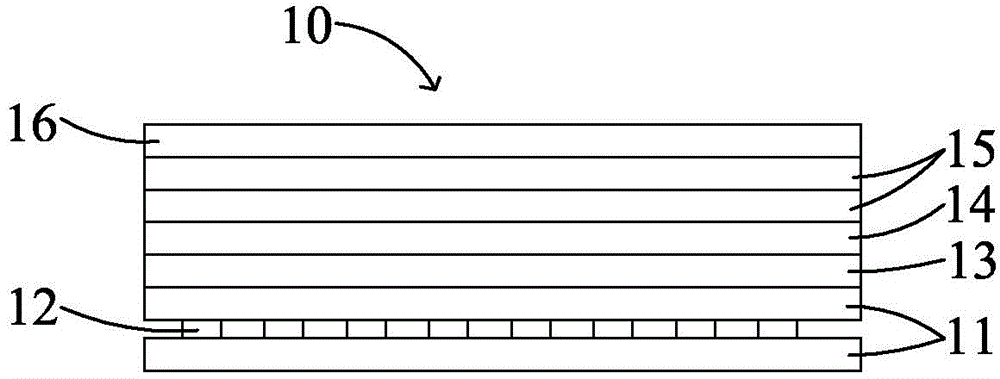

Method for manufacturing high-density integrally-molded inductor

ActiveUS20170345540A1Easy to manufactureLow production costPermanent magnetsInorganic material magnetismElectrical conductorHigh density

Provided is a method for manufacturing a high-density integrally-molded induct comprising the following steps: (1) winding an enameled wire coil to be spiral; (2) mechanically pressing first ferromagnetic powder into a magnetic core; (3) mounting the magnetic core into a. hollow cavity of the enameled wire coil; (4) mounting the enameled wire coil provided with the magnetic core into an injection mold; (5) uniformly mixing and stirring resin glue, a coupling agent and an accelerant, to obtain high-temperature resin glue; (6) uniformly stirring second ferromagnetic powder and the high-temperature resin glue, to obtain a magnetic composite material; (7) injecting the magnetic composite material into a mold cavity of the injection mold for molding, and solidifying the magnetic composite material to obtain an outer magnet; and (8) cooling and de-molding the outer magnet, to obtain a molded inductor. The inductor obtained using the above method is small in size, high in density, high in relative permeability, better in heat dissipation, and lone in service life. The inductor is simply manufactured using an integral molding method, thus reducing the production cost.

Owner:POCO HLDG CO LTD

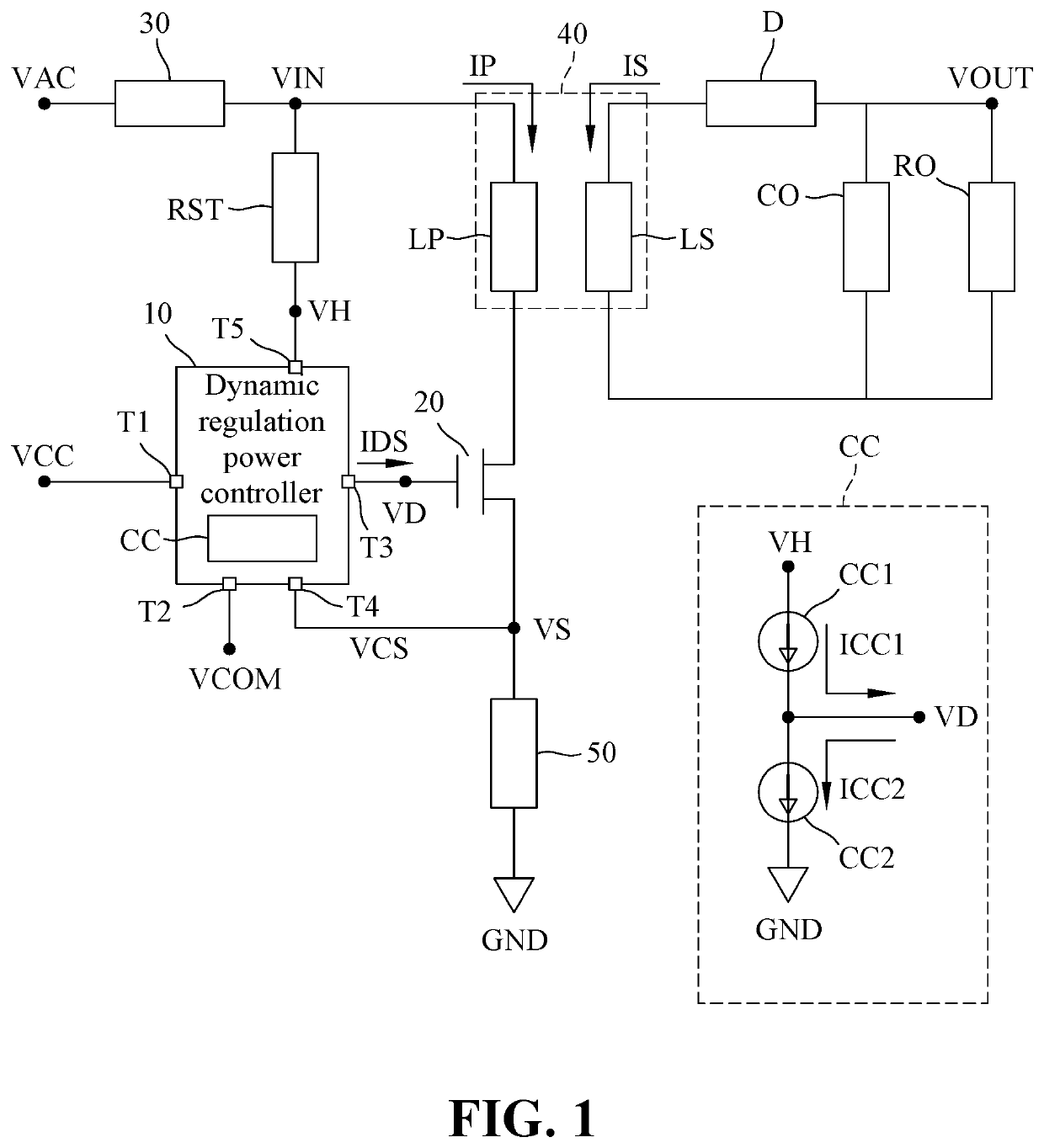

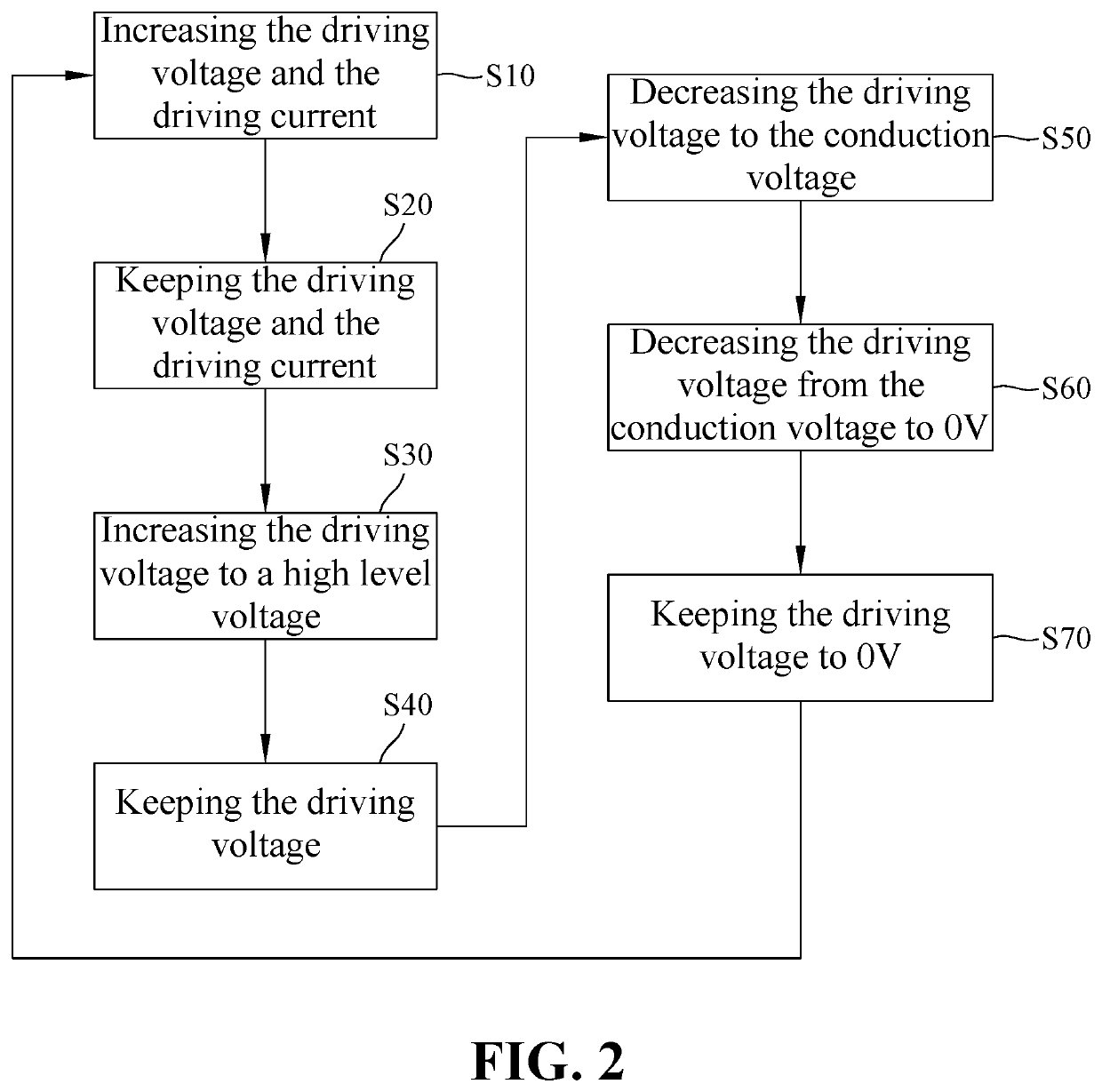

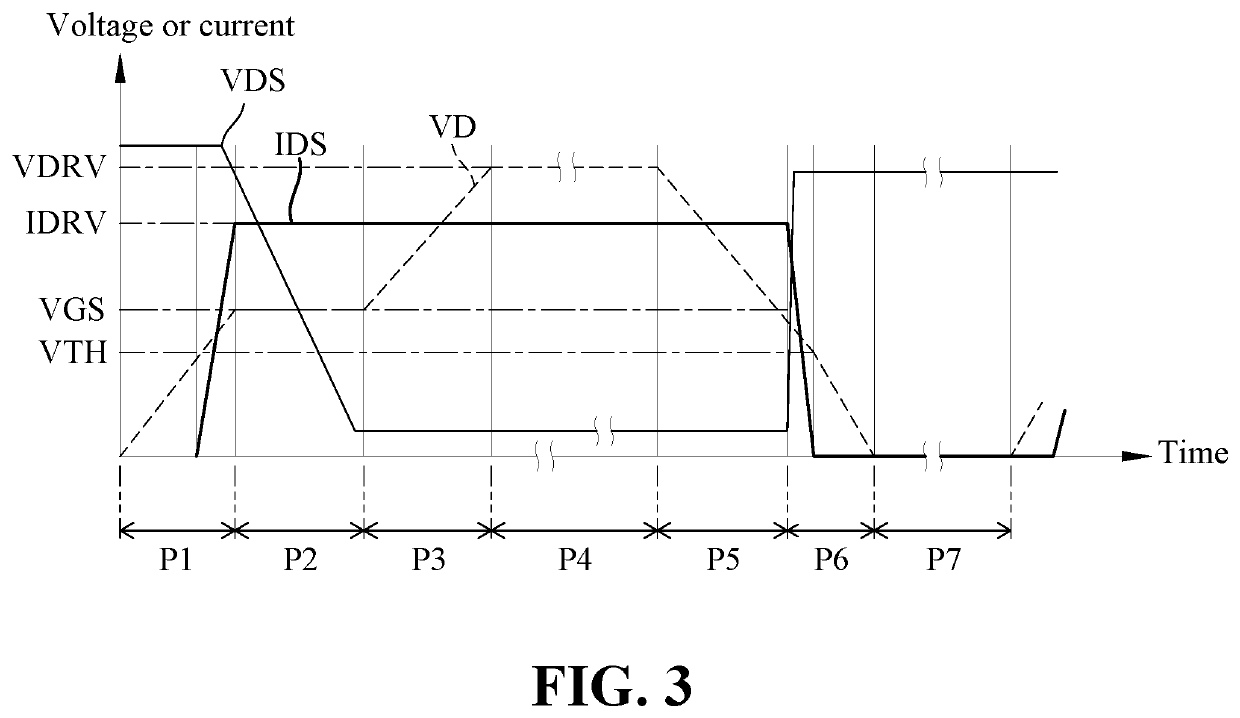

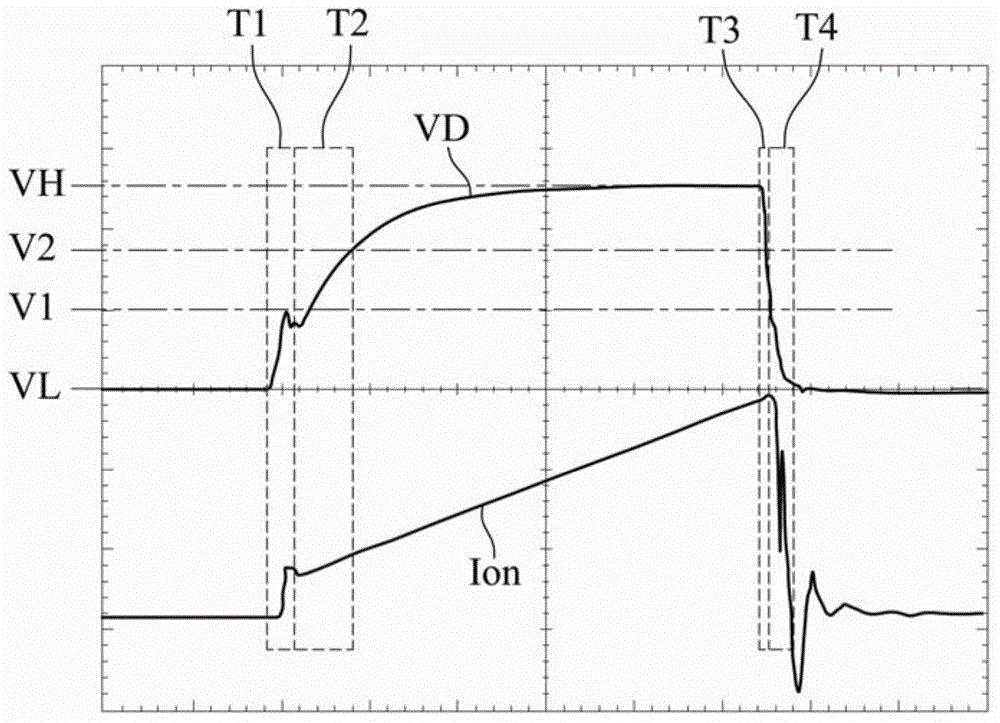

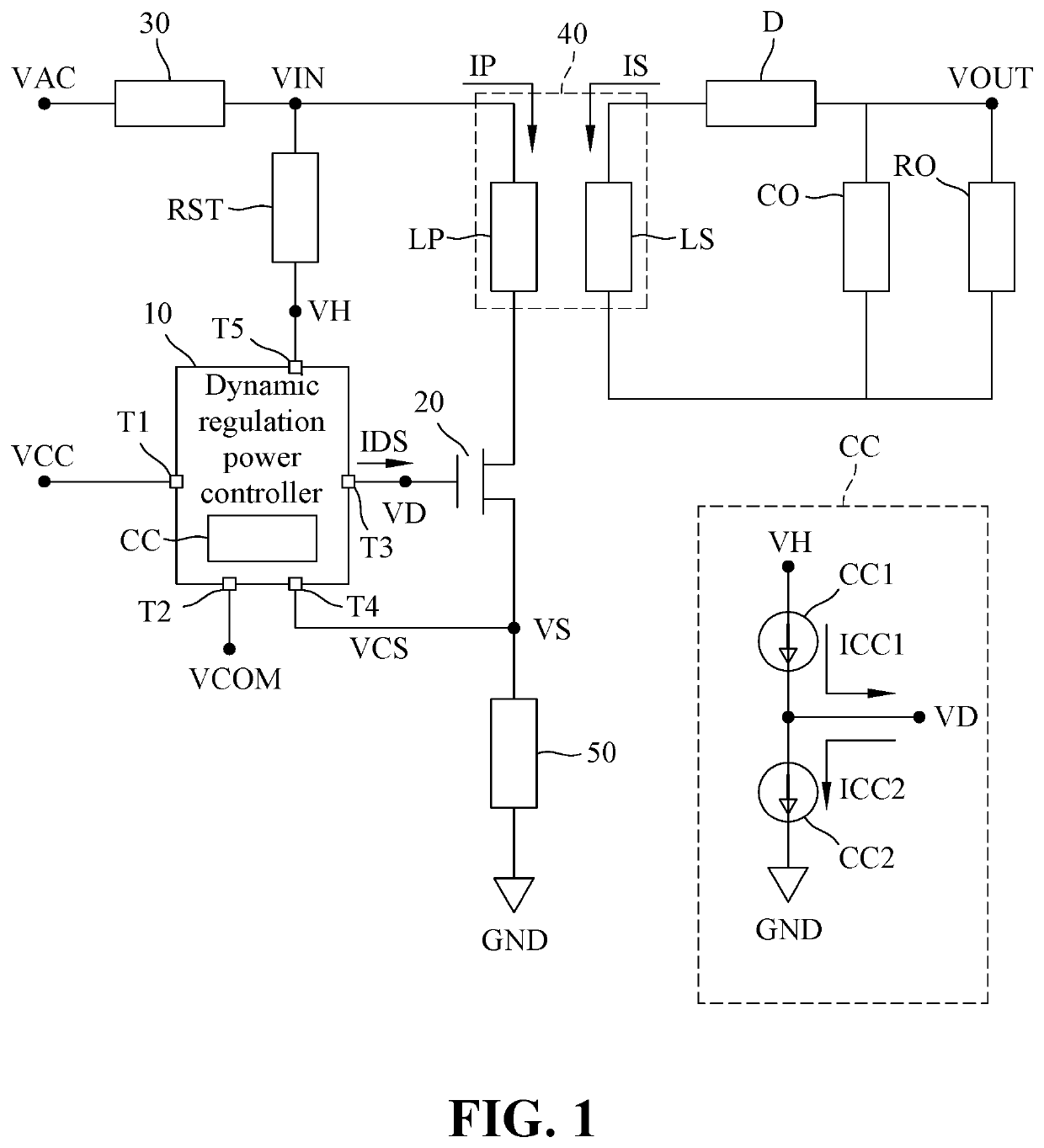

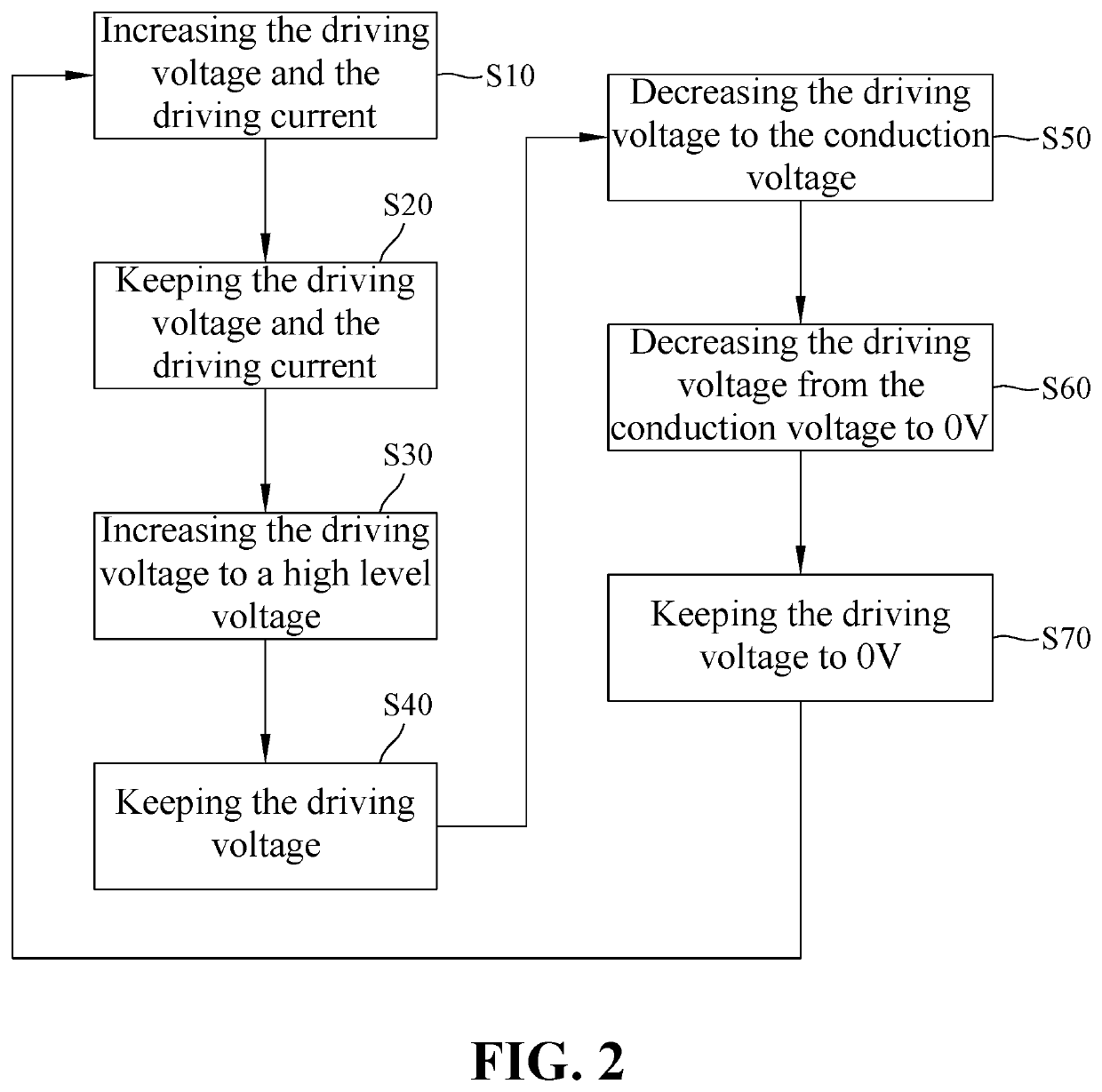

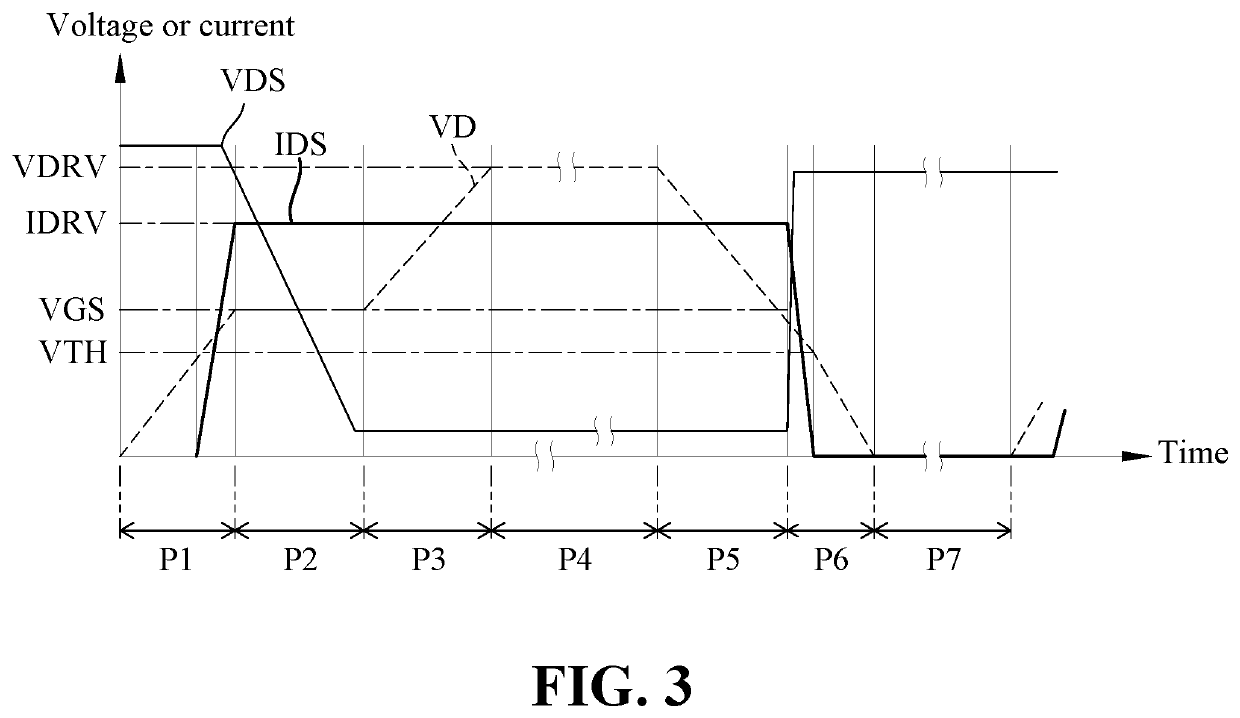

Dynamic regulation power controller

ActiveUS11018591B1Improve power efficiencyGood EMI effectEfficient power electronics conversionDc-dc conversionTransformerElectric power

Disclosed is a dynamic regulation power controller having a work voltage input pin, a feedback voltage input pin, a driving voltage output pin, a current sensing input pin, and a regulation power input pin, and being in collocation with a switching unit, an input power processing unit, a transformer, a current sensing resistor, a power regulation unit, an output rectification unit, and an output capacitor for converting an input AC voltage into an output voltage for supplying a load. In particular, the driving voltage and the driving current are dynamically adjusted according to the feedback voltage and the current sensing signal, thereby greatly increasing efficiency of power conversion and Electromagnetic Interference (EMI).

Owner:INNOTECH CO LTD

Power control apparatus with dynamic adjustment of driving capability

ActiveUS20160134193A1Improve efficiencyIncrease the EMI marginEfficient power electronics conversionDc-dc conversionTransformerElectrical performance

A power control apparatus with dynamical adjustment of driving capability for converting an input power into an output power includes a transformer, a switch transistor connected to the transformer, a pulsed width modulation (PWM) driving controller generating a PWM signal and connected to the switch transistor, an isolation element, an output diode and an output capacitor. The first side coil of the transformer and the switch transistor are connected to the input power, the second side coil of the transformer is connected to the output diode and further connected to the output capacitor and an external load. The isolation element converts the output power into a feedback signal providing the PWM driving controller to dynamically control the PWM driving signal through adjustment so as to implement the optimal turn-on current for the switch transistor. Therefore, electrical performance and conversion efficiency are greatly improved by reducing the switching loss.

Owner:INNOTECH CO LTD

Novel high-density magnetic composite material for inductor

InactiveUS20170330662A1Save investmentLow production costInorganic material magnetismTransformers/inductances detailsHigh densityInitial permeability

Disclosed is a novel high-density magnetic composite material for an inductor. The material is composed of 6-12% of high-temperature resin glue and 88-94% of magnetic powder body in percentage by weight. An integrated inductor magnetic core is simply prepared by means of the magnetic composite material of the disclosure without a large press, thus saving the device investment. The mold loss in a pressing process is reduced, and the production cost is reduced. The operation is simple, a magnet of a complex shape can be produced, and an oversized magnet can be produced. A closed magnetic circuit is formed, and the EMI effect is good. The magnetic composite material of the disclosure enables the density of a solidified magnet to be high under the action of special high-temperature resin glue, it can be guaranteed that the density is 5.5-6.2 g / cm3, the sensitive quality value for preparing an inductor is high, and the initial permeability can be 14μ or above. The magnetic composite material of the disclosure can bear a higher temperature, and can work at the temperature of 180° C. The magnetic composite material of the disclosure is high in utilization rate, low in scrap rate and low in dust rate, and meets the requirement for environmental protection.

Owner:POCO HLDG CO LTD

Power control device with dynamic driving ability regulation function

InactiveCN105656311AReduce the driving voltageFirst rise timeDc-dc conversionElectric variable regulationCapacitanceTransformer

The invention relates to a power control device with a dynamic driving ability regulation function, comprising a transformer, a pulse width modulation driving controller, a switching transistor, an isolation component, an output diode and an output capacitor, wherein the pulse width modulation driving controller is connected with the switching transistor, the switching transistor is connected with the transformer, a primary inductor of the transformer and the switching transistor are connected with an input power supply, and a secondary inductor of the transformer is connected with the output diode and further connected with the output capacitor and a load. The isolation component converts an output power supply into a feedback signal and sends the feedback signal to the pulse width modulation driving controller, and the pulse width modulation driving controller adjusts the feedback signal and dynamically controls a pulse width modulation driving signal to achieve optimal switching-on current of the switching transistor. The electromagnetic interference margin is increased, the switching loss is reduced, and the overall electrical quality and power conversion efficiency are improved.

Owner:产晶积体电路股份有限公司

Method for manufacturing high-density integrally-molded inductor

ActiveUS10283250B2Eliminate the effects ofLow densityTransformers/inductances casingsPermanent magnetsHigh densityEngineering

Provided is a method for manufacturing a high-density integrally-molded inductor, comprising the following steps: (1) winding an enameled wire coil to be spiral; (2) mechanically pressing first ferromagnetic powder into a magnetic core; (3) mounting the magnetic core into a hollow cavity of the enameled wire coil; (4) mounting the enameled wire coil provided with the magnetic core into an injection mold; (5) uniformly mixing and stirring resin glue, a coupling agent and an accelerant, to obtain high-temperature resin glue; (6) uniformly stirring second ferromagnetic powder and the high-temperature resin glue, to obtain a magnetic composite material; (7) injecting the magnetic composite material into a mold cavity of the injection mold for molding, and solidifying the magnetic composite material to obtain an outer magnet; and (8) cooling and de-molding the outer magnet, to obtain a molded inductor.

Owner:POCO HLDG CO LTD

A new manufacturing method of high-density integrated molded inductor

ActiveCN104900390BSimple winding processRealize automated productionInductances/transformers/magnets manufactureMagnetic materialsHigh densityResin adhesive

The invention discloses a novel high density integrated electric inductance manufacturing method, which comprises: (1) winding an varnished wire coil into a spiral shape; (2) making first iron magnetic powers into a magnetic core through mechanical pressing; (3) packing the magnetic core into a hollow cavity of the varnished wire coil; (4) packing the varnished wire coil packed with the magnetic core into an injection mold; (5) uniformly mixing and blending resin adhesive, coupling agent and accelerant to obtain high temperature resin adhesive; (6) uniformly mixing and blending the second iron magnetic powers and the high temperature resin adhesive to obtain magnetism composite material; (7) injecting the magnetism composite material into a mold cavity of the injection mold to mold, and solidifying to obtain external magnetic body; and (8) cooling and stripping to obtain molded electric inductance. According to the invention, the volume of the electric inductance manufactured with the method provided herein is small; the density is high; the relative magnetic conductivity is high; the cooling performance is good; the service life is long; the electric inductance is molded as a whole; and the manufacturing method of the electric inductance is simple, thus reducing the production cost.

Owner:POCO HLDG CO LTD +2

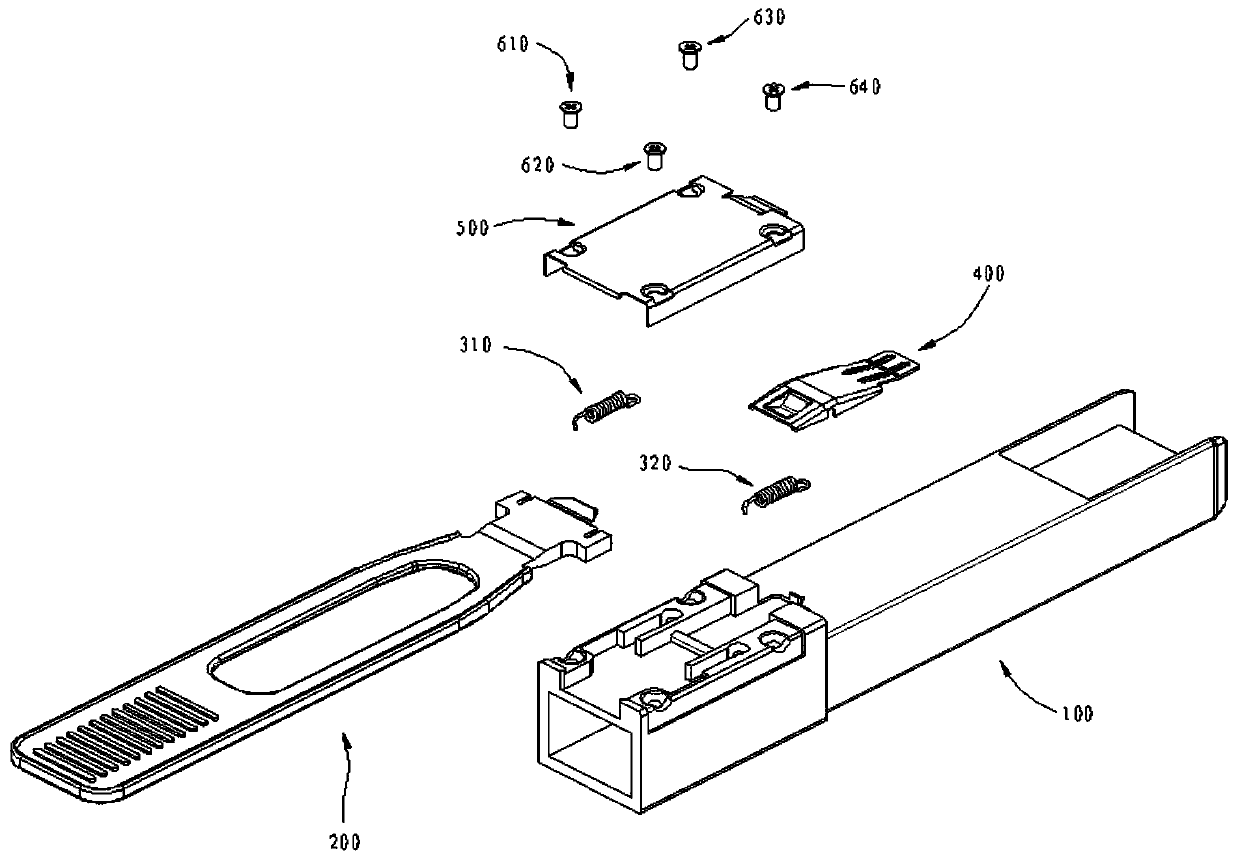

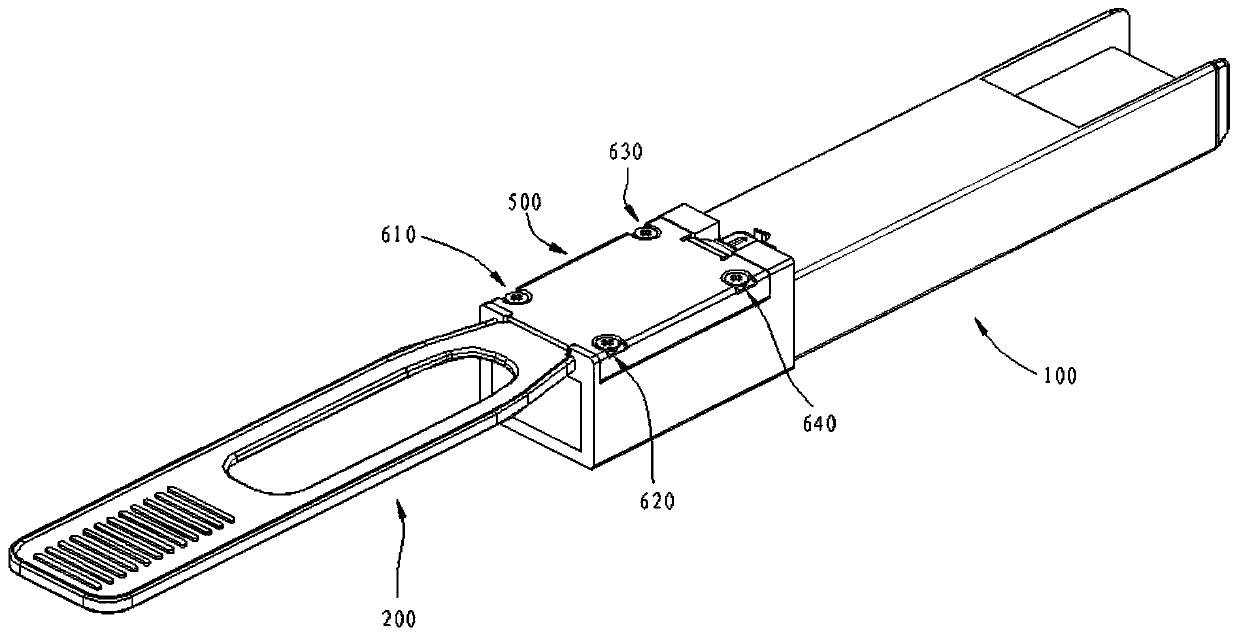

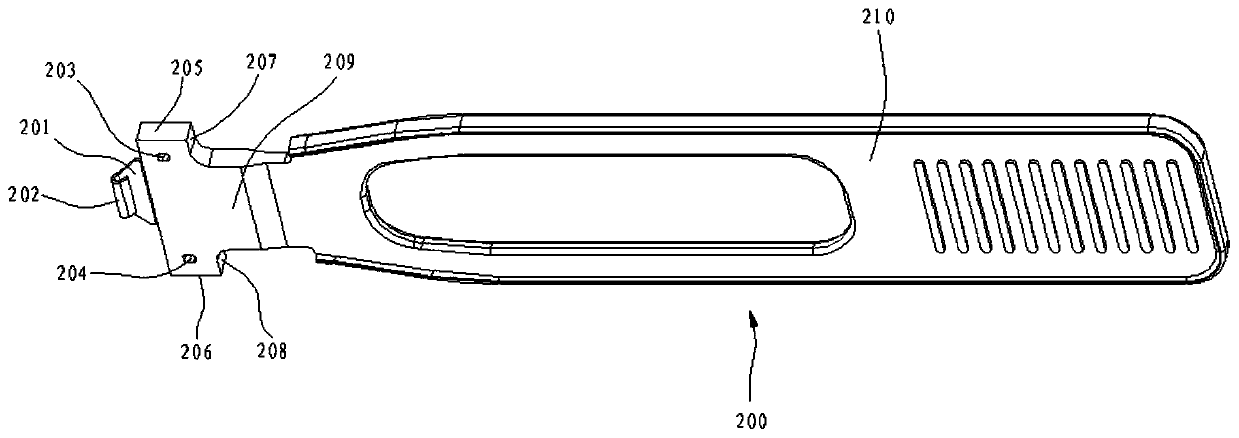

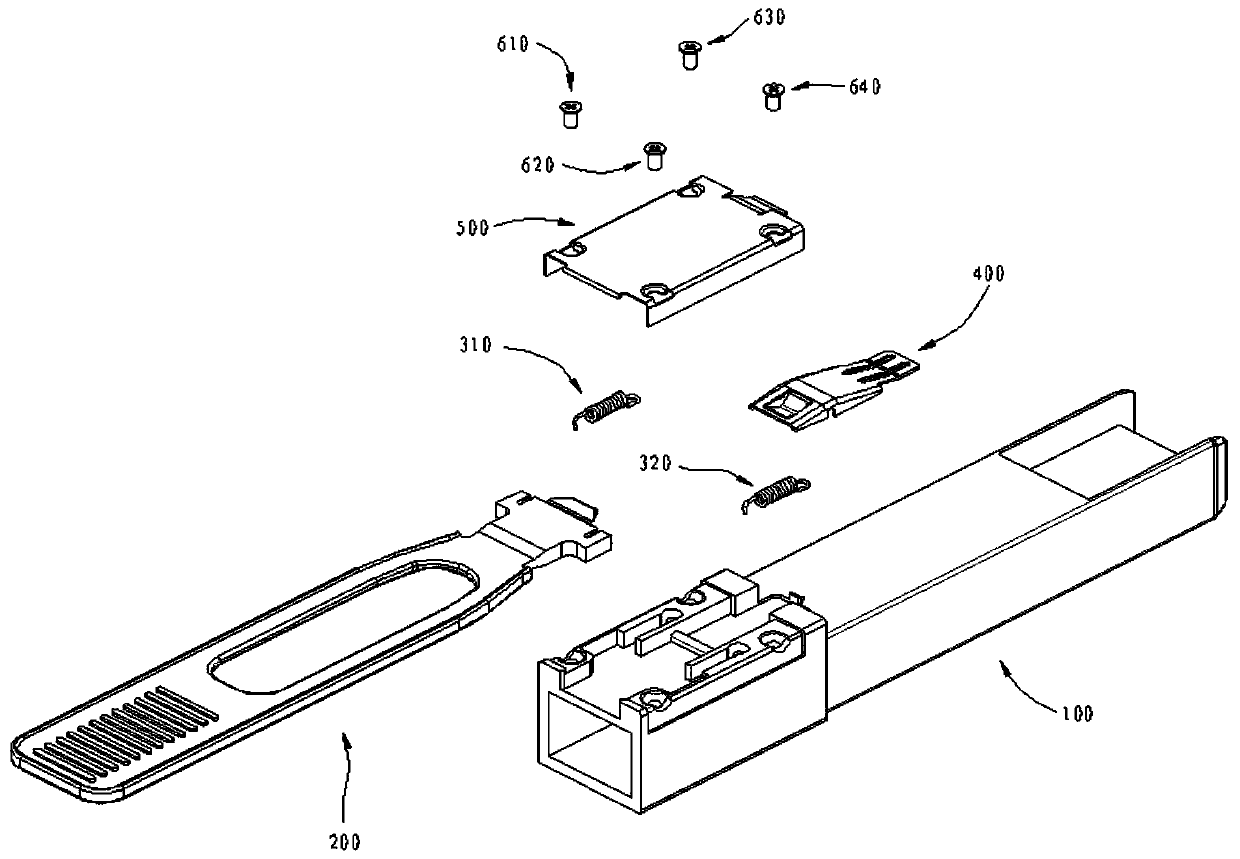

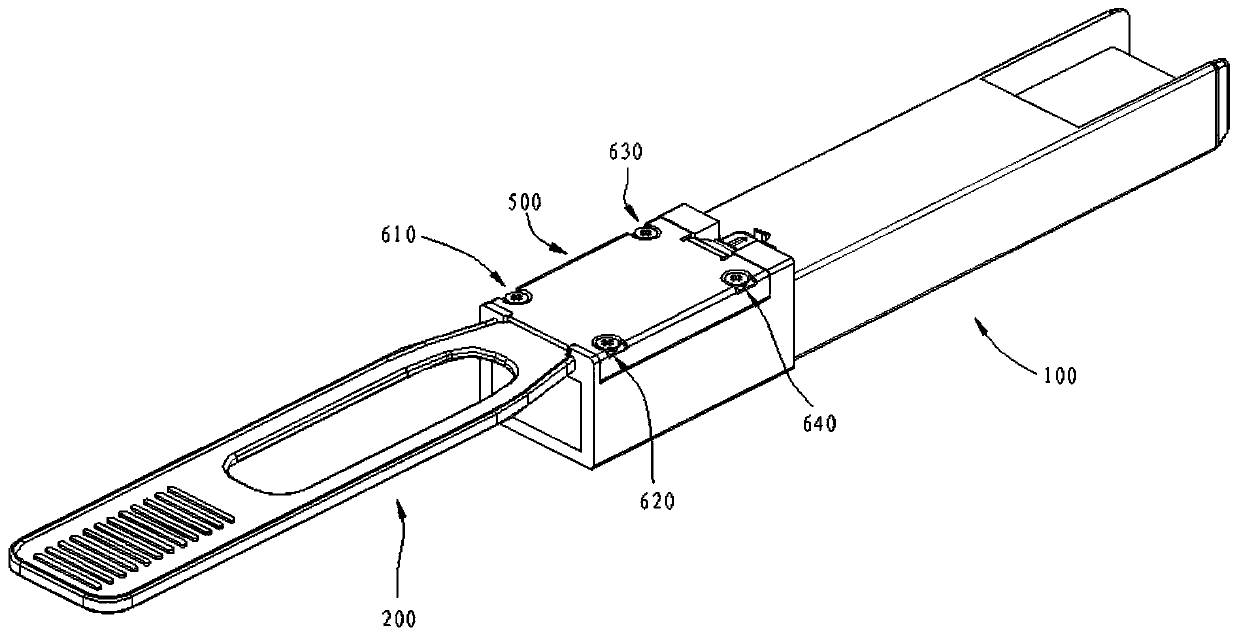

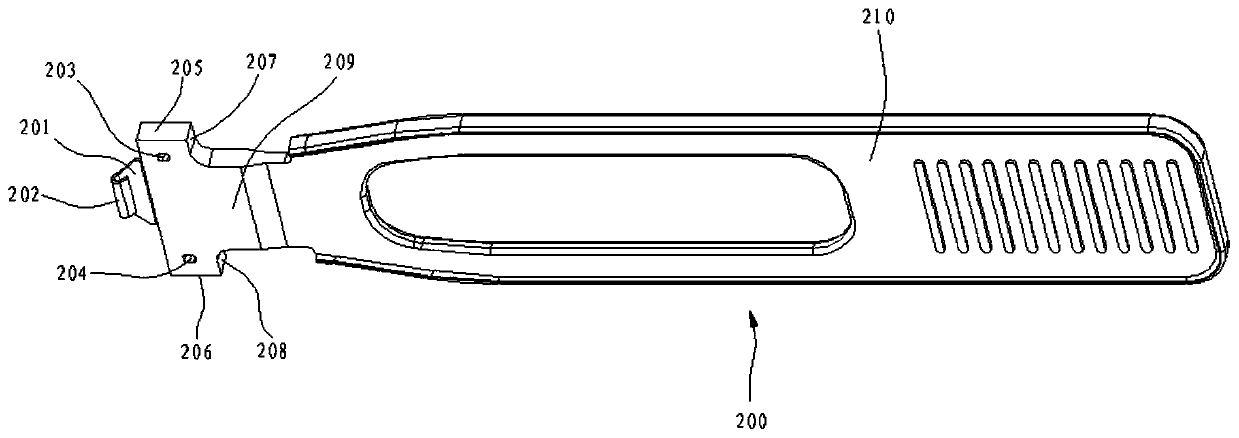

Long handle module mounting and unloading device

ActiveCN110068901AGuaranteed closureIntegrity guaranteedCoupling light guidesStructural reliabilityShaped beam

The invention belongs to the technical field of optical communication, and discloses a long handle module mounting and unloading device, comprising a shell, a pull ring, a tension spring, a brake padand a cover plate, wherein the shell comprises a first cavity, a second cavity and a U-shaped beam, and the U-shaped beam separates the first cavity and the second cavity; the brake pad comprises a matrix, a first U-shaped groove, a second U-shaped groove, a bent structure and a third inclined plane, the first U-shaped groove, the second U-shaped groove and the bent structure are arranged on the matrix, and the third inclined plane is arranged on the bent structure; the pull ring comprises a handle, a pressure lever and a pressure head; and the cover plate comprises a pressing tongue. According to the long handle module mounting and unloading device disclosed by the invention, the brake pad is tilted downward to unload a module by unclenching a shielding cage lock catch, the problems thatthe requirements of a straight pull type loading and unloading mechanism of the module for the wall thickness of the shell are high, the shell is designed with an evasion structure to affect the EMI performance, and the loading and unloading mechanism has relatively poor reliability, narrow application range and complicated installation in the prior art are solved.

Owner:GUANGXUN SCI & TECH WUHAN

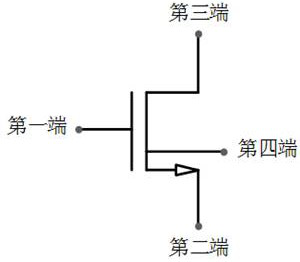

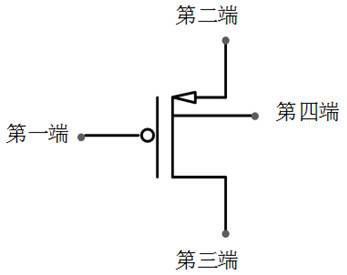

Driving circuit, control chip circuit, power adapter and electronic equipment

ActiveCN113676025AGood EMI effectEfficient power electronics conversionPower conversion systemsHemt circuitsControl theory

The invention provides a driving circuit, a control chip circuit, a power adapter and electronic equipment. The driving circuit comprises an operational amplifier circuit, a comparator, a first NMOS tube, a second NMOS tube, a third NMOS tube, a first PMOS tube, a second PMOS tube, a first driving control module and a second driving control module. A first resistor, a second resistor and the first NMOS tube are used for forming an LDO negative feedback system. By adopting the embodiment of the invention, the EMI problem caused by a GaN power tube in the charging application can be solved, and the accuracy requirement of the driving voltage of the GaN power tube can be met.

Owner:SHENZHEN INJOINIC TECH

Voltage division step-down Cuk converter circuit

InactiveCN103023313BInput and output current continuousSmall pulsationApparatus without intermediate ac conversionElectric variable regulationCapacitancePower flow

The invention relates to a voltage division step-down Cuk converter circuit which comprises a power switch tube S, a diode D1, a diode D2, a diode D3, a diode D4, a capacitor C1, a capacitor C2, an output electrolytic capacitor Co, an inductor L1 and an inductor L2. The capacitor C1, the capacitor C2, the diode D2, the diode D3 and the diode D4 form a voltage division circuit structure, and a step-down range is widened. The voltage division step-down Cuk converter circuit can realize large step-down change, reasonable PWM (pulse width modulation) duty ratio control and floor control for a switch, and has the advantages of continuous input and output current, low pulse, high circuit conversion efficiency, fine EMI (electro-magnetic interference) effect, convenience in control and the like.

Owner:FUZHOU UNIV

Flat cable

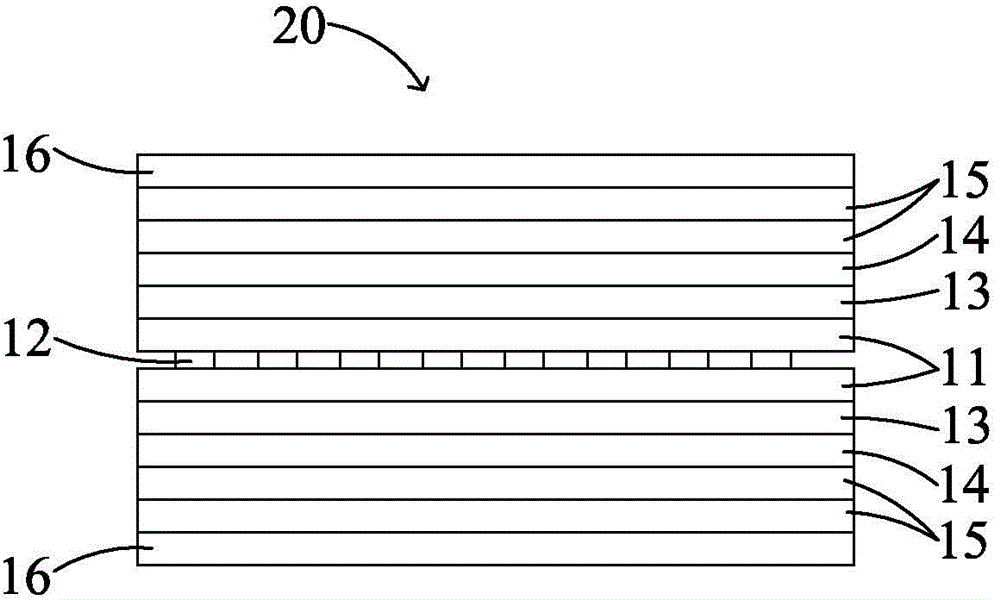

InactiveCN104658650AImprove high frequency performanceFunction as a shuntFlat/ribbon cablesInsulated conductorsElectrical conductorCompanion animal

The invention relates to a flat cable which comprises a pair of insulating films, a plurality of conductors, a dielectric layer, at least one bonding layer and a coating layer, wherein the conductors are clamped between the insulating films and arranged left and right at intervals, and the dielectric layer, the bonding layer and the coating layer sequentially cover the outer side of one insulating film; the dielectric layer is made of PET, PE, PP or CPP; the surface of the bonding layer is bonded with a permeability magnetic material, and the bonding layer can provide a good EMI effect. The high-frequency performance of the flat cable is improved.

Owner:BOZHOU LIAN TAO ELECTRONICS

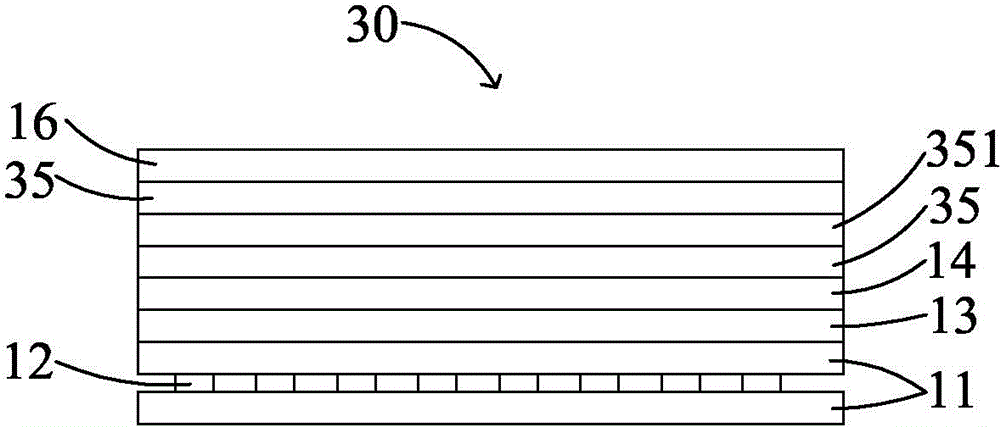

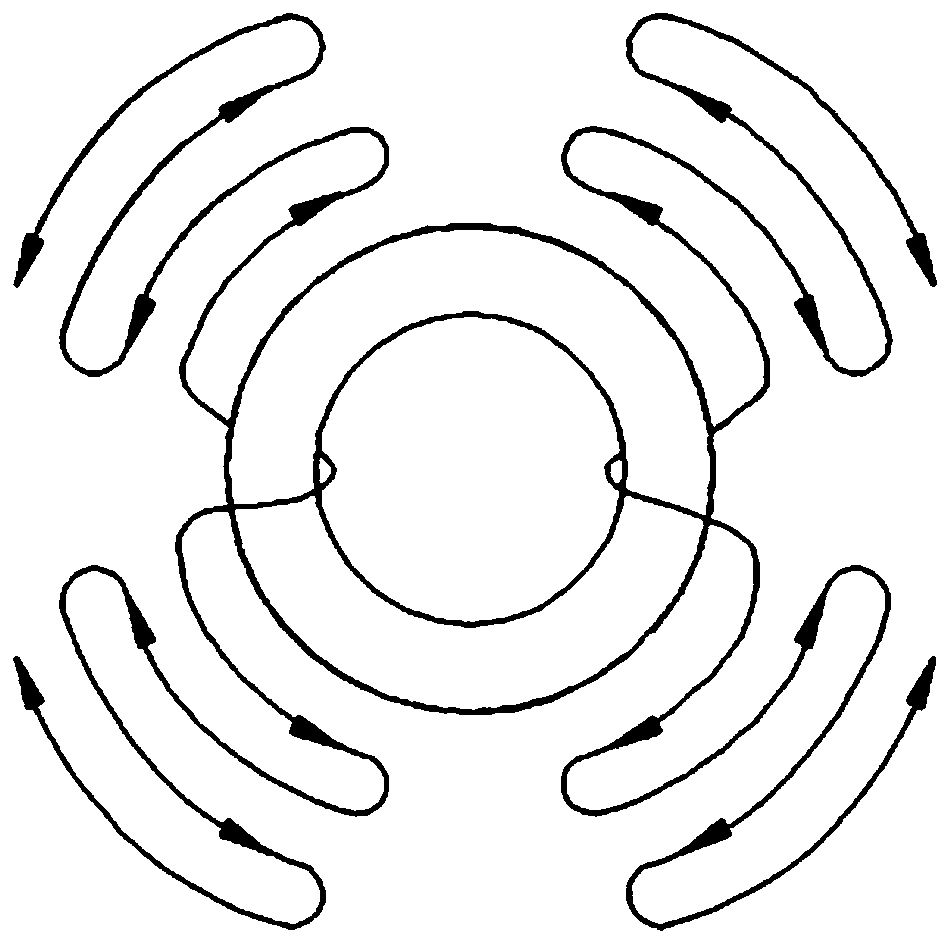

New winding method of emi common mode inductor and its winding method

ActiveCN107195428BChange distributionReduce distributed capacitanceTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringInductor

The embodiments of the present invention disclose an EMI common-mode inductor of a new winding method and a winding method for the EMI common-mode inductor, relating to the technical field of common-mode inductors. The EMI common-mode inductor of the new winding method comprises a toroidal magnetic core, and wound at symmetric positions on two sides of the toroidal magnetic core, two windings and four lead ends. Each winding is a multi-segment winding, and multiple layers are wound around each segment of a winding. Two lead ends of each winding are disposed at two ends of the winding respectively, and one of the lead ends is positioned at the innermost layer of the winding and the other lead end is positioned at the outermost layer of the winding. The embodiments of the present invention can ensure EMI effect, realize automatic winding, effectively improve production efficiency, greatly save labor, lower reject ratio, reduce product cost, and achieve win-win between a client and a supplier.

Owner:SHANDONG ZHONGRUI ELECTRONICS

A long handle module installation and unloading device

Disclosed is a loading and unloading device for a long handle module, comprising a housing (100), a pull ring (200), tension springs (310, 320), a brake disc (400) and a cover plate (500). The housing (100) comprises a first cavity (116), a second cavity (102) and a U-shaped beam (115), the U-shaped beam (115) separating the first cavity (116) from the second cavity (102). The brake disc (400) comprises a base body (412), a first U-shaped groove (409), a second U-shaped groove (410), a bend structure (403) and a third inclined surface (401). The first U-shaped groove (409), the second U-shaped groove (410) and the bend structure (403) are provided on the base body (412), and the third inclined surface (401) is provided on the bending structure (403). The pull ring (200) comprises a handle (210), a pressing rod (201) and a pressing head (202), and the pressing head (202) is arranged on the pressing rod (201). The cover plate (500) includes a pressing tongue (506). The brake disc (400) in the device tilts downwards to pry the tongue (701) of a shielding cage (700) from a lock catch (101) of the housing (100) to unload the module, thereby solving the following problems: the direct-pulling type loading and unloading mechanism for modules in the prior art has high requirements on the wall thickness of the housing (100), a relief structure designed for the housing (100) influences the EMI performance, and the structure of the loading and unloading mechanism has poor reliability, narrow application range, and installation complicity.

Owner:GUANGXUN SCI & TECH WUHAN

Switch tube control method, device and air conditioner

ActiveCN106998133BImprove power factorGood EMI effectEfficient power electronics conversionPower conversion systemsAC - Alternating currentPower factor

The invention discloses a control method and device of a switch tube and an air conditioner. When the control method is used, a frequency of an input power supply of a power factor correction (PFC) circuit is periodically acquired, a switch frequency of a power switch tube is set, an output duty ratio of the power switch tube is calculated according to an AC voltage value an AC current value, which are acquired, of the input power supply of the PFC circuit and an acquired DC bus voltage value, and the power switch tube is driven to be periodically switched off or switched on according to the switch frequency and the output duty ratio. By the control method, the switch-on and the switch-off of the power switch tube can be controlled according to different frequencies of the input power supply, the power factor of the PFC circuit is increased, so that the optimal electro magnetic interference (EMI) effect is achieved.

Owner:GD MIDEA AIR CONDITIONING EQUIP CO LTD

A high-power circular reactor and its manufacturing method

ActiveCN104835616BReduce investmentSave materialTransformers/inductances magnetic coresInductances/transformers/magnets manufactureEngineeringResin adhesive

The invention discloses a novel circular-ring-shaped high-power electric reactor. The electric reactor comprises a magnetic core and a coil. The magnetic core is a circular-ring-shaped magnetic core formed by two identical semicircular-ring-shaped magnetic core bodies in a combined mode, the diameter of the circular-ring-shaped magnetic core ranges from 7 inches-20 inches, and the magnet density of the circular-ring-shaped magnetic core ranges from 5.5 g / cm<3> to 6.2 g / cm<3>. The two semicircular-ring-shaped magnetic core bodies are sleeved with the coil which is a spiral varnished wire coil formed by a flat wire in a vertical winding mode. The semicircular-ring-shaped magnetic core bodies are formed by pouring a magnetic composite material composed of ferromagnetic powder and high-temperature resin adhesive through a semicircular-ring-shaped mould. The electric reactor is simple in structure, low in production cost, light in weight, low in noise, low in loss, good in surface heat dissipation and long in service life; the process is simple, and automatic operation is easy to achieve; the utilization rate of the magnetic core is high, magnetic leakage is small, and the EMI effect is good.

Owner:POCO HLDG CO LTD +2

Drive circuit and related products

ActiveCN113676026BDrive voltage rises smoothlyGood EMI effectEfficient power electronics conversionDc-dc conversionDriving currentControl engineering

The present application provides a drive circuit and related products, the drive circuit includes: a first segment drive circuit and a second segment drive circuit, wherein the first segment drive circuit is connected to the second segment drive circuit; The second section of the driving circuit is used to drive the external power transistor to realize the driving function; the driving current of the second section of the driving circuit is E times of the driving current of the first section, and the said E is greater than 1. Adopting the embodiment of the present application, since the first section of the driving circuit is driven by a small current, and the second section of the driving circuit is driven by a large current, the change of di / dt can be reduced, the driving voltage of the power tube can be increased smoothly, and the EMI effect of the chip can be improved.

Owner:SHENZHEN INJOINIC TECH

Dynamic regulation power controller

ActiveUS20210175812A1Improve power efficiencyGood EMI effectEfficient power electronics conversionDc-dc conversionCapacitanceTransformer

Disclosed is a dynamic regulation power controller having a work voltage input pin, a feedback voltage input pin, a driving voltage output pin, a current sensing input pin, and a regulation power input pin, and being in collocation with a switching unit, an input power processing unit, a transformer, a current sensing resistor, a power regulation unit, an output rectification unit, and an output capacitor for converting an input AC voltage into an output voltage for supplying a load. In particular, the driving voltage and the driving current are dynamically adjusted according to the feedback voltage and the current sensing signal, thereby greatly increasing efficiency of power conversion and Electromagnetic Interference (EMI).

Owner:INNOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com