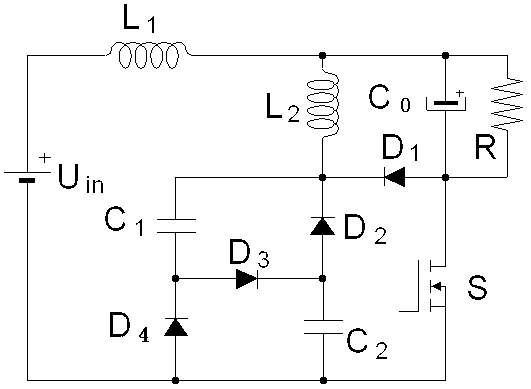

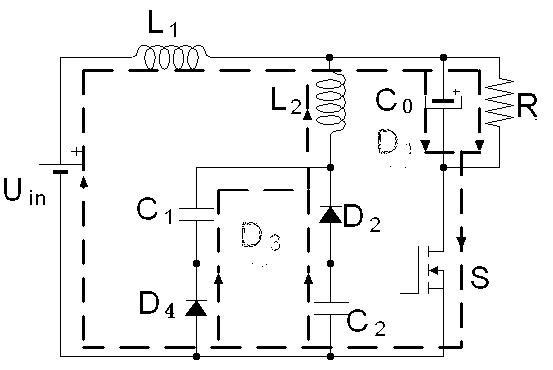

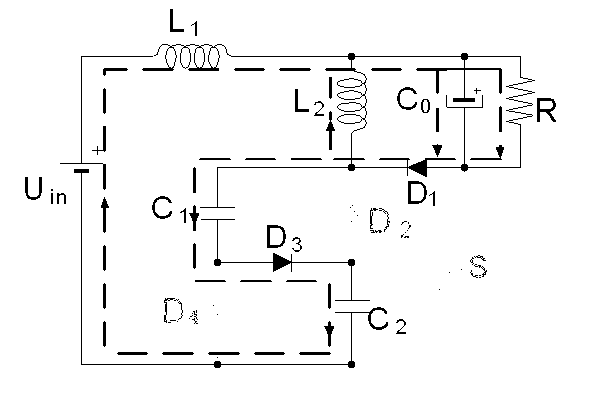

Voltage division step-down Cuk converter circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

[0024] The present invention provides a voltage-dividing step-down Cuk converter circuit, including a power switch tube S, characterized in that: the control terminal of the power switch tube S is connected to a PWM control signal, and one end of the power switch tube S is used as The negative pole of the output end of the voltage-dividing buck Cuk converter circuit is connected to the negative pole of an output electrolytic capacitor Co and the anode of a diode D1; the cathode of the diode D1 is connected to one end of an inductor L2, one end of a capacitor C1 and A cathode of a diode D2; the positive pole of the output electrolytic capacitor Co is used as the positive pole of the output terminal of the voltage-dividing step-down Cuk converter circuit and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com