Damper assembly for reducing combustion-chamber pulsation

A technology of muffler and burner, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve problems such as unpopular solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

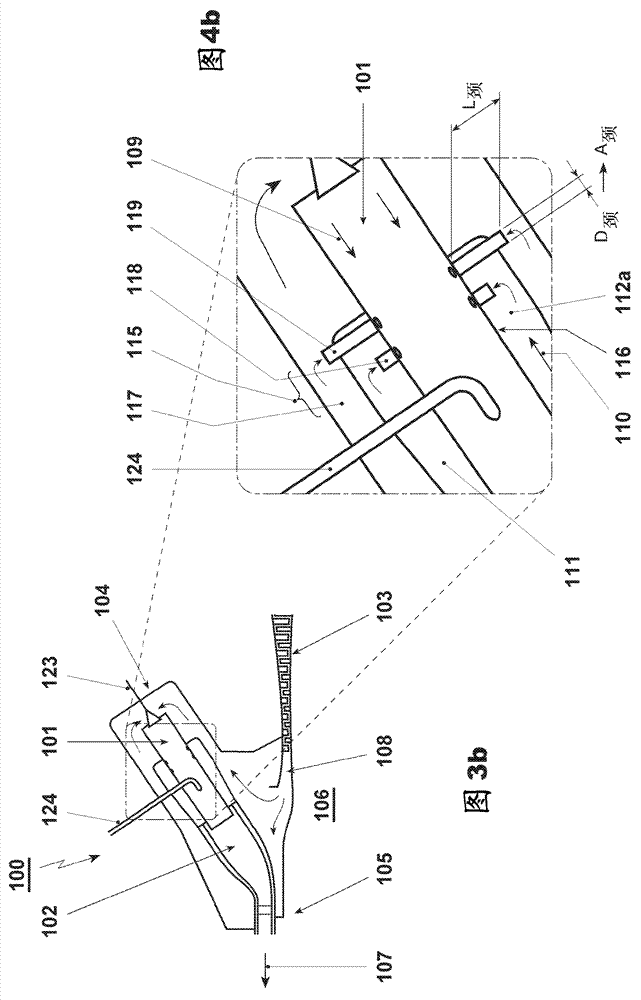

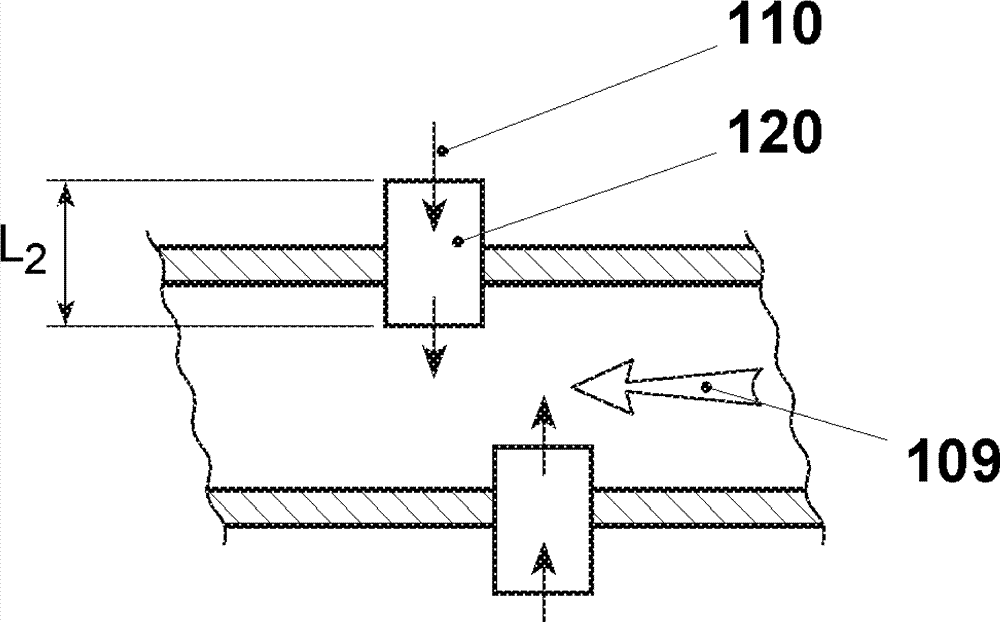

[0083] In a cross-flow configuration, the oscillating gaseous fuel is injected perpendicular to the flow of oxidant.

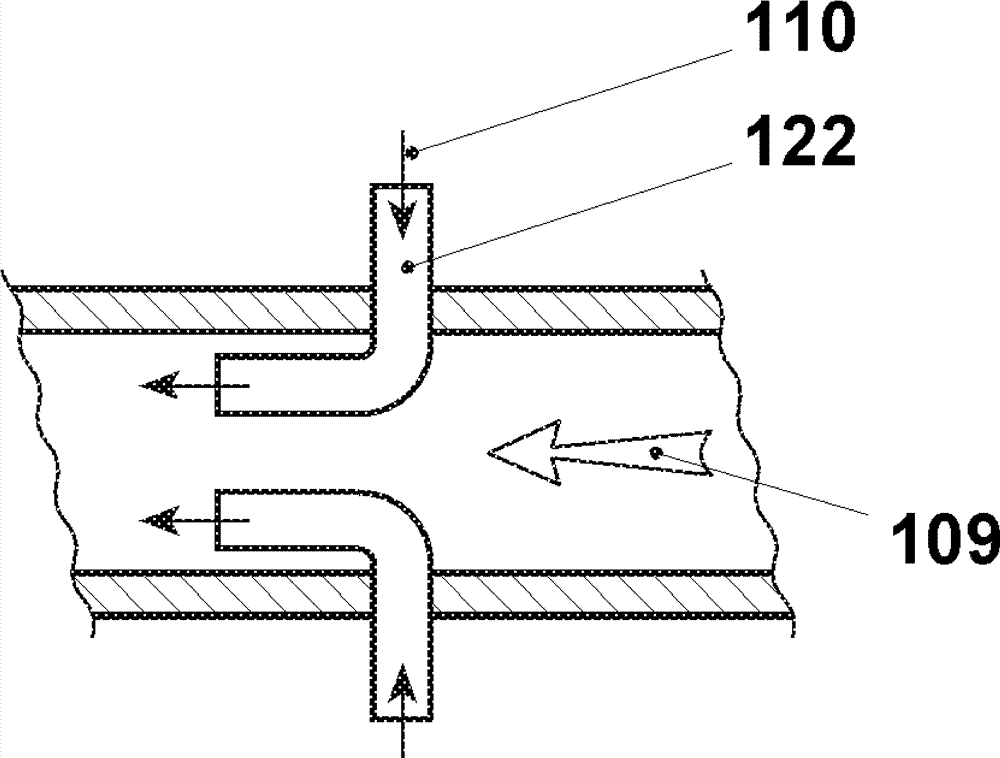

[0084] In an in-line configuration, an oscillating gaseous fuel is injected parallel to the flow of oxidant.

[0085] The oscillating gaseous fuel is injected at an oblique angle between 0° and 90° relative to the oxidant flow.

[0086] EP 0 646 705 A1 relates to a method for establishing part-load operation in a gas turbine bank with sequential fuel, EP 0 646 704 A1 relates to a method for controlling a gas turbine installation equipped with two combustion chambers, and

[0087] EP 0 718 470 A1 relates to a method for operating a gas turbine equipped with two combustion chambers while providing part-load operation, which also forms an integral part of the present description.

[0088] Some compressed air 108 is tapped off as high pressure cooling air, fed as cooling air to the primary and / or secondary combustors or recooled by a high pressure cooling air coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com