Long handle module mounting and unloading device

A technology of unloading device and handle, which is applied in the field of optical communication, can solve the problems of high shell wall thickness, complicated installation, and narrow application range, so as to ensure sealing and integrity, high structural reliability, and good EMI effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

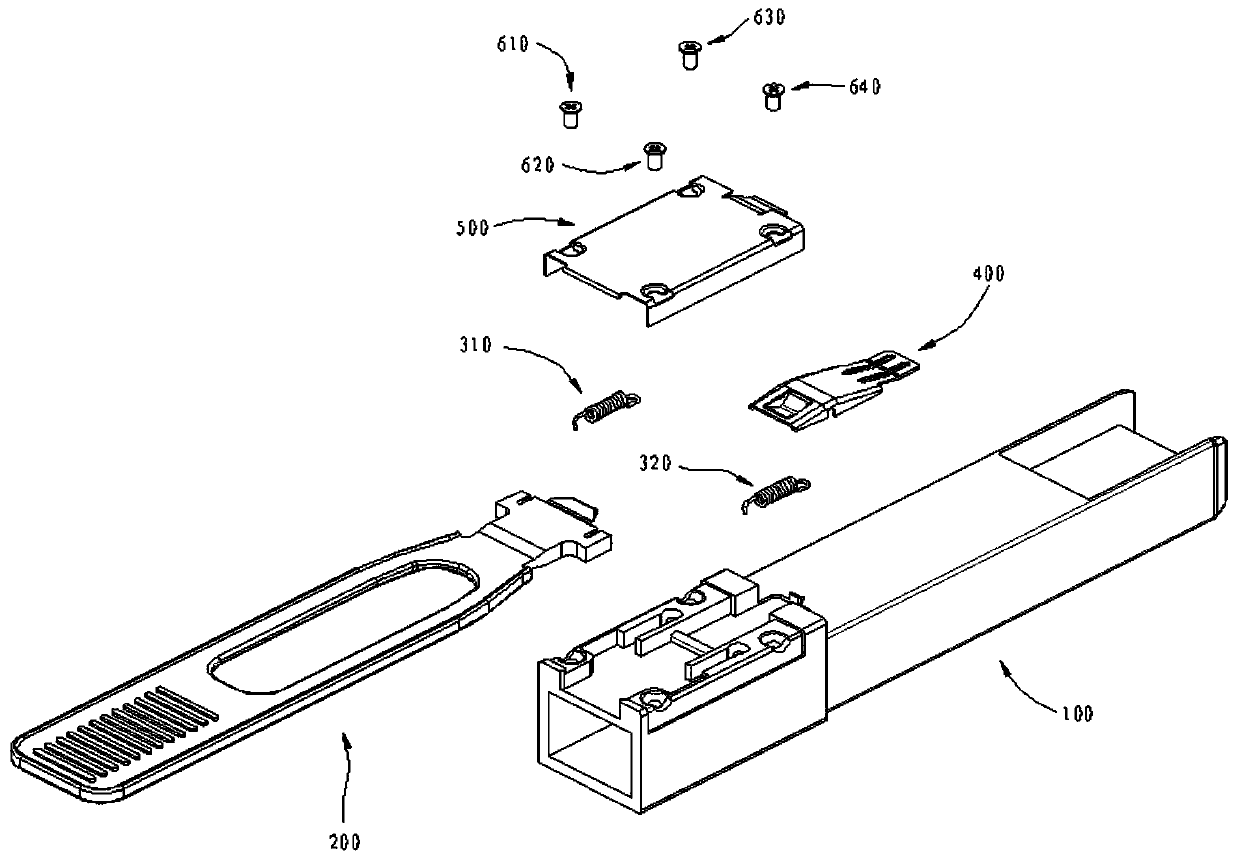

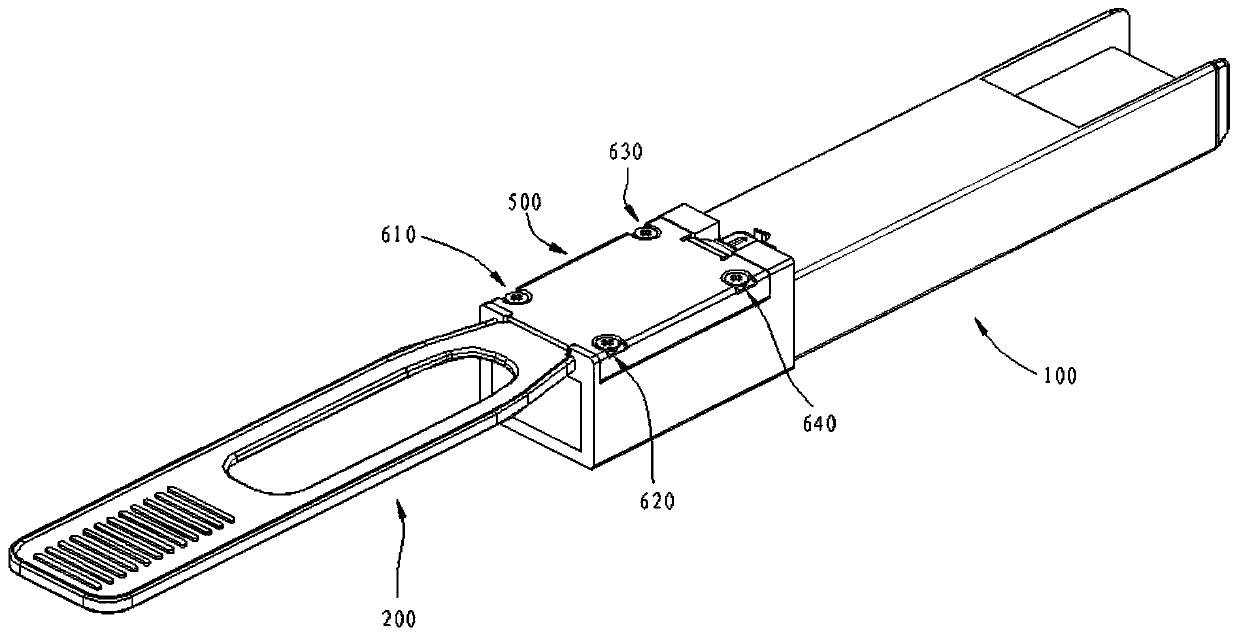

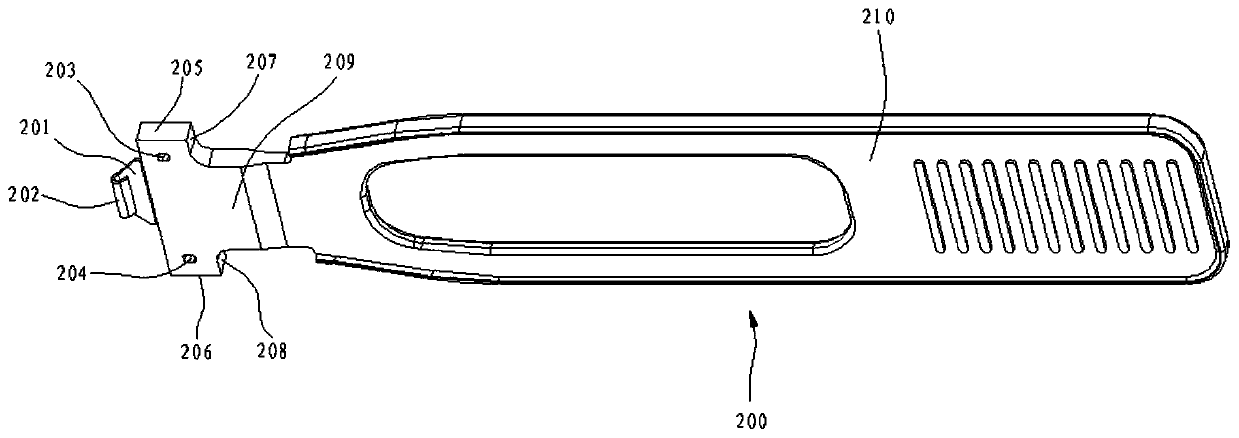

[0084] This embodiment provides a long handle module installation and unloading device, such as figure 1 , figure 2 As shown, it mainly includes: a housing 100 , a pull ring 200 , a tension spring (including a first tension spring 310 and a second tension spring 320 ), a brake pad 400 , and a cover plate 500 . In addition, screws for fixing (including the first screw 610 , the second screw 620 , the third screw 630 and the fourth screw 640 ) are also included.

[0085] Each component will be described separately below.

[0086] (1) Shell.

[0087] Such as Figure 8 , Figure 9 As shown, the housing 100 is provided with a first cavity 116 and a second cavity 102 at the upper rear, and the first cavity 116 and the second cavity 102 are separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com