Novel circular-ring-shaped high-power electric reactor and manufacturing method thereof

A manufacturing method and circular technology, which are applied in the manufacture of inductors/transformers/magnets, transformers/inductor cores, circuits, etc., can solve problems such as difficulty in meeting application requirements, complex production processes, and high core noise. The effect of saving equipment investment, simplifying production process and low eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

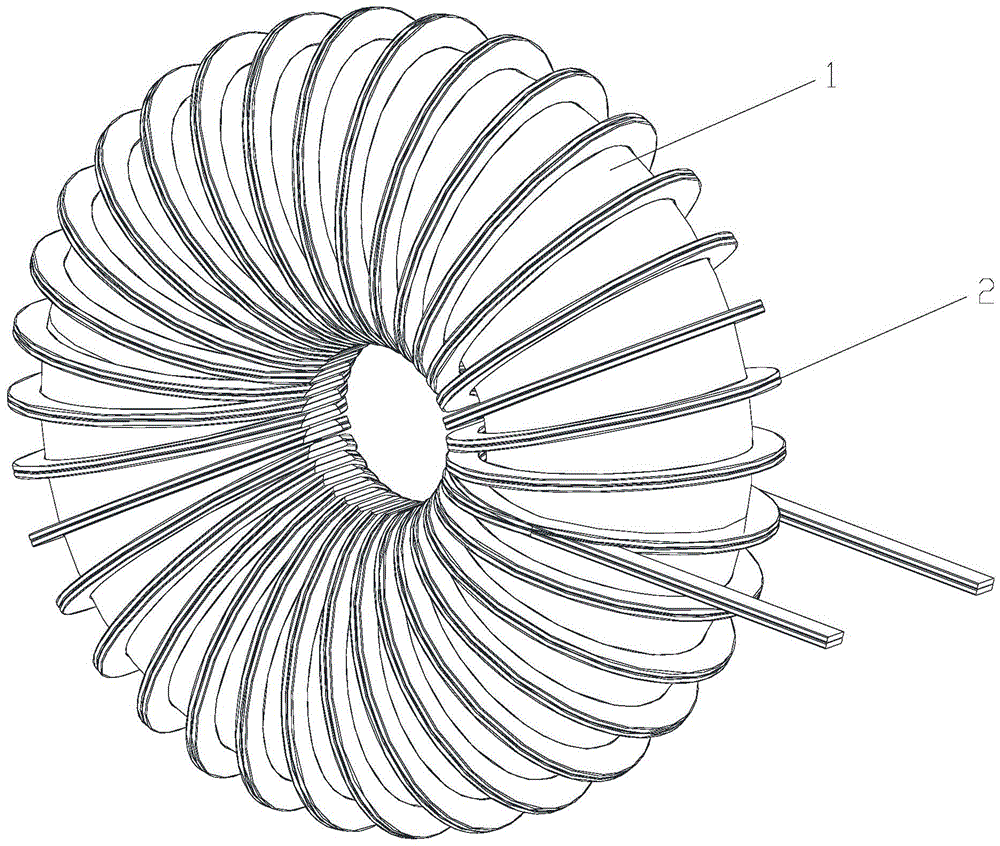

[0037] A new high-power annular reactor, including a magnetic core 1 and a coil 2, the magnetic core 1 is a circular magnetic core formed by two identical semi-circular magnetic cores fixedly connected by glue, the semi-circular magnetic core The cross section of the circular magnetic core is circular, the diameter of the circular magnetic core is 20 inches, and the magnet density of the circular magnetic core is 6.2g / cm 3 , the coil 2 is set on the two semi-circular magnetic cores, the coil 2 is a spiral enameled wire coil made of a flat wire vertically wound, and the semi-circular magnetic core is made of ferromagnetic powder and high temperature resin glue The composed magnetic composite material is made by pouring into a semi-circular mold.

[0038] The above-mentioned high-power annular reactor is manufactured by the following method, including the following steps:

[0039] 1) Use the automatic winding machine to vertically wind the flat wire into a spiral enameled wire ...

Embodiment 2

[0045] A new high-power annular reactor, including a magnetic core 1 and a coil 2, the magnetic core 1 is a circular magnetic core formed by two identical semi-circular magnetic cores fixedly connected by glue, the semi-circular magnetic core The cross section of the circular magnetic core is circular, the diameter of the circular magnetic core is 15 inches, and the magnet density of the circular magnetic core is 5.9g / cm 3 , the coil 2 is set on the two semi-circular magnetic cores, the coil 2 is a spiral enameled wire coil made of a flat wire vertically wound, and the semi-circular magnetic core is made of ferromagnetic powder and high temperature resin glue The composed magnetic composite material is made by pouring into a semi-circular mold.

[0046] The above-mentioned high-power annular reactor is manufactured by the following method, including the following steps:

[0047] 1) Use the automatic winding machine to vertically wind the flat wire into a spiral enameled wire co...

Embodiment 3

[0053] A new high-power annular reactor, including a magnetic core 1 and a coil 2, the magnetic core 1 is a circular magnetic core formed by two identical semi-circular magnetic cores fixedly connected by glue, the semi-circular magnetic core The cross section of the circular magnetic core is circular, the diameter of the circular magnetic core is 7 inches, and the magnet density of the circular magnetic core is 5.5g / cm 3 , the coil 2 is set on the two semi-circular magnetic cores, the coil 2 is a spiral enameled wire coil made of a flat wire vertically wound, and the semi-circular magnetic core is made of ferromagnetic powder and high temperature resin glue The composed magnetic composite material is made by pouring into a semi-circular mold.

[0054] The above-mentioned high-power annular reactor is manufactured by the following method, including the following steps:

[0055] 1) Use the automatic winding machine to vertically wind the flat wire into a spiral enameled wire c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com