New winding method of emi common mode inductor and its winding method

A common mode inductance and winding technology, applied in the production field of toroidal common mode inductance coils, can solve the problems of many technical requirements of staff, inability to realize automatic winding, and inability to machine butterfly winding, etc., and meet the requirements of staff Low cost, manpower saving, simple winding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

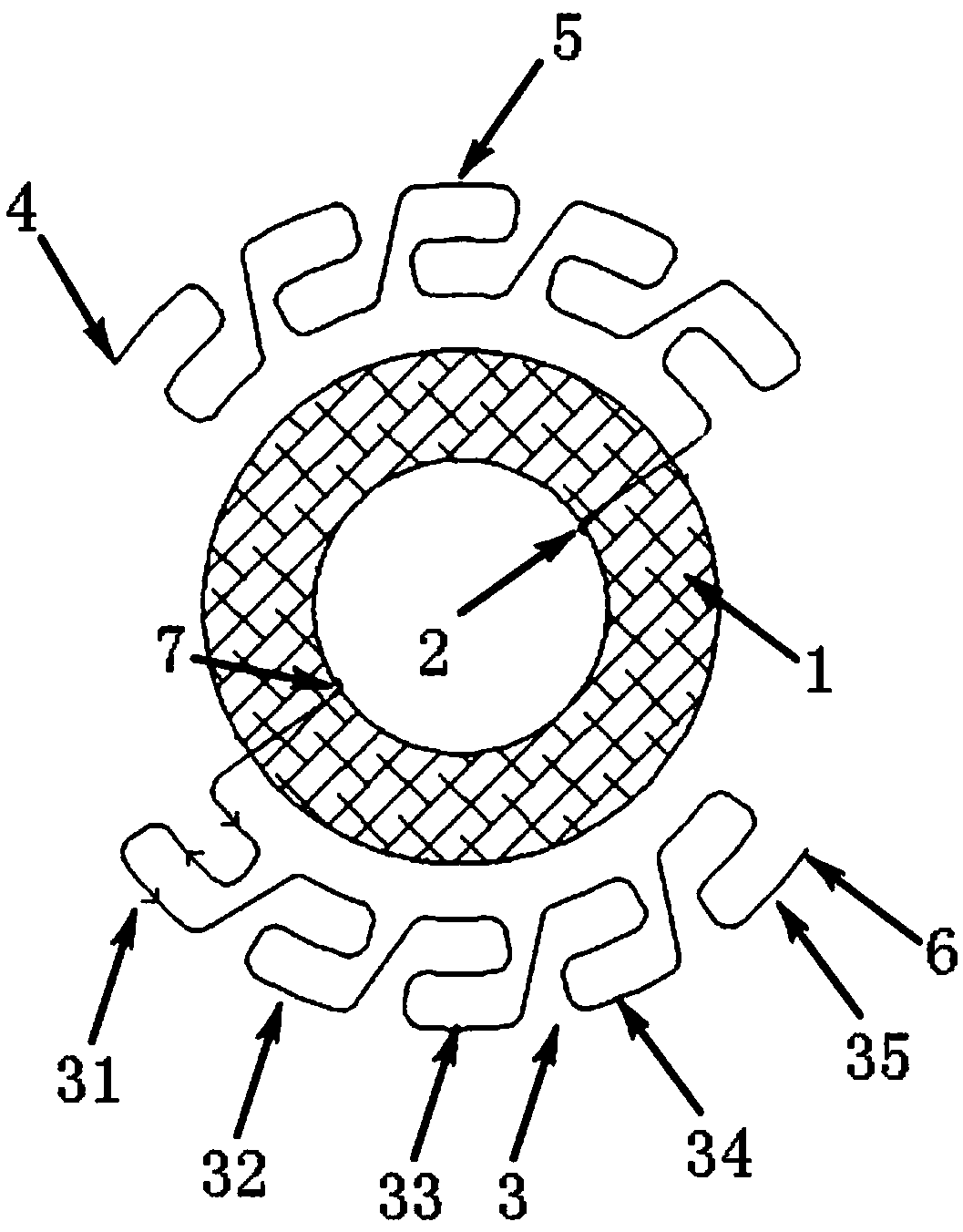

[0029] The present invention provides a kind of EMI common mode inductor of novel winding method, such as figure 2 As shown, it includes a ring core 1, two windings 3, 5 and four lead ends 2, 4, 6 and 7 wound symmetrically on both sides of the ring core 1, and each winding 3 or 5 is a multi-segment winding 31, 32, 33, 34 and 35, the number of winding layers of each winding is multi-layer; the two lead ends of each winding are respectively located at both ends of the winding, and one of the lead ends is located at the innermost layer 2 of the winding (or 7), the other lead end is located in the outermost layer 4 (or 6) of the winding.

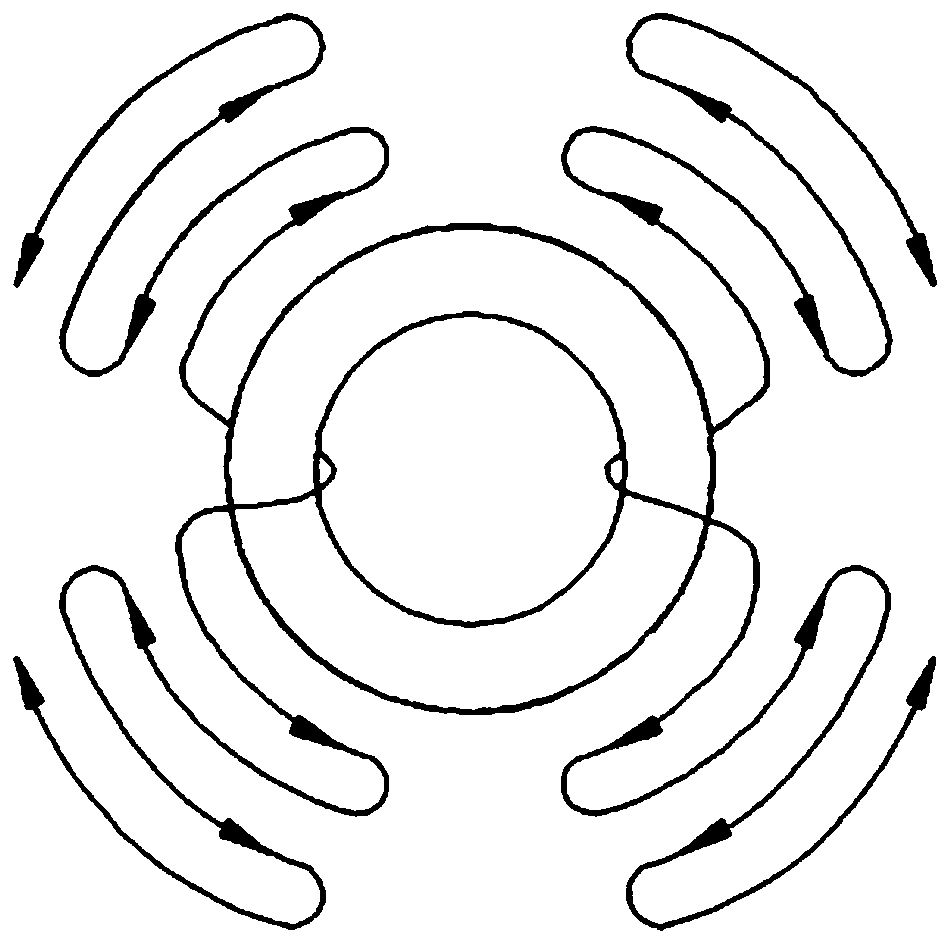

[0030] The inventors have found that by fixing one end for winding, automatic winding can be realized, but the anti-el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com