A kind of radiation-resistant ceramic fiber thermal insulation composite material and its preparation method

A ceramic fiber and composite material technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of high hydrophobicity, high thermal conductivity, high corrosion, etc., achieve good neutron radiation resistance and ensure technical performance , to ensure the full effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

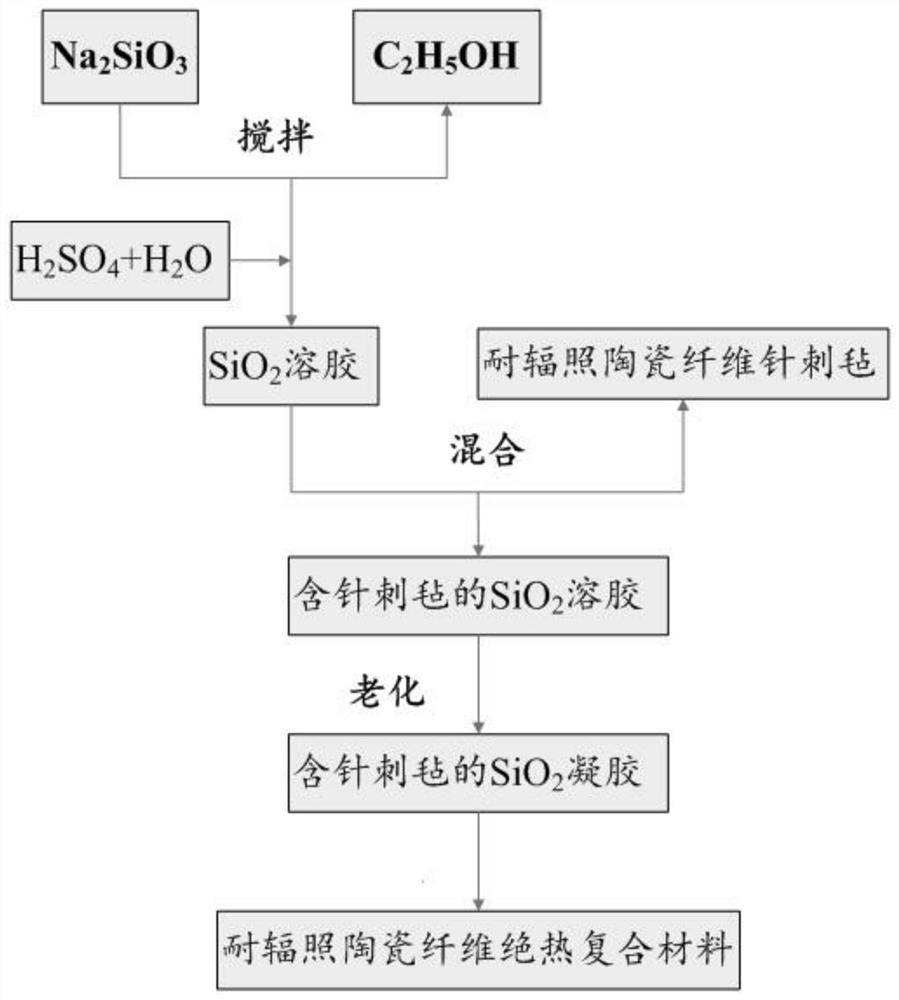

Method used

Image

Examples

Embodiment 1

[0039] According to the chemical composition shown in Table 2 below, the radiation-resistant ceramics were fired by the conventional process, and the ceramic fibers were drawn by a general-purpose crucible or pool kiln to form tows with an average diameter of 11 μm. The net and needle punching process form a thickness of 3mm and a bulk density of 108kg / m 3 Radiation-resistant ceramic fiber needle felt.

[0040] Ceramic chemical composition in table 2 embodiment 1

[0041] serial number Element content(%) 1 SiO 2

59.85 2 al 2 o 3

13.12 3 CaO 22.63 4 MgO 2.71 5 Li 2 o

0.023 6 B 2 o 3

0.042

[0042] Take Na 2 SiO 3 as the precursor, C 2 h 5 OH is the solvent, H 2 SO 4 As a catalyst, the C 2 h 5 OH / Na 2 SiO 3 =4 (molar ratio, the same below) Na 2 SiO 3 with C 2 h 5 OH mixed and stirred, adding H to the stirring mixture 2 O / Na 2 SiO 3 = 3.5 deionized water and H 2 SO 4 / Na 2 SiO 3 ...

Embodiment 2

[0047] According to the chemical composition shown in Table 4 below, the radiation-resistant ceramics were fired by the conventional process, and the ceramic fibers were drawn by a general-purpose crucible or pool kiln to form tows with an average diameter of 9 μm. The mesh and needle punching process form a thickness of 6mm and a bulk density of 102kg / m 3 Radiation-resistant ceramic fiber needle felt.

[0048] Ceramic chemical composition in table 4 embodiment 2

[0049] serial number Element content(%) 1 SiO 2

59.67 2 Al 2 o 3

12.71 3 CaO 22.46 4 MgO 2.37 5 Li 2 o

0.008 6 B 2 o 3

0.012

[0050] Take Na 2 SiO 3 as the precursor, C 2 h 5 OH is the solvent, H 2 SO 4 As a catalyst, the C 2 h 5 OH / Na 2 SiO 3 Na = 8 2 SiO 3 with C 2 h 5 OH mixed and stirred, adding H to the stirring mixture 2 O / Na 2 SiO 3 = 4 deionized water and H 2 SO 4 / Na 2 SiO 3 =3.0×10 -3 H 2 SO 4 , let st...

Embodiment 3

[0055] According to the chemical composition shown in Table 6 below, the radiation-resistant ceramics are fired by the conventional process, and the ceramic fibers are drawn by a general-purpose crucible or a pool kiln to form a tow with an average diameter of 13 μm. The thickness of the mesh and acupuncture process is 6mm, and the bulk density is 112kg / m 3 Radiation-resistant ceramic fiber needle felt.

[0056] Ceramic chemical composition in table 6 embodiment 3

[0057] serial number Element content(%) 1 SiO 2

60.26 2 al 2 o 3

13.17 3 CaO 22.52 4 MgO 2.76 5 Li 2 o

0.022 6 B 2 o 3

0.032

[0058] Take Na 2 SiO 3 as the precursor, C 2 h 5 OH is the solvent, H 2 SO 4 As a catalyst, the C 2 h 5 OH / Na 2 SiO 3 Na = 6 2 SiO 3 with C 2 h 5 OH mixed and stirred, adding H to the stirring mixture 2 O / Na 2 SiO 3 = 4 deionized water and H 2 SO 4 / Na 2 SiO 3 =2.5×10 -3 H 2 SO 4 , let s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com