Ultra-soft low-loss cable for narrow space

A narrow space, ultra-soft technology, used in insulated cables, bendable cables, cables with double-stranded/quad-stranded, etc. , bending resistance and poor environmental resistance, to achieve the effect of small outer diameter, ensuring product shielding performance, ensuring phase stability and attenuation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

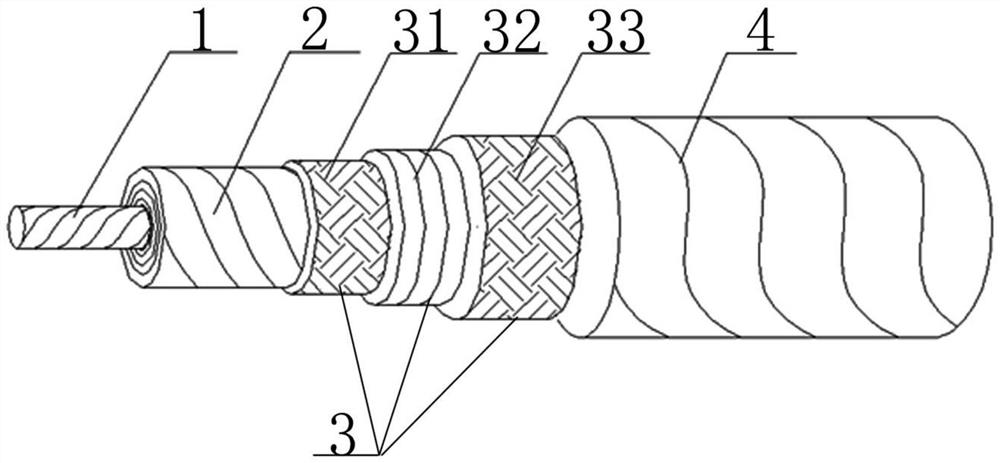

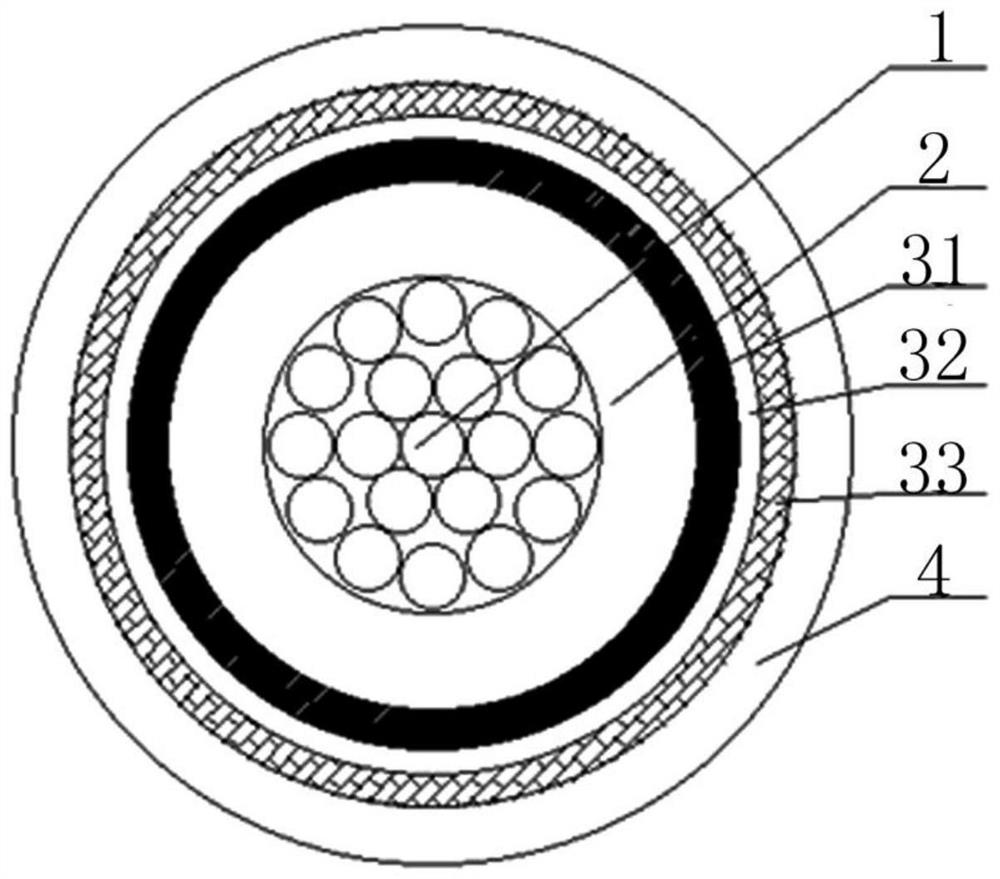

[0024] like figure 1 , figure 2 As shown, an ultra-flexible low-loss cable for a narrow space, the cable includes an inner conductor 1 twisted by a plurality of silver-plated copper alloy wires, and an insulating layer 2, a shielding layer 3 and Combination sheath layer 4; combination sheath layer 4 is made of microporous polytetrafluoroethylene tape and polytetrafluoroethylene tape wrapped around the outer shielding layer 33 and sintered, the thickness of composite sheath layer 4 is 0.5 mm. The outer diameter of the cable is 2.37mm, and the bending radius of the cable is <12mm.

[0025] In actual processing, the outer diameter of the cable is less than or equal to 2.4mm. The inner conductor 1 can be twisted with silver-plated copper wire or silver-plated copper alloy wire, and the composite sheath layer 4 is wrapped around the outer shielding layer 33 with a microporous polytetrafluoroethylene tape and a polytetrafluoroethylene tape. And sintered, the use of this technic...

Embodiment 2

[0031] like figure 1 , figure 2 As shown, an ultra-flexible low-loss cable for a narrow space, the cable includes an inner conductor 1 twisted by a plurality of silver-plated copper alloy wires, and an insulating layer 2, a shielding layer 3 and Composed of composite sheath layer 4; composite sheath layer 4 is made of microporous polytetrafluoroethylene tape and polytetrafluoroethylene tape wrapped around the outer shielding layer 33 and sintered, and the thickness of composite sheath layer 4 is 0.4 mm. The outer diameter of the cable is 2.4mm, and the bending radius of the cable is <12mm.

[0032] In actual use, the inner conductor 1 is twisted with silver-plated copper wire or silver-plated copper alloy wire, and the combined sheath layer 4 is wrapped around the outer shield with microporous polytetrafluoroethylene tape and polytetrafluoroethylene tape. layer 33 and sintered. Adopting this technical measure has the advantages of good cable flexibility and extremely smal...

Embodiment 3

[0038] like figure 1 , figure 2 As shown, an ultra-flexible low-loss cable for a narrow space, the cable includes an inner conductor 1 twisted by a plurality of silver-plated copper alloy wires, and an insulating layer 2, a shielding layer 3 and Combination sheath layer 4; combination sheath layer 4 is made of microporous polytetrafluoroethylene tape and polytetrafluoroethylene tape wrapped around the outer shielding layer 33 and sintered, the thickness of composite sheath layer 4 is 0.46 mm. The outer diameter of the cable is 2.38mm, and the bending radius of the cable is <12mm.

[0039] In actual use, the inner conductor 1 is twisted with silver-plated copper wire or silver-plated copper alloy wire, and the combined sheath layer 4 is wrapped around the outer shield with microporous polytetrafluoroethylene tape and polytetrafluoroethylene tape. layer 33 and sintered. Adopting this technical measure has the advantages of good cable flexibility and extremely small bending ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com