Improved vertical type spiral discharge filtering centrifuge

A screw unloading and centrifuge technology, applied to centrifuges, centrifuges with rotating drums, etc., can solve the problems of easy broken solid materials, small diameter of pipe holes, inconvenient installation and use of centrifuges, etc. easily broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

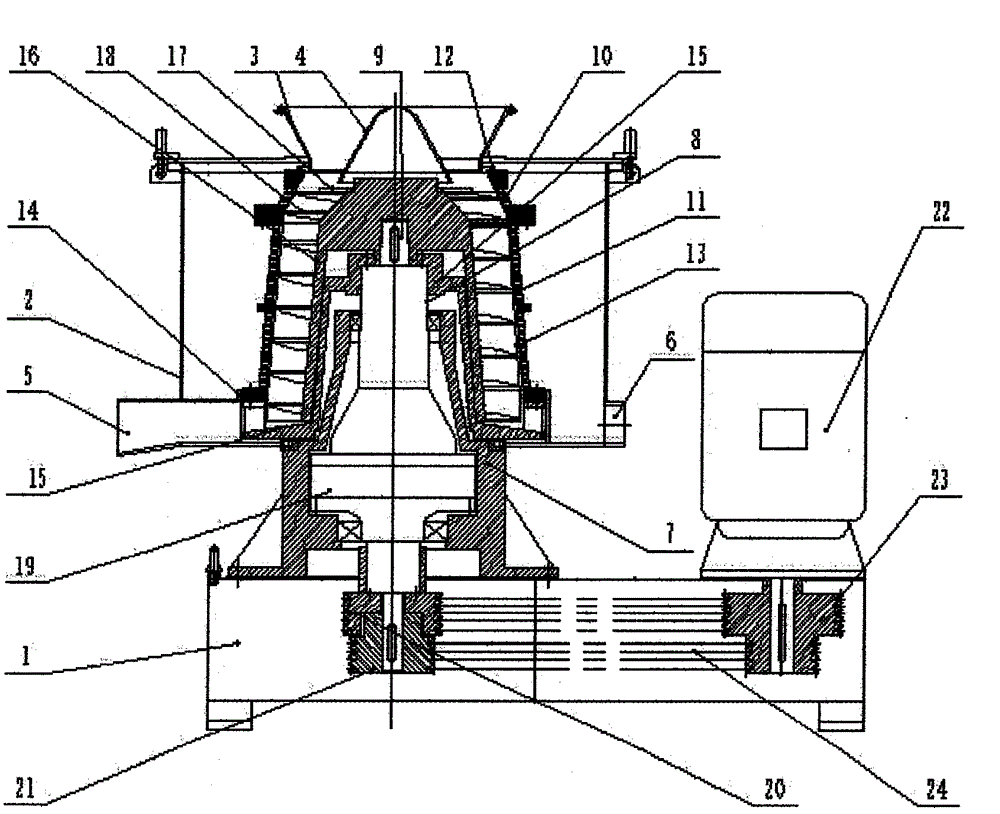

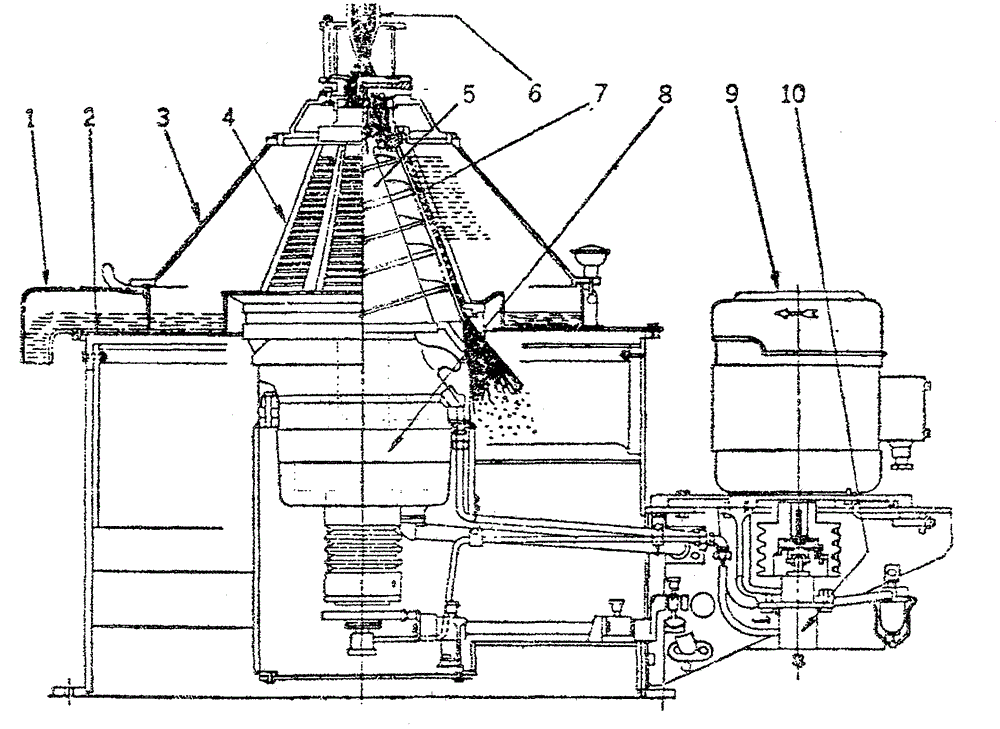

[0018] Below in conjunction with the embodiment shown in the accompanying drawings, the scheme of the present invention is described in detail as follows:

[0019] as attached figure 1 As shown, an improved vertical screw discharge filter centrifuge of the present invention, the frame 1 is fixed with a bearing seat 7 and a motor 22 is fixed. The flange at the upper end of the bearing housing 7 is connected with the housing 2 . Described drum transmission shaft 8 and coaxial line described screw conveyor transmission shaft 9 are installed in described bearing block 7, and two axles can rotate relatively. The lower end of the drum drive shaft 8 is connected with the casing of the differential 19, the drum drive shaft 8 is connected with the drum fixing flange 15, and the upper cone of the rotary drum is The drum 10 and the lower conical or cylindrical drum 11 are connected with the drum fixing flange 15, and the lower end of the screw conveyor transmission shaft 9 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com