Graded purification device and graded purification method for dusty gas

A technology for purifying equipment and gases, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., which can solve problems such as equipment blockage, low processing efficiency, and large proportion of ultrafine ash in the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

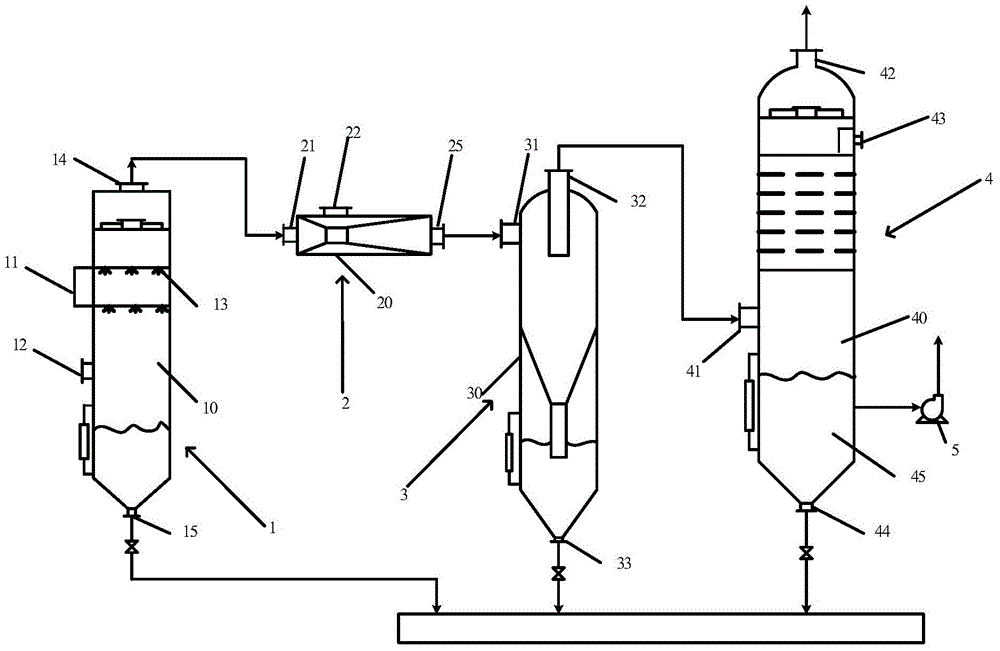

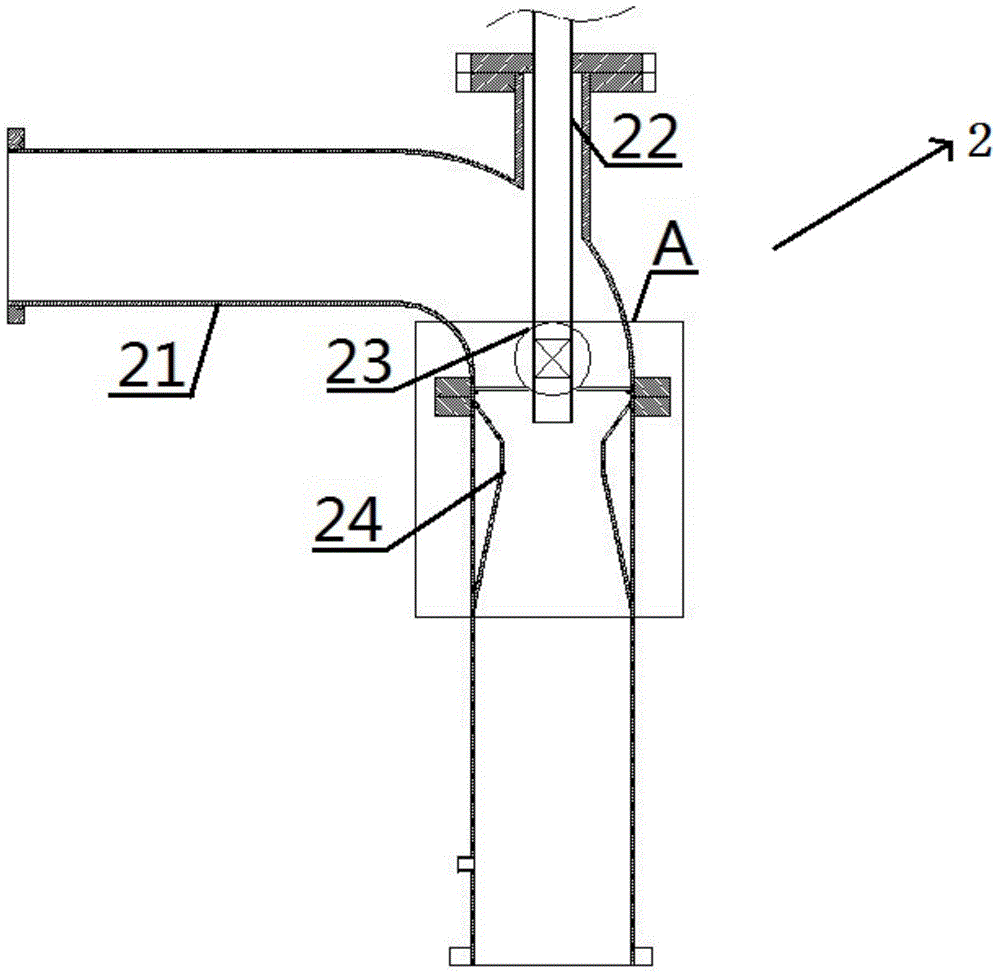

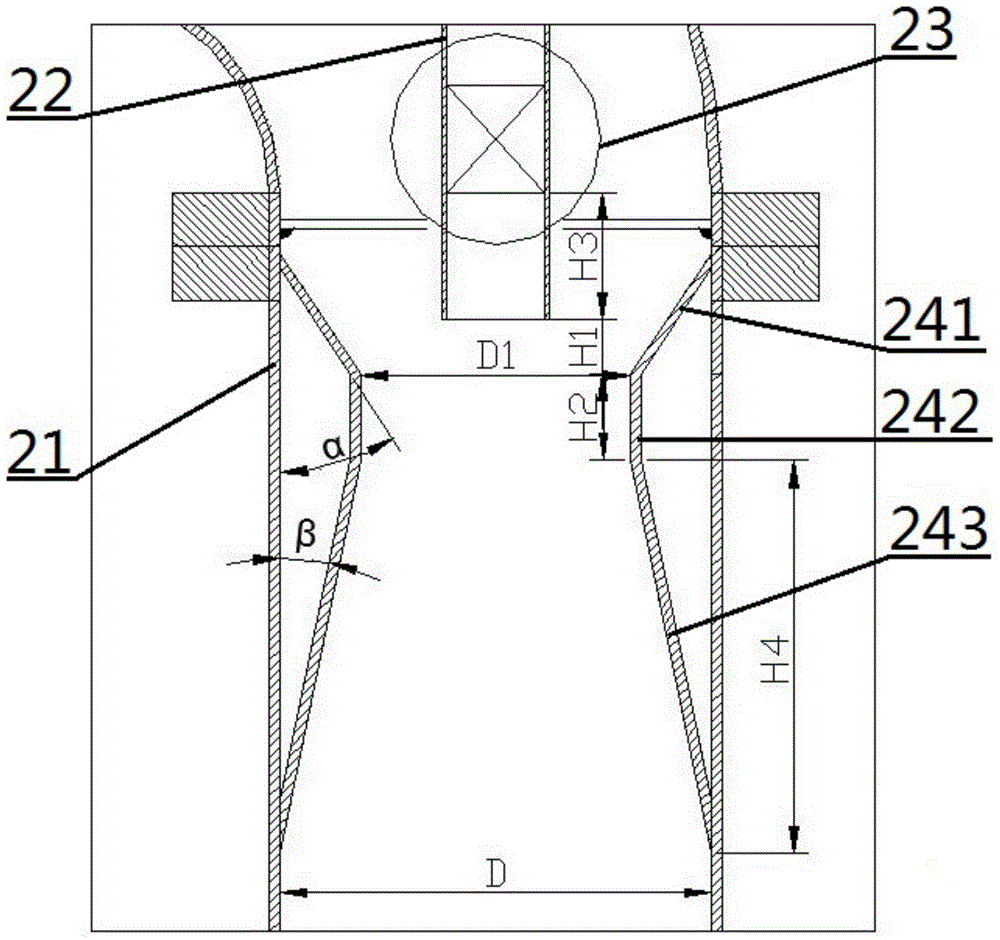

[0055] A kind of graded purification equipment for ash-containing gas, such as figure 1 As shown: the classification purification equipment includes a spray tower 1, a venturi scrubber 2, a separator 3, a foam scrubber 4 and a circulating water pump 5 connected in sequence;

[0056] (1) Spray tower:

[0057] The spray tower 1 can be a separate spray tower, or a spray tower coupled with other equipment in the upstream process;

[0058] This spray tower 1 comprises a spray tower tower body 10, a spray layer 13, a first liquid inlet 11, a first gas inlet 12, a first gas outlet 14 and a first waste water outlet 15; The shower layer 13 is located on the upper part of the spray tower 1 and communicates with the first liquid inlet 11; the first gas inlet 12 and the first liquid inlet 11 are located on the side of the spray tower body 10, the The first gas inlet 12 is positioned below the first liquid inlet 11; the first gas outlet 14 is positioned at the top of the spray tower body...

Embodiment 2

[0071] A kind of graded purification equipment for ash-containing gas, such as figure 1 As shown: the classification purification equipment includes a spray tower 1, a venturi scrubber 2, a separator 3, a foam scrubber 4 and a circulating water pump 5 connected in sequence;

[0072] (1) Spray tower:

[0073] The spray tower 1 can be a separate spray tower, or a spray tower coupled with other equipment in the upstream process;

[0074] This spray tower 1 comprises a spray tower tower body 10, a spray layer 13, a first liquid inlet 11, a first gas inlet 12, a first gas outlet 14 and a first waste water outlet 15; The shower layer 13 is located on the upper part of the spray tower 1 and communicates with the first liquid inlet 11; the first gas inlet 12 and the first liquid inlet 11 are located on the side of the spray tower body 10, the The first gas inlet 12 is positioned below the first liquid inlet 11; the first gas outlet 14 is positioned at the top of the spray tower body...

Embodiment 3

[0087] A kind of graded purification equipment for ash-containing gas, such as figure 1 Shown: the equipment includes a spray tower 1, a venturi scrubber 2, a separator 3, a foam scrubber 4 and a circulating water pump 5 connected in sequence;

[0088] (1) Spray tower:

[0089] The spray tower 1 can be a separate spray tower, or a spray tower coupled with other equipment in the upstream process;

[0090] This spray tower 1 comprises a spray tower tower body 10, a spray layer 13, a first liquid inlet 11, a first gas inlet 12, a first gas outlet 14 and a first waste water outlet 15; The shower layer 13 is located on the upper part of the spray tower 1 and communicates with the first liquid inlet 11; the first gas inlet 12 and the first liquid inlet 11 are located on the side of the spray tower body 10, the The first gas inlet 12 is positioned below the first liquid inlet 11; the first gas outlet 14 is positioned at the top of the spray tower body 10; the first waste water outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com