Integrated treatment method for thickening, drying and purifying municipal sludge

A technology for concentration and dehydration of municipal sludge, applied in water/sludge/sewage treatment, water/sewage treatment, adsorption water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

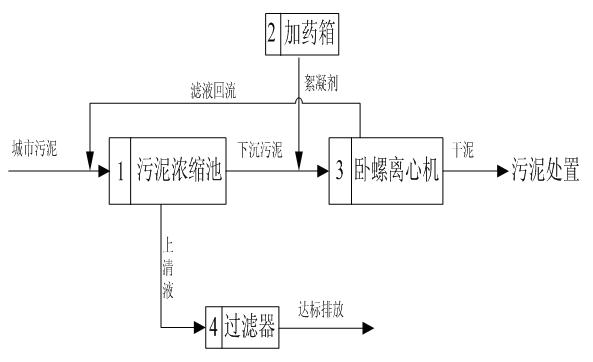

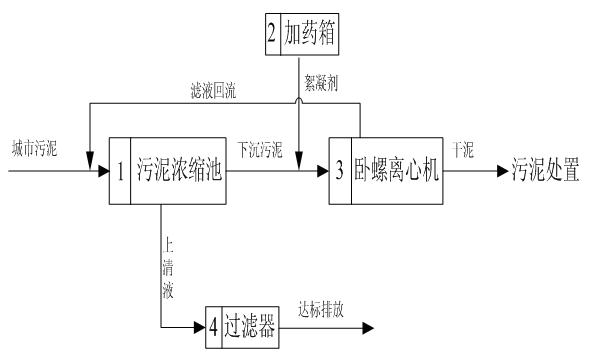

Image

Examples

Embodiment

[0020] This embodiment deals with urban sludge with a water content of 99.1%-99.6%. The steps of the specific example are as follows: firstly, the municipal sludge with a water content of 99.1%-99.6% is fed into the sludge thickening tank 1 for 12 hours of thickening time. The water content is reduced to 75%~80%. The supernatant is filtered by the filter 4 and discharged up to the standard. The settled sludge is mixed with the flocculant in the drum of the decanter centrifuge 2 through the pipeline. Add 2.54 g of cationic PAM to the dry sludge to make the dispersed sludge particles aggregate to produce larger flocs, and the sludge and water are separated under the centrifugal action of the decanter centrifuge 2, and the drum speed is controlled between 2200rpm and 2400rpm. On the premise that the flocculant dosage remains unchanged, by adjusting the rotation speed of the sludge screw pump, the sludge is fed according to the maximum flow rate, and the differential speed is gradu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com