Maintenance wiping method and maintenance wiping wet tissue for ink-jet printer nozzle

An inkjet printer and nozzle technology, applied in the field of inkjet printer nozzle maintenance and wipe, inkjet printer nozzle maintenance wipe wipes, can solve the problems of reducing the service life of the nozzle, damage the nozzle, etc., to prolong the service life, save costs, wipe obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

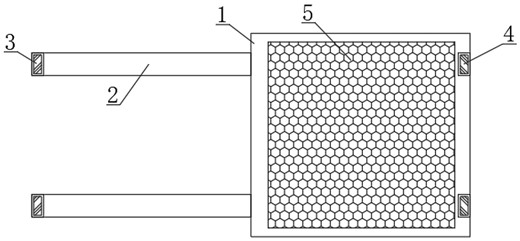

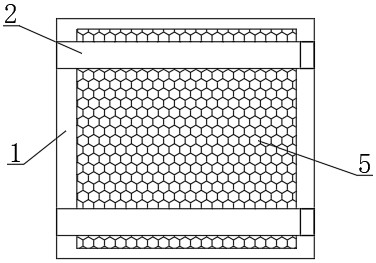

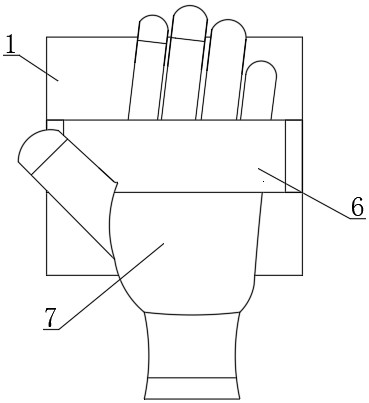

[0027] see figure 1 , figure 2 , image 3 , the present invention provides a technical solution: an inkjet printer nozzle maintenance wipe wipes, composed of NPGDA, TPGDA, HDDA, DPGDA, its components by weight percentage: NPGDA10%, TPGDA33%, HDDA24%, DPGDA33% .

[0028] A method for using a wet wipe for wiping nozzles of an inkjet printer, comprising the steps of:

[0029] Step 1: Material preparation: foam 1, wet wipe body 5;

[0030] Step 2: Pick up the foam 1 and place it flat;

[0031] Step 3: overcome the adhesive force of the Velcro rough surface 3 and the Velcro thorn surface 4, uncover the fixing belt 2, and keep one end of the fixing belt 2 away from the foam 1;

[0032] Step 4: Take the wet wipe body 5 and place the wet wipe body 5 on top of the foam 1;

[0033] Step 5: Rotate the fixing belt 2, and make the Velcro rough surface 3 on the fixing belt 2 and the Velcro stabbing surface 4 on the foam 1 stick together;

[0034] Step 6: The user picks up the foam 1...

Embodiment 2

[0038] see figure 1 , figure 2 , the present invention provides a technical solution: an inkjet printer nozzle maintenance wipe wet tissue, composed of NPGDA, TPGDA, HDDA, DPGDA, surfactant, its components are calculated by weight percentage: NPGDA10%, TPGDA33%, HDDA24 %, DPGDA23%, surfactant 10%, the addition of surfactant increases the bactericidal effect.

[0039] A method for using a wet wipe for wiping nozzles of an inkjet printer, comprising the steps of:

[0040] Step 1: Material preparation: foam 1, wet wipe body 5;

[0041] Step 2: Pick up the foam 1 and place it flat;

[0042] Step 3: overcome the adhesive force of the Velcro rough surface 3 and the Velcro thorn surface 4, uncover the fixing belt 2, and keep one end of the fixing belt 2 away from the foam 1;

[0043] Step 4: Take the wet wipe body 5 and place the wet wipe body 5 on top of the foam 1;

[0044] Step 5: Rotate the fixing belt 2, and make the Velcro rough surface 3 on the fixing belt 2 and the Velc...

Embodiment 3

[0049] see figure 1 , figure 2 , image 3 , the present invention provides a technical solution: an inkjet printer nozzle maintenance wipe wet tissue, composed of NPGDA, TPGDA, HDDA, DPGDA, surfactant, its components are calculated by weight percentage: NPGDA10%, TPGDA33%, HDDA24 %, DPGDA23%, surfactant 10%, the addition of surfactant increases the bactericidal effect.

[0050] A method for using a wet wipe for wiping nozzles of an inkjet printer, comprising the steps of:

[0051] Step 1: Material preparation: foam 1, wet wipe body 5;

[0052] Step 2: Pick up the foam 1 and place it flat;

[0053] Step 3: overcome the adhesive force of the Velcro rough surface 3 and the Velcro thorn surface 4, uncover the fixing belt 2, and keep one end of the fixing belt 2 away from the foam 1;

[0054] Step 4: Take the wet wipe body 5 and place the wet wipe body 5 on top of the foam 1;

[0055] Step 5: Rotate the fixing belt 2, and make the Velcro rough surface 3 on the fixing belt 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com