Gardening crusher

A shredder and gardening technology, applied in the field of garbage shredders, can solve the problems of affecting the cooling effect of the cooling air duct of the machine, the health of the operator, and the increase of wind resistance, etc., so as to solve the dust spray phenomenon and improve the heat dissipation performance , Reduce the effect of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

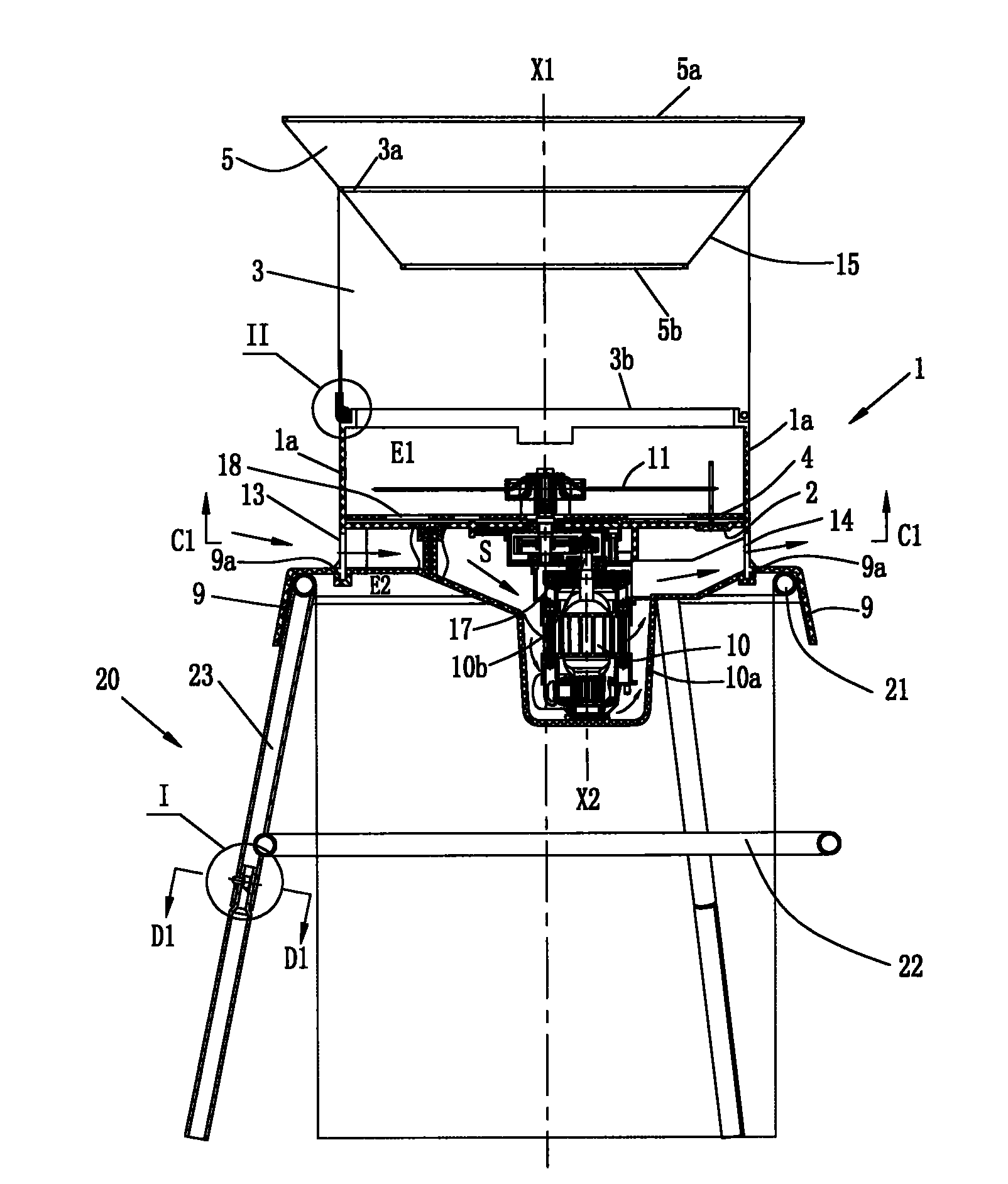

[0045] refer to Image 6 , Figure 7 Shown is the third embodiment of the air duct of the cooling motor 10 of the horticultural pulverizer of the present invention. In this embodiment, the support plate 2 is no longer provided separately, but the partition plate that is originally rotated relative to the main body 1 is changed to It is fixed relative to the main body. At this time, the partition is a support plate 4' that has the function of dust removal and motor support. That is, the support plate 4' includes an opening 18'. The size of the opening can be calculated in advance and used to support Enclosed area 30 of motor 10, see for details Image 6 In the area surrounded by two dotted lines, the closed area 30 is preferentially arranged in the center of the support plate 4' and arranged radially along the main body 1, and the openings 18 are evenly arranged on both sides of the closed area 30; the motor 10 is fixedly connected to the closed area 30, the motor casing 10a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com