Reaction device for uranium fluorination reaction in molten salt system and operation method thereof

A reaction device, fluorination reaction technology, applied in the direction of reactors, reactor fuel elements, greenhouse gas reduction, etc., can solve problems such as difficulty in ensuring long-term safe operation of reactors, blockage of reactor outlet gas pipe valves, etc., and achieve long-term safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Reaction device for uranium fluorination reaction in molten salt system

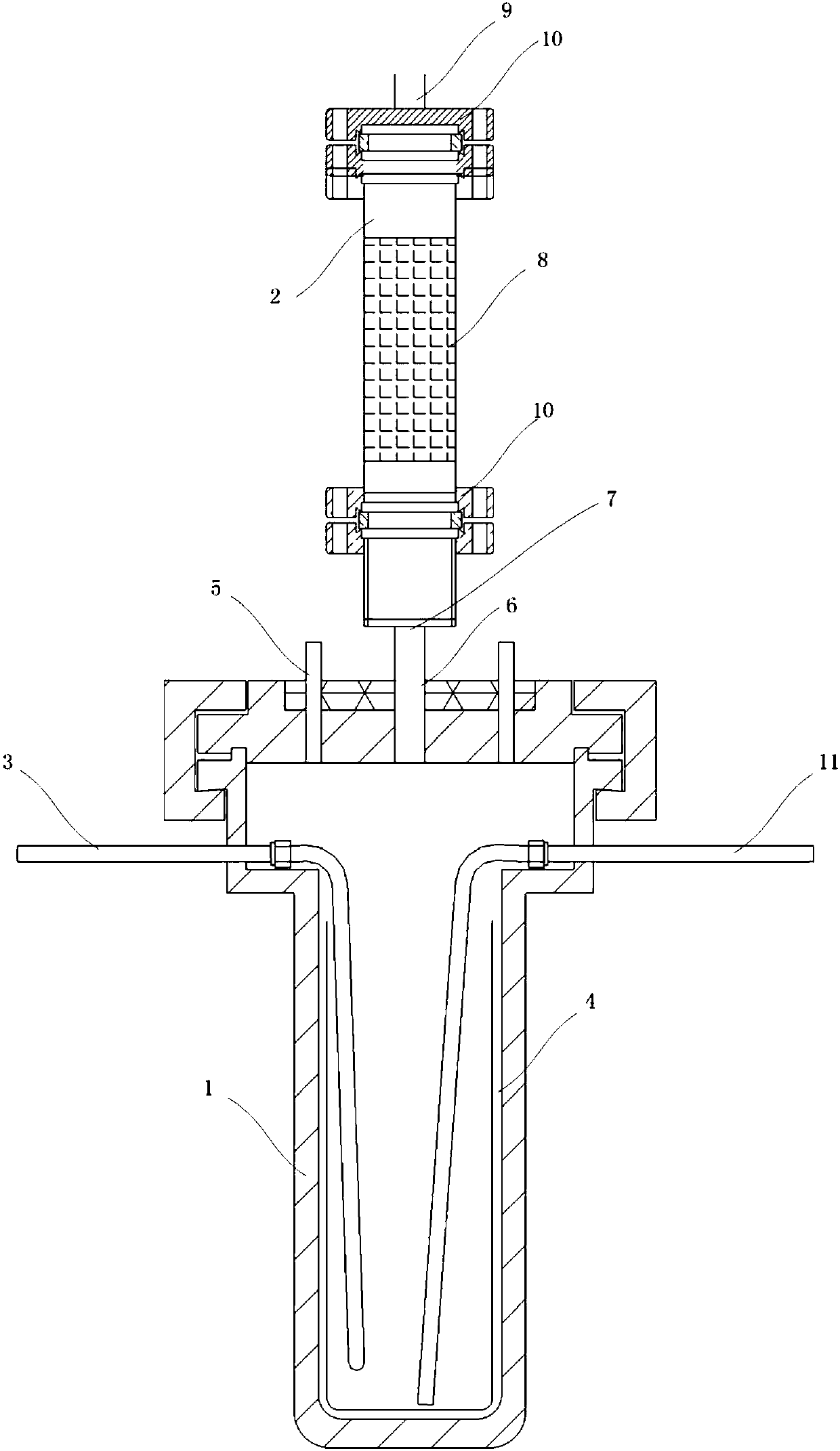

[0053] Such as figure 1 The shown reaction device for the uranium fluorination reaction in the molten salt system, the reaction device includes a fluorination reactor 1, a filter 2 and a ventilation pipe 3; the inner wall of the fluorination reactor 1 is provided with a nickel metal crucible lining 4, The thickness of the crucible lining 4 is 2mm, and the crucible lining 4 is used for contacting with the molten salt system, and the fluorination reactor 1 is also provided with an inert gas inlet 5 and a gas product outlet 6; The mixed gas is passed into the inner cavity of the fluorination reactor 1; the filter 2 is provided with a gas product inlet 7 and a purified gas outlet, and the filter 2 between the gas product inlet 7 and the purified gas outlet is filled with a filter filler 8 , the filter filling 8 is NaF particles, the particle size of the fluoride particles is 2-6mm; the filling dia...

Embodiment 2

[0070] 1. Reaction device for uranium fluorination reaction in molten salt system

[0071] Such as figure 1 In the shown reaction device for uranium fluorination in a molten salt system, the inner wall of the fluorination reactor 1 is provided with a ceramic crucible lining 4, the thickness of the crucible lining 4 is 2mm, and the filter filler 8 is magnesium fluoride. The particle size of the fluoride particles is 2-6mm; the filling diameter of the filter filling 8 is 10cm, the ratio of the filling height of the filter filling 8 to the filling diameter of the filter filling 8 is 3, and the vent pipe 3 is made of silicon carbide, The temperature jacket 11 is made of silicon carbide, and the rest are the same as in Embodiment 1.

[0072] 2. The operation method of the above-mentioned reaction device for uranium fluorination reaction in molten salt system

[0073] The operation method includes the following steps:

[0074] (1) KF-ZrF with uranium content of 8wt% 4 Fusion sal...

Embodiment 3

[0081] 1. Reaction device for uranium fluorination reaction in molten salt system

[0082] Such as figure 1 In the shown reaction device for uranium fluorination in a molten salt system, the inner wall of the fluorination reactor 1 is provided with a graphite crucible lining 4, the thickness of the crucible lining 4 is 5mm, and the filter filler 8 is barium fluoride particles and potassium fluoride particles, the particle size of the fluoride particles is 2-6mm; the filling diameter of the filter filling 8 is 10cm, the ratio of the filling height of the filter filling 8 to the filling diameter of the filter filling 8 is 10, and the ventilation pipe 3 It is made of nickel metal, and the temperature jacket 11 is made of nickel metal, and the rest is the same as that of Embodiment 1.

[0083] 2. The operation method of the above-mentioned reaction device for uranium fluorination reaction in molten salt system

[0084] The operation method includes the following steps:

[0085]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com