A thermal management method for a semi-finished lithium battery, and a manufacturing method for a lithium battery

A production method and lithium battery technology, which can be used in battery temperature control, secondary battery, final product manufacturing, etc., can solve the problem of long cooling time and achieve the effect of ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0054] In order to ensure good quality, the winding body formed by winding, or the stack formed by overlapping, needs to be dehydrated and dried before being put into the bag or shell. The drying temperature of this process is generally 80-90°C, which is a high temperature. dry. Before proceeding to the next step, the temperature needs to be lowered to a suitable processing temperature, which should be lower than 40°C. The current method is to keep the temperature in sections, and use multiple thermostats with different temperatures to cool down. The time required is about 1.5 -3 hours, time consuming and energy consuming. The reason for this is that if the temperature is directly dropped from 80-90°C to below 40°C, condensation and core material deformation will easily occur, which will reduce the quality of the product and cause defective products.

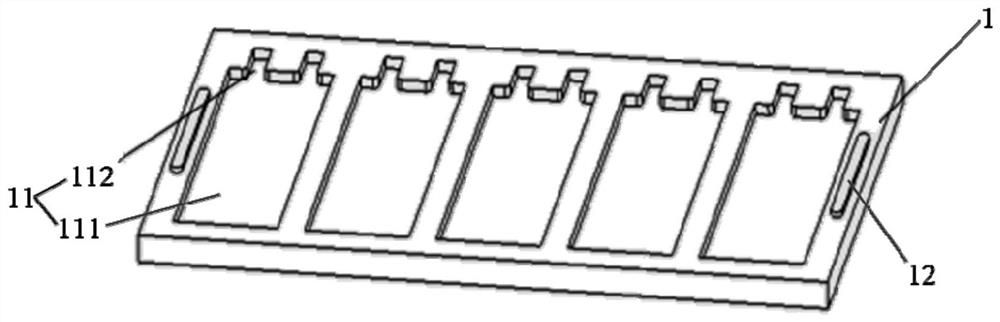

[0055] In view of this situation, according to the plasticity, good thermal conductivity and temperature control ability of t...

specific Embodiment 2

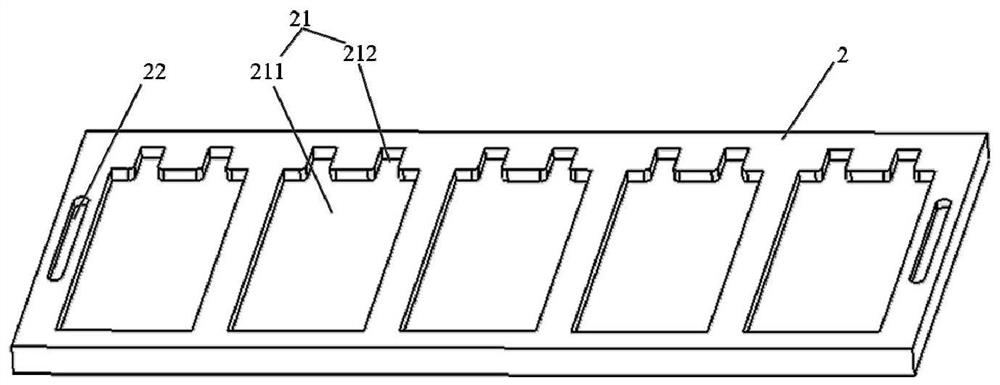

[0060] In the high-temperature drying process before liquid injection, since the wound body or laminated body has been put into an aluminum-plastic film bag or into a steel case to form a side-sealed battery cell, the heat treatment method of the composite phase change material after drying is different from the previous one. The temperature of this drying process is also 80-90°C. It is also necessary to reduce the temperature to the requirement of liquid injection before the liquid injection. The reason is that there are many volatile and toxic compounds in the electrolyte. If the temperature is too high, it will decompose. Reducing the charge conduction capacity of the electrolyte in the lithium battery will also cause unsafe use of the lithium battery.

[0061] Since the side-sealed battery cell has been put into the aluminum-plastic film bag or the steel shell, it has a certain mechanical strength, and the composite phase change material can be injection-molded into a large...

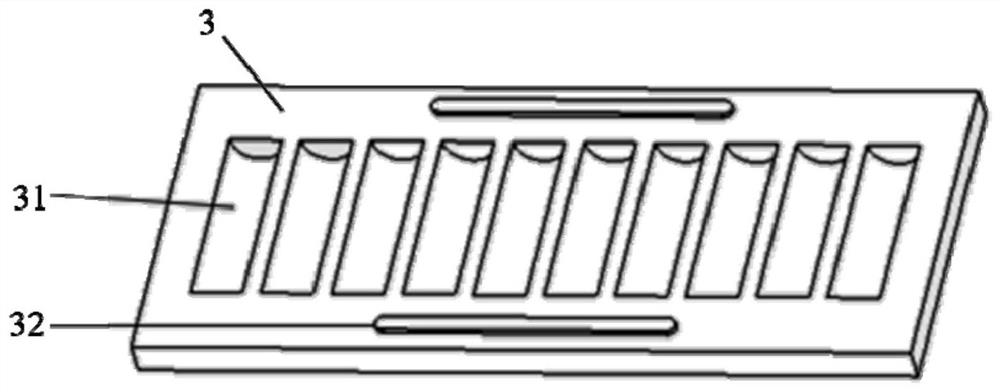

specific Embodiment 3

[0063] Such as Figure 8 As shown, before assembling the lithium battery pack, the positive tab 7 of the polymer lithium battery needs to be welded to nickel, because the melting point of the two metals needs to reach the melting point of the two metals for effective and firm welding, and the temperature can reach above 150 degrees. The position of the tab glue is at the top seal position, which separates the tab 7 from the aluminum-plastic film, and is closer to the nickel-transfer welding position, only 10-20mm away. The thermal conductivity of the tab 7 is very good, and it is easy to install The high temperature generated during welding is transmitted to the position of the ear glue. After the ear glue is subjected to high temperature, it is easy to cause degumming and poor viscosity, resulting in air and liquid leakage of lithium batteries, resulting in defective products, and also affects the quality of lithium batteries. .

[0064]Therefore, the good heat conduction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com