Patents

Literature

983 results about "Thermal management of electronic devices and systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

All electronic devices and circuitry generate excess heat and thus require thermal management to improve reliability and prevent premature failure. The amount of heat output is equal to the power input, if there are no other energy interactions. There are several techniques for cooling including various styles of heat sinks, thermoelectric coolers, forced air systems and fans, heat pipes, and others. In cases of extreme low environmental temperatures, it may actually be necessary to heat the electronic components to achieve satisfactory operation.

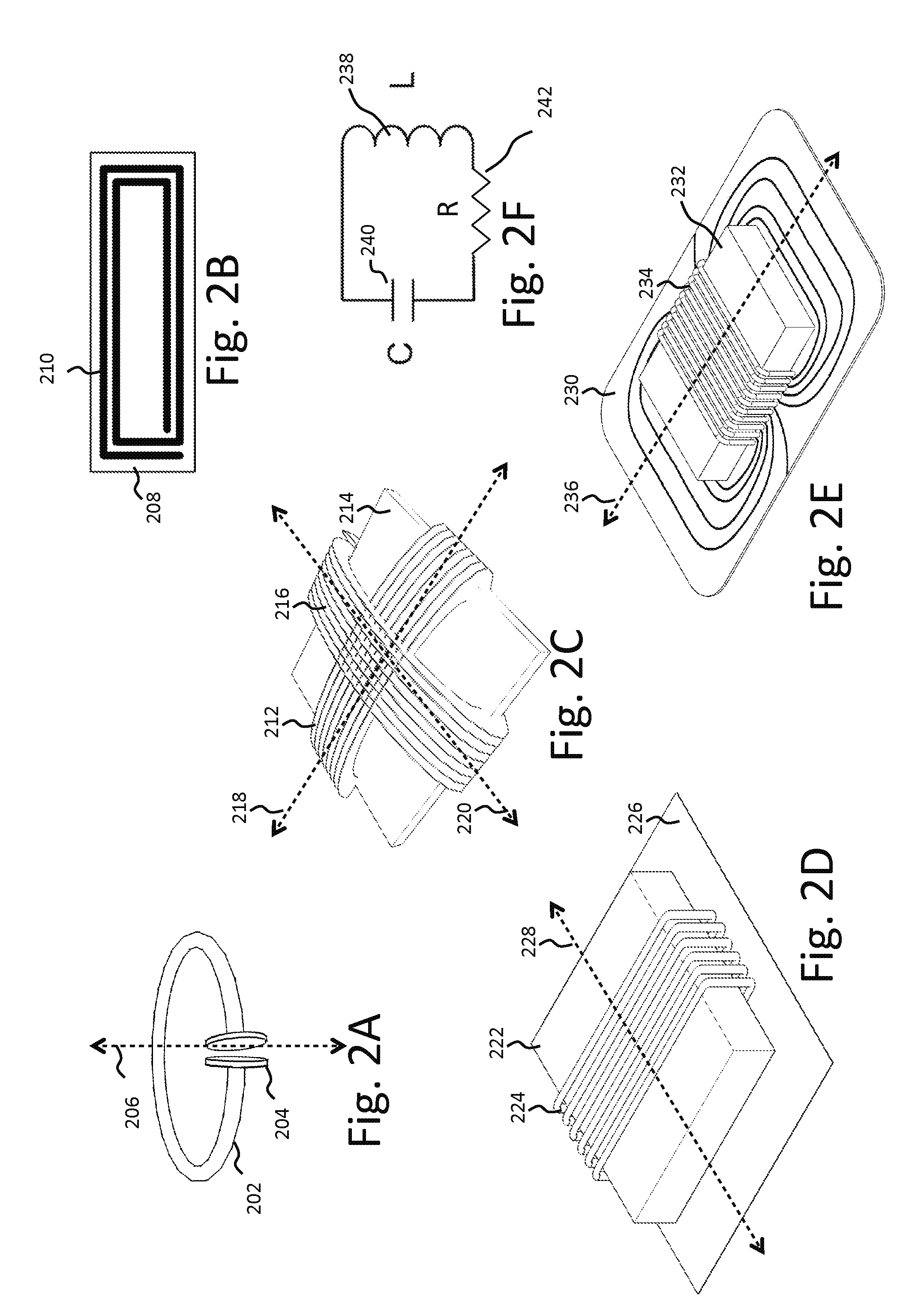

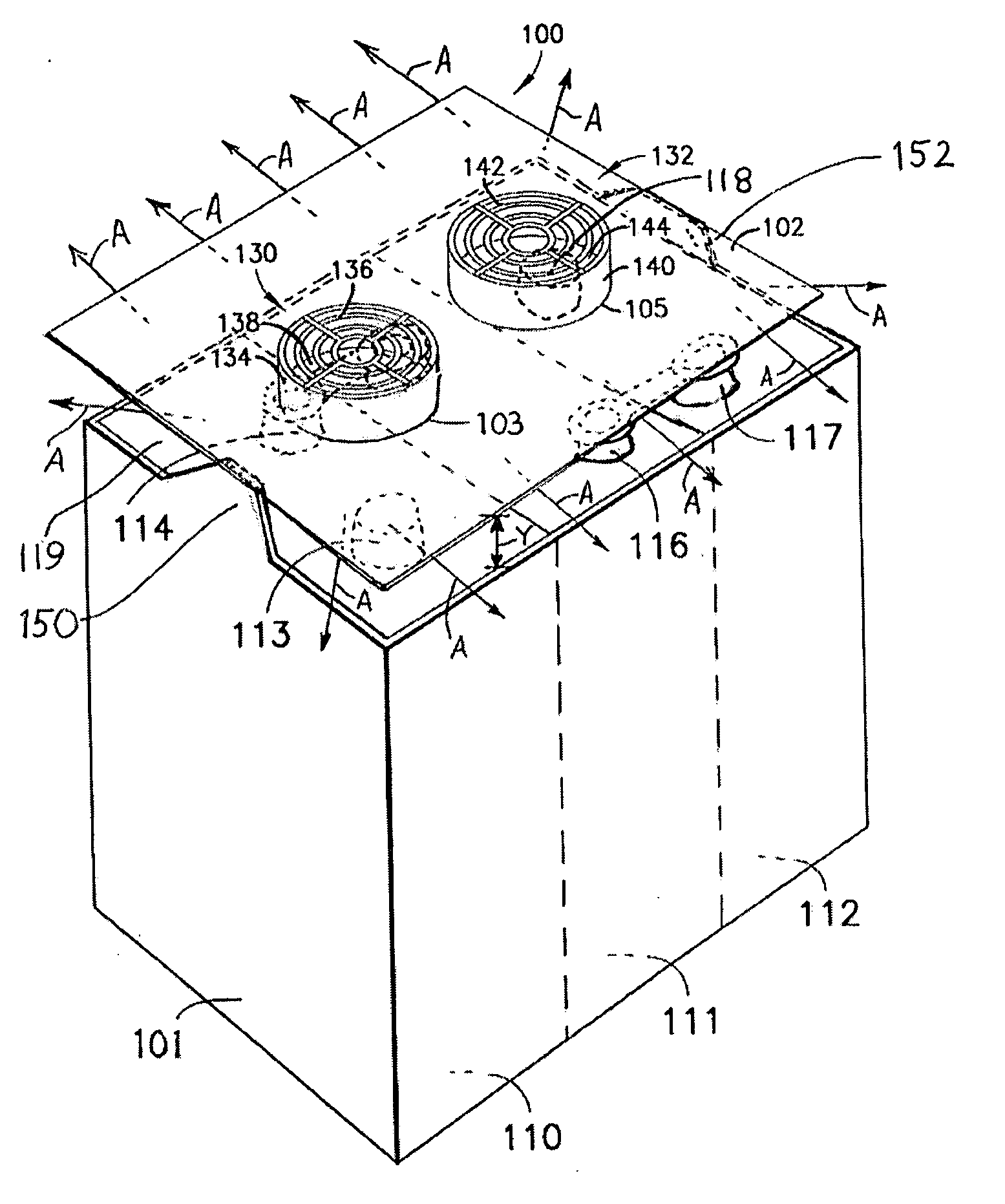

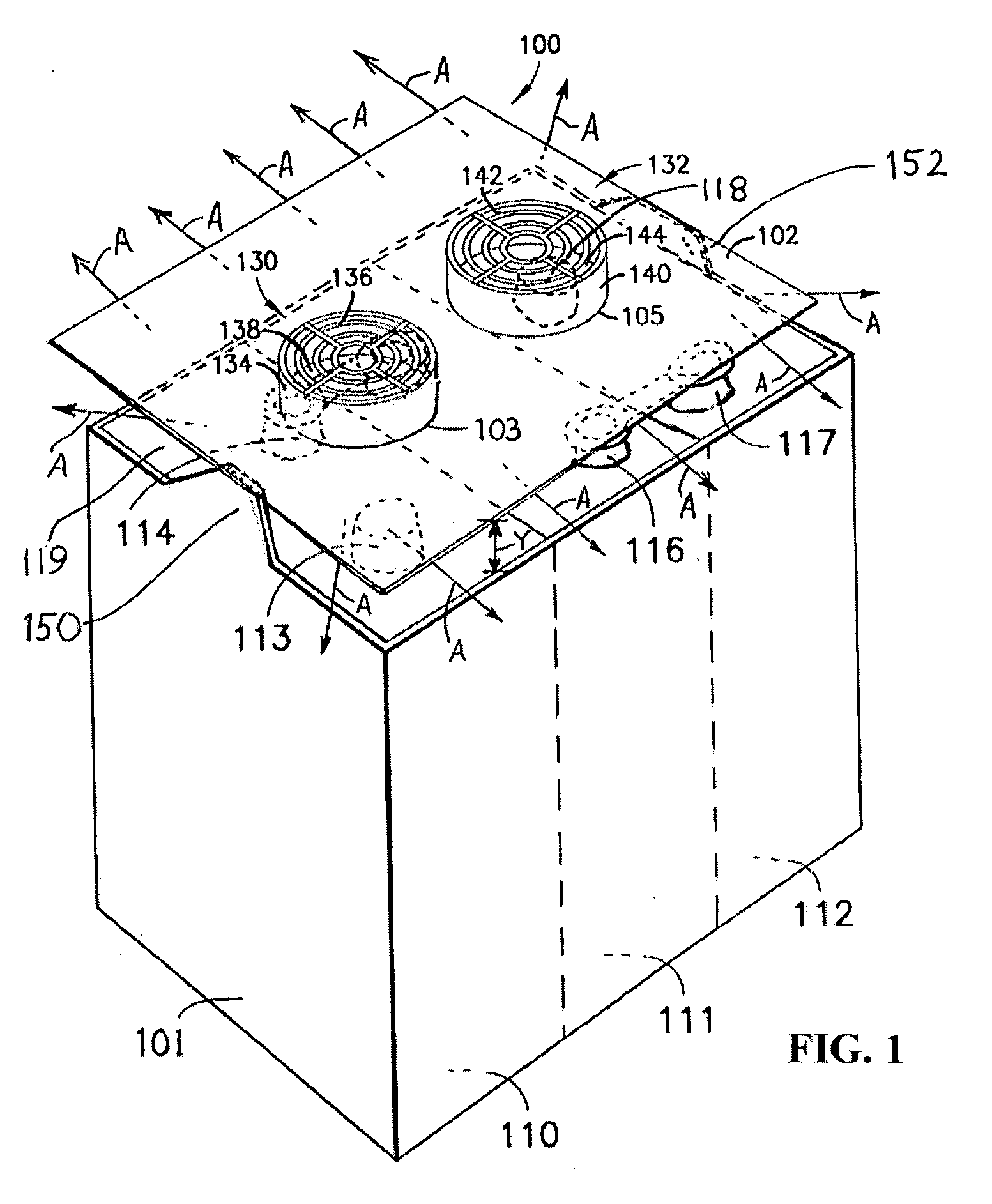

Wireless energy transfer resonator thermal management

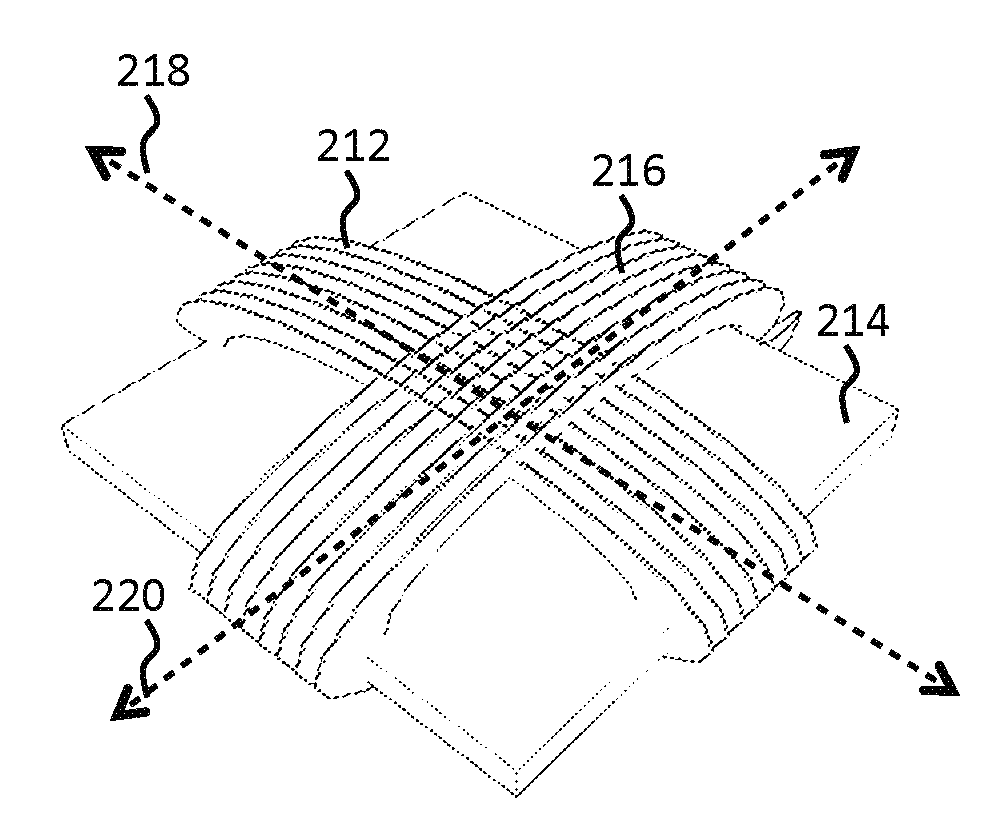

ActiveUS20110121920A1Minimize the numberMultiple-port networksTransformers/inductances coolingResonatorThermal management of electronic devices and systems

Described herein are improved configurations for a wireless power transfer. Described are methods and designs to reduce and manage heating and heat dissipation in resonator structures. Configuration and orientation of magnetic material as well as heat sinking material with respect to the dipole moment of the resonator is used to reduce and control thermal properties of the resonator structure and reduce the effects of heating on the performance of wireless power transfer.

Owner:WITRICITY CORP

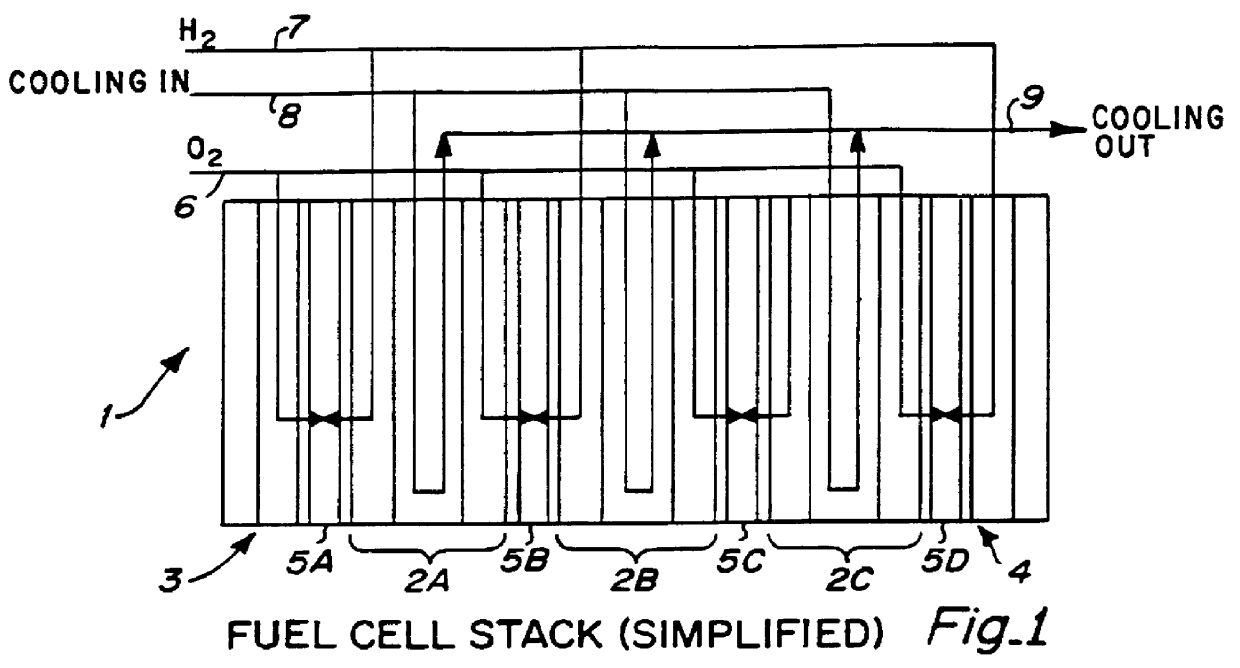

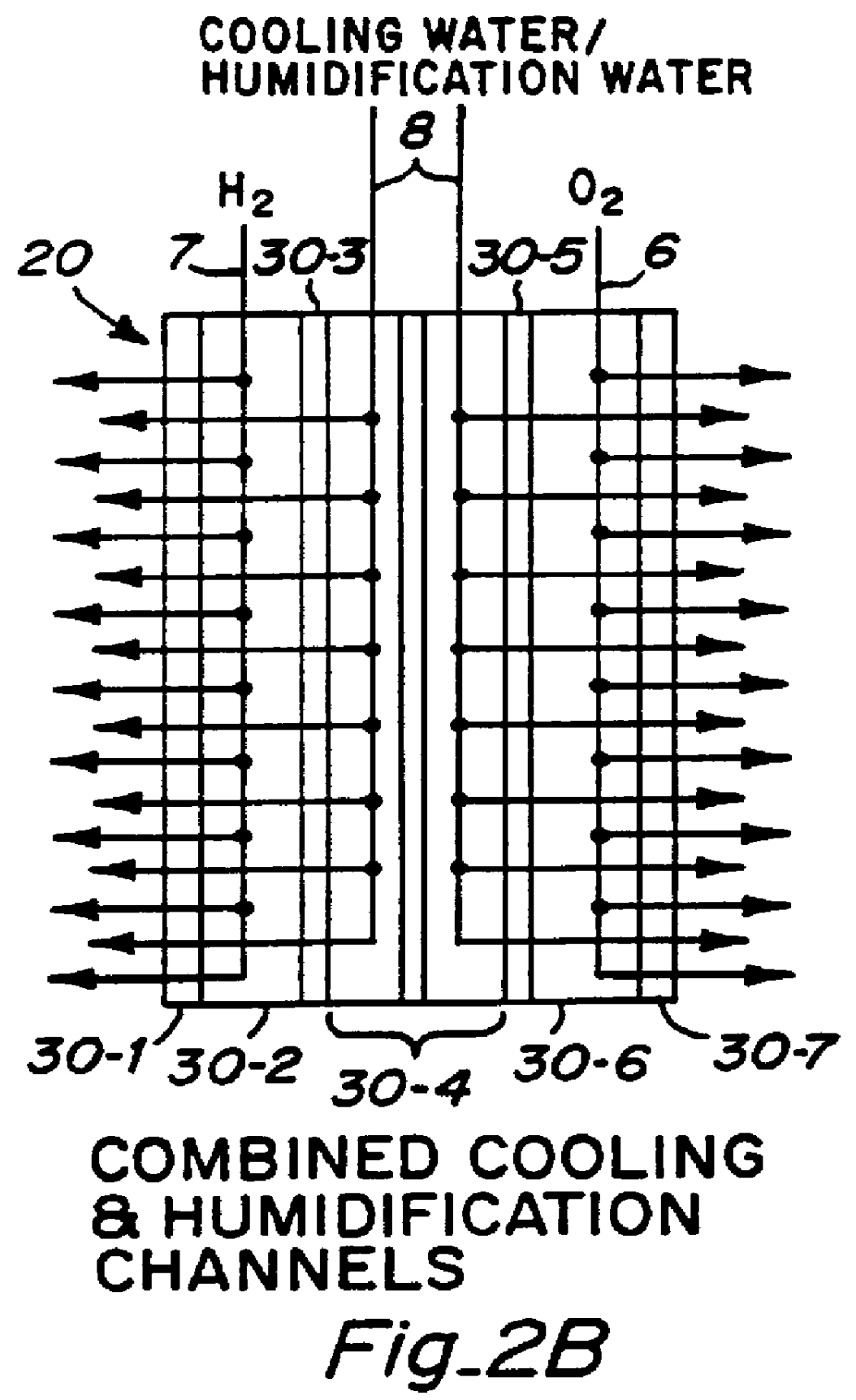

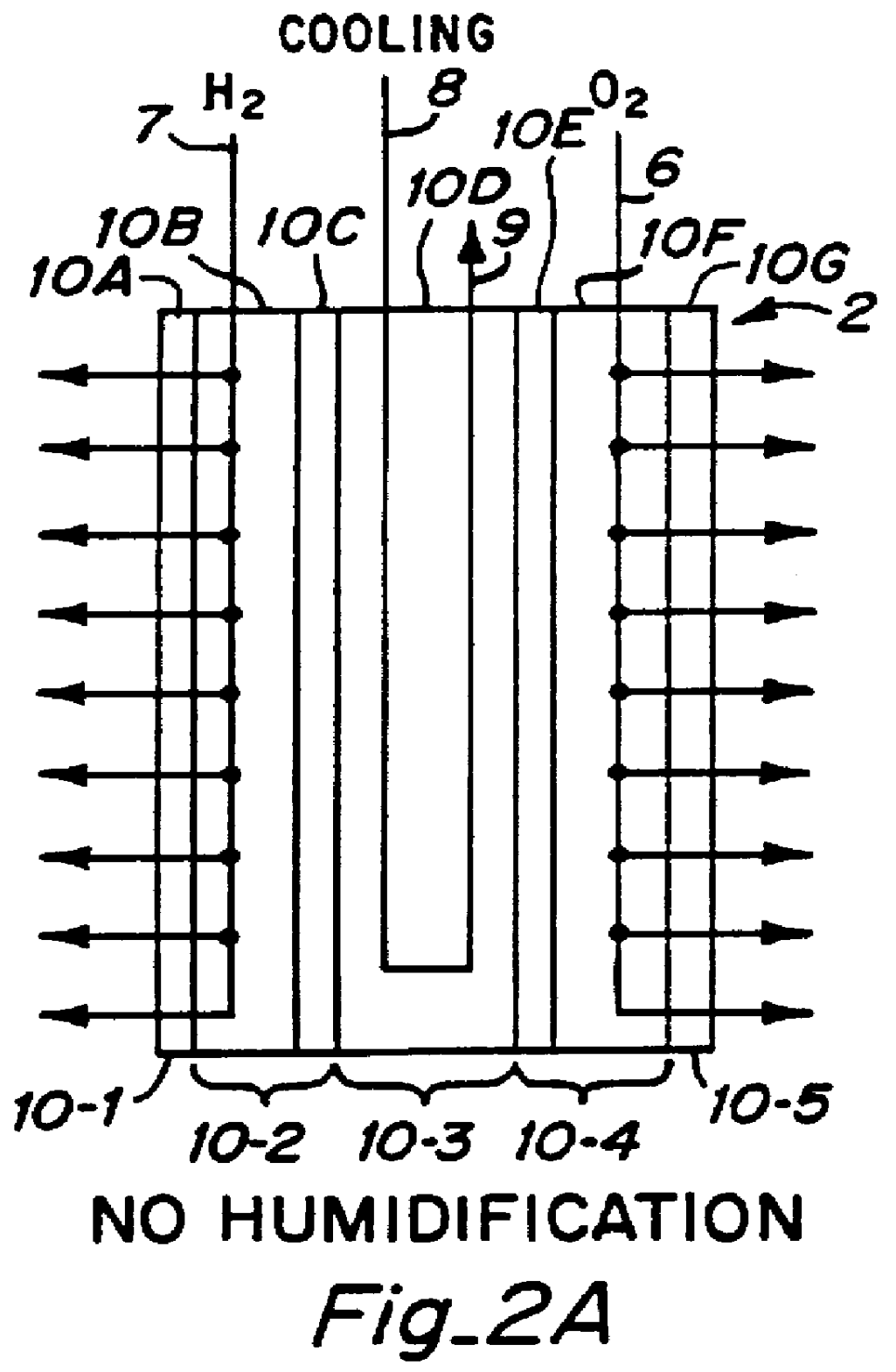

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

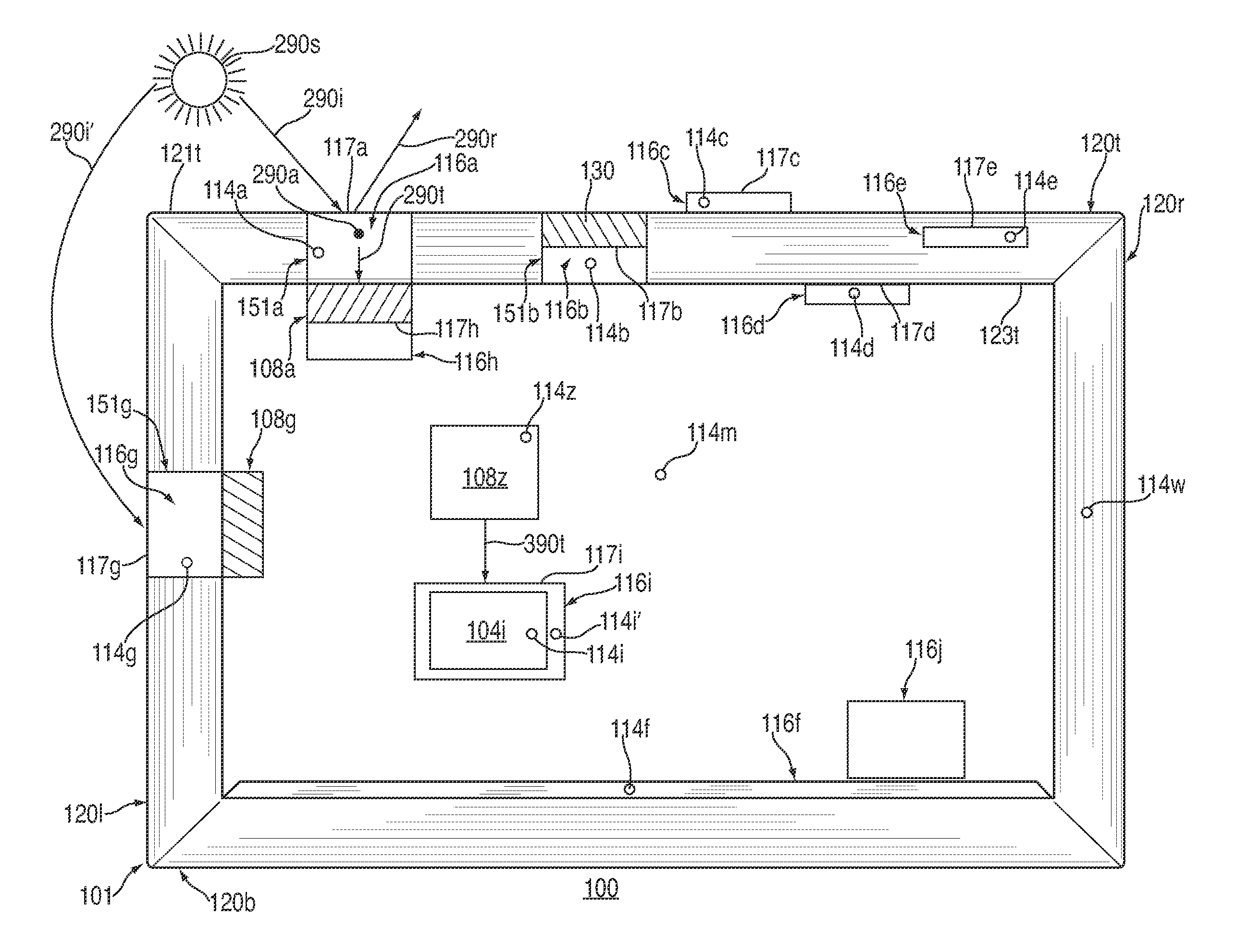

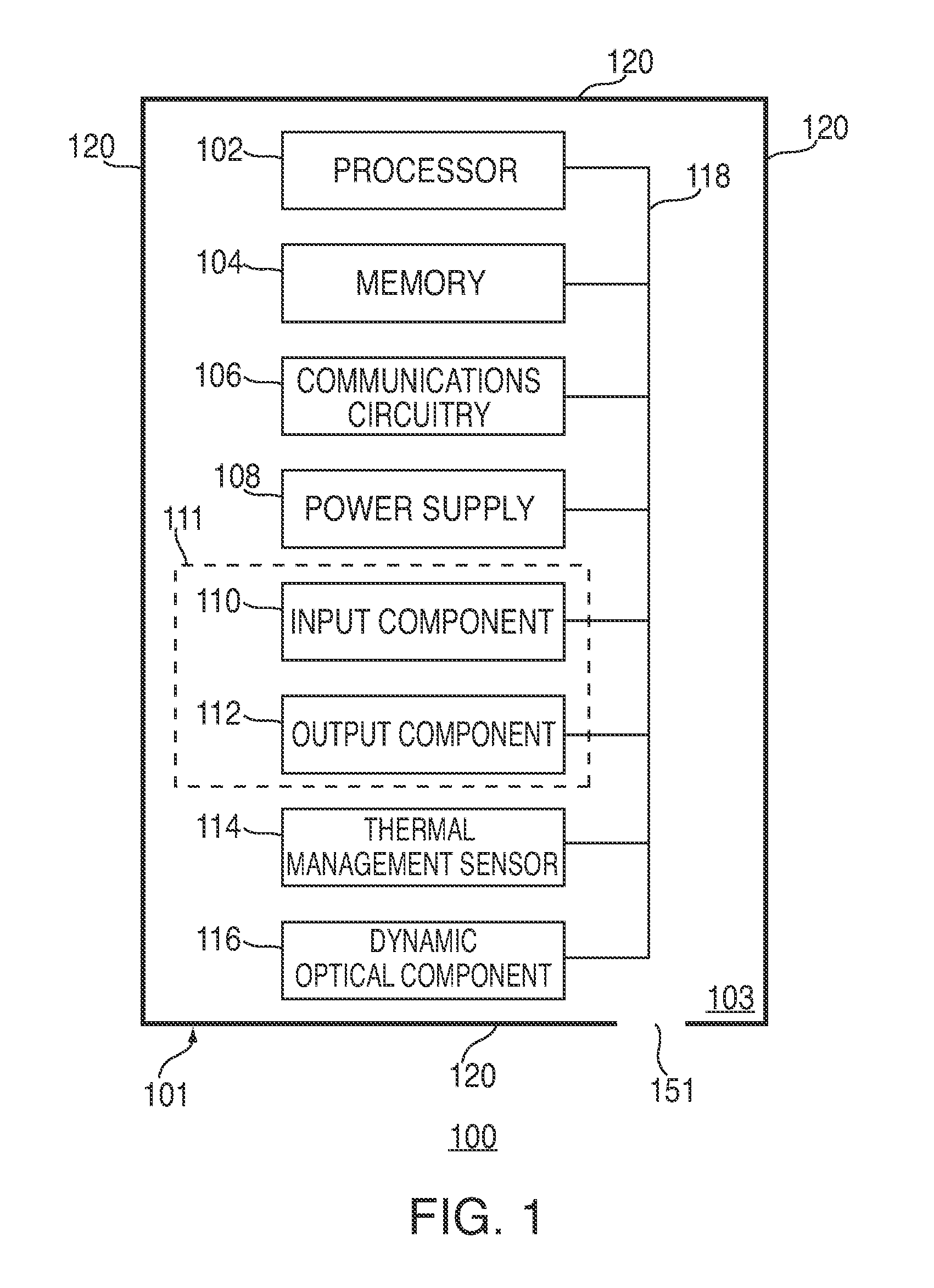

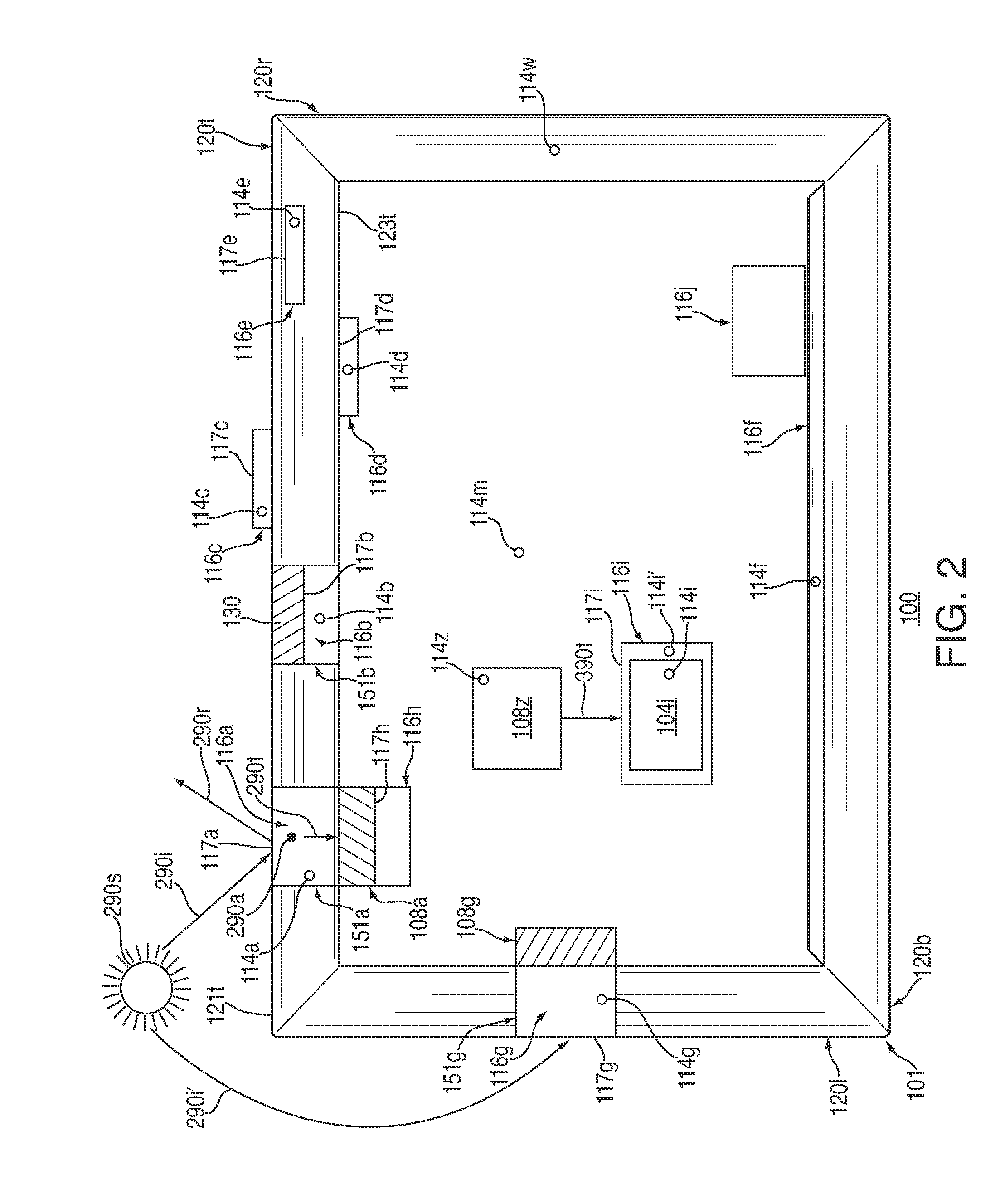

Systems, methods, and computer-readable media for thermally managing electronic devices using dynamic optical components

ActiveUS20120228392A1Coolant flow controlRadiation/particle handlingTransmittanceElectromagnetic radiation

Systems, methods, and computer-readable media. for thermally managing electronic devices using dynamic optical components are provided. At least one of the reflectance and the transmittance of incident electromagnetic radiation of a dynamic optical component on an electronic device may be adjusted based on a detected variable device characteristic of the device, such as a temperature of a device component. By adjusting the reflectance and / or the transmittance of the dynamic optical component, different portions of the incident electromagnetic radiation may be directed from the dynamic optical component for changing the variable device characteristic.

Owner:APPLE INC

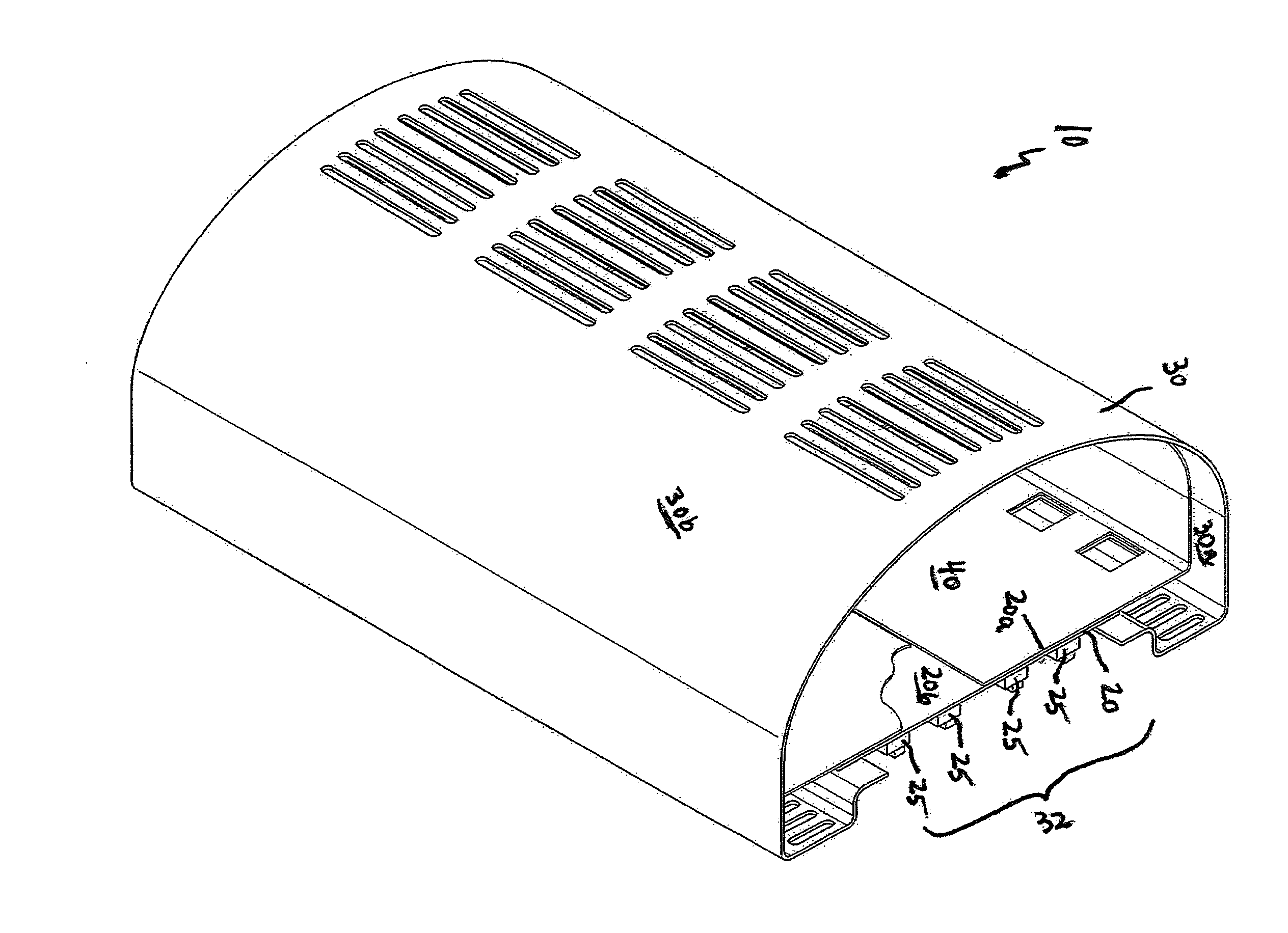

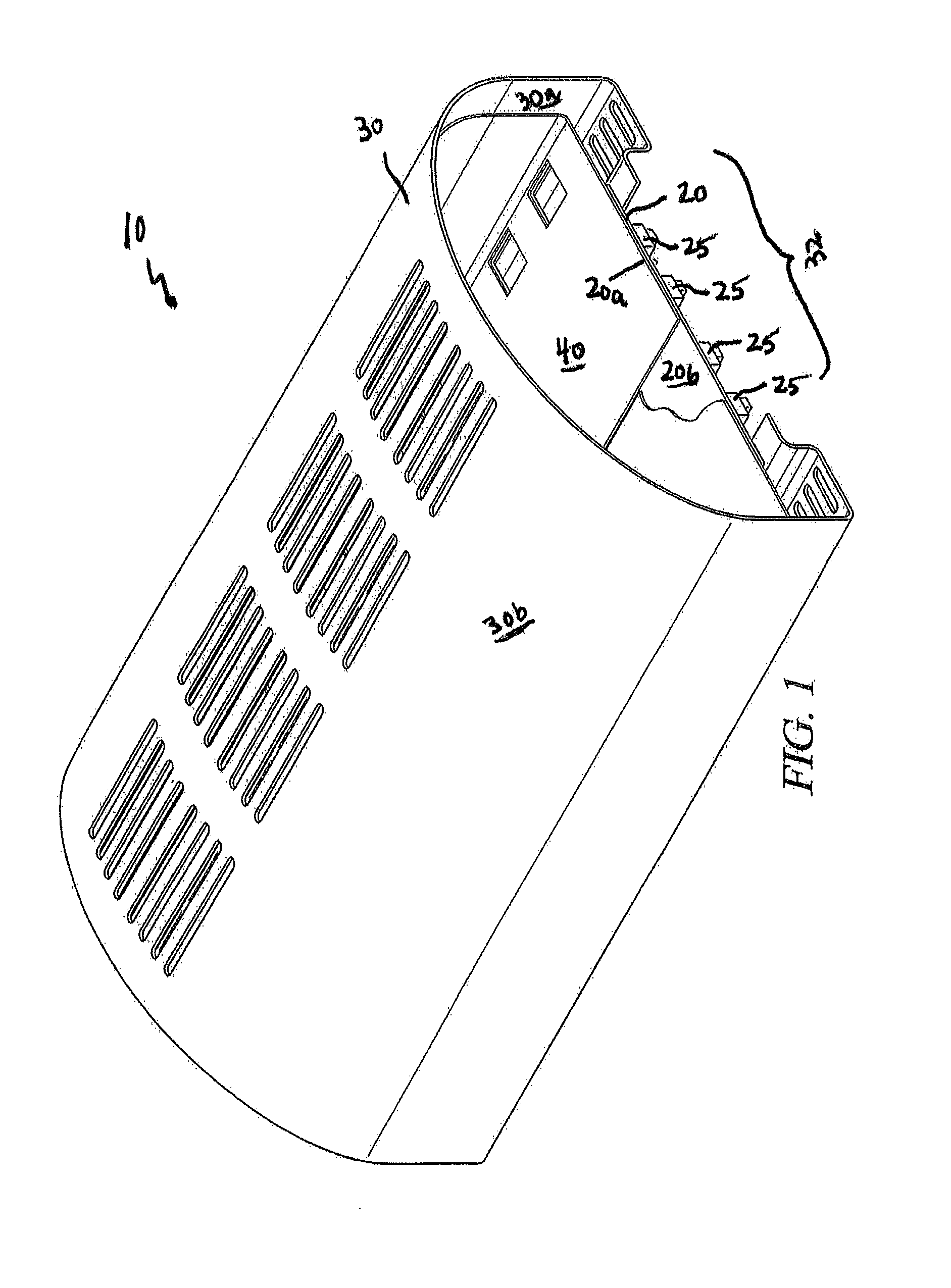

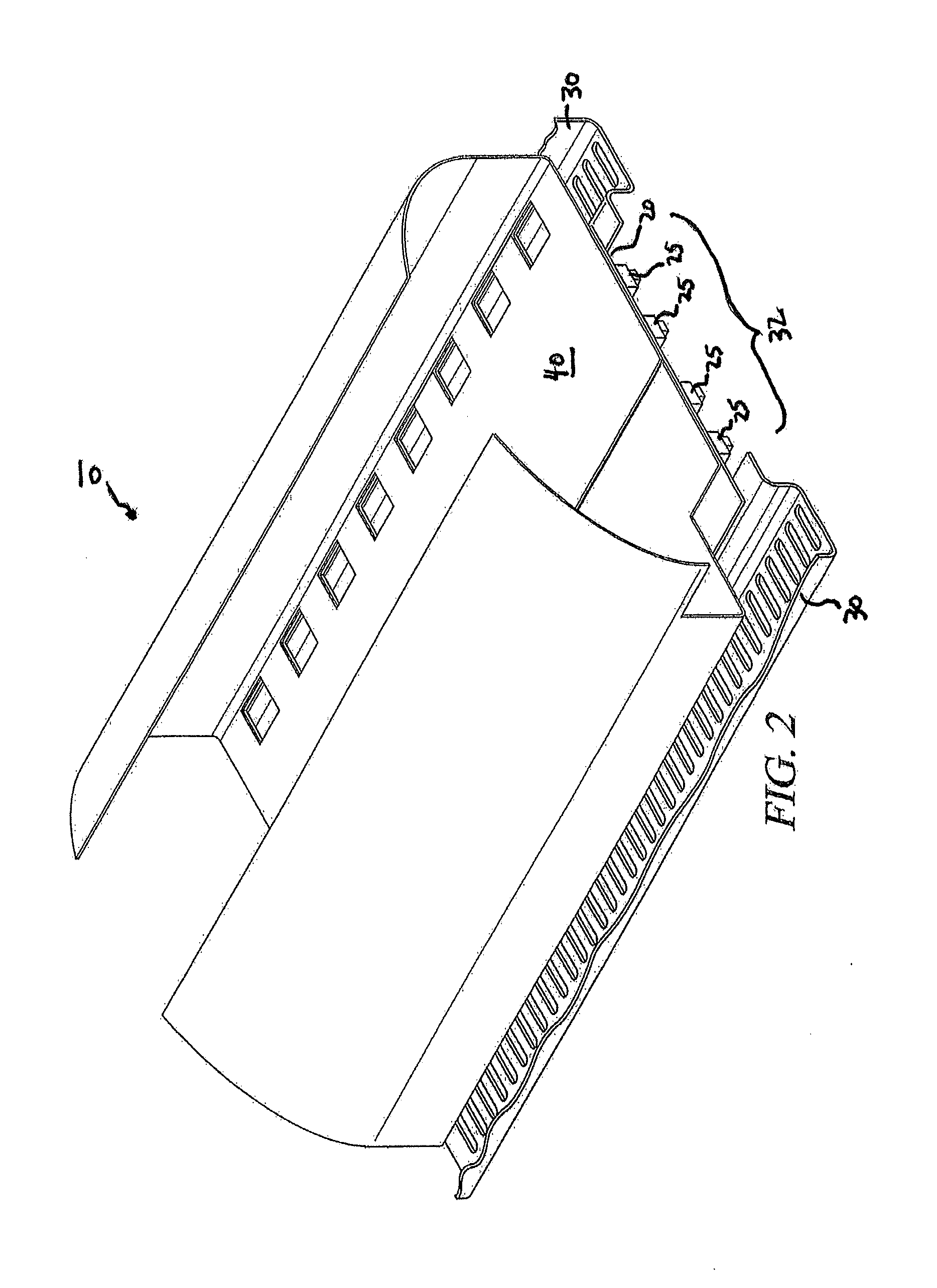

LED Light Fixture With Improved Thermal Management

A light fixture (10), having a circuit board (20) having first and second major surfaces (20a and 20b); at least one light emitting diode (25) mounted on the first major surface (20a) of the circuit board (20); an enclosure (30) formed of a material having two major surfaces (30a and 30b) and a thermo-mechanical design constant of at least 20 mm-W / m*K and shaped so as to define an opening (32) and a cavity (33), one of the major surfaces (30a) of the material defining the surface of the cavity (33) and the enclosure (30) positioned so as to enclose the second major surface (20b) of the circuit board (20); a heat spreader (40) having a surface area at least twice that of the circuit board and a thermo-mechanical design constant of at least 10 mm-W / m*K, the heat spreader (40) positioned in thermal contact with both the circuit board (20) and the enclosure (30).

Owner:GRAFTECH INT HLDG INC

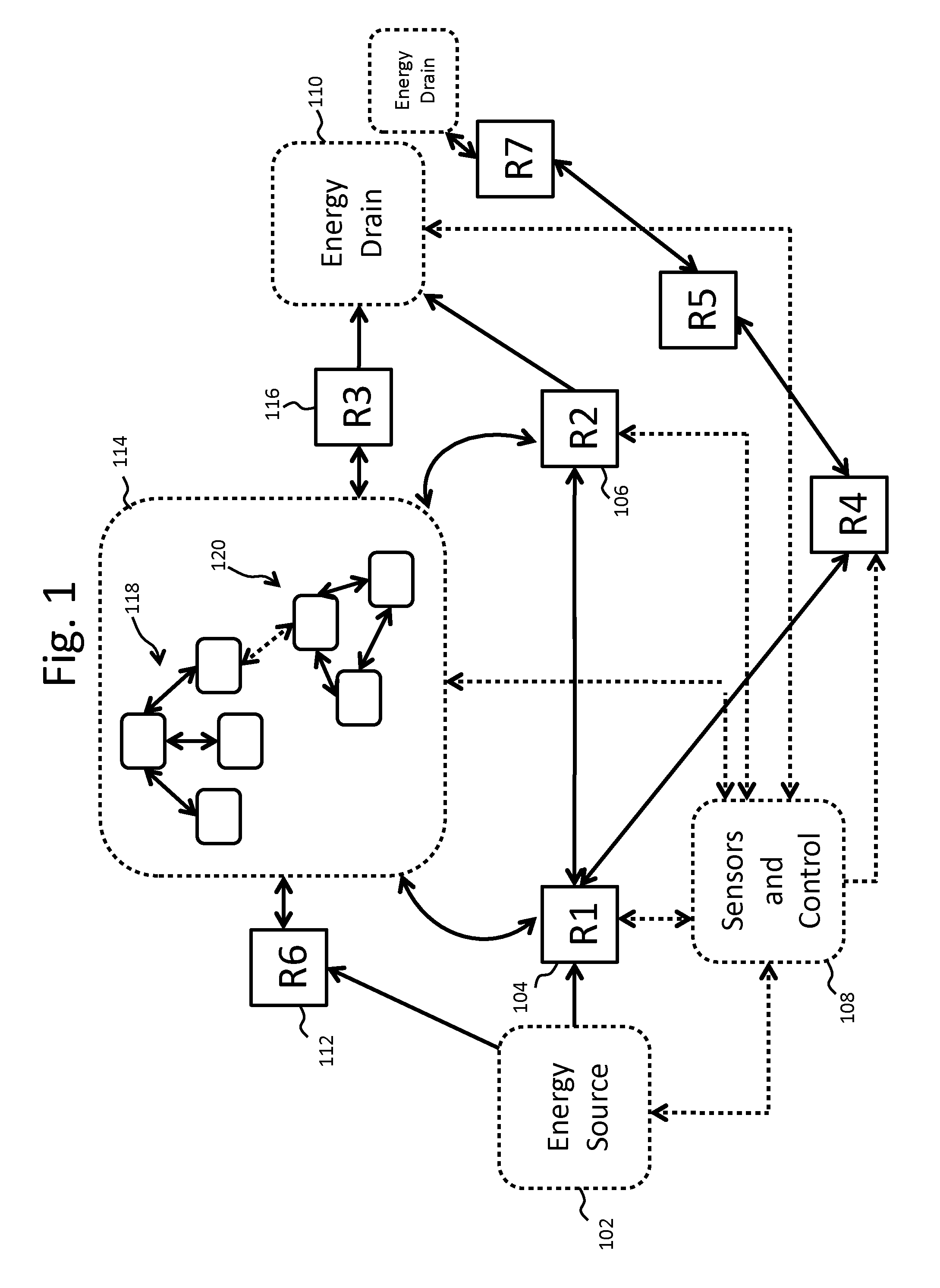

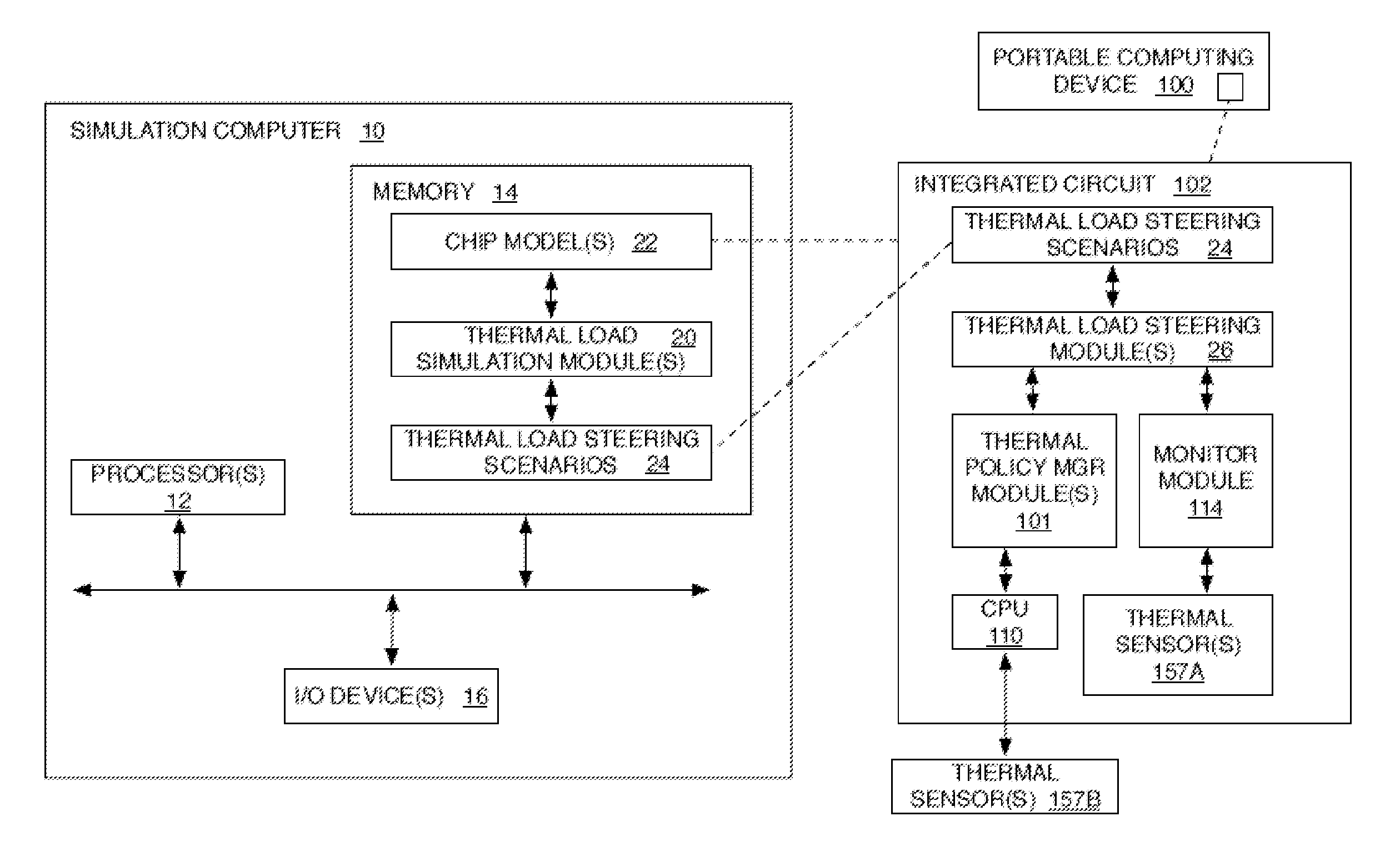

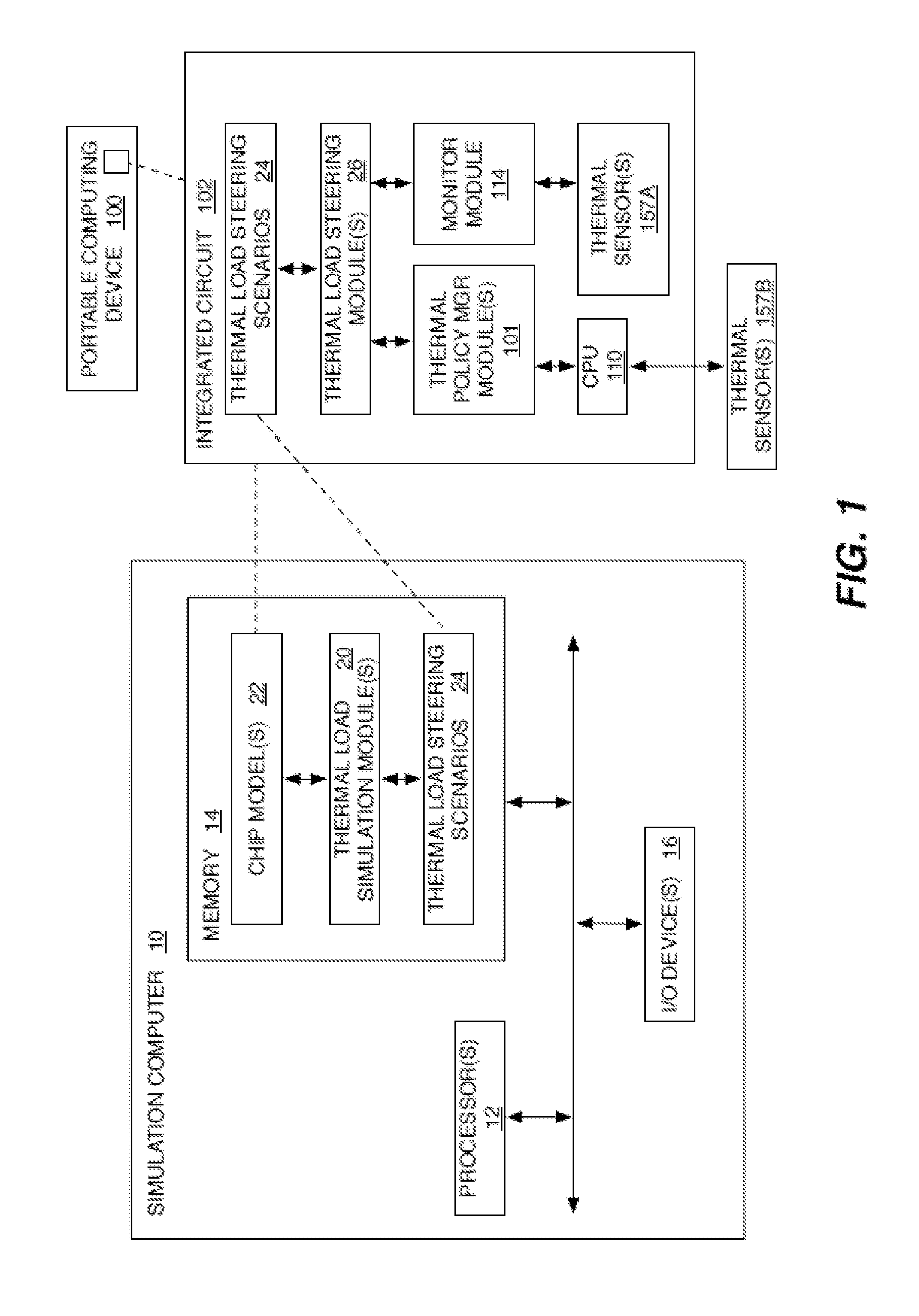

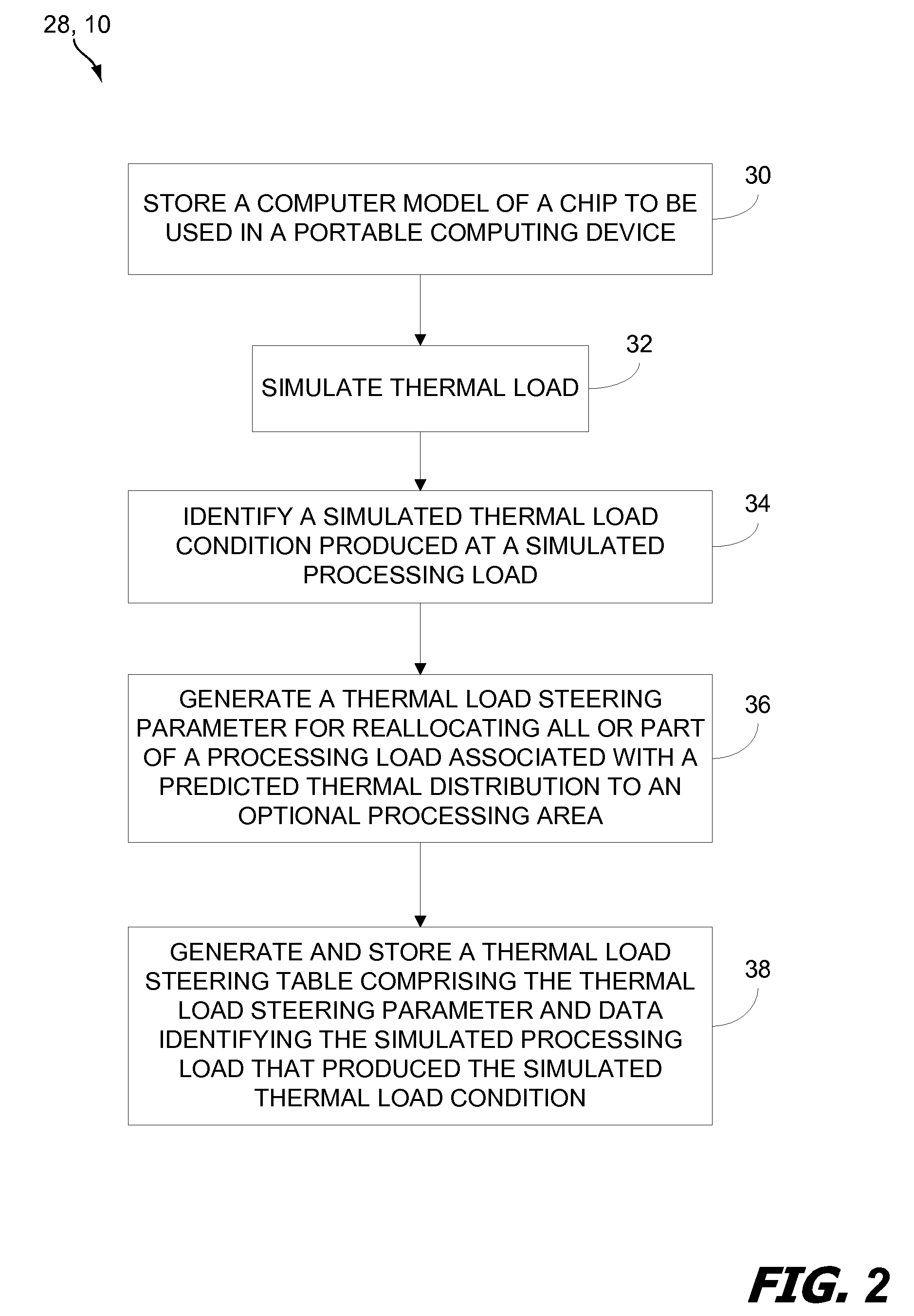

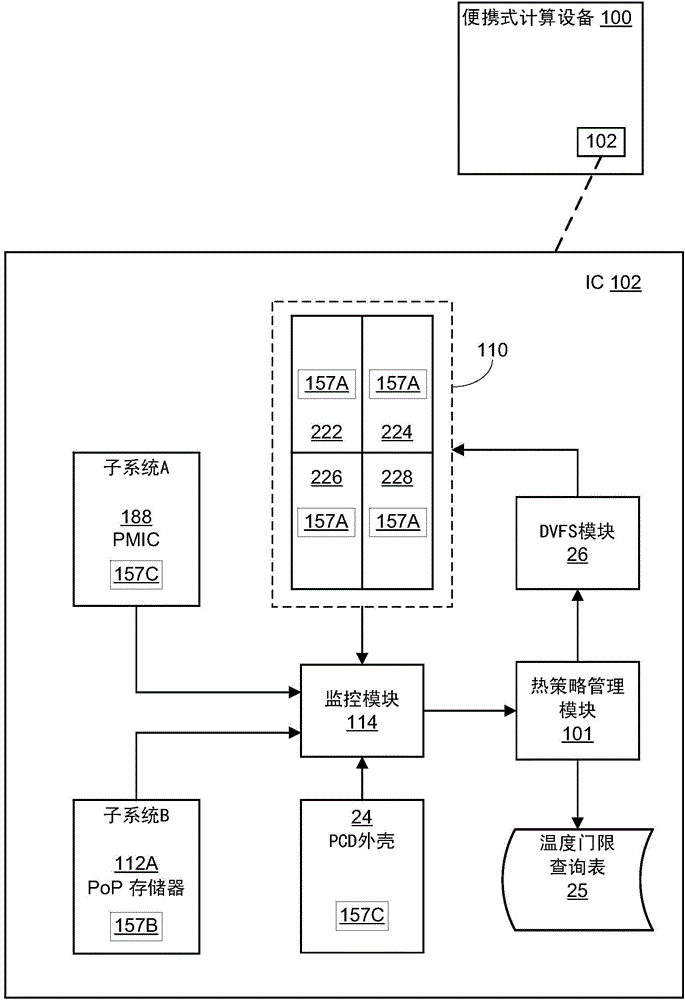

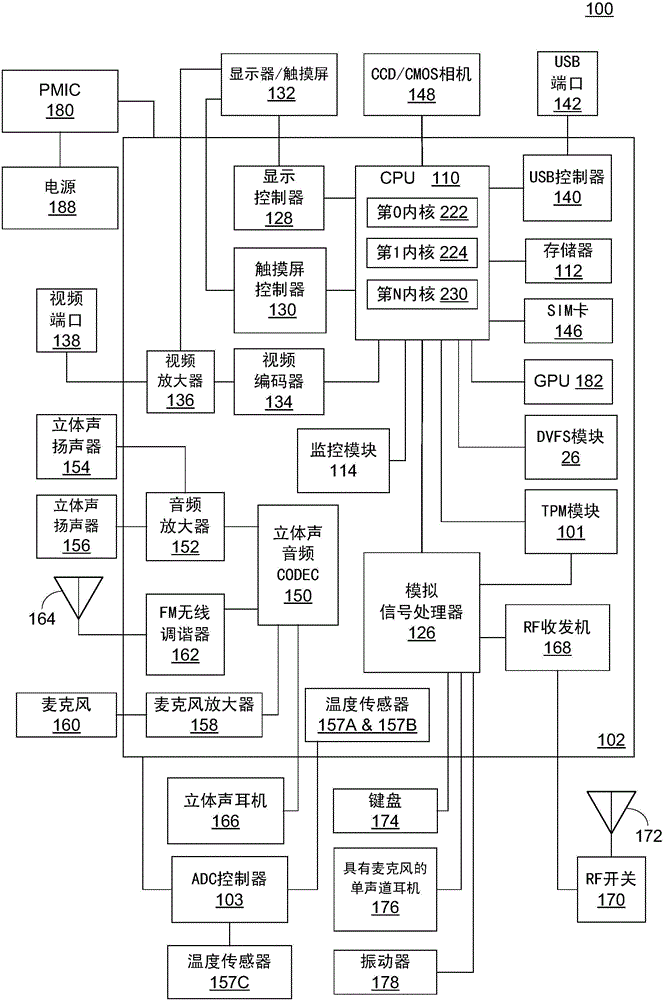

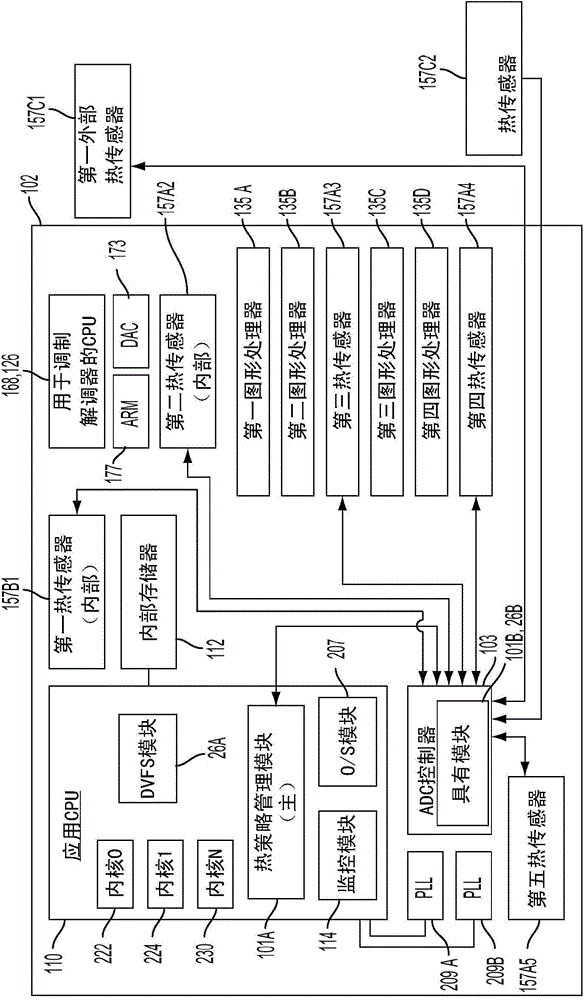

Method and system for thermal load management in a portable computing device

ActiveUS20120271481A1Reduce power densityLower quality of serviceEnergy efficient ICTDigital data processing detailsProcessingHeat energy

Methods and systems for leveraging temperature sensors in a portable computing device (“PCD”) are disclosed. The sensors may be placed within the PCD near known thermal energy producing components such as a central processing unit (“CPU”) core, graphical processing unit (“GPU”) core, power management integrated circuit (“PMIC”), power amplifier, etc. The signals generated by the sensors may be monitored and used to trigger drivers running on the processing units. The drivers are operable to cause the reallocation of processing loads associated with a given component's generation of thermal energy, as measured by the sensors. In some embodiments, the processing load reallocation is mapped according to parameters associated with pre-identified thermal load scenarios. In other embodiments, the reallocation occurs in real time, or near real time, according to thermal management solutions generated by a thermal management algorithm that may consider CPU and / or GPU performance specifications along with monitored sensor data.

Owner:QUALCOMM INC

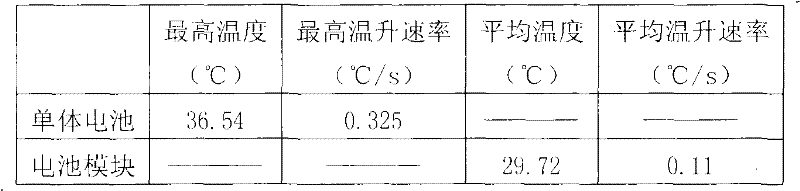

Thermal management device for power batteries and thermal management method for power batteries

InactiveCN102496747ACell temperature controlSecondary cells servicing/maintenancePower batteryElectrical battery

The invention discloses a thermal management device for power batteries and a thermal management method for the power batteries under abnormal working conditions. The thermal management device for the power batteries comprises an acquisition module, an evaluation module, a forecast module, a display module and a control module, wherein the forecast module is used for calculating the heat generation rate and the specific heat capacity according to temperature and temperature rise rate information obtained by the acquisition module and the evaluation module and information such as types, operating states, states of charge and the like of the power batteries so as to obtain forecasted temperature field distribution of a battery unit, and the display module is used for displaying the temperature field distribution of the battery unit forecasted by the forecast module and a current alarm status of the battery unit to a user. The thermal management method for the power batteries is capable of forecasting the temperature field distribution of the battery unit according to acquired temperature and temperature rise data, and at least one of control measures such as turn-off, heat dissipation, alarm and the like is effectively taken, so that the danger of an automobile due to the power batteries can be reduced under the abnormal working conditions.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

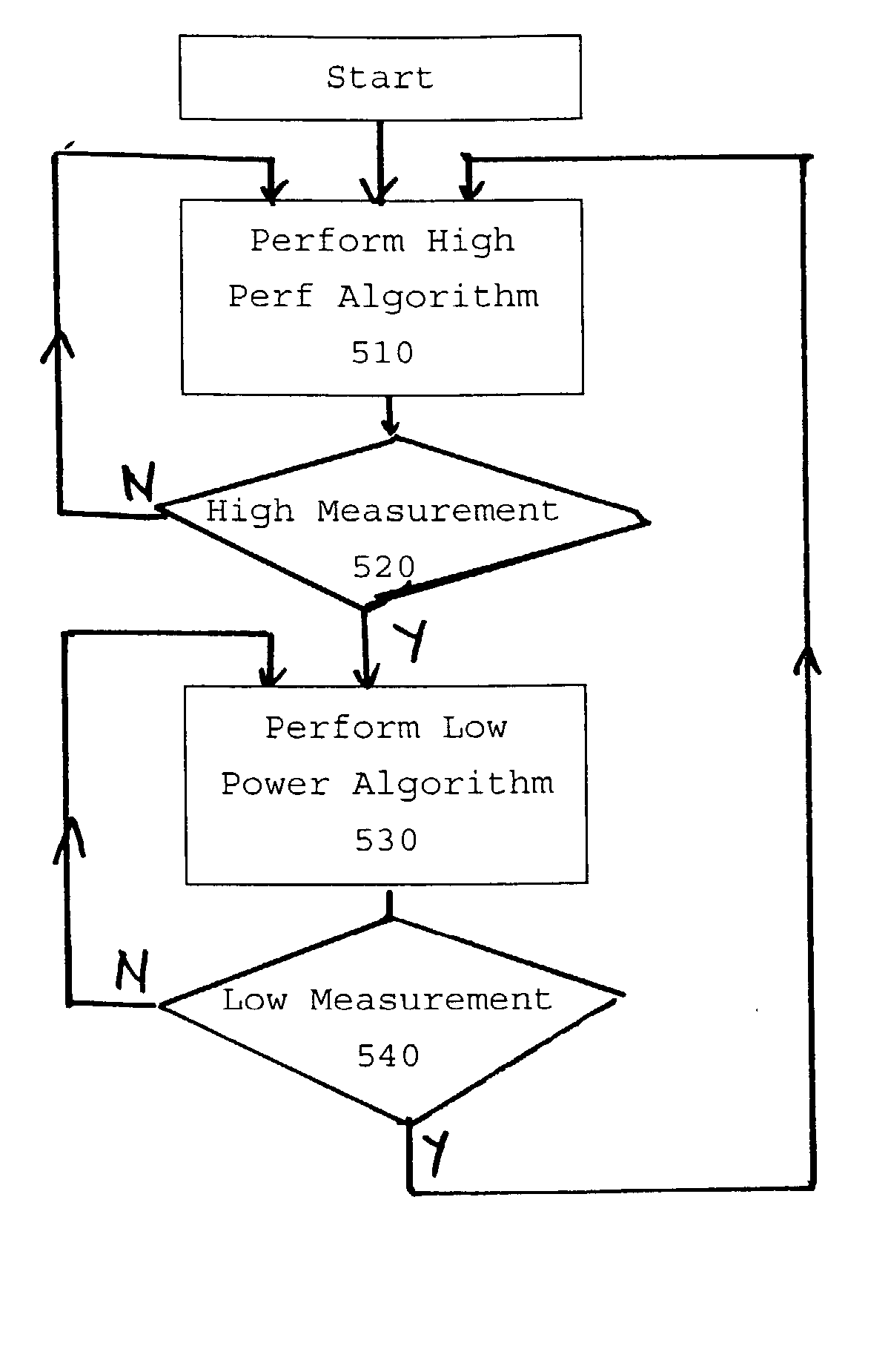

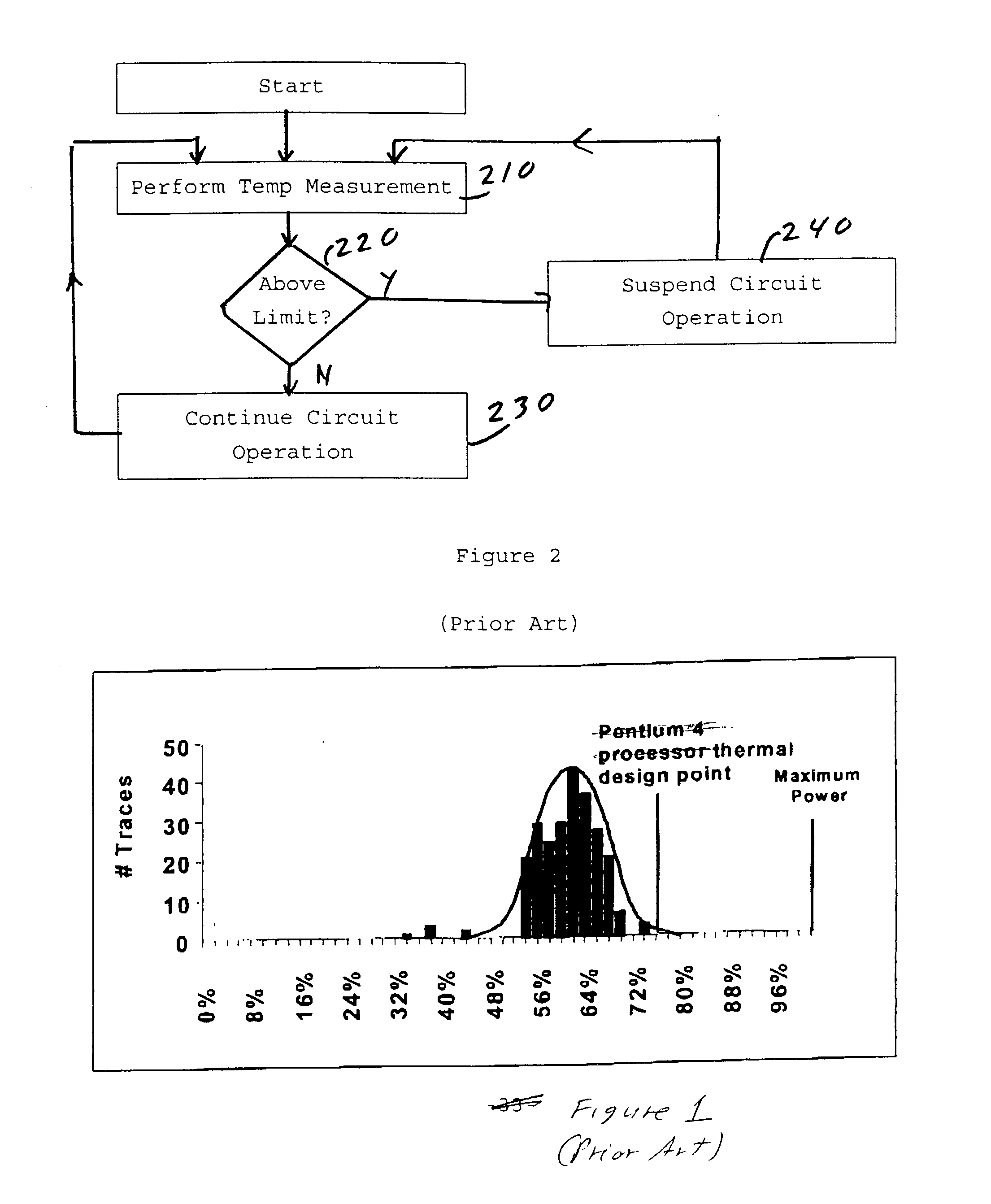

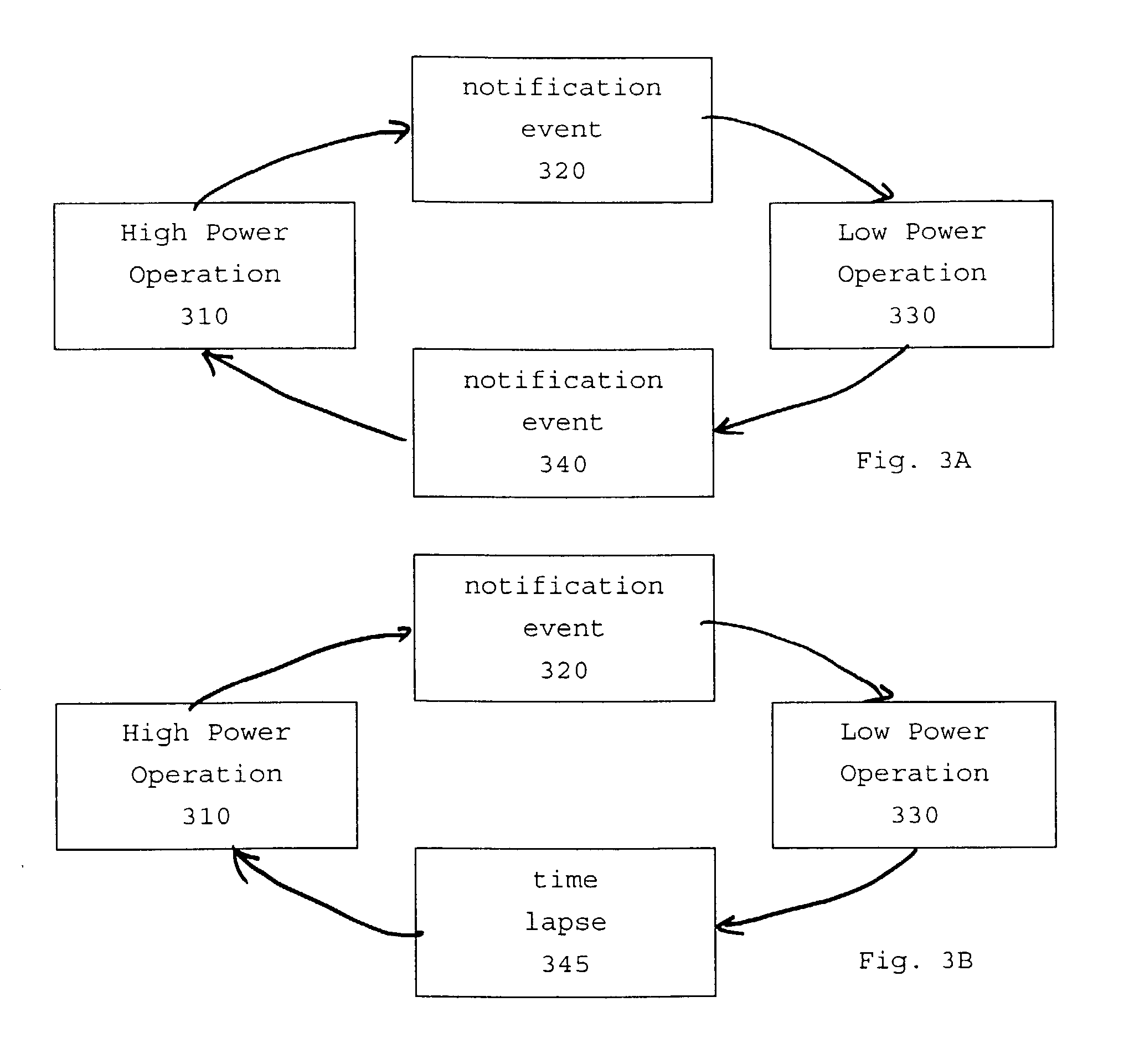

Method and apparatus for software-assisted thermal management for electronic systems

InactiveUS20030217297A1Energy efficient ICTVolume/mass flow measurementElectronic systemsOperational system

In a computer system, a device for measuring power dissipation (e.g., using on-die thermal sensors) is linked to both a hardware-based thermal management solution and with a means for causing a notification event to software, so that, initially, the operating system software and / or the application software modifies its behavior in response to the notification event to reduce overall system power dissipation and the hardware-based thermal management solution is only triggered if the software solution is not effective; with both operating system and application software resuming higher-performance algorithms when power dissipation is no longer critical.

Owner:FOCUS GLOBAL SOLUTIONS LLC

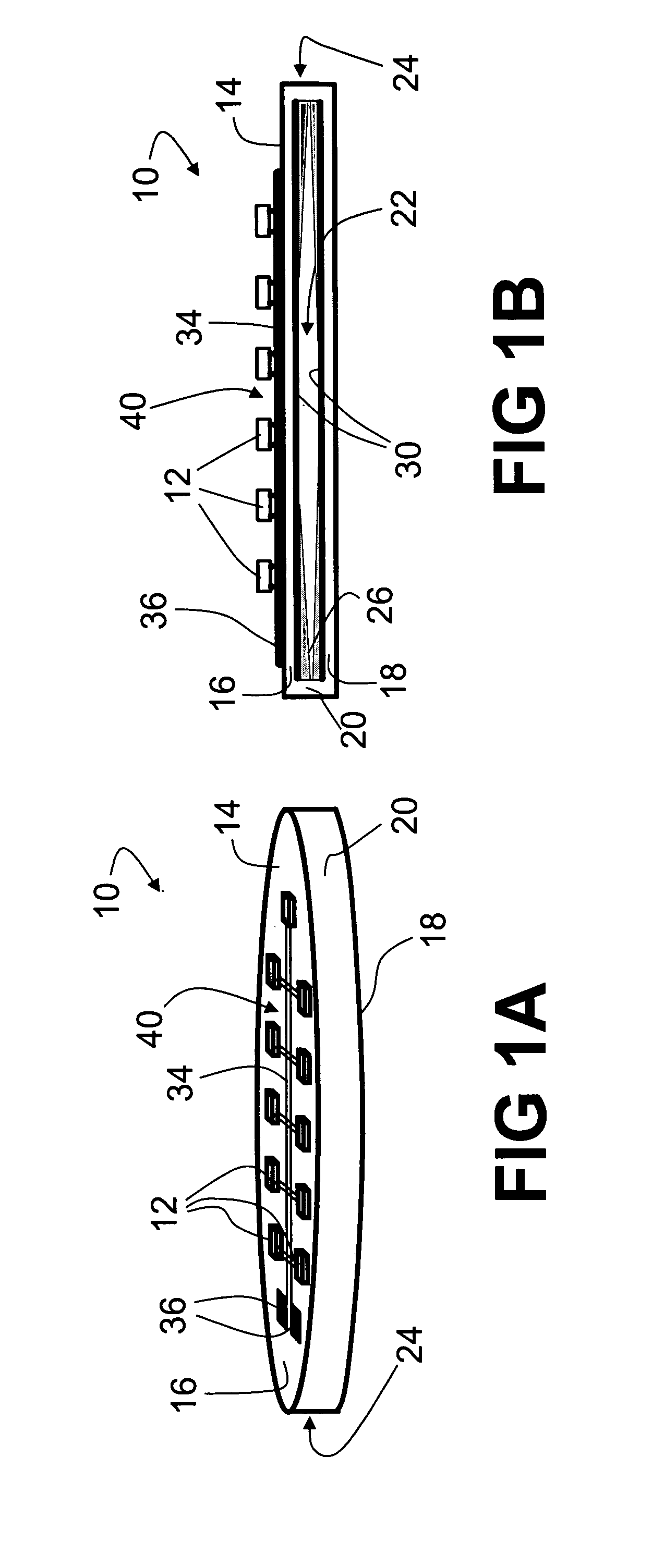

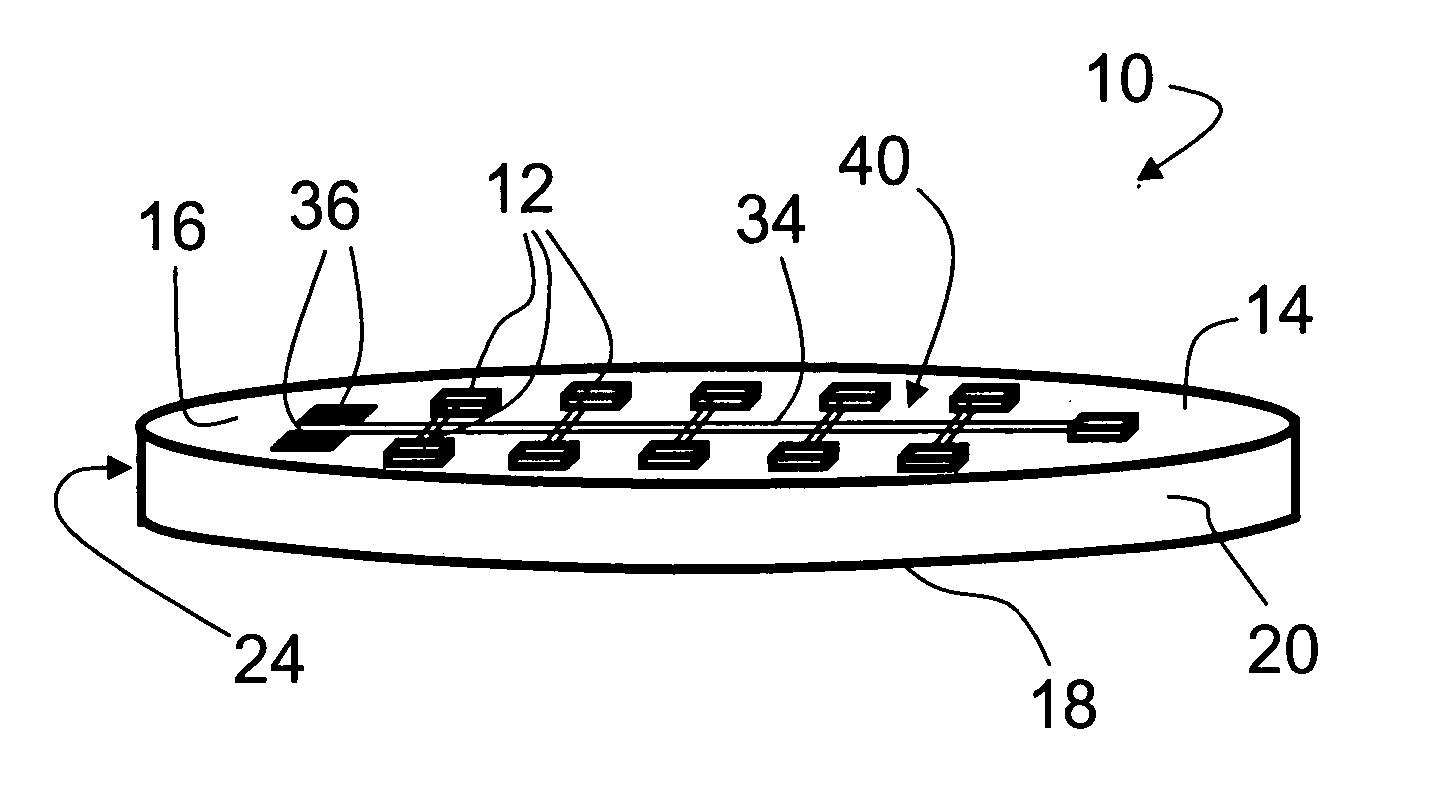

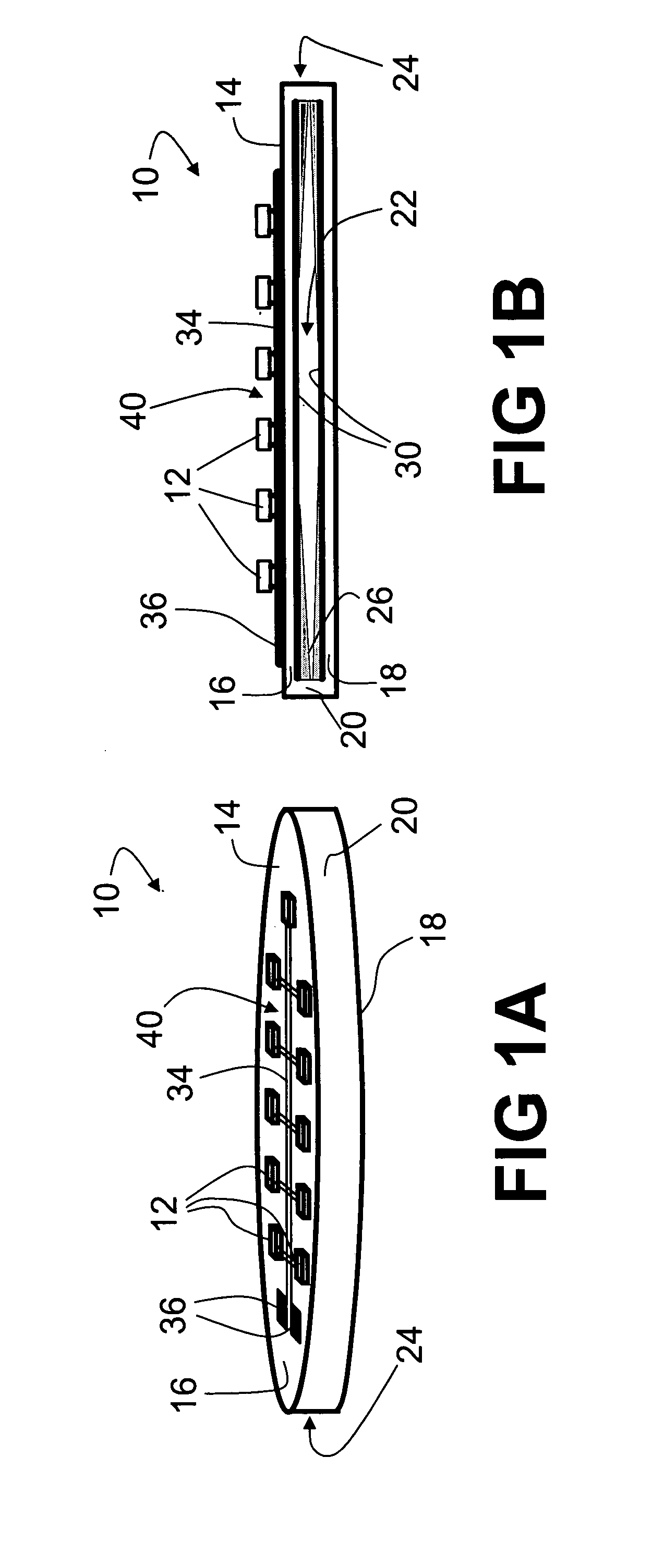

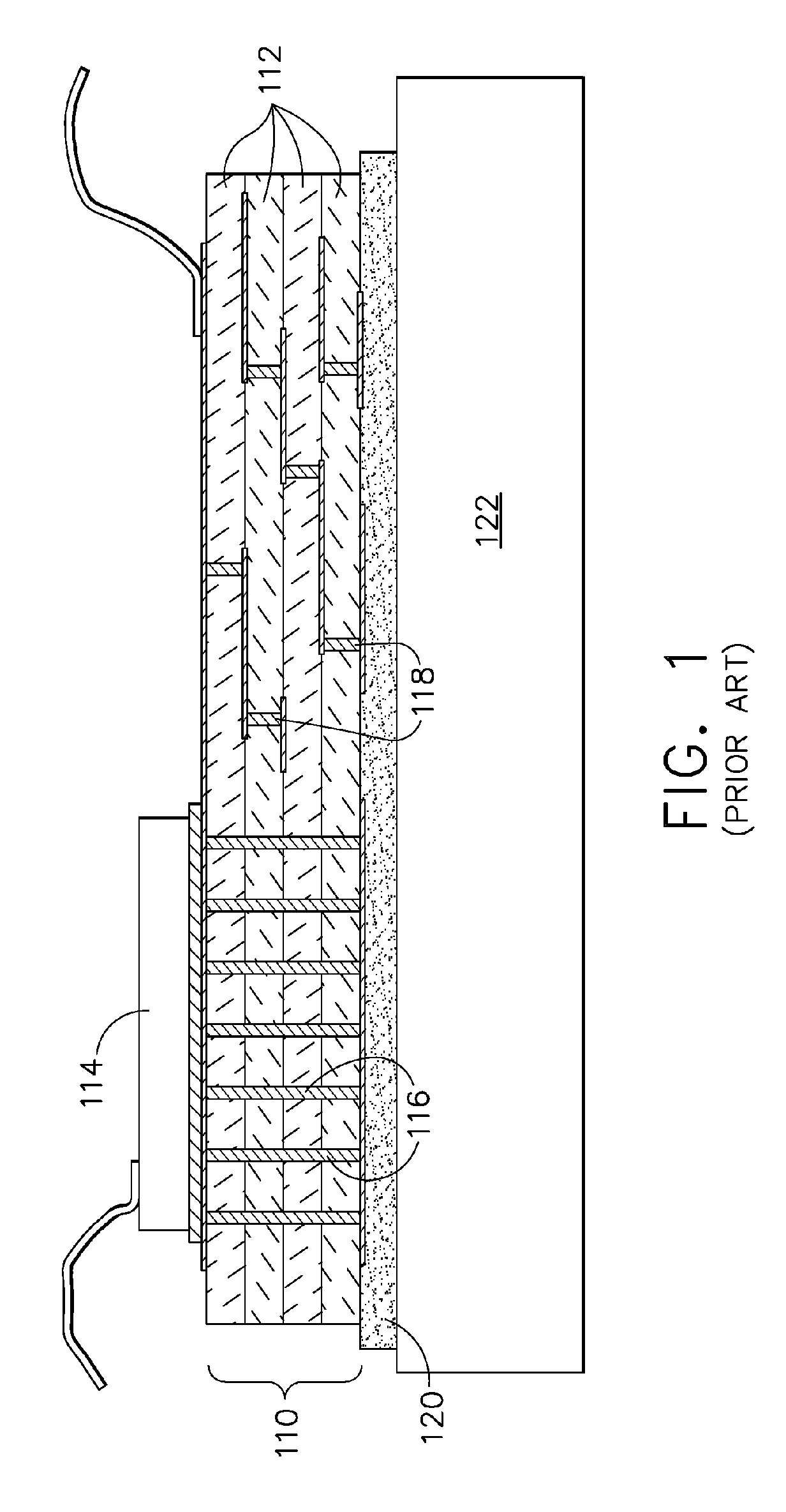

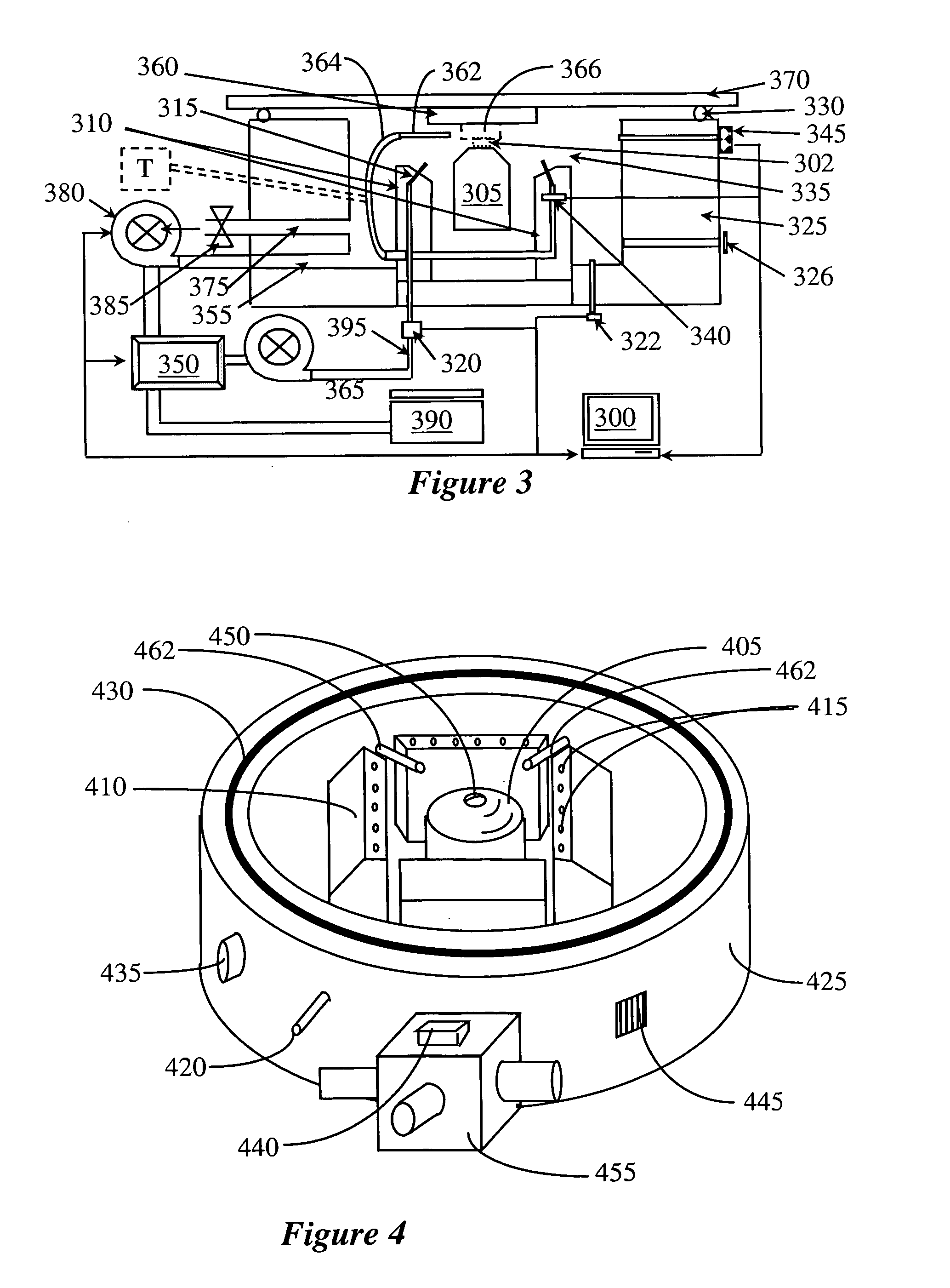

Light emitting diode apparatuses with heat pipes for thermal management

InactiveUS7095110B2Semiconductor/solid-state device detailsLighting heating/cooling arrangementsEngineeringHeat transfer fluid

A light emitting apparatus (10, 110, 210, 310, 410) includes one or more light emitting diode chips (12, 112, 212, 312, 412) disposed on a chip support wall (16, 116, 216) including printed circuitry (34, 134, 234, 360, 362, 460, 462) connecting with the light emitting diode chips. A heat pipe (24, 124, 224, 324, 424) has a sealed volume (22, 122, 222, 322, 422) defined by walls including the chip support wall and at least one additional wall (18, 20, 118, 120, 218). The heat pipe further includes a heat transfer fluid (26, 226, 326, 426) disposed in the sealed volume.

Owner:GELCORE LLC (US)

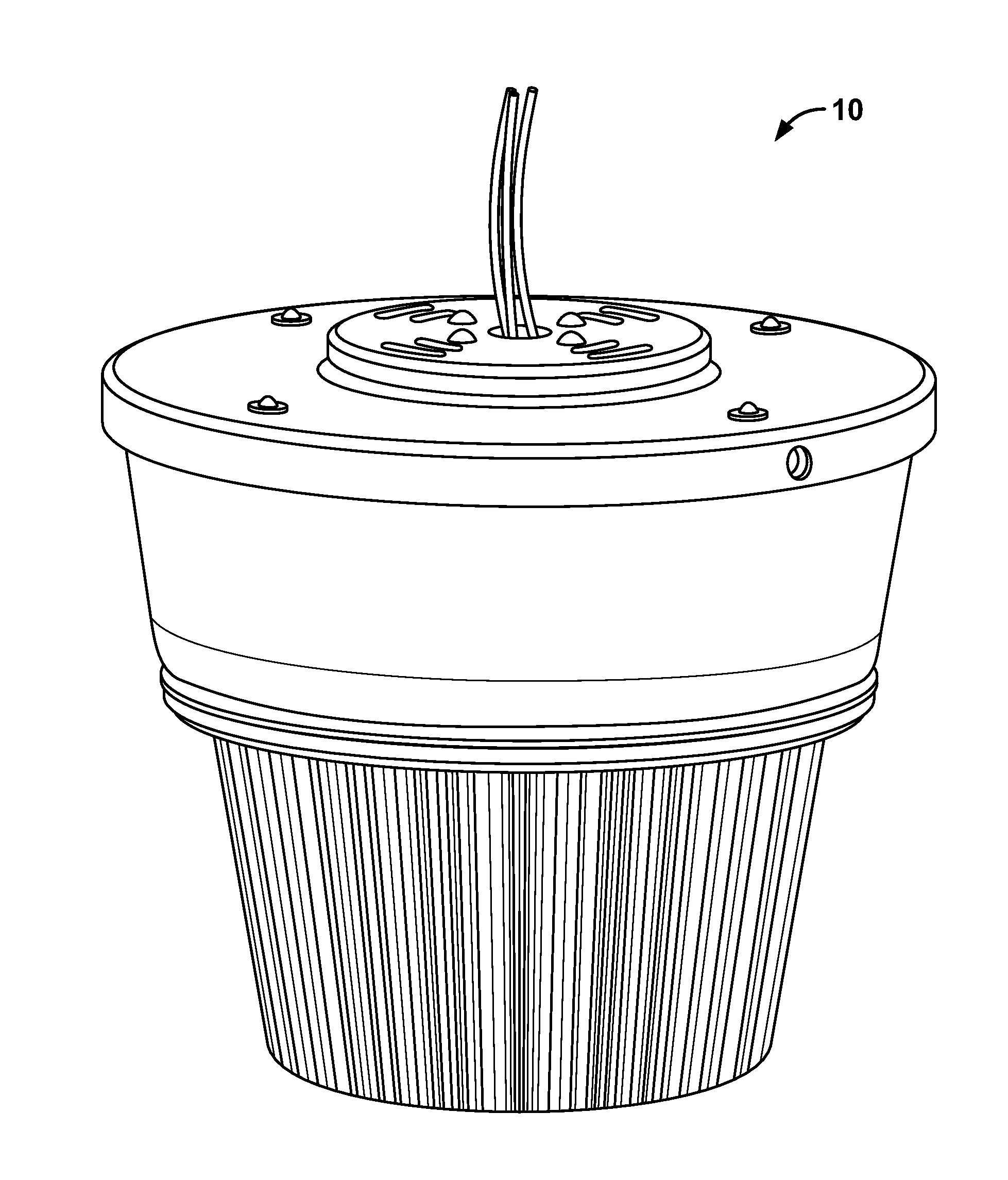

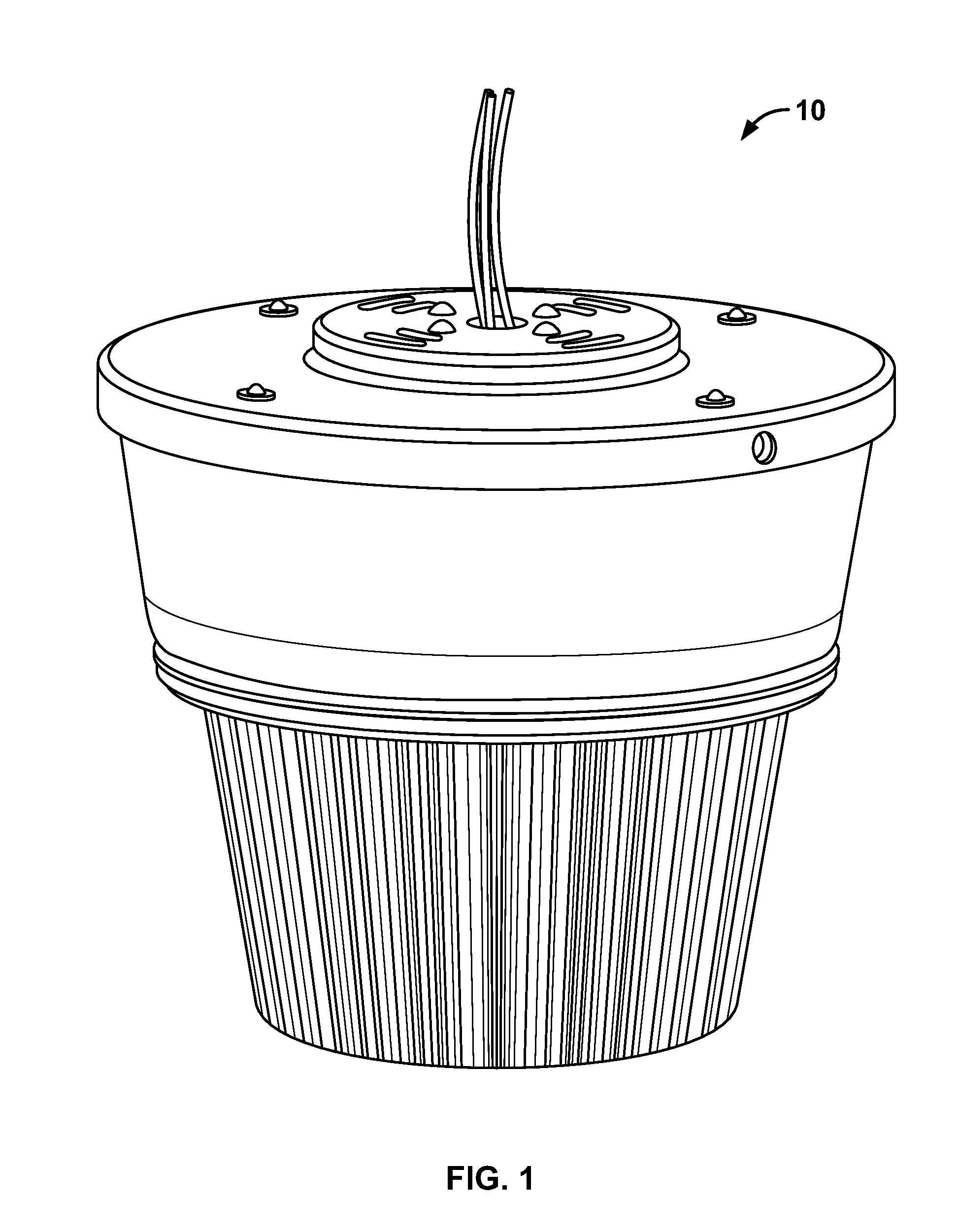

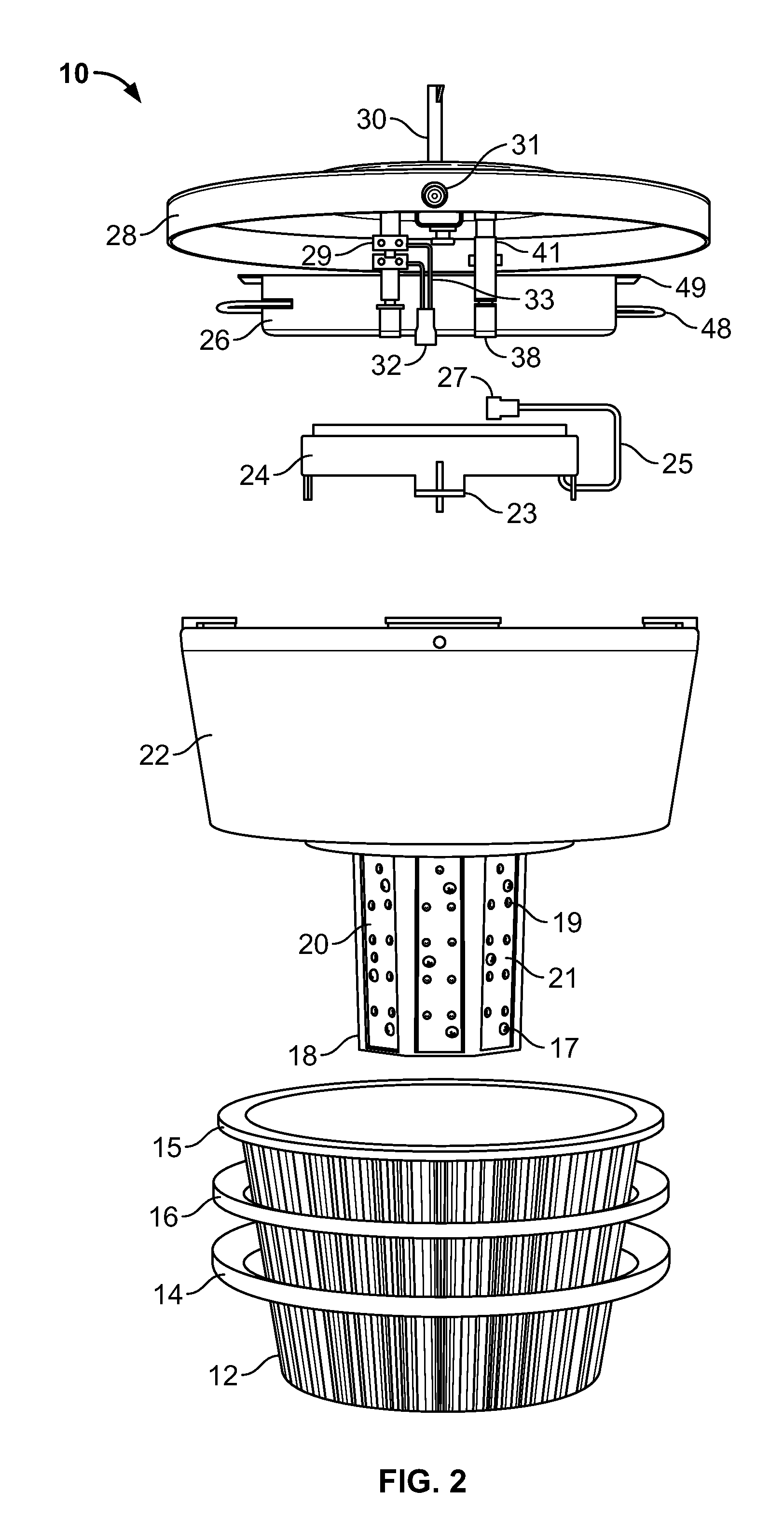

Solid state low bay light with integrated and sealed thermal management

InactiveUS20110228529A1Effective coolingIncrease airflowMechanical apparatusPoint-like light sourceSolid-stateAir current

A lighting fixture utilizing LED light sources for illumination of commercial, outdoor and other large area applications incorporates efficient heat dissipation and improved convective air flow. An integrated heat transfer assembly is disclosed that is configured to enhance heat dissipation by providing an efficient thermal conductive pathway for radiation of heat to an external environment. The lighting fixture body is configured with a lens body and heat sink having a chimney tube with internally facing finned heat sink arrangement for providing enhanced convective air flow through the light fixture body. When the heat sink transfers heat from the LED light sources during operation so as to create heated air surrounding the heat sink, ambient air is drawn through the chimney and the heated air is exhausted through air gaps so as to create a conductive air current with the environment. The heat sink fins are configured to enhance the natural air draw through the chimney by tapering the surface areas of the fins.

Owner:INFINILUX

Light emitting diode apparatuses with heat pipes for thermal management

InactiveUS20050258438A1Semiconductor/solid-state device detailsLighting heating/cooling arrangementsHeat managementEngineering

A light emitting apparatus (10, 110, 210, 310, 410) includes one or more light emitting diode chips (12, 112, 212, 312, 412) disposed on a chip support wall (16, 116, 216) including printed circuitry (34, 134, 234, 360, 362, 460, 462) connecting with the light emitting diode chips. A heat pipe (24, 124, 224, 324, 424) has a sealed volume (22, 122, 222, 322, 422) defined by walls including the chip support wall and at least one additional wall (18, 20, 118, 120, 218). The heat pipe further includes a heat transfer fluid (26, 226, 326, 426) disposed in the sealed volume.

Owner:GELCORE LLC (US)

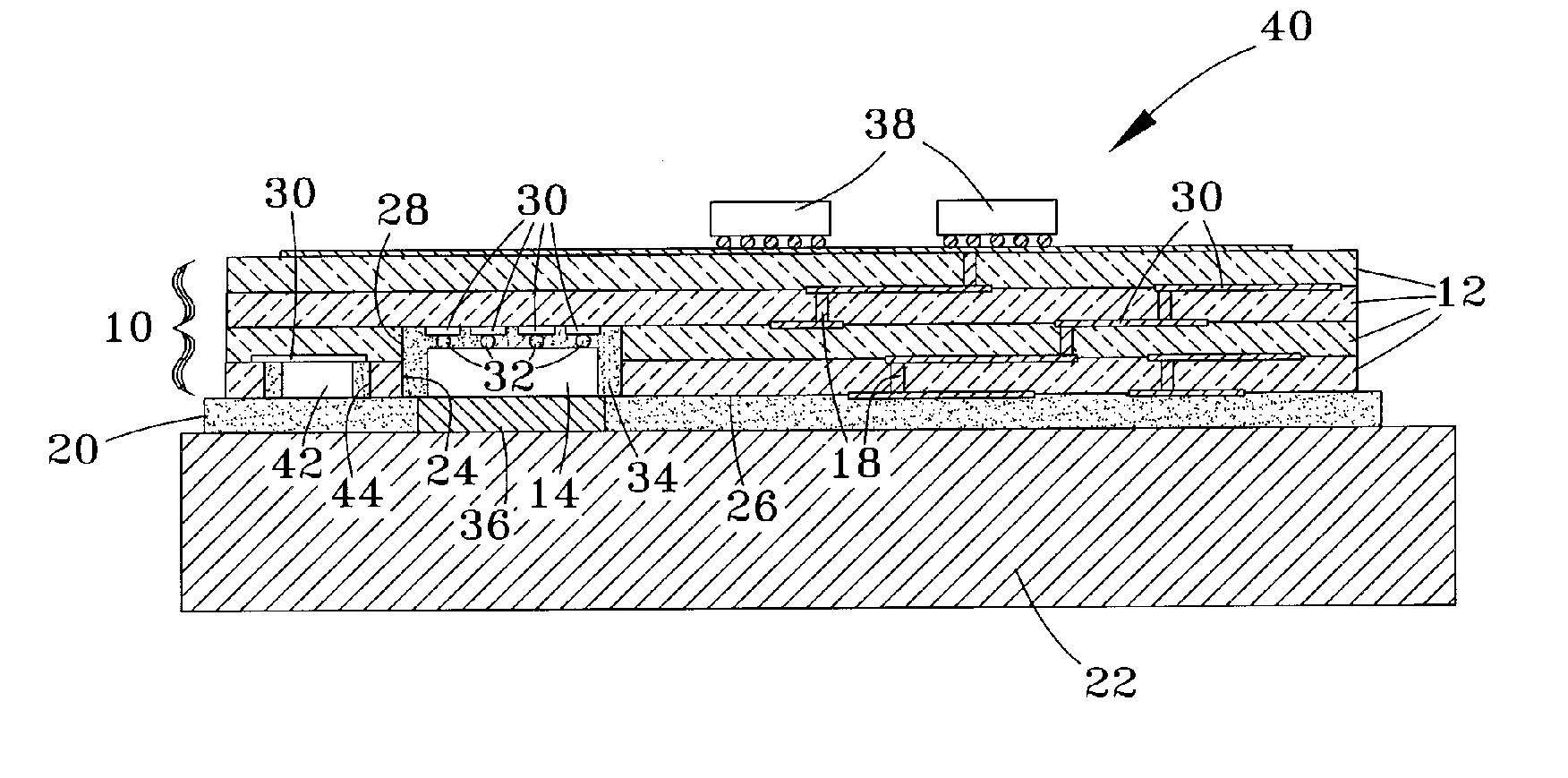

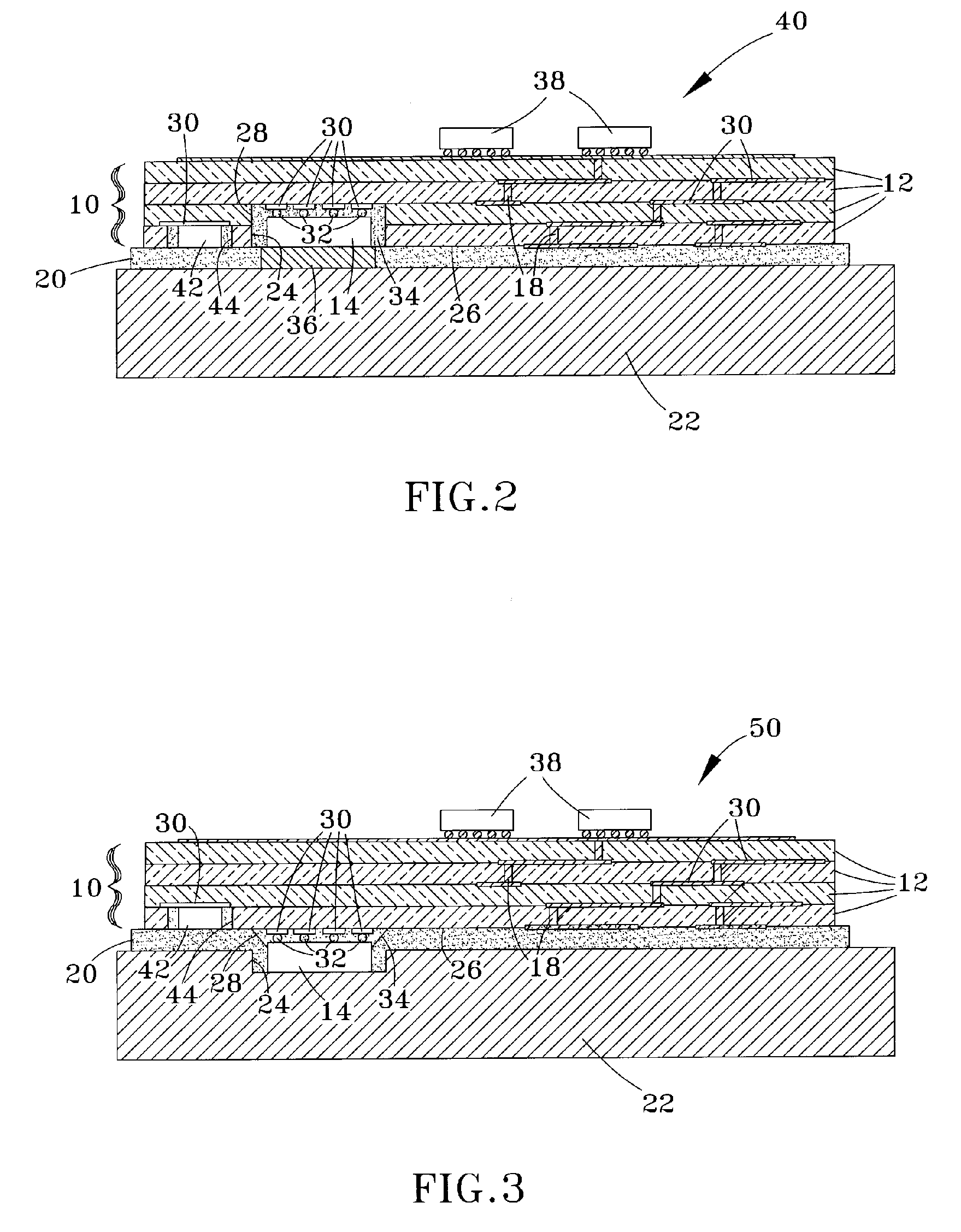

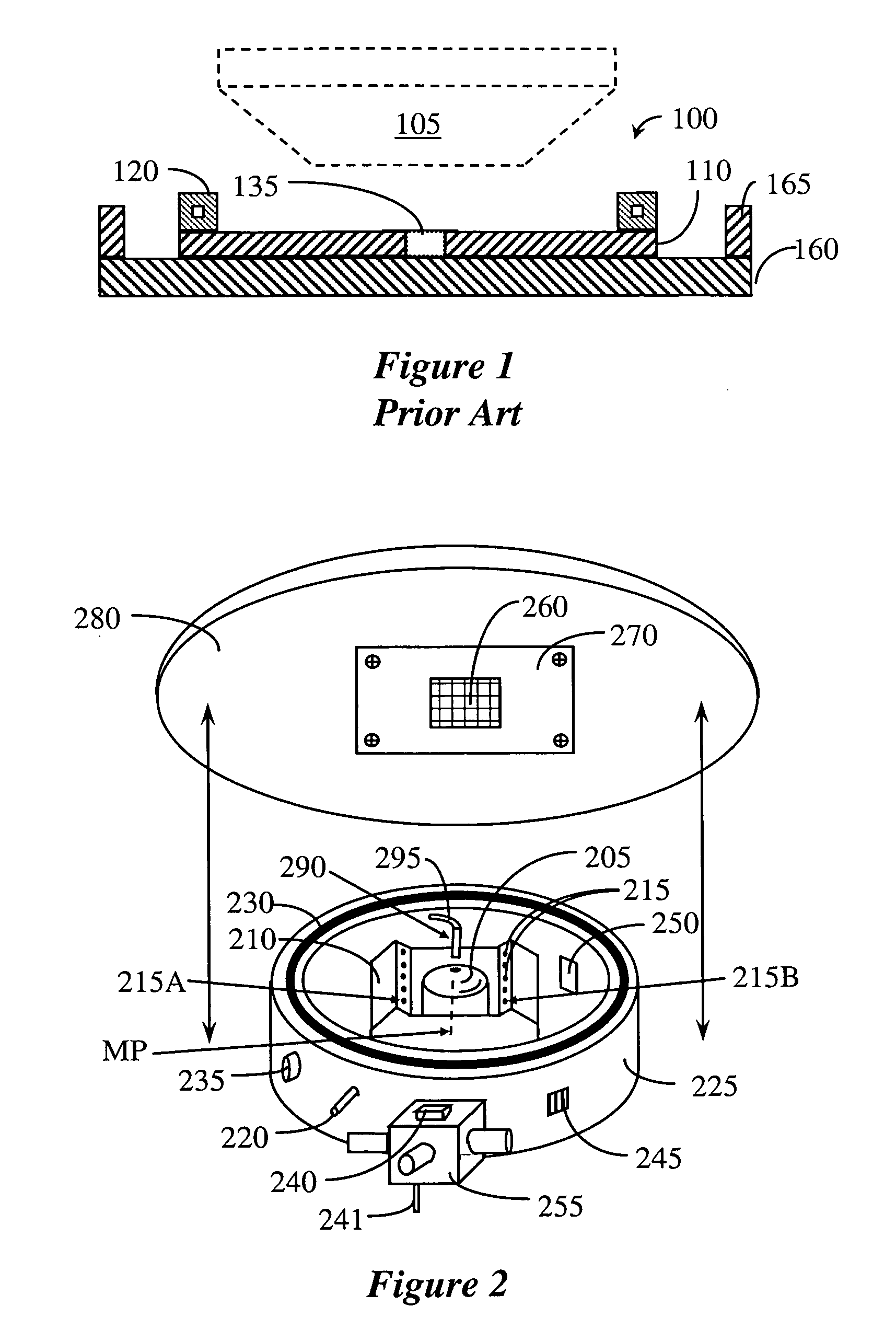

Thermal management of surface-mount circuit devices

ActiveUS20060120058A1Improved thermal managementSemiconductor/solid-state device detailsPrinted electric component incorporationElectrical conductorHeat management

A circuit board assembly having a laminate construction of multiple layers, such as a LTCC ceramic substrate, with conductor lines between adjacent pairs of layers. A heat sink is bonded to a first surface of the substrate, and a cavity is defined by and between the heat sink and the substrate such that a base wall of the cavity is defined by one of the layers with conductor lines thereof being present on the base wall. A surface-mount circuit device is received within the cavity, mounted to the base wall, and electrically connected to the conductor lines on the base wall. The device is received within the cavity such that a surface of the device contacts a surface region of the heat sink. The surface of the device is bonded to the surface region of the heat sink to provide a substantially direct thermal path from the device to the heat sink.

Owner:DELPHI TECH IP LTD

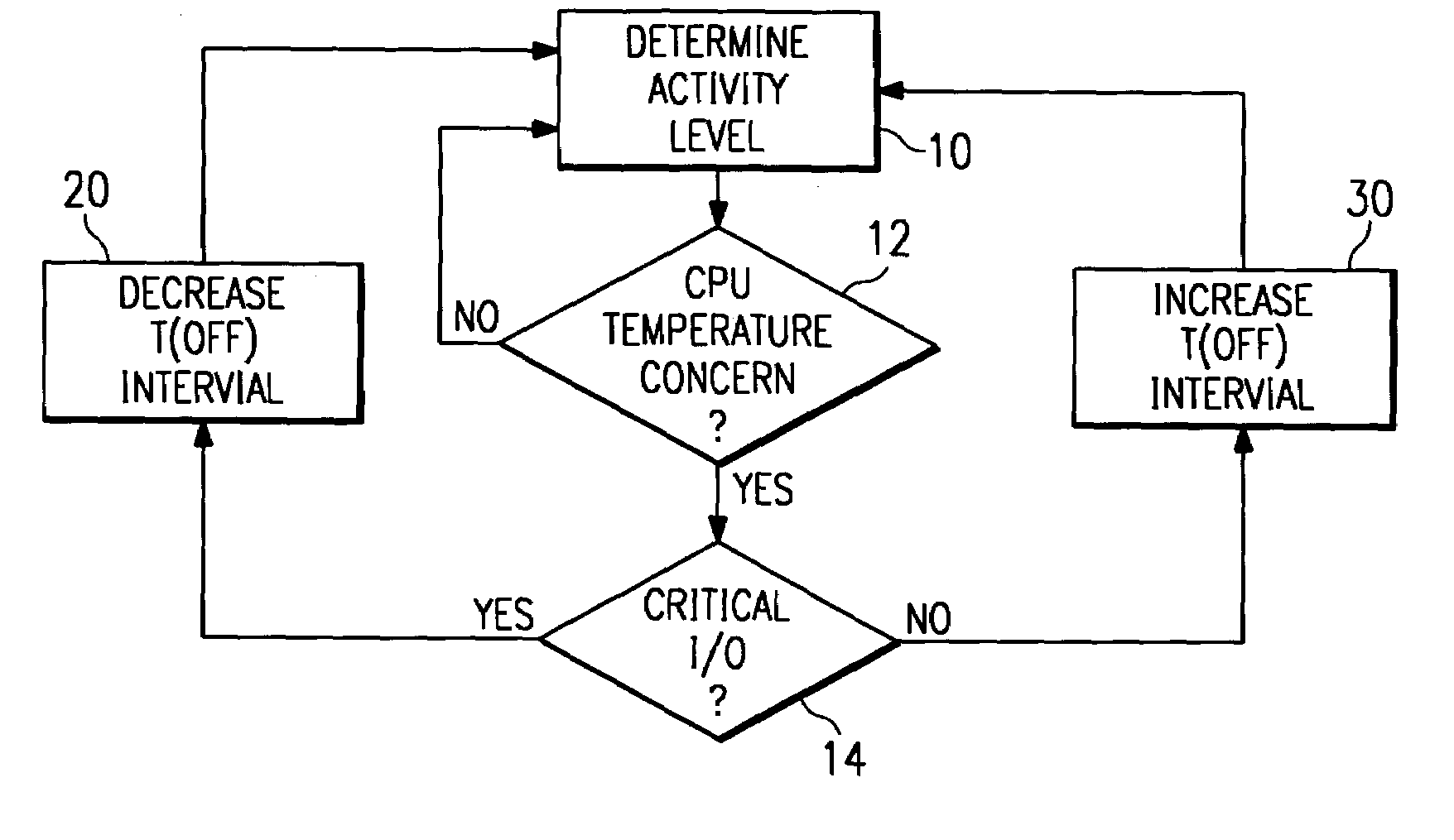

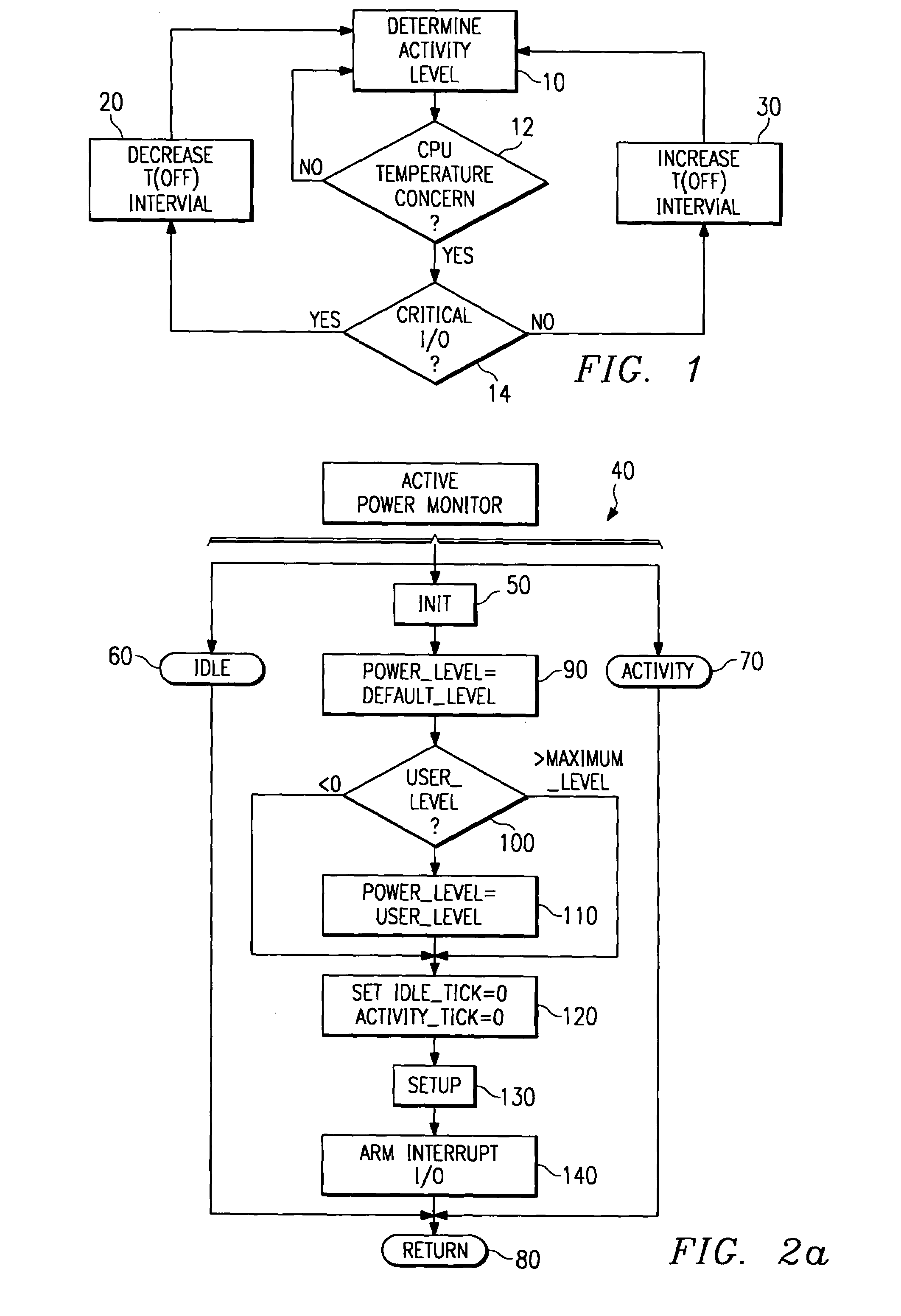

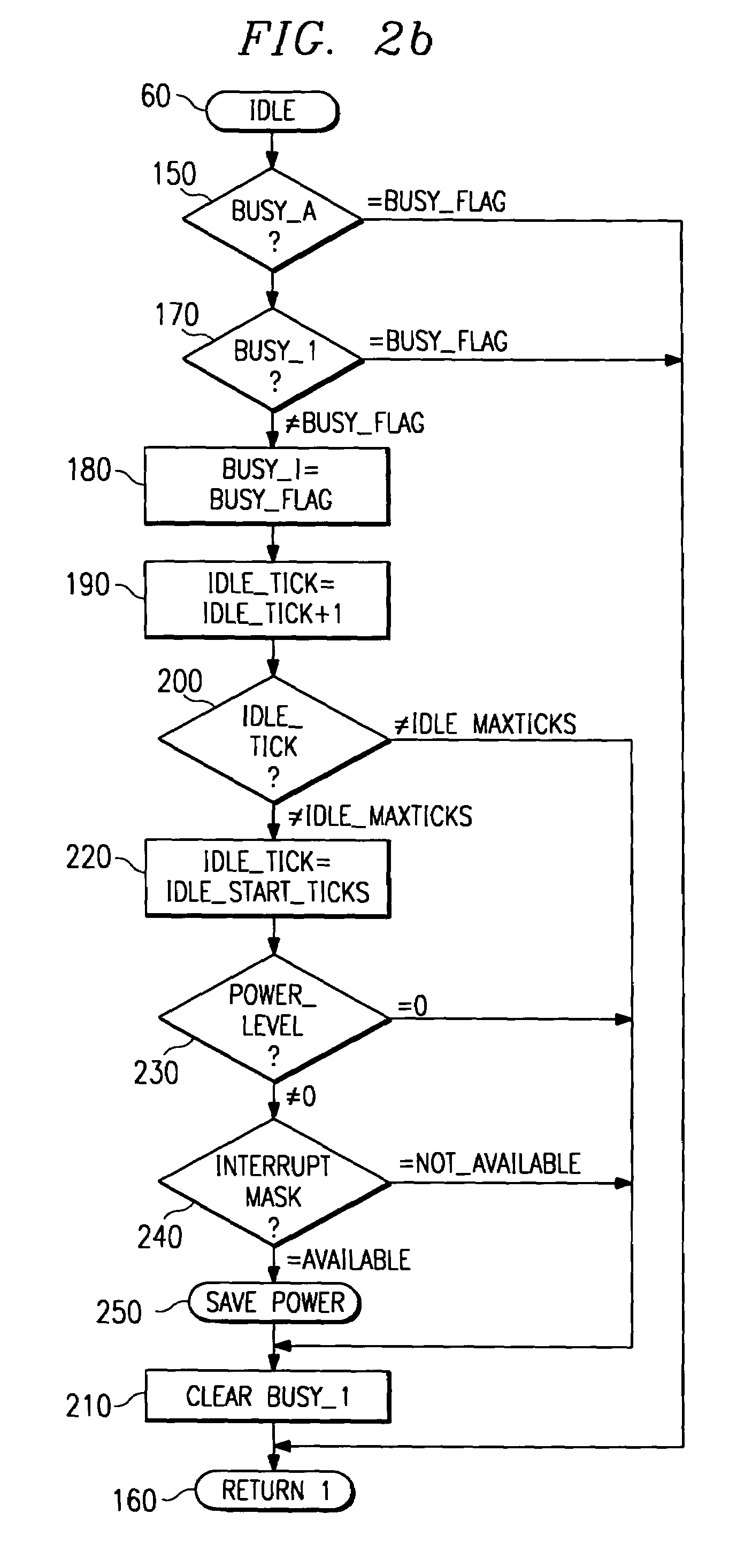

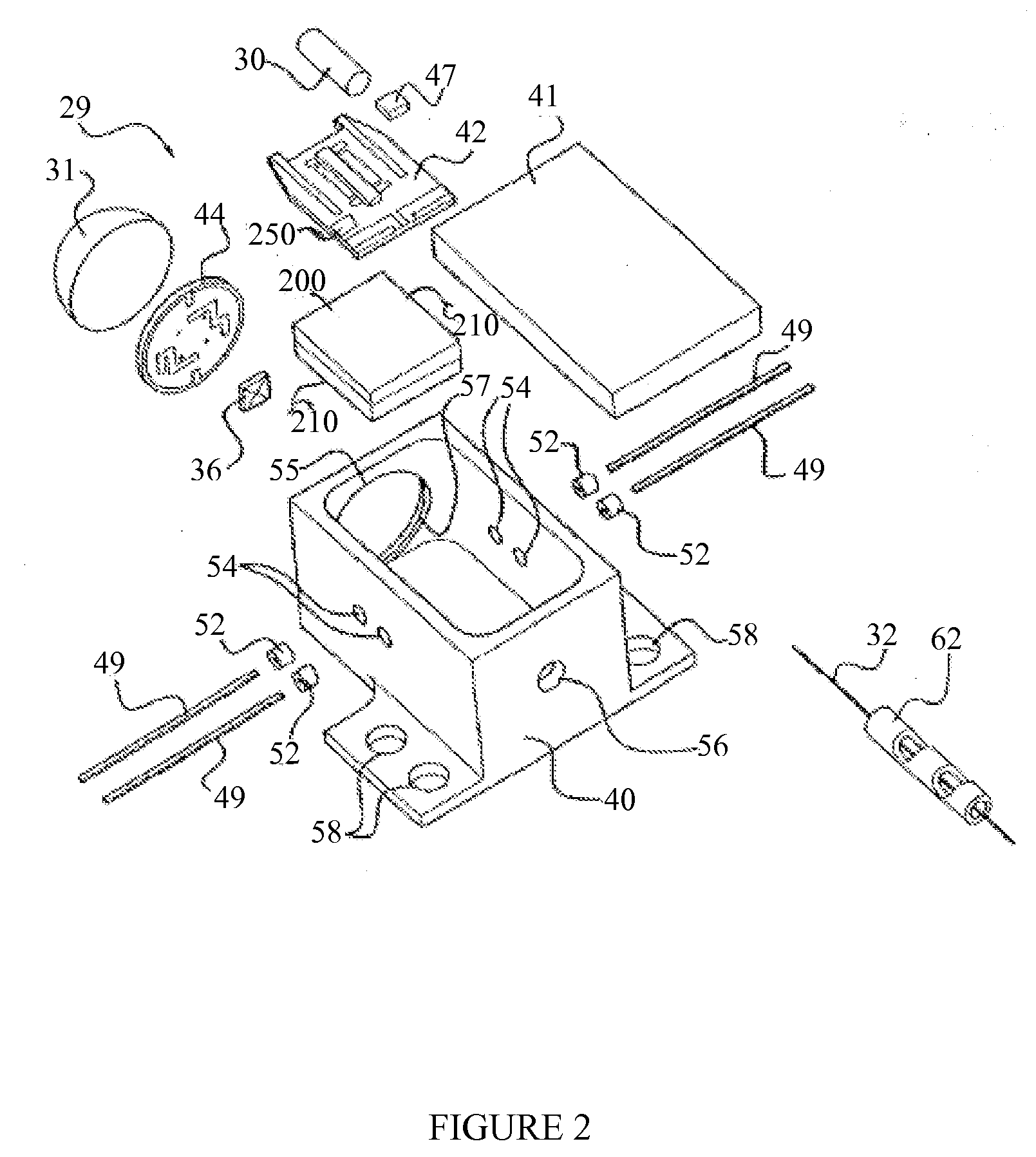

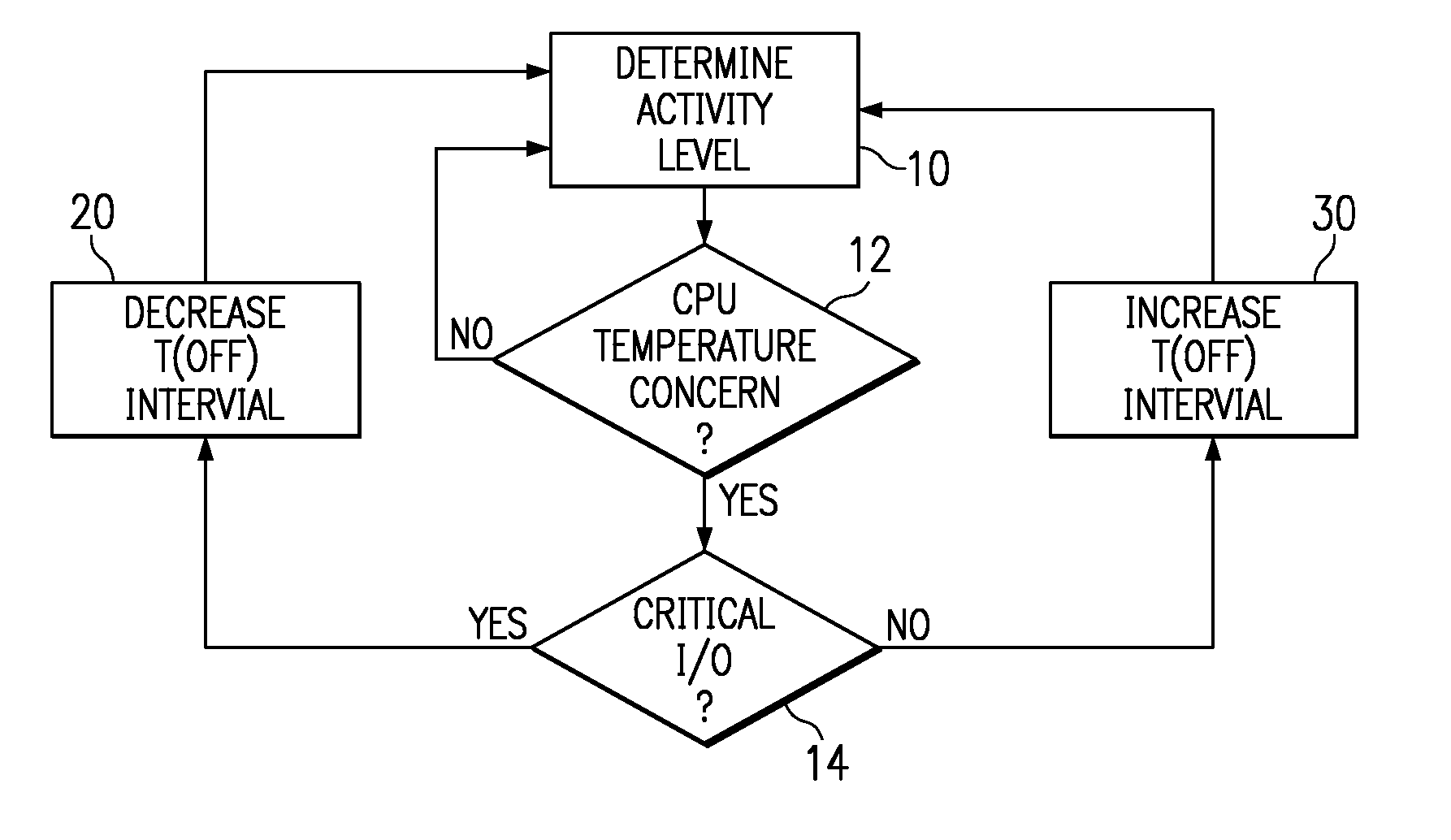

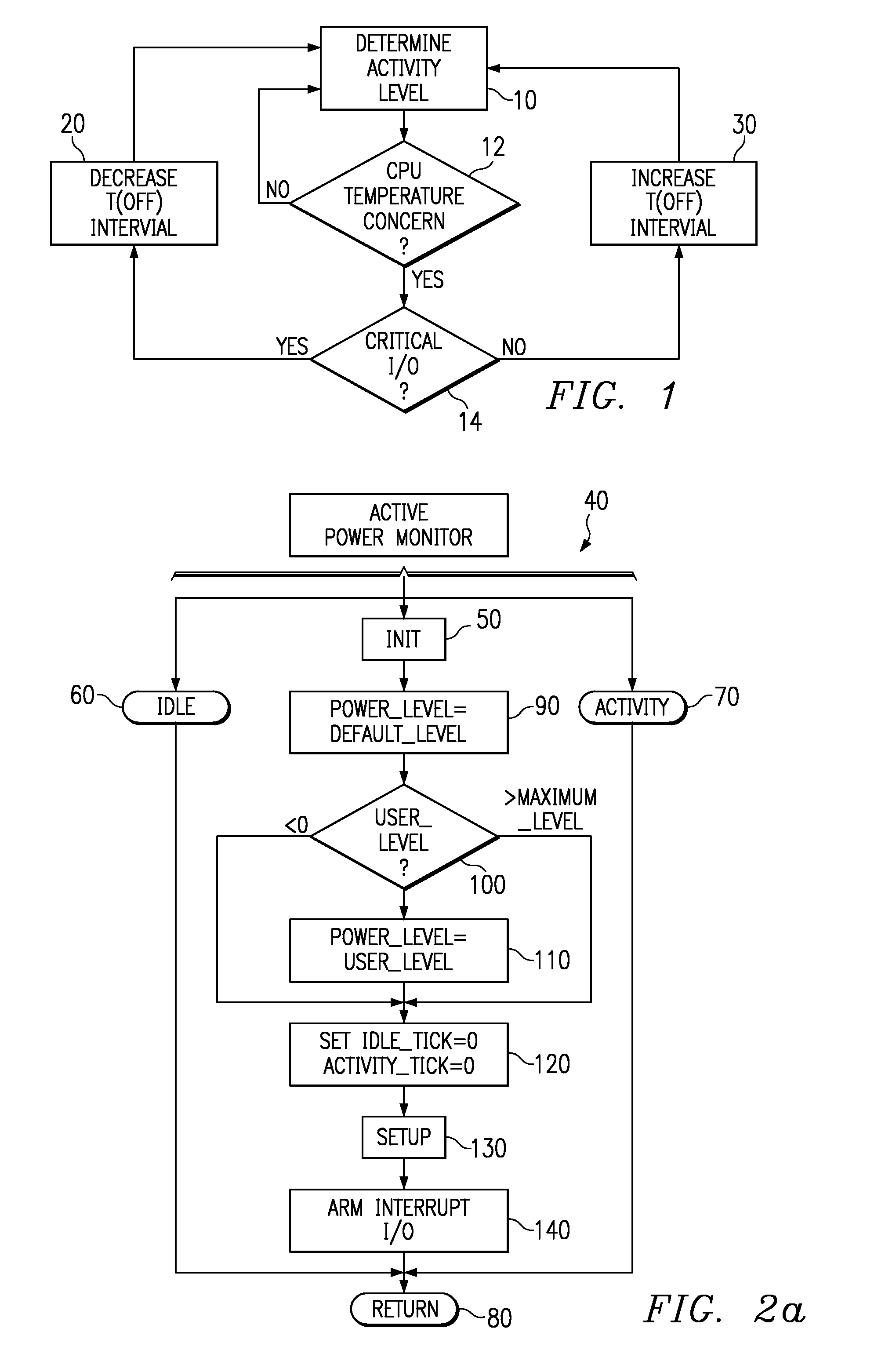

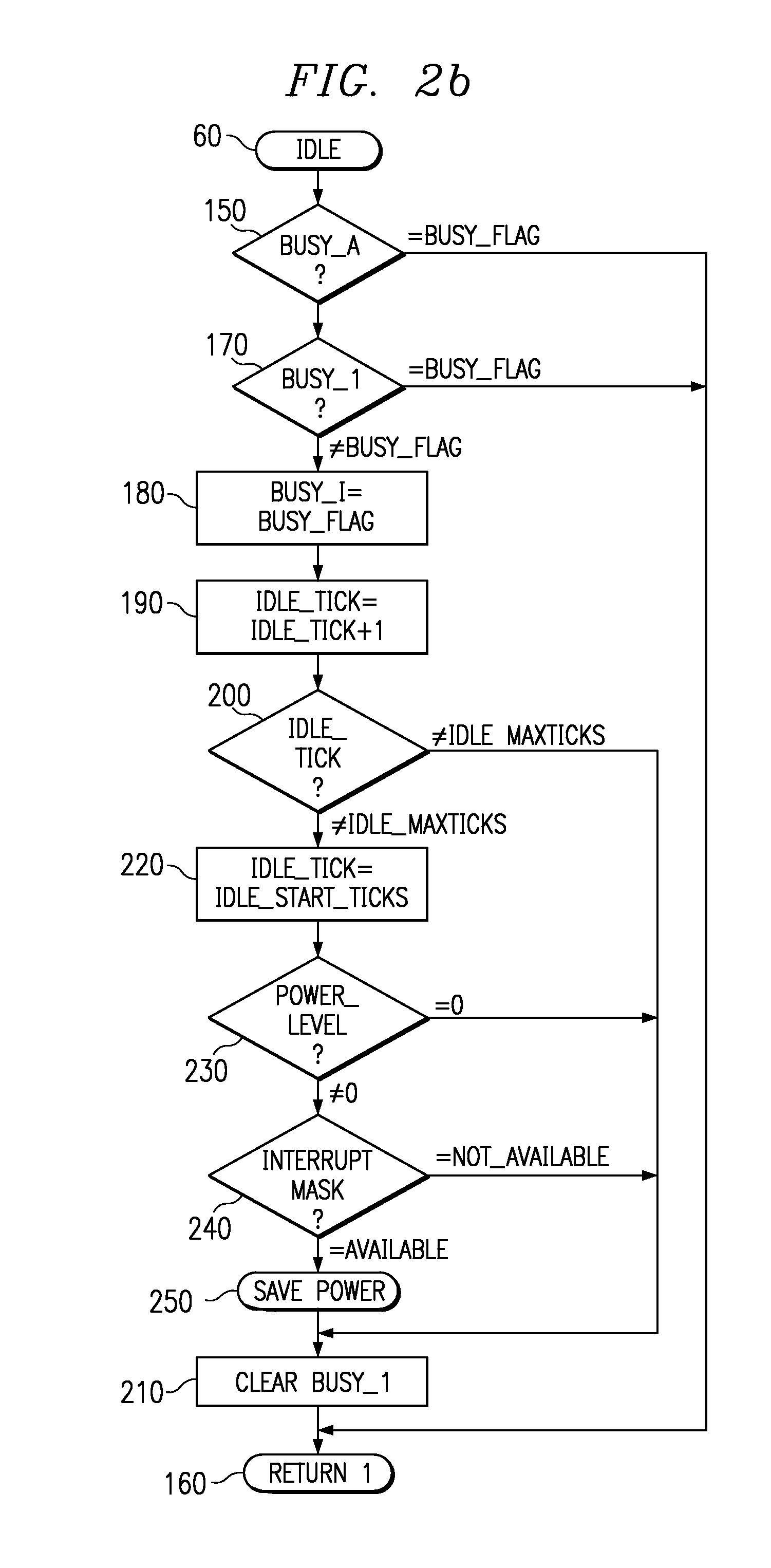

Real-time thermal management for computers

A real-time thermal management apparatus and method for a computer employs a monitor (40) to determine whether a CPU may rest based upon real-time sampling of temperature levels and CPU activity levels within the computer. The monitor activates a hardware selector to carry out the monitor's determination. If the monitor determines the CPU may rest, the hardware selector reduces CPU clock time; if the CPU is to be active, the hardware selector returns the CPU to its previous high speed clock level. Switching back into full operation from its rest state occurs without a user having to request it and without any delay in the operation of the computer while waiting for the computer to return to a “ready” state. Furthermore, the monitor (40) adjusts the performance level of the computer in response to the real-time sampling of CPU activity and temperature levels. Such adjustments are accomplished within the CPU cycles and do not affect the user's perception of performance and do not affect any system application software executing on the computer.

Owner:TEXAS INSTR INC

Magnetocaloric refrigerator

InactiveUS9702594B2Improve rendering capabilitiesImprove conductivityEnergy efficient heating/coolingMachines using electric/magnetic effectsIceboxEngineering

Owner:AIP MANAGEMENT LLC

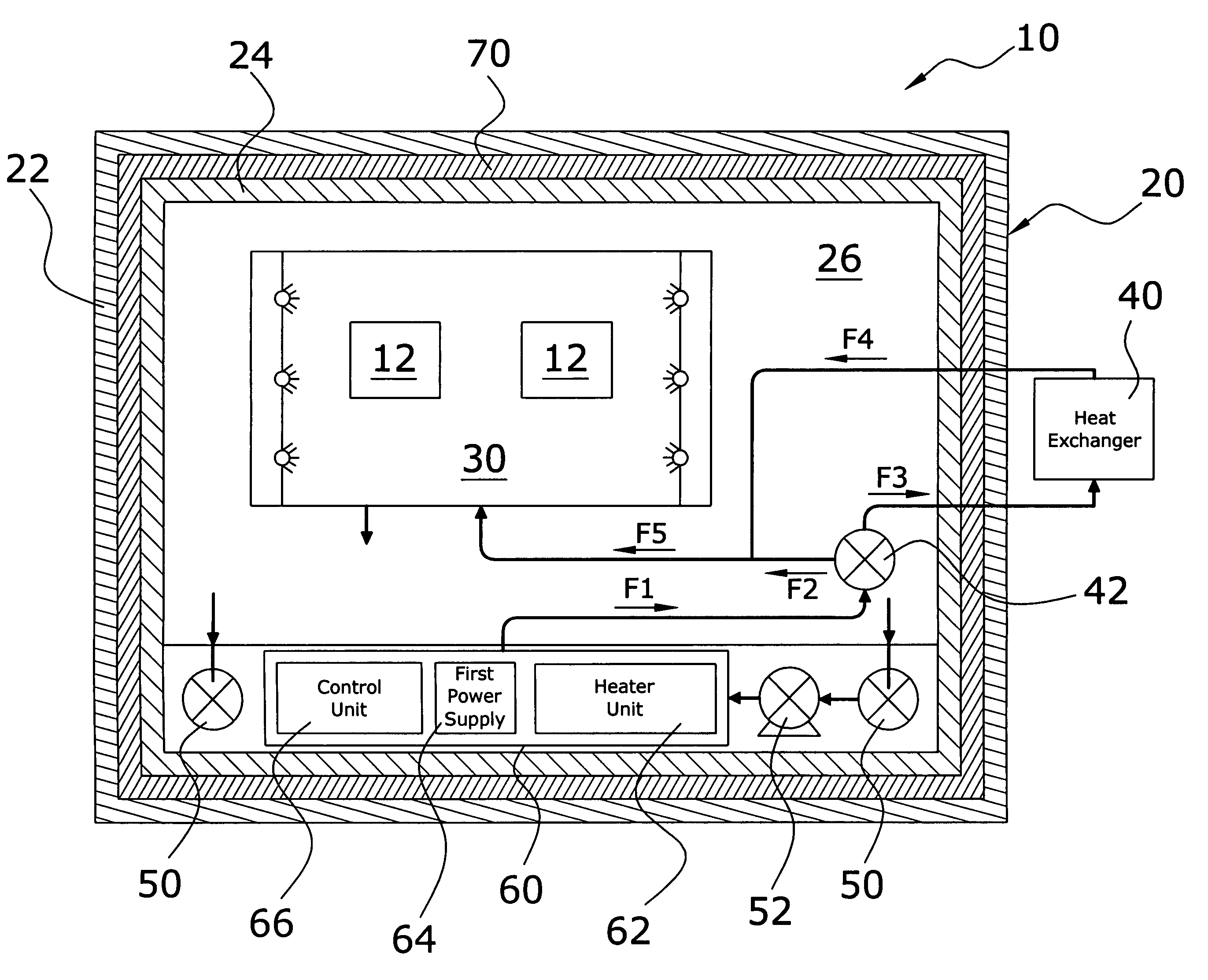

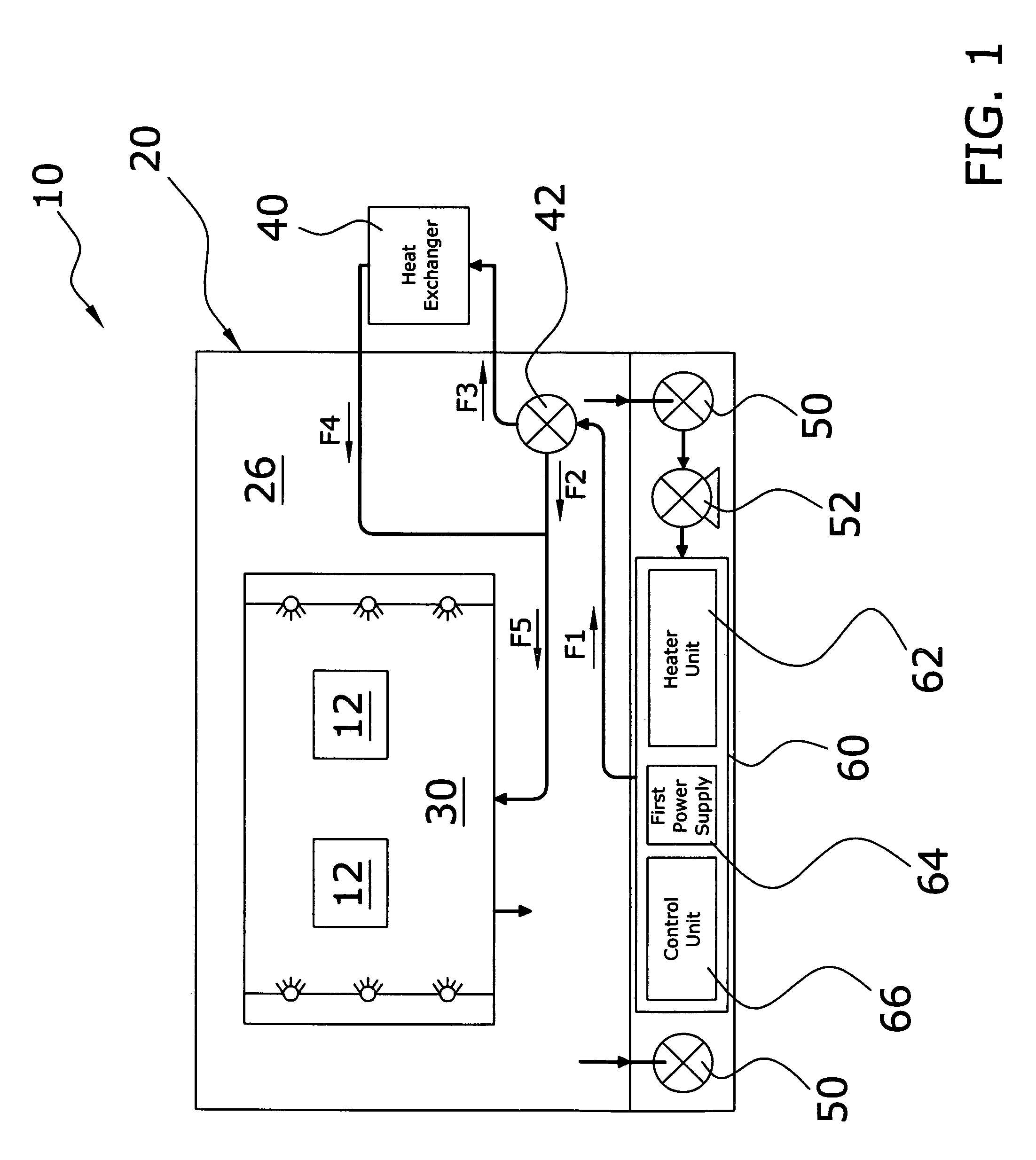

Insulated spray cooling system for extreme environments

ActiveUS7806166B1Improve electronic performanceLimitation for transferSemiconductor/solid-state device detailsSolid-state devicesSpray coolingExtreme environment

An insulated spray cooling system for extreme environments for providing a desired enclosed environment for electronic devices regardless of external environmental conditions. The insulated spray cooling system for extreme environments includes an insulated enclosure that isolates the electronic devices being thermally managed from the external environment and a thermal management unit within the enclosure for thermally managing electronic devices.

Owner:PARKER INTANGIBLES LLC

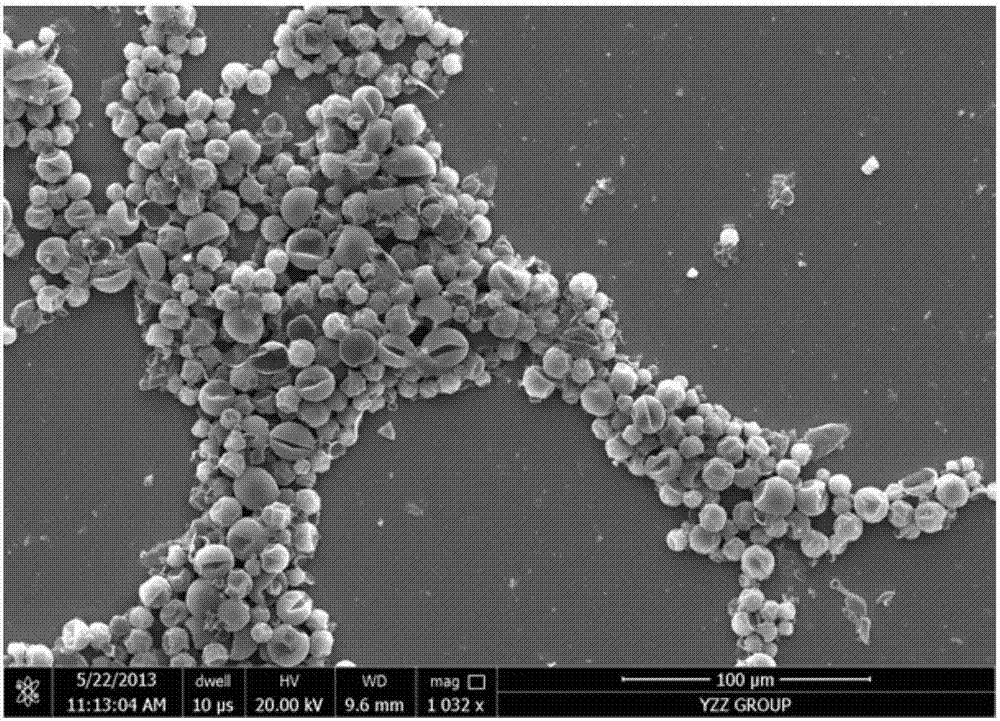

Silicon dioxide coated phase-change microcapsules and preparation method and application thereof

ActiveCN107513375AIncrease coverageReduce breakage rateHeat-exchange elementsMicroballoon preparationToxic materialSilicon dioxide

The invention discloses silicon dioxide coated phase-change microcapsules and a preparation method and an application thereof, wherein the phase-change microcapsules include a core material and a wall material; the core material includes a phase-change material, and the wall material is silicon dioxide; the enthalpy value retention rate of the silicon dioxide coated phase-change microcapsules is 20-99%; the average particle size of the microcapsules is 0.1-100 microns. Through a sol-gel reaction on an emulsion interface, the silicon dioxide coated phase-change material is obtained by one step; no toxic substances are generated in the preparation process, so the preparation process is green and environmentally friendly; the prepared phase-change energy-storage microcapsules are high in coating rate and low in damage rate, the supercooling degree of the phase-change material is effectively reduced, the obtained phase-change material has no volatile gases, the use is safe, and an application scope is expanded; the preparation method has the advantages of simple process, low cost, cheap and easily obtained used raw materials, and easily achieved industrialization. The phase-change energy-storage microcapsules can be widely applied to the fields of textile, building energy conservation, electronic part and component thermal management, waste heat recovery and the like.

Owner:中科世宇(北京)科技有限公司

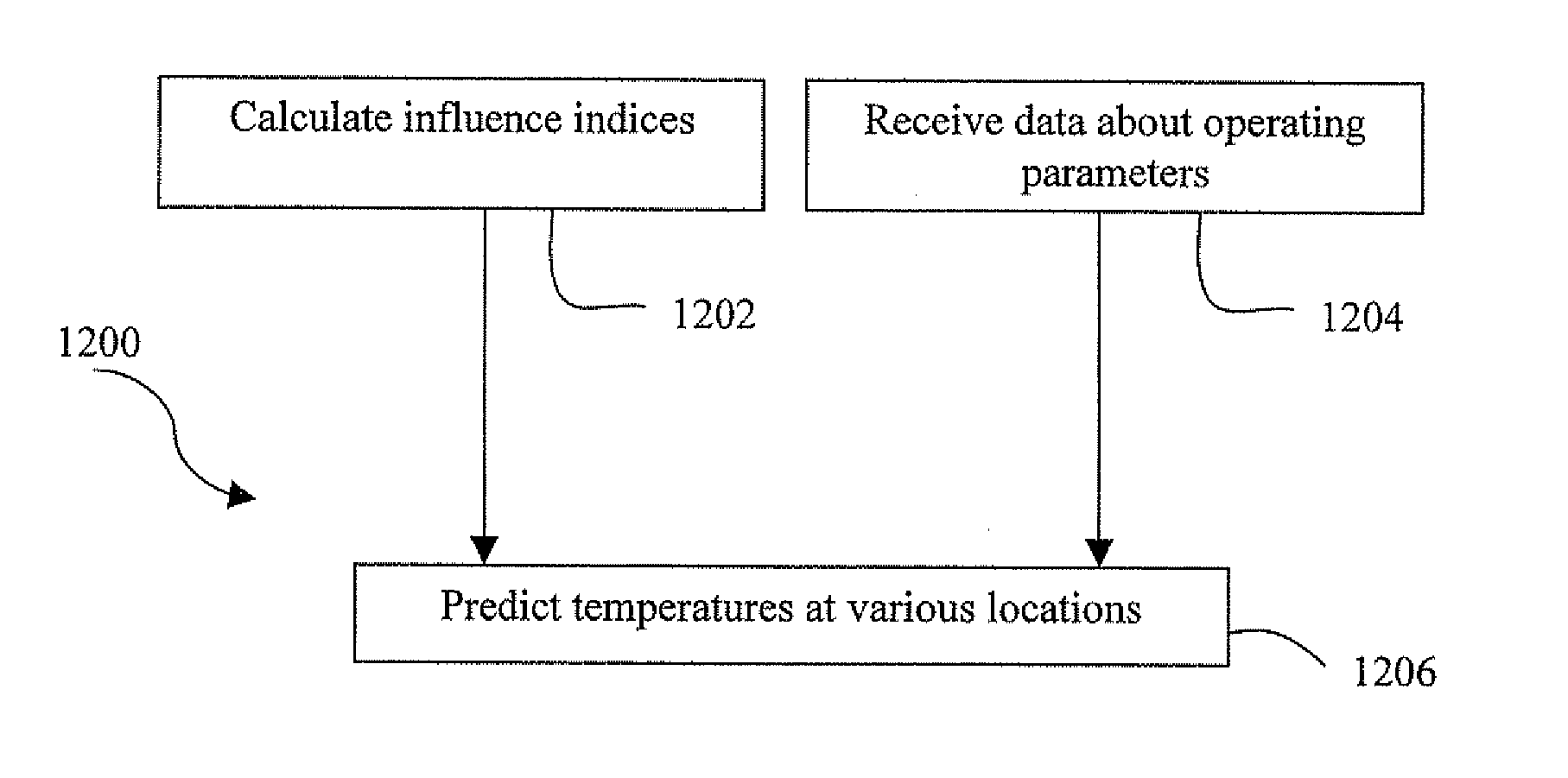

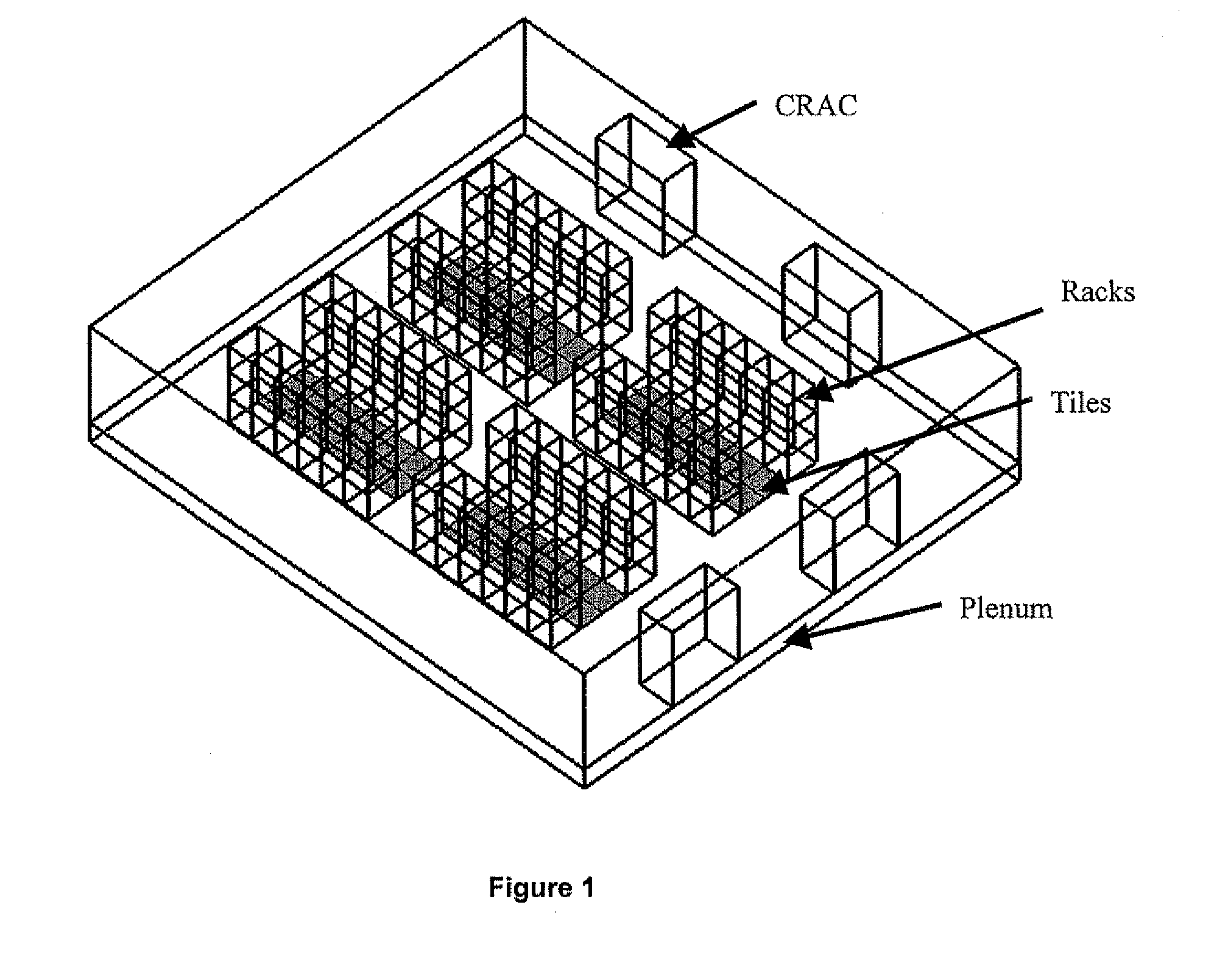

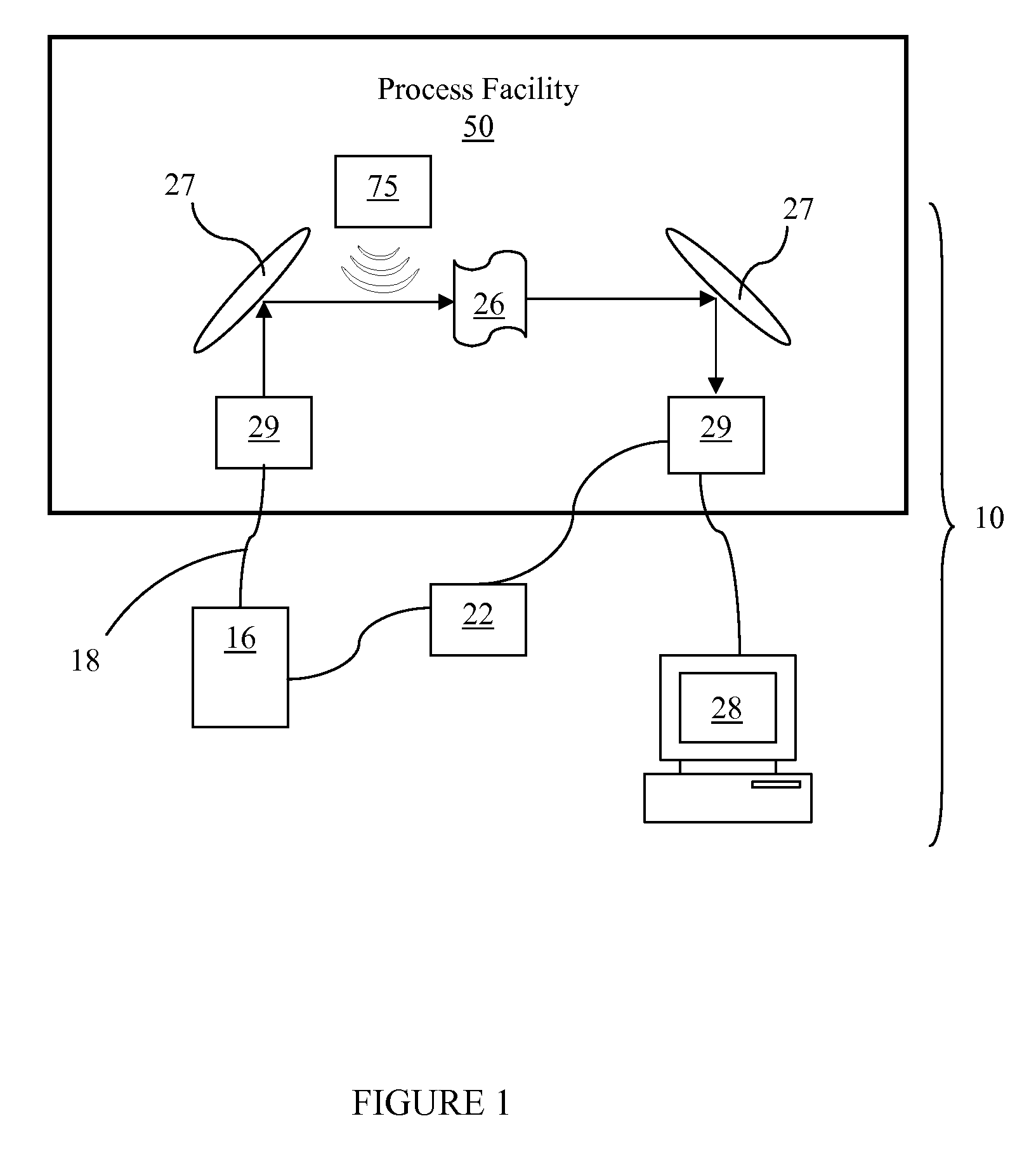

Method and system for thermal management by quantitative determination of cooling characteristics of data center

ActiveUS20120232877A1Efficient thermal managementIncrease heat loadEnergy efficient ICTError detection/correctionQuantitative determinationData center

The invention provides a method and system for quantitative determination of cooling characteristics of a data center by calculating thermal influence indices. The invention further provides a method and system for providing effective thermal management in a data center using quantitative determination of cooling characteristics of a data center.

Owner:TATA CONSULTANCY SERVICES LTD

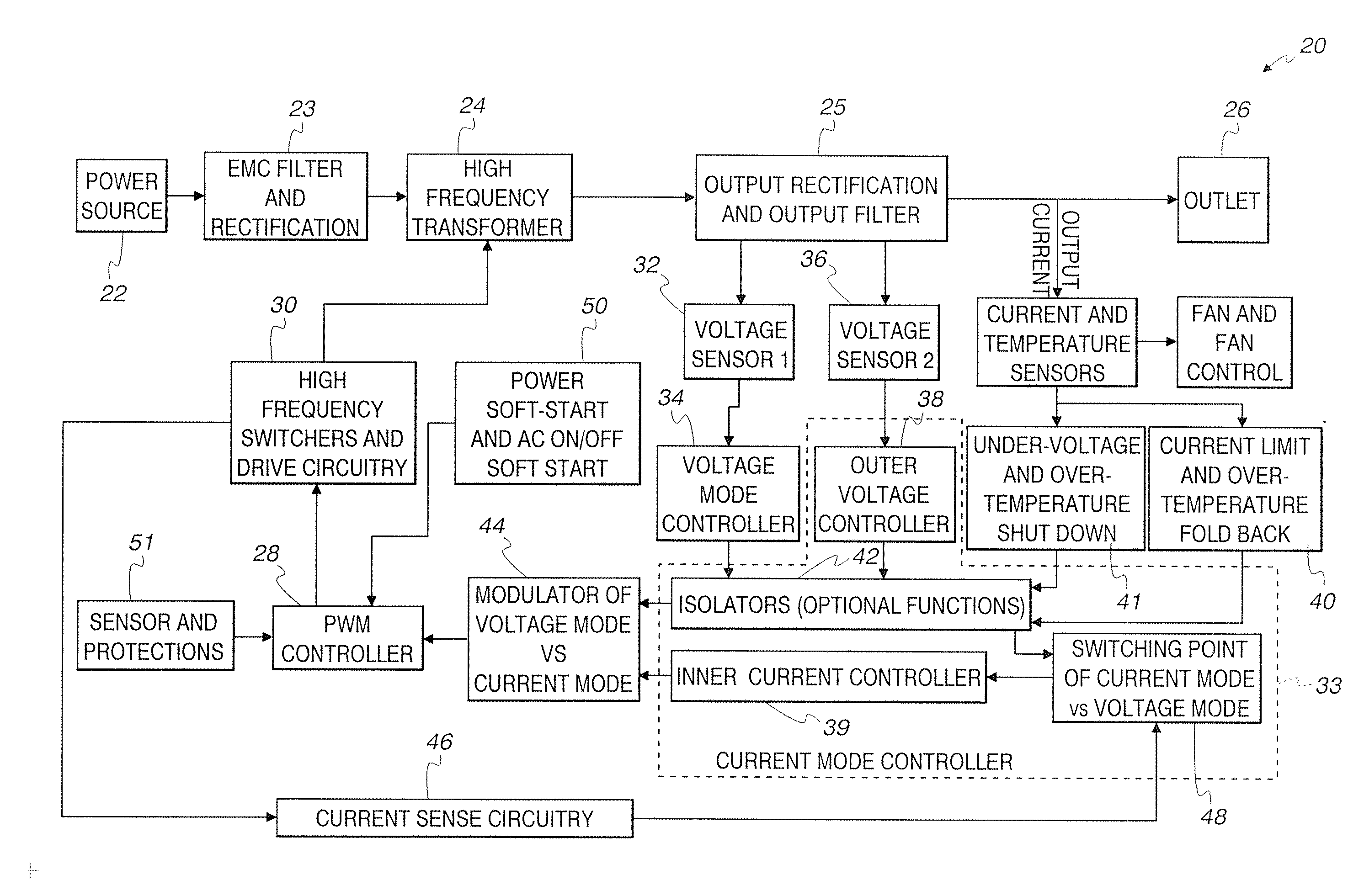

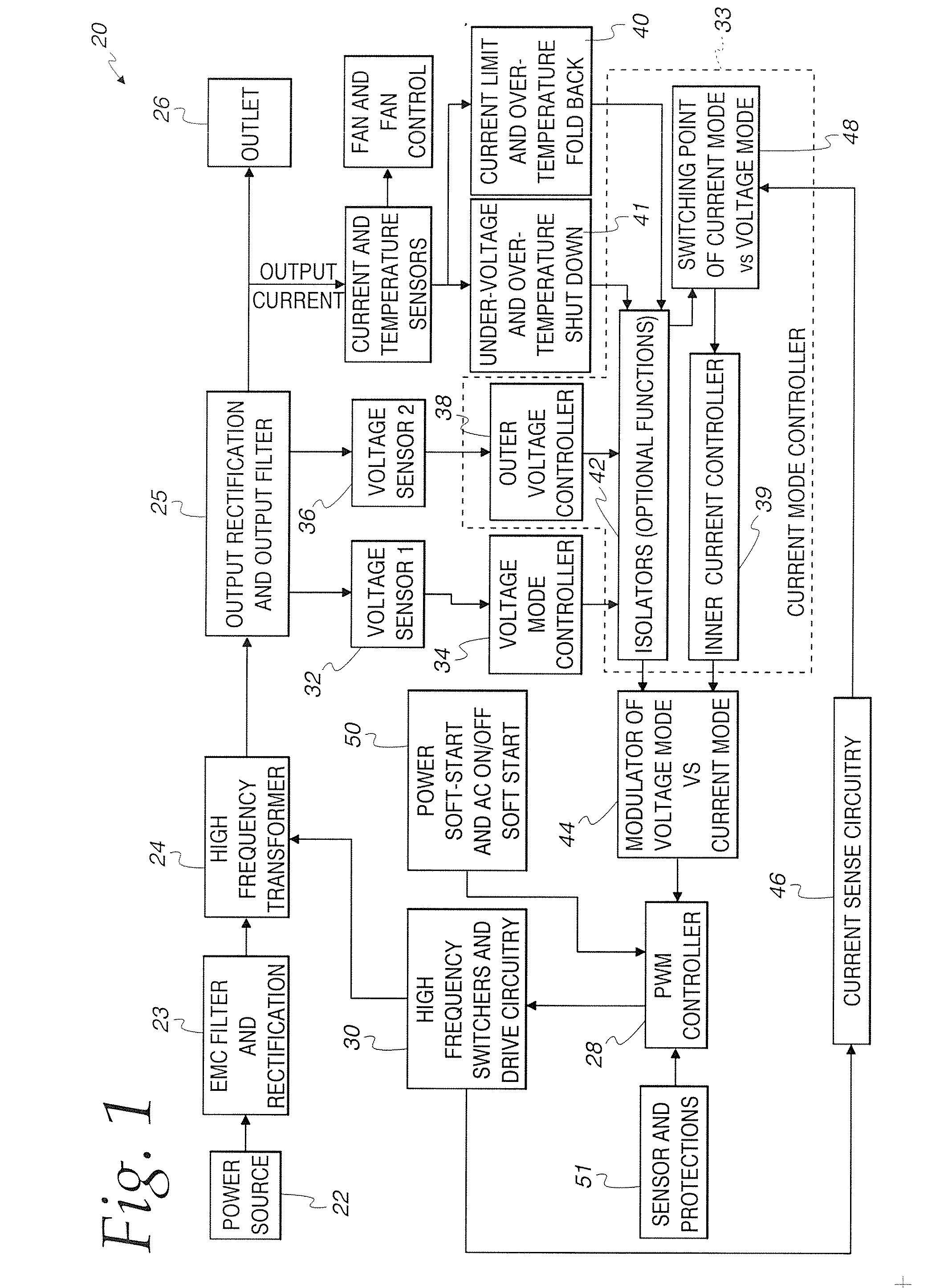

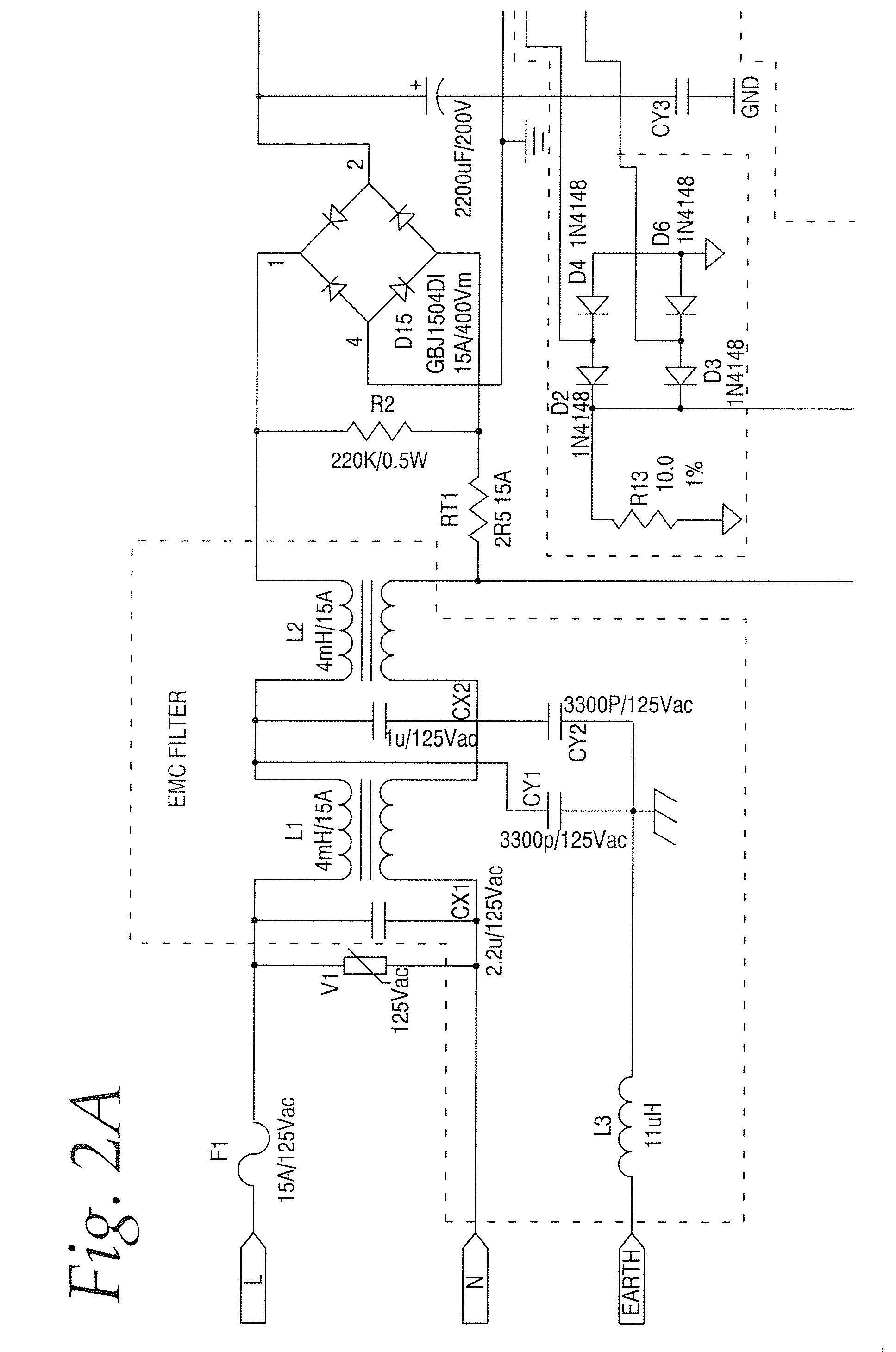

RV converter with current mode and voltage mode switching

ActiveUS20070176584A1Fast transient responseAvoid noiseEfficient power electronics conversionConversion with intermediate conversion to dcCurrent mode controlHemt circuits

A switched mode converter is disclosed that includes both voltage mode and current mode control. The switched mode converter also includes mode logic for switching between a voltage mode and a current mode. The converter includes current sensing circuitry for sensing the switcher current on the primary side of the transformer and the load current on the secondary side as well as voltage sensing circuitry for sensing the converter output voltage. When the load current is less than a predetermined value, the converter operates in a voltage mode. During the voltage mode, the output voltage of the voltage mode controller is used to control the duty cycle of a pulse width modulation (PWM) controller. When the load current is greater than a predetermined value, the converter operates in a current mode. In a current mode, the primary switcher current is used to control the PWM controller. As such, during a light load in which the converter is voltage controlled, there is no need for a minimum load to stabilize the control loop. In a current-mode, the control loop will have a relatively faster transient response and avoid flux imbalance in push-pull topology. As such, the converter provides the advantages of both known voltage controlled and current controlled switched mode converters. In addition, by the careful arrangement of the locations of a EMC filter, a primary heat sink, a secondary heat sink, a power transformer T1 and other power devices as well as a cooling fan, a smaller EMC filter can be used due to the primary heat sink performing a dual function of thermal management and additionally providing EMC shielding to prevent the noise, for example, the noise generated by the transformer, from reaching the filter. In addition, the primary heat sink is configured to face the air flow while the secondary heat sink is placed close to the fan with its fin direction the same as the direction of the air flow. As such, both the primary and the secondary heat sink get maximum air flow, allowing smaller heat sinks to be used in order to provide a reliable and cost-effective switched mode converter.

Owner:SCHUMACHER ELECTRIC CORP

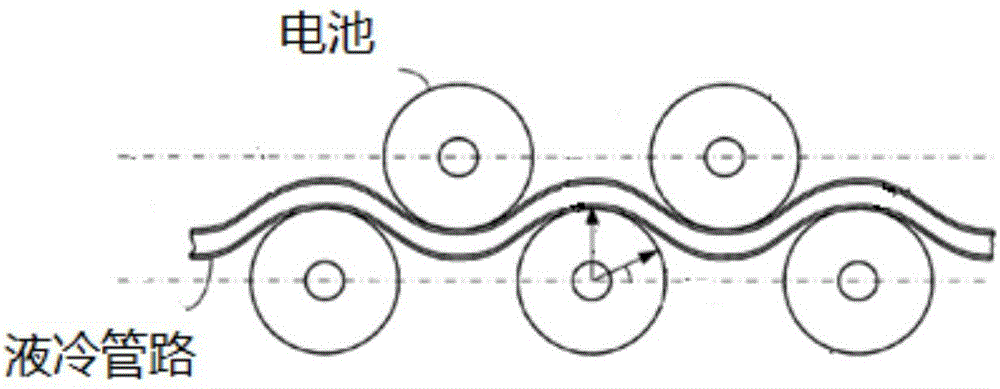

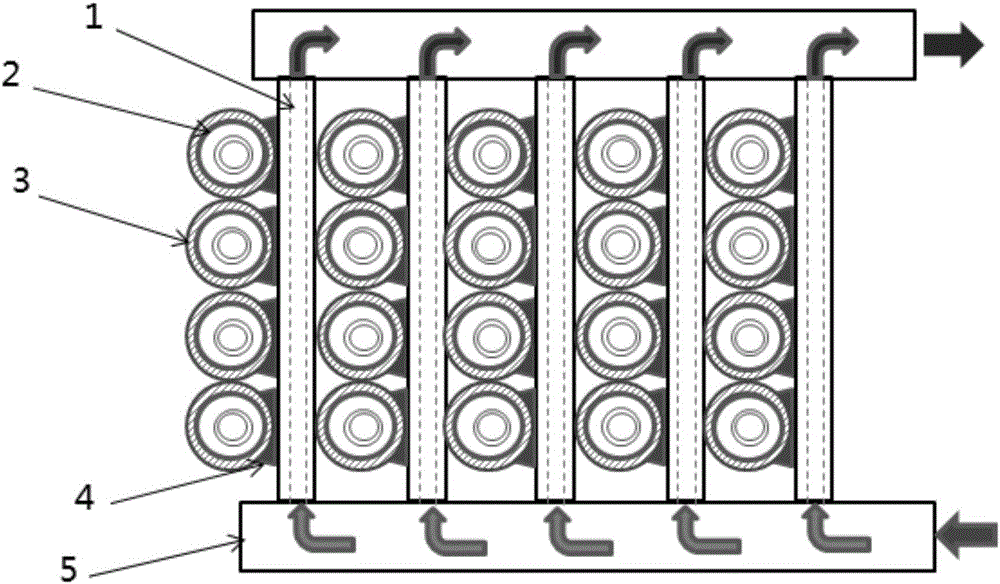

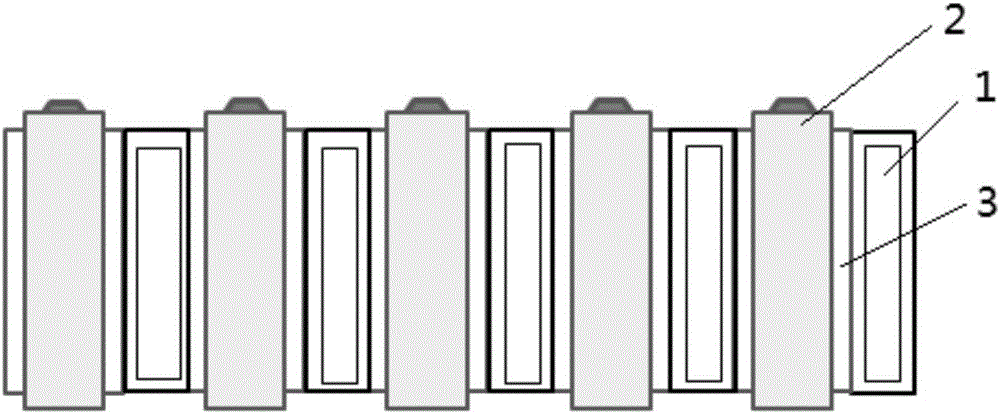

Thermal management method and device for battery pack

InactiveCN105742753AImprove thermal conductivityReduce the maximum temperatureSecondary cellsPower batteryElectrical battery

The invention relates to a thermal management technology for power batteries, and belongs to the field of power batteries. A thermal management method for a battery pack is characterized in that a heat-conducting sleeve coating one battery is arranged outside one battery cell of the battery pack; each heat-conducting sleeve is connected with a heat-conducting pipe with a heat transfer function; and heat exchange is achieved for the batteries of the battery pack through heat transmission of the heat-conducting pipe. A device for thermal management employing the thermal management method for the battery pack is characterized by comprising the heat-conducting pipes and the heat-conducting sleeves, wherein each heat-conducting sleeve is fixedly connected with the corresponding heat-conducting pipe; each heat-conducting sleeve coats the outside of each battery cell of the battery pack; the internal sizes of the heat-conducting sleeves are matched with the external sizes of the batteries; the outer side of each heat-conducting sleeve is fixedly connected to the corresponding heat-conducting pipe; the heat-conducting pipes transmit the heat generated by the batteries through heat transmission; and heat exchange is achieved for the batteries of the battery pack. According to the thermal management method and device, the temperature adjusting effect is improved; the mechanical properties of the batteries and the thermal management device are strengthened; and the device is portable and easy to assemble.

Owner:SHANGHAI UNIV OF ENG SCI

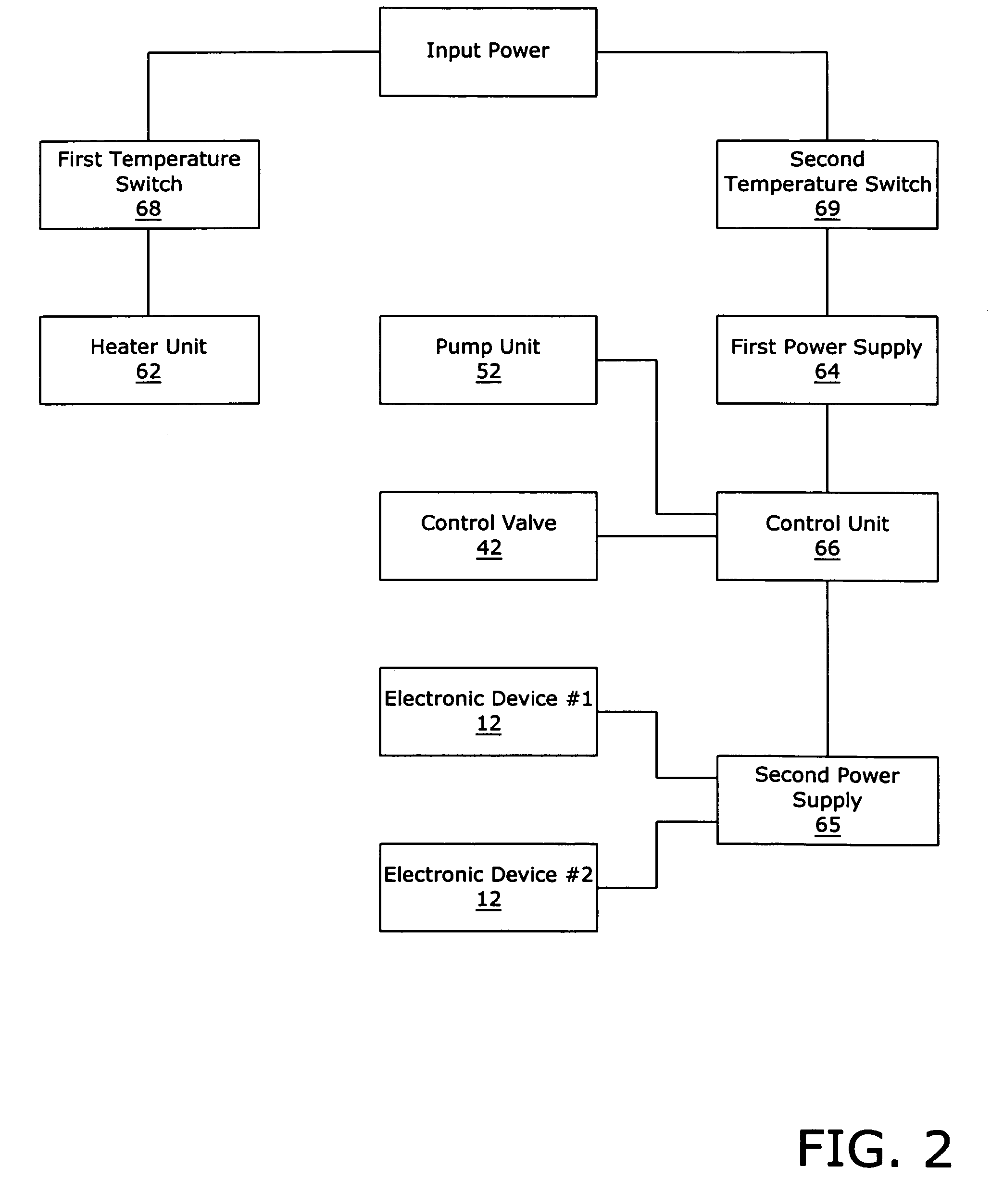

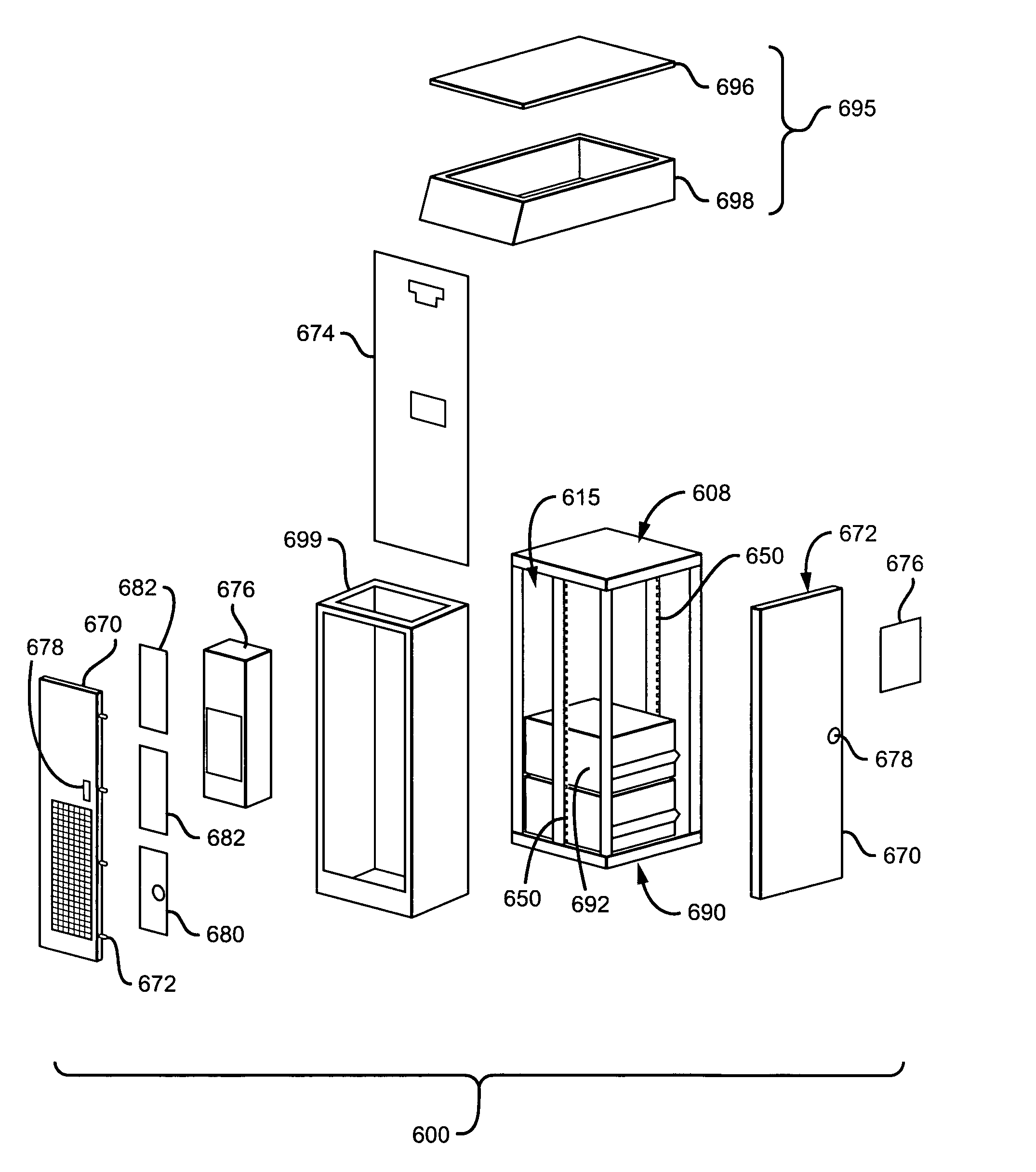

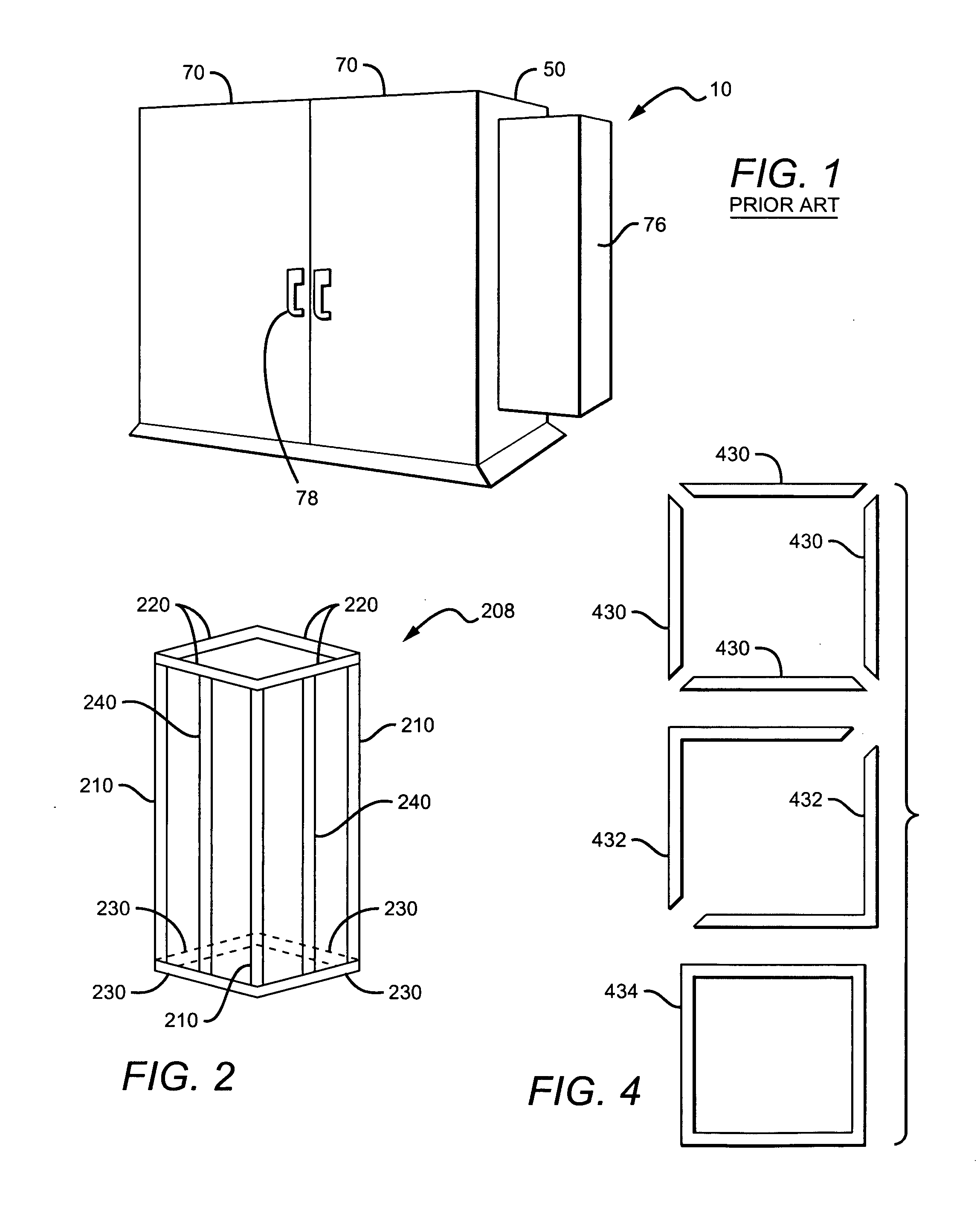

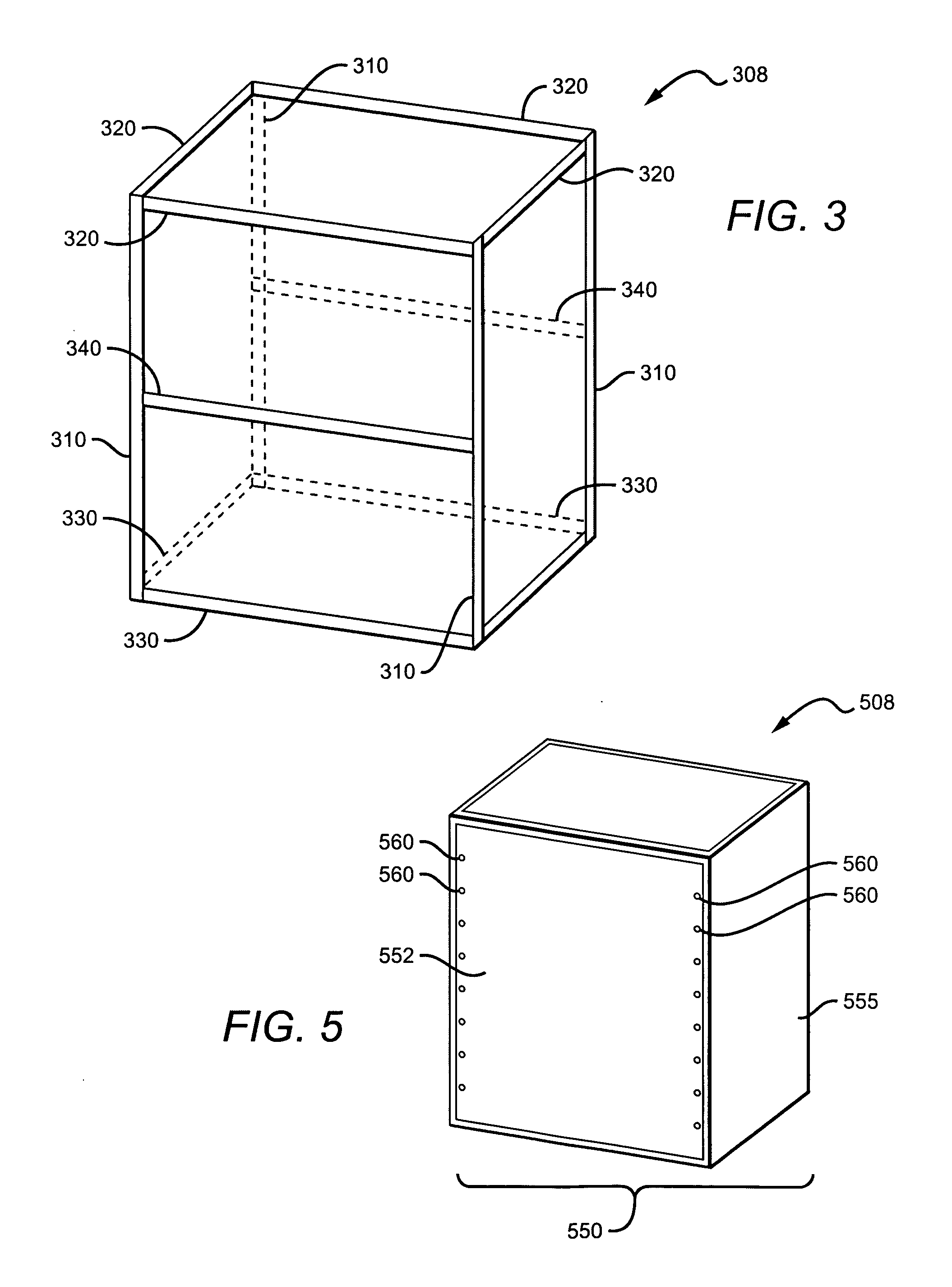

Remote enclosure systems and methods of production thereof

InactiveUS20050128722A1Easily configurableImprove scalabilityCasings/cabinets/drawers detailsCurrent supply arrangementsModularityRadio frequency

Remote enclosure systems have now been designed and are described herein that meet the following goals: a) consolidate electrical terminations in one system; b) pre-terminate AC and DC equipment loads before site installation; c) provide multiple access points for facilitating equipment repair and installation; d) are easily configurable and expanded through the use of a modular frame design that accommodates a variety of customized side panels or the attachment of a variety of expansion cabinets; e) are aesthetically functional given the cable entry and routing structure; f) provide exceptional thermal management and g) reduce problems inherent in conventional electronic setups. Remote enclosure systems contemplated generally include: a) a frame system further comprising at least two side panels; b) at least one door coupled to the frame system; c) a cable management top assembly coupled to the frame system; d) at least one removable radio frequency (RF) management system, such as at least one RF port plate, at least one RF port, at least one RF cable or any other suitable system for managing RF signals and a combination thereof, coupled to at least one of the side panels, coupled to and / or located within the cable management top assembly and / or coupled to and / or located within the frame system or a combination thereof and e) a bottom panel coupled to the frame system. The remote enclosure system may also comprise any number of components suitable for electronics, wireless and cable-based data and telecommunications applications, including air conditioner exhaust member, an air conditioner unit, a battery pack, a meter base, a power receptacle box, an alarm system or alarm device, an expansion cabinet, a coupling device or system, a pre-wiring system and / or a demarcation component.

Owner:PURCELL SYST

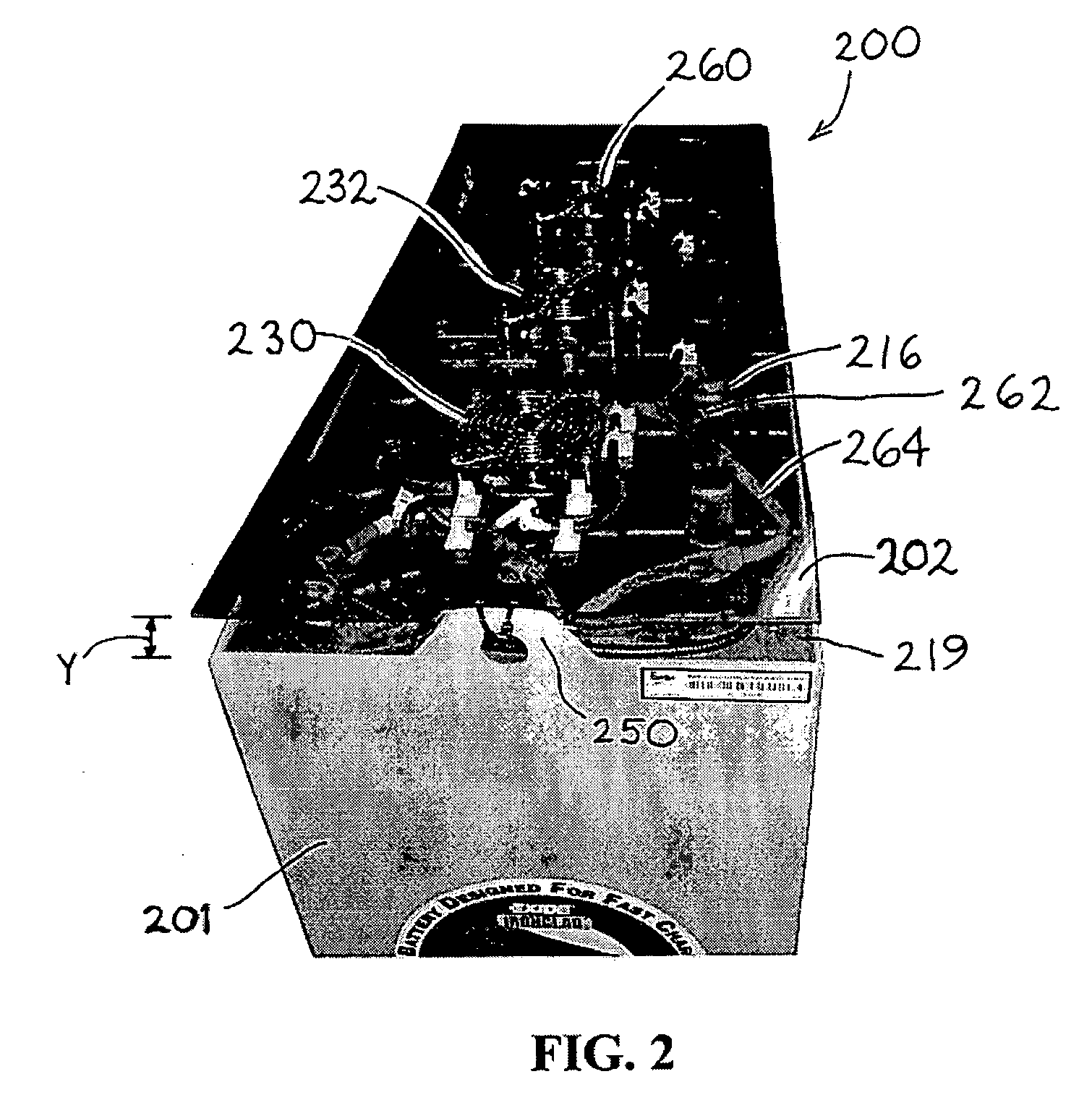

High capacity battery with integrally-powered cooling assembly

InactiveUS20060188776A1Effective maintenanceCell temperature controlSecondary cells charging/dischargingOn boardPower apparatus

A high capacity battery including terminals on a terminal-bearing face thereof, and a plate member coupled in spaced-apart relationship to the terminal-bearing face to define a coolant gas flow space therebetween including a peripheral gap for coolant gas communication with an exterior environment of the battery. One or more motive coolant gas drivers is mounted on the plate member and arranged for effecting flow of coolant gas through the coolant gas flow space and the peripheral gap, and the motive coolant gas drivers are electrically coupled with the terminal-bearing face for powering of such drivers. Such high capacity battery can be substituted for a conventional battery in a battery-powered apparatus such as a forklift vehicle, to provide extended use operation as a result of the on-board thermal management capability of the battery.

Owner:AKER WADE POWER TECH

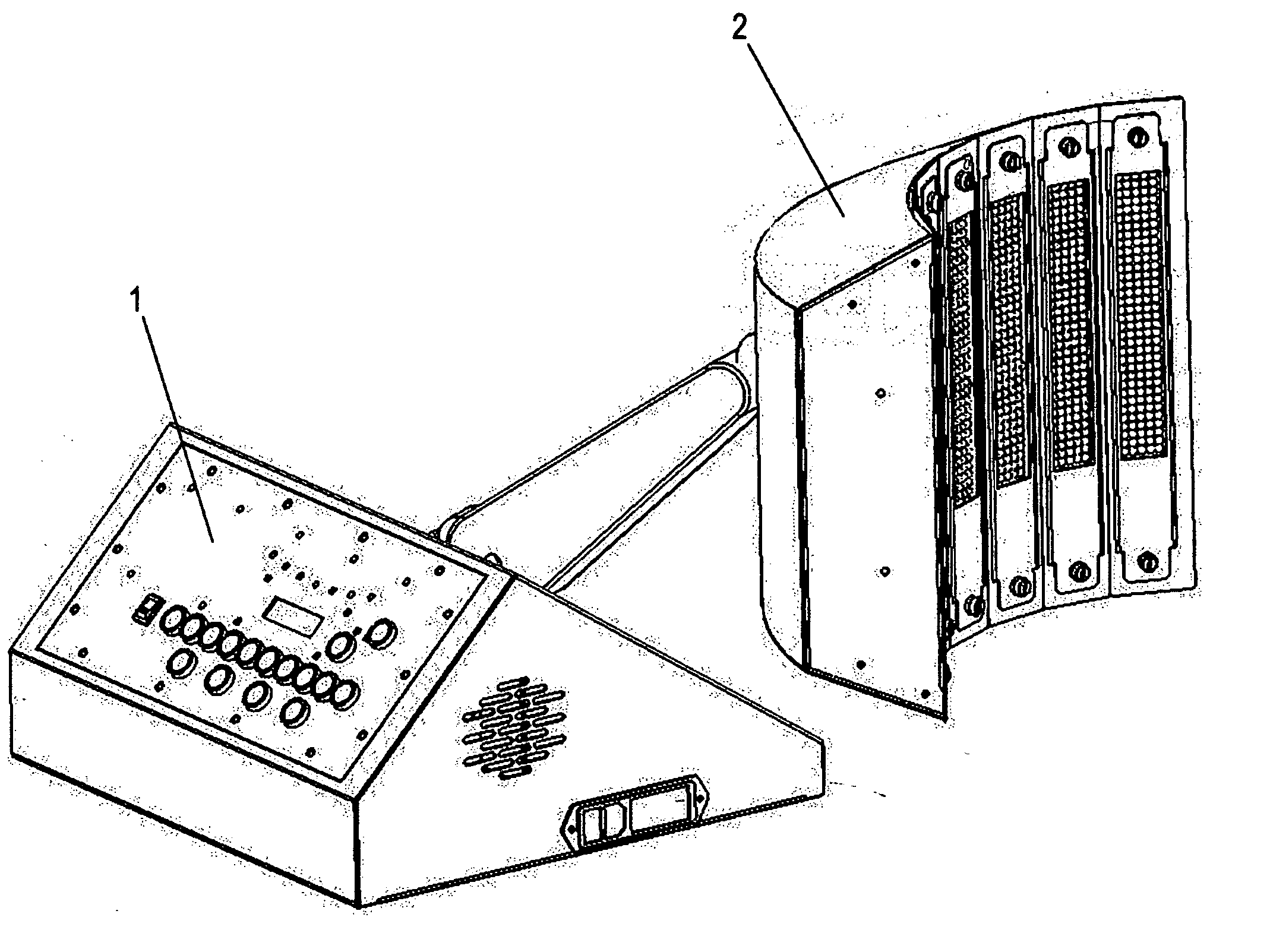

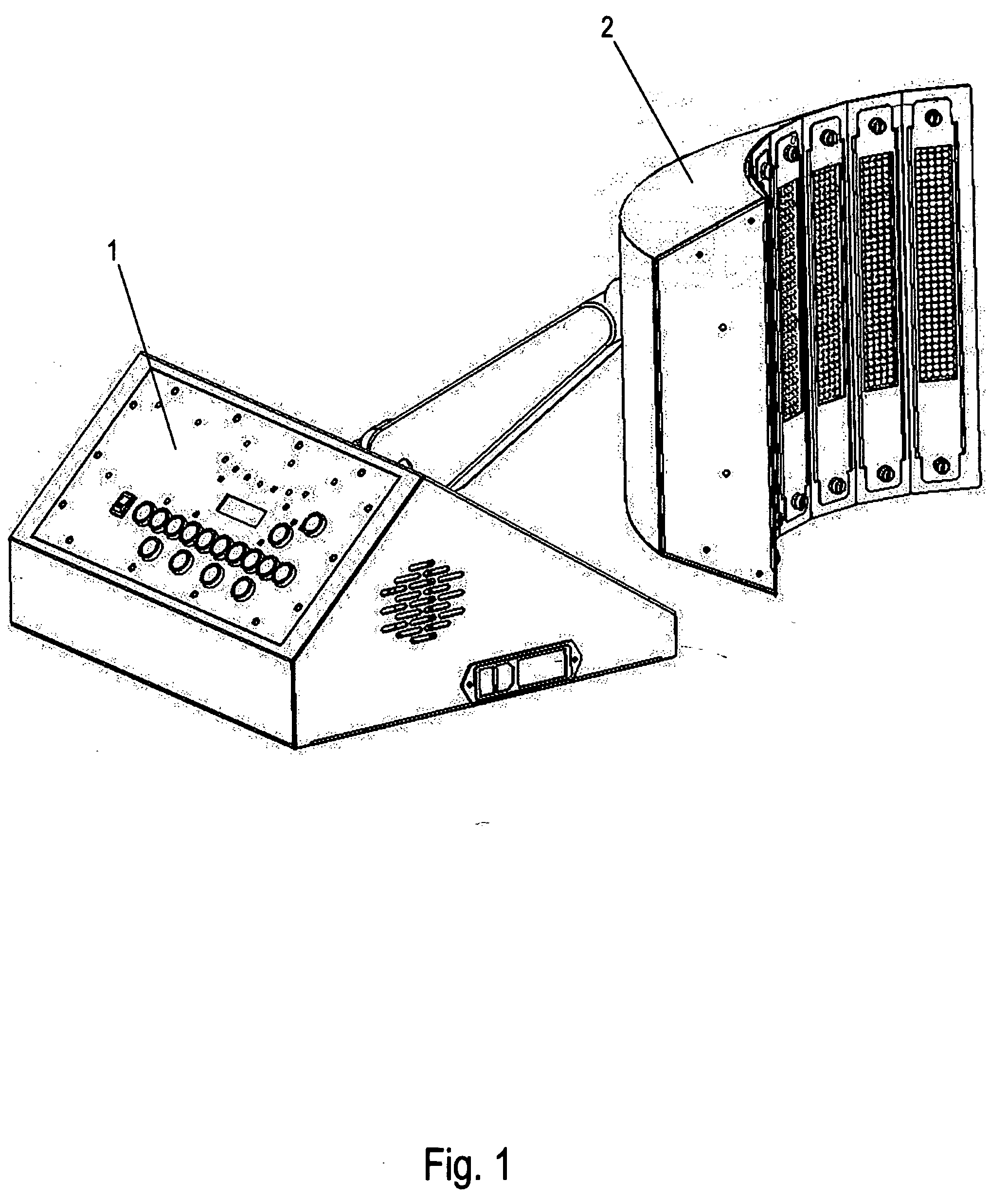

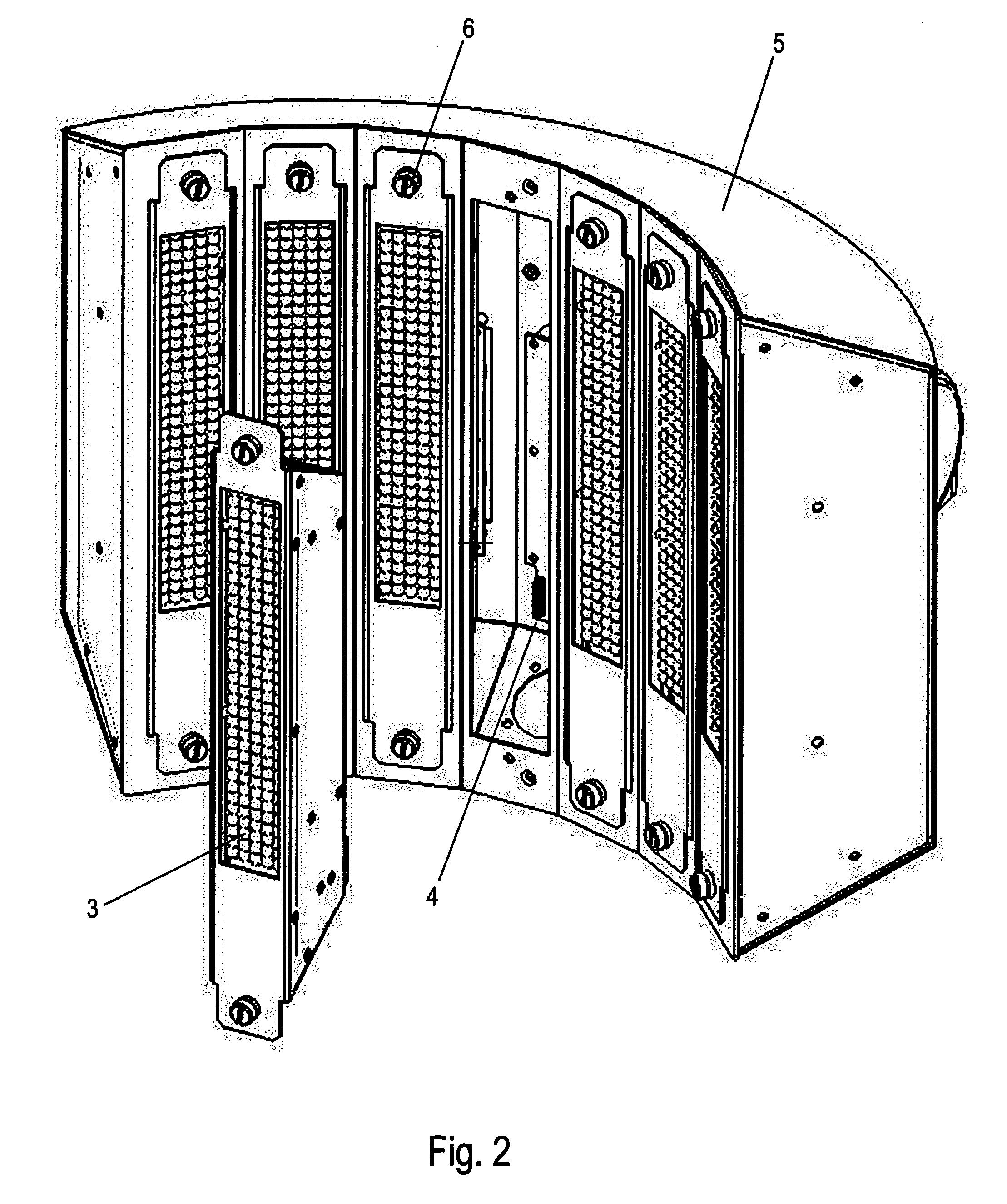

Light therapy device heat management

InactiveUS20060020308A1Increase light intensityShorten treatment timeLight therapyDiseaseEngineering

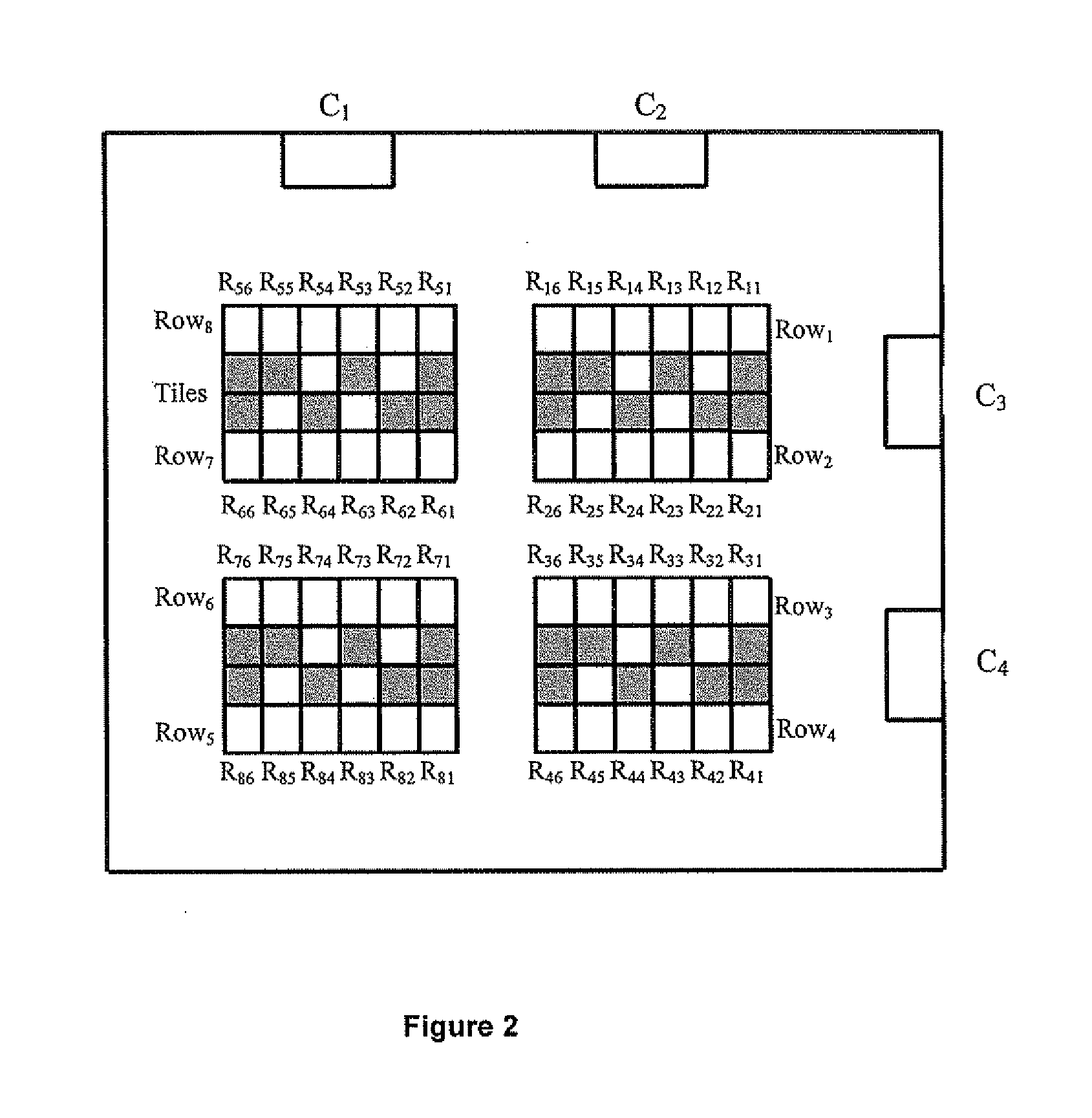

This device incorporates an array of light emitting diodes (LED) of several specific wavelengths that are used to provide therapy to visible and invisible living tissue or skin disorders that react to various wavelengths of light. Furthermore the device uses a combination of high level of perforation metal core circuit boards, heat transfer pads, heat sinks and forced air cooling and electronic thermal management to achieve continuous high intensity light output to therapy areas along with long LED life. The invention is using replaceable LED modules enabling device maintenance by user operators not trained as maintenance technicians.

Owner:MULDNER JAMES SCOTT

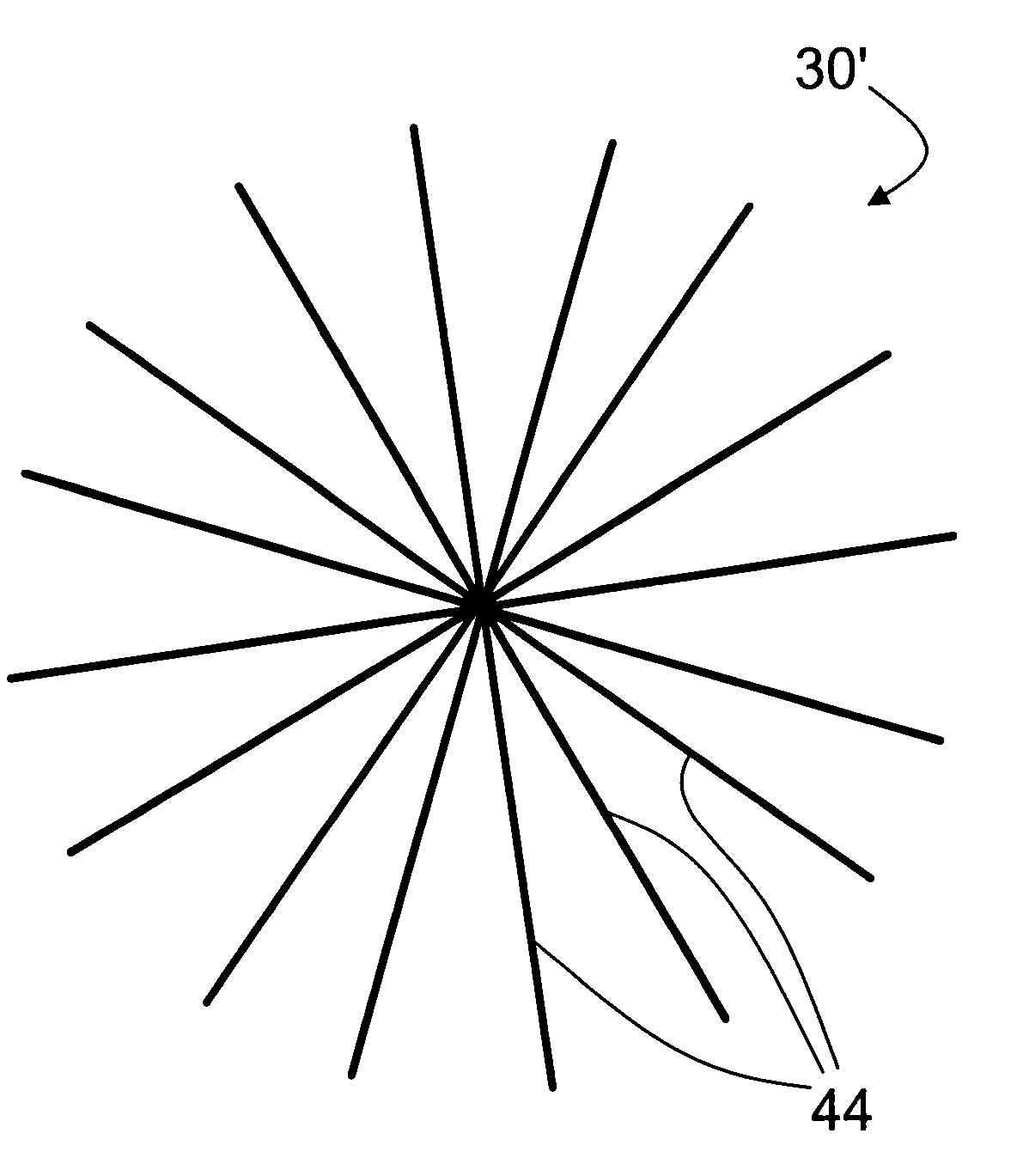

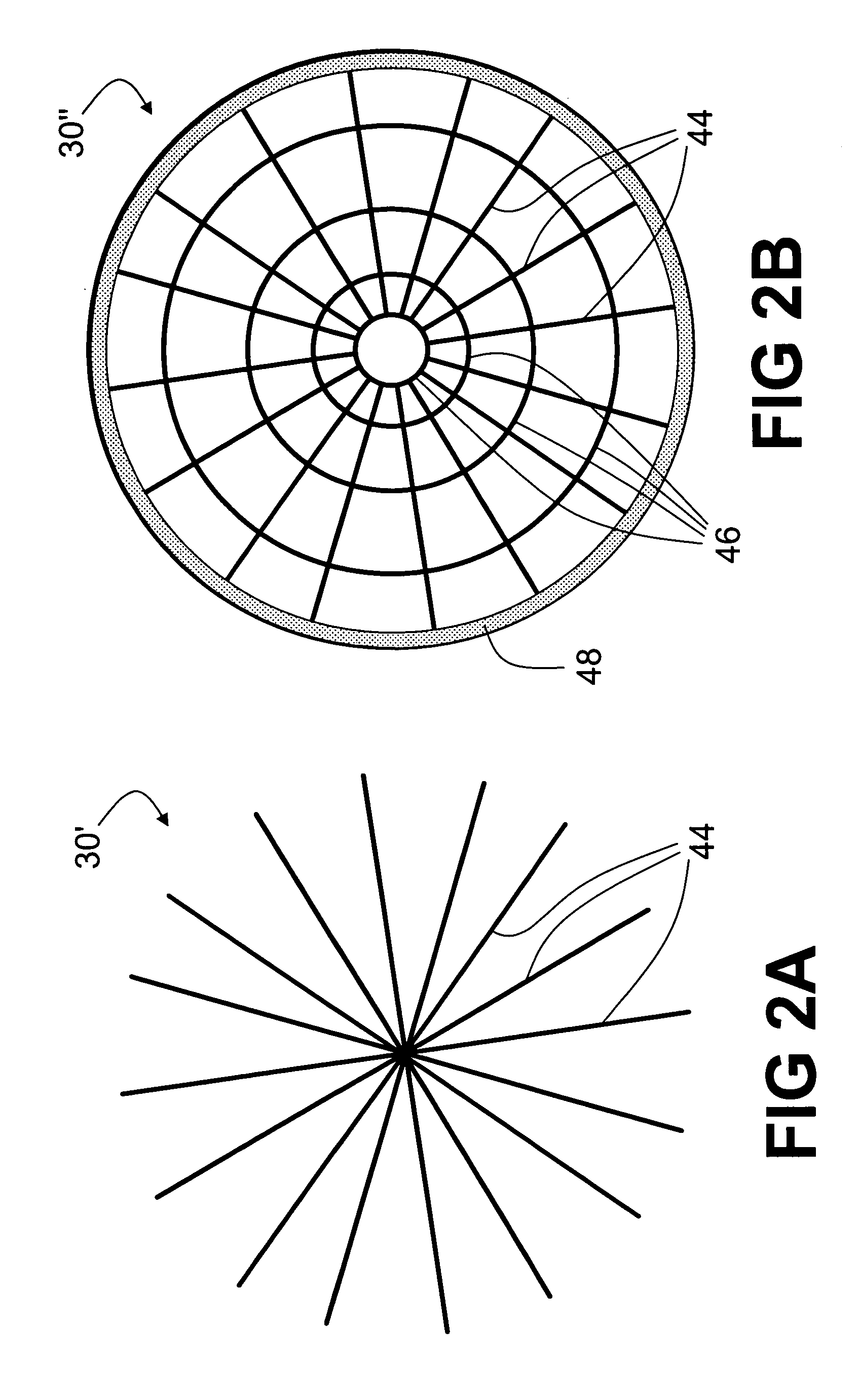

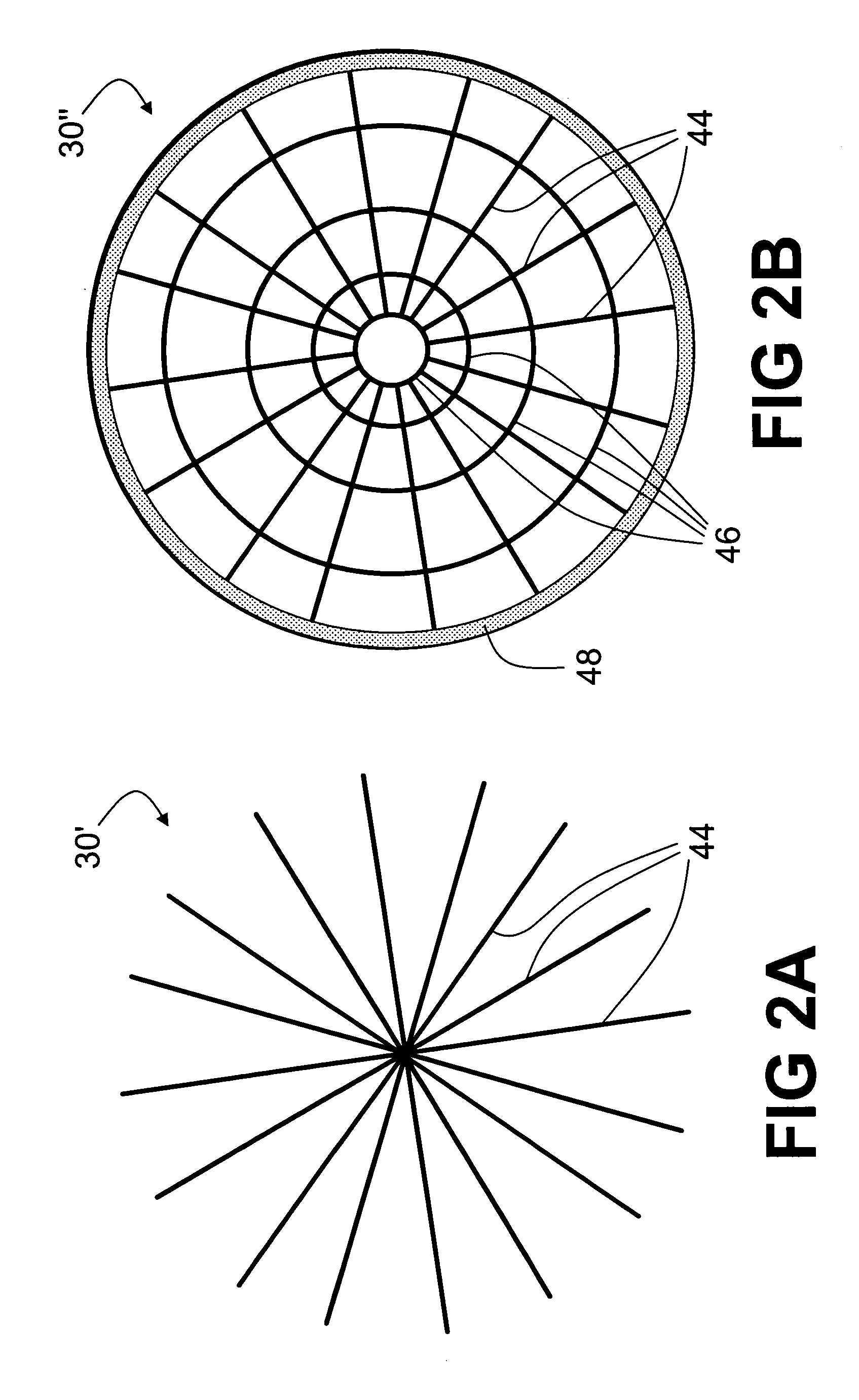

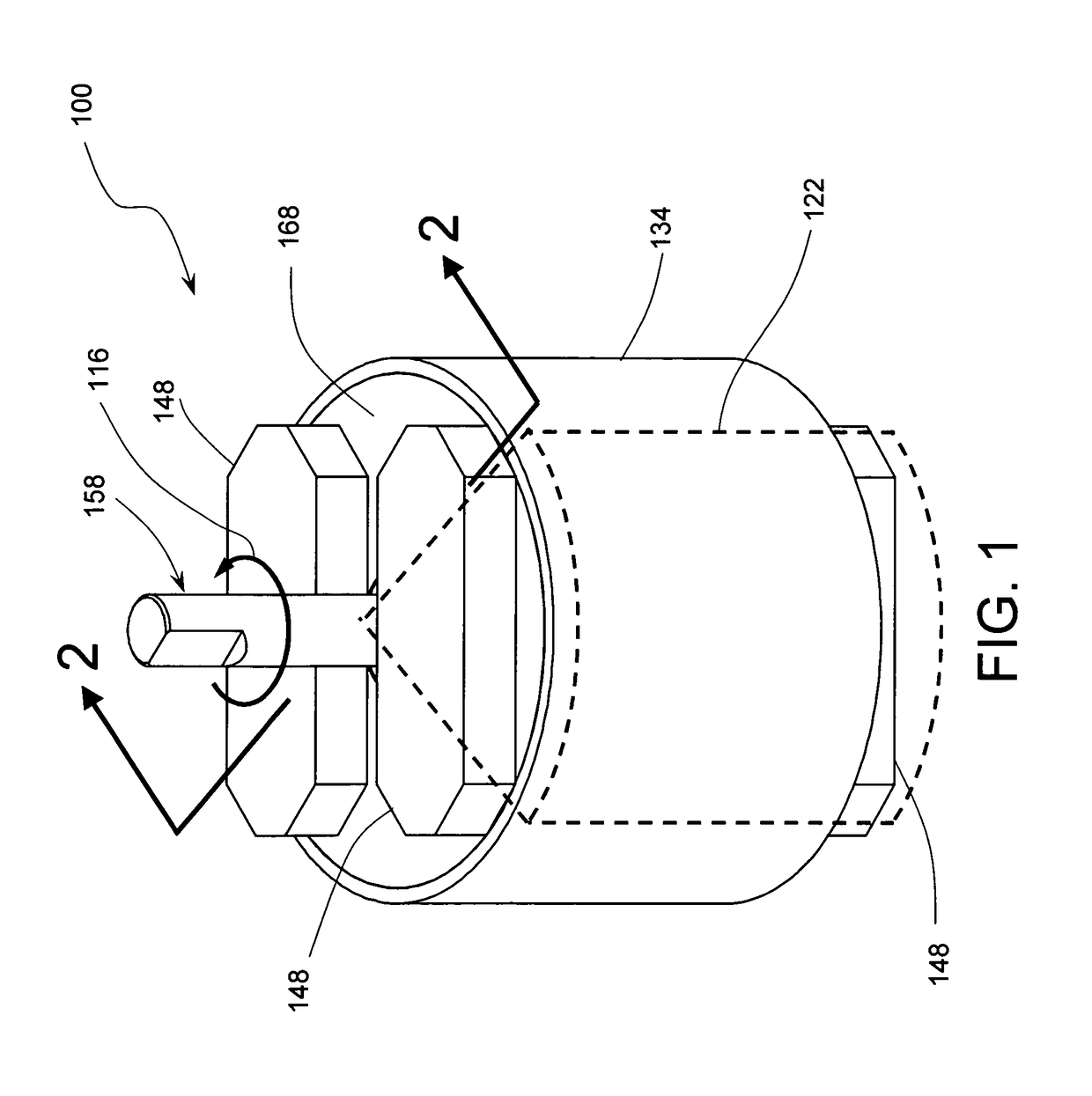

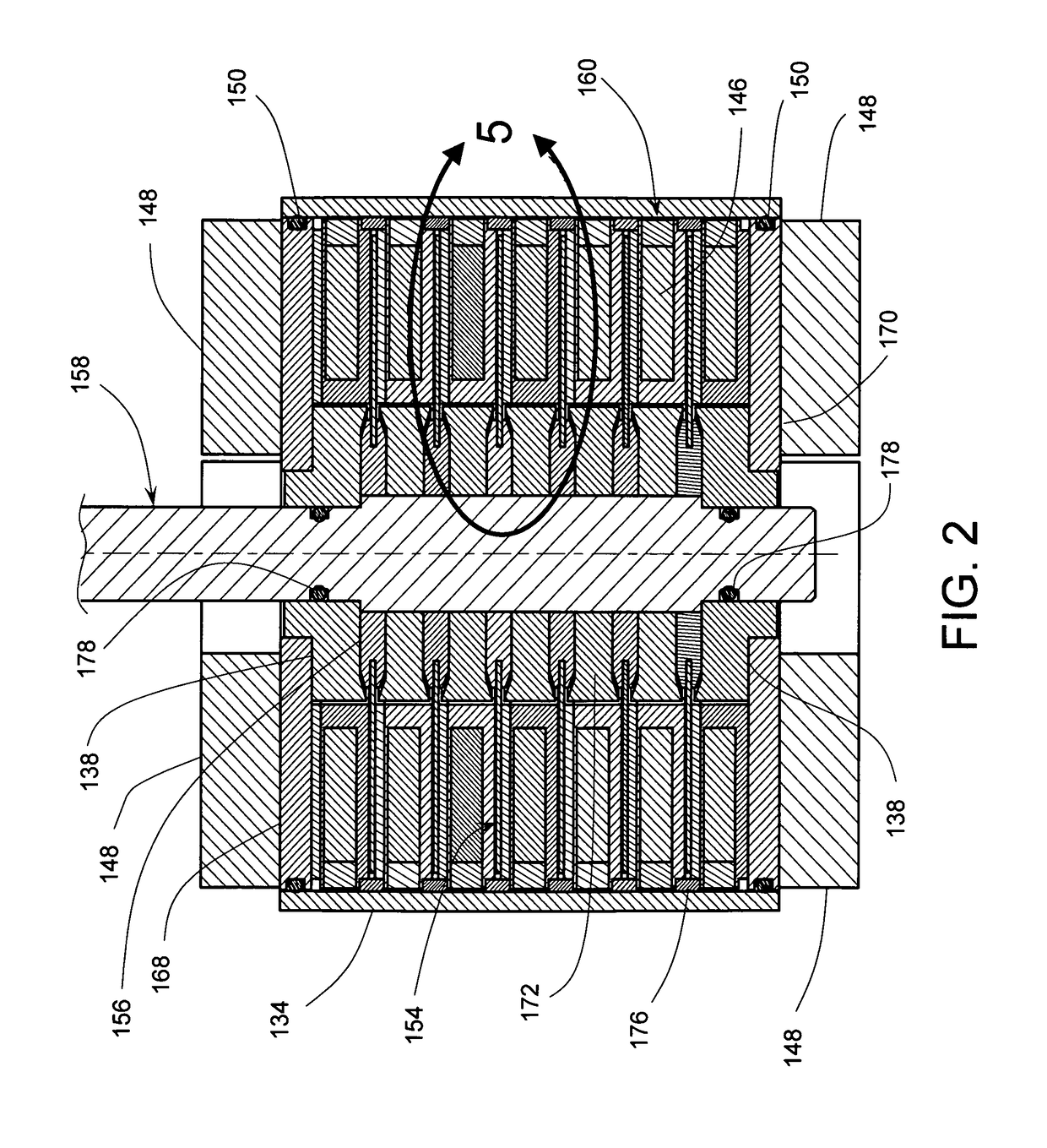

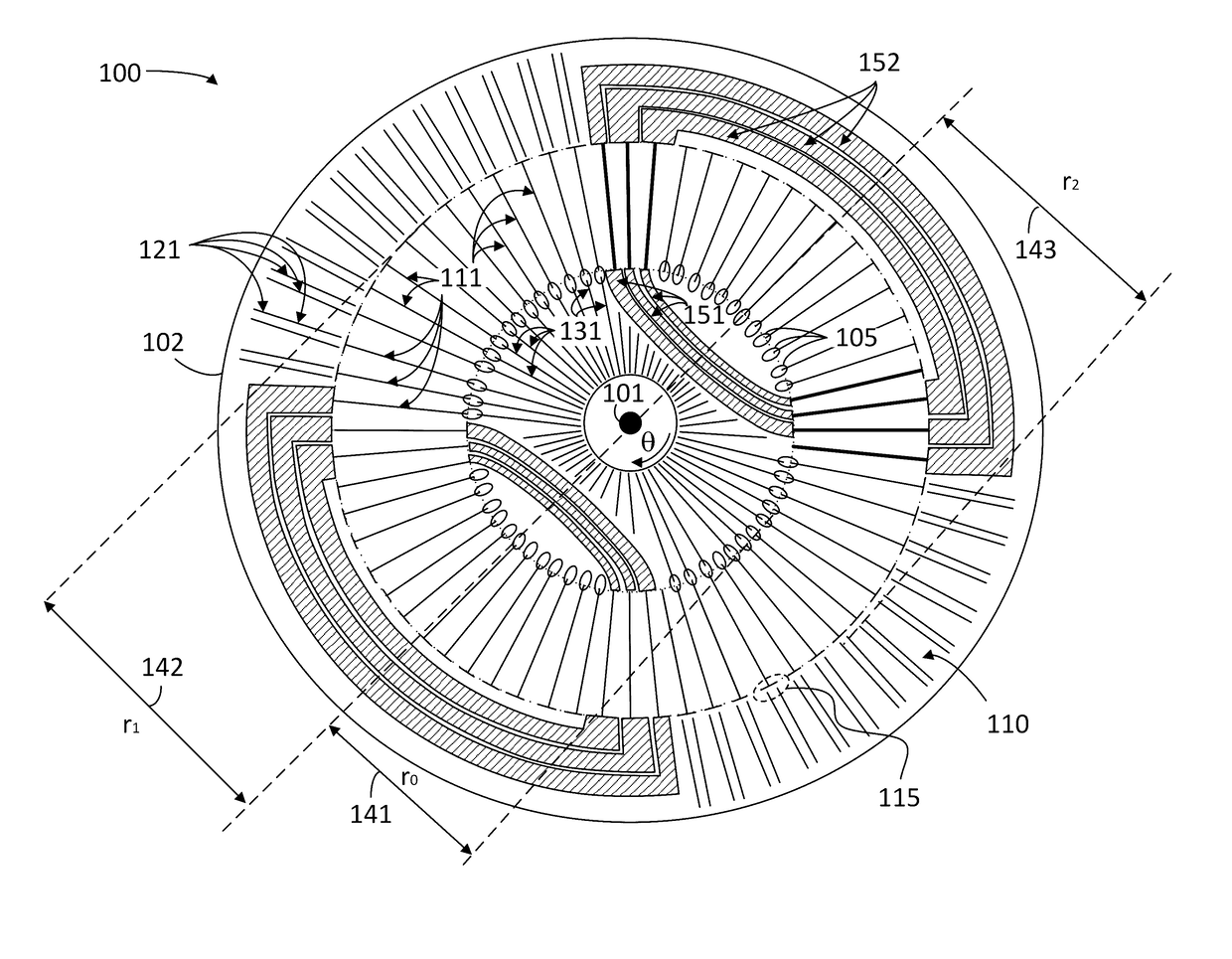

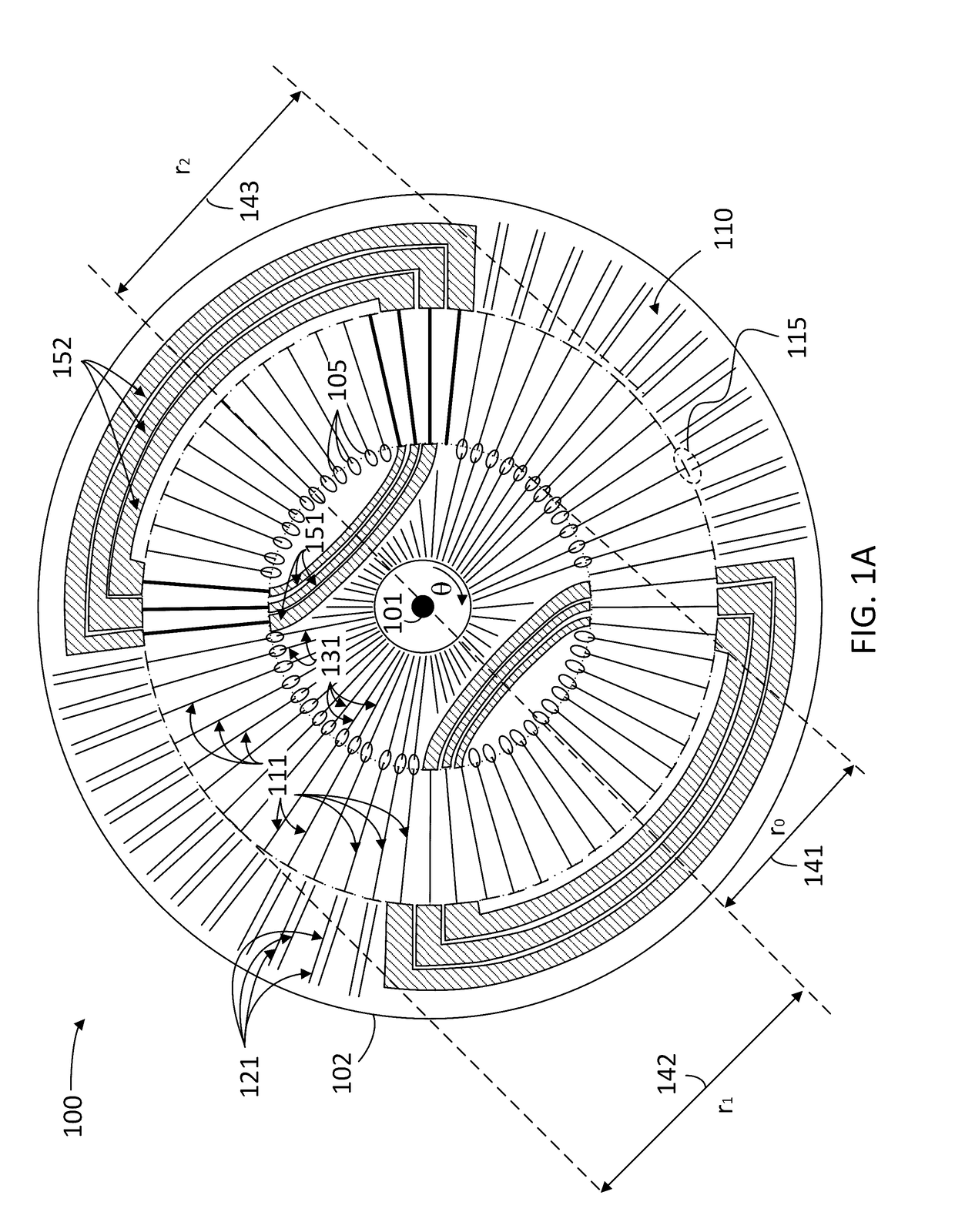

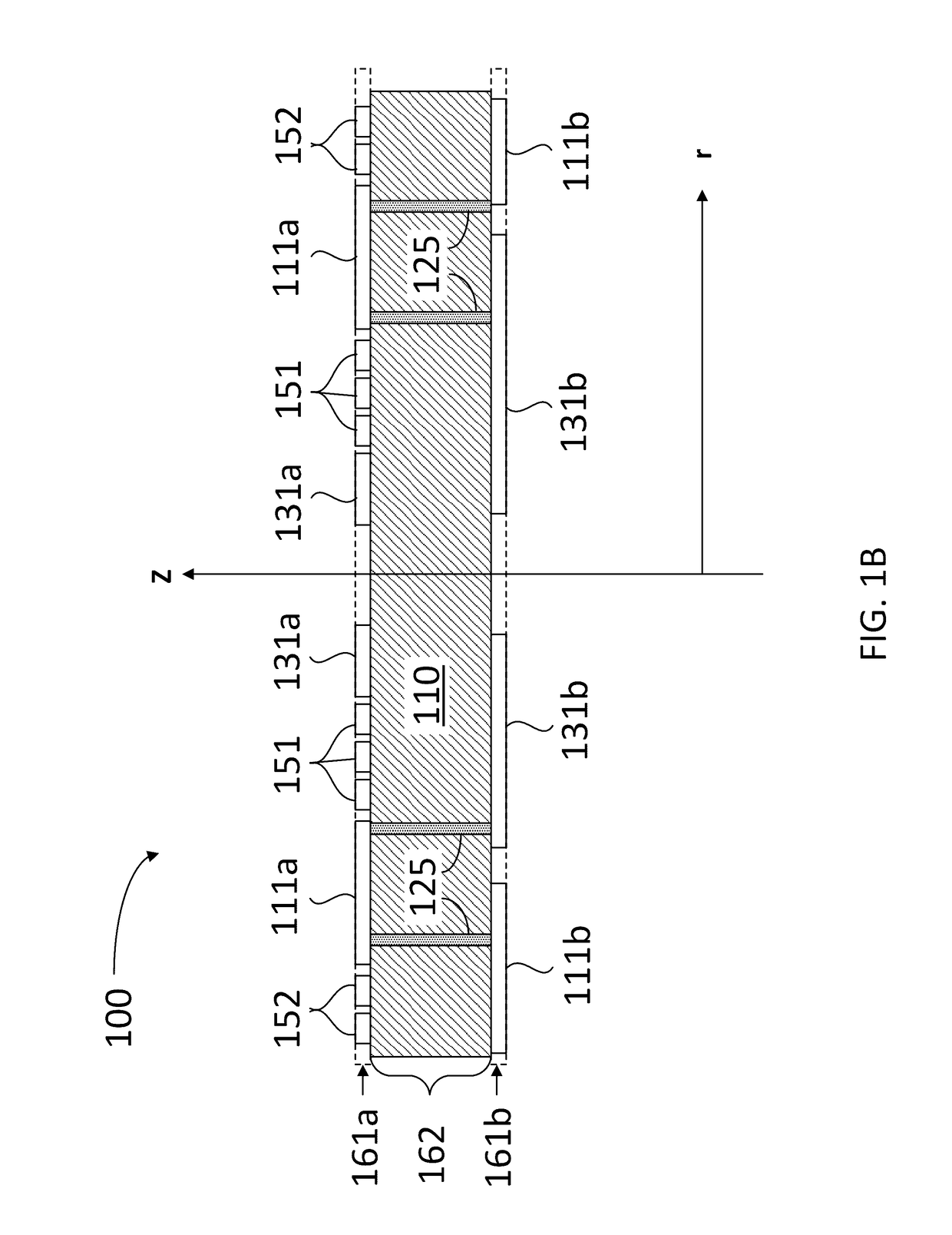

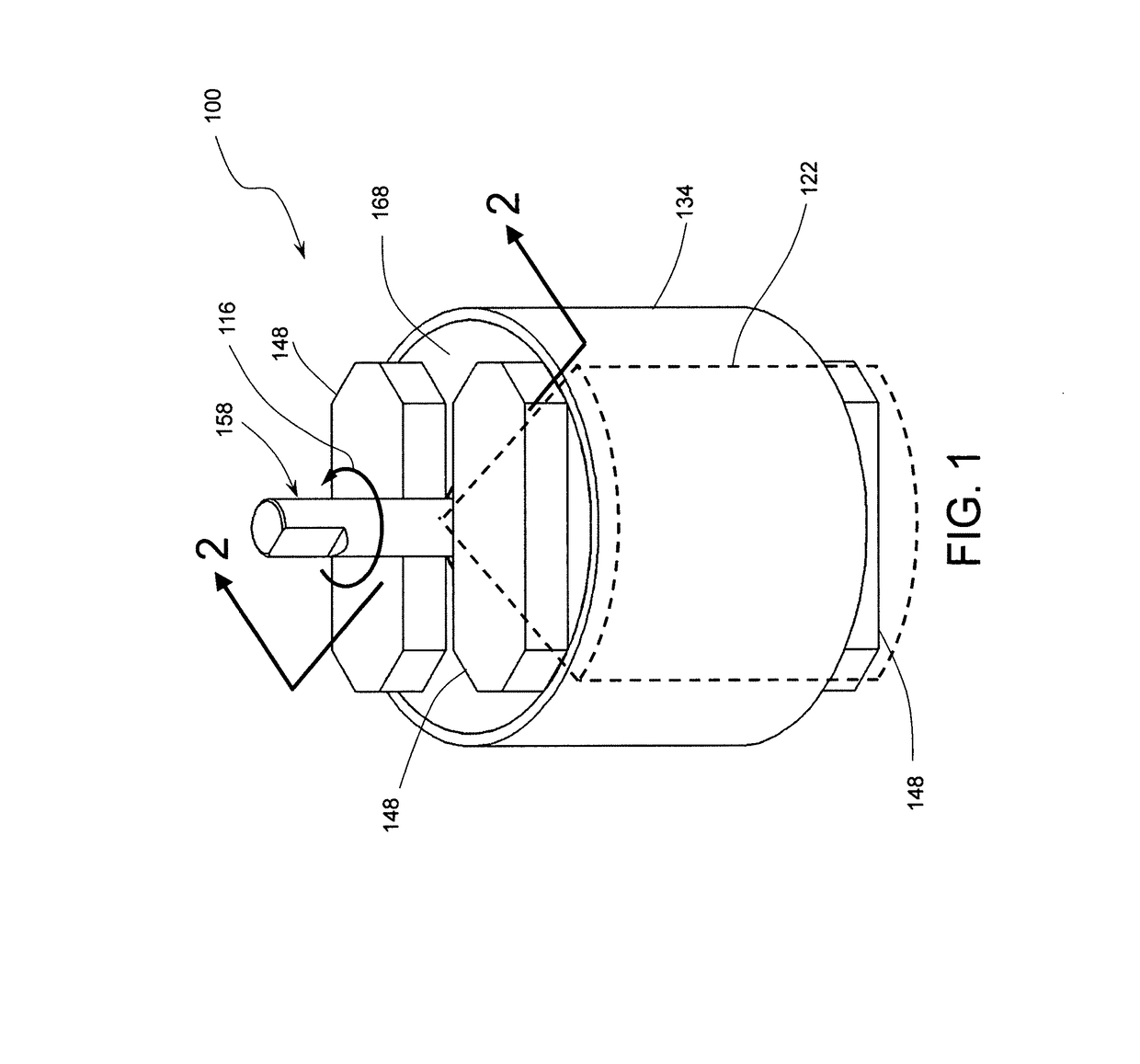

Structures and methods for thermal management in printed circuit board stators

A stator for a motor or generator including a planar composite structure (PCS) having at least one dielectric layer and a plurality of conductive layers is provided. The stator includes first conductive elements extending radially to a distance r1 from a center of, and disposed angularly on, the PCS. Each first conductive element includes a preferred termination structure to connect with at least one of a plurality of second conductive elements extending radially from a radius r2 from the center of, and disposed angularly on, the PCS.

Owner:E CIRCUIT MOTORS INC

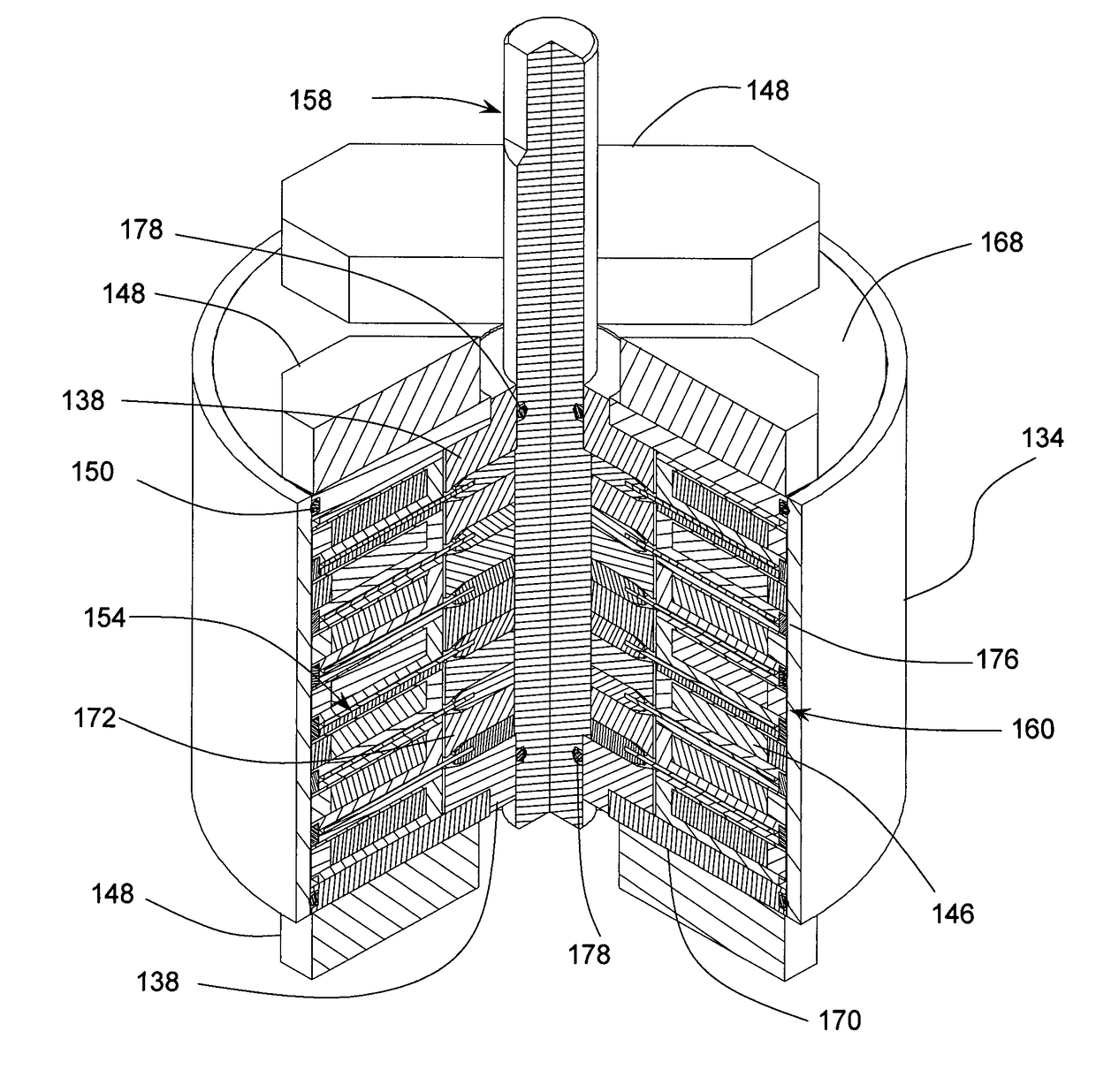

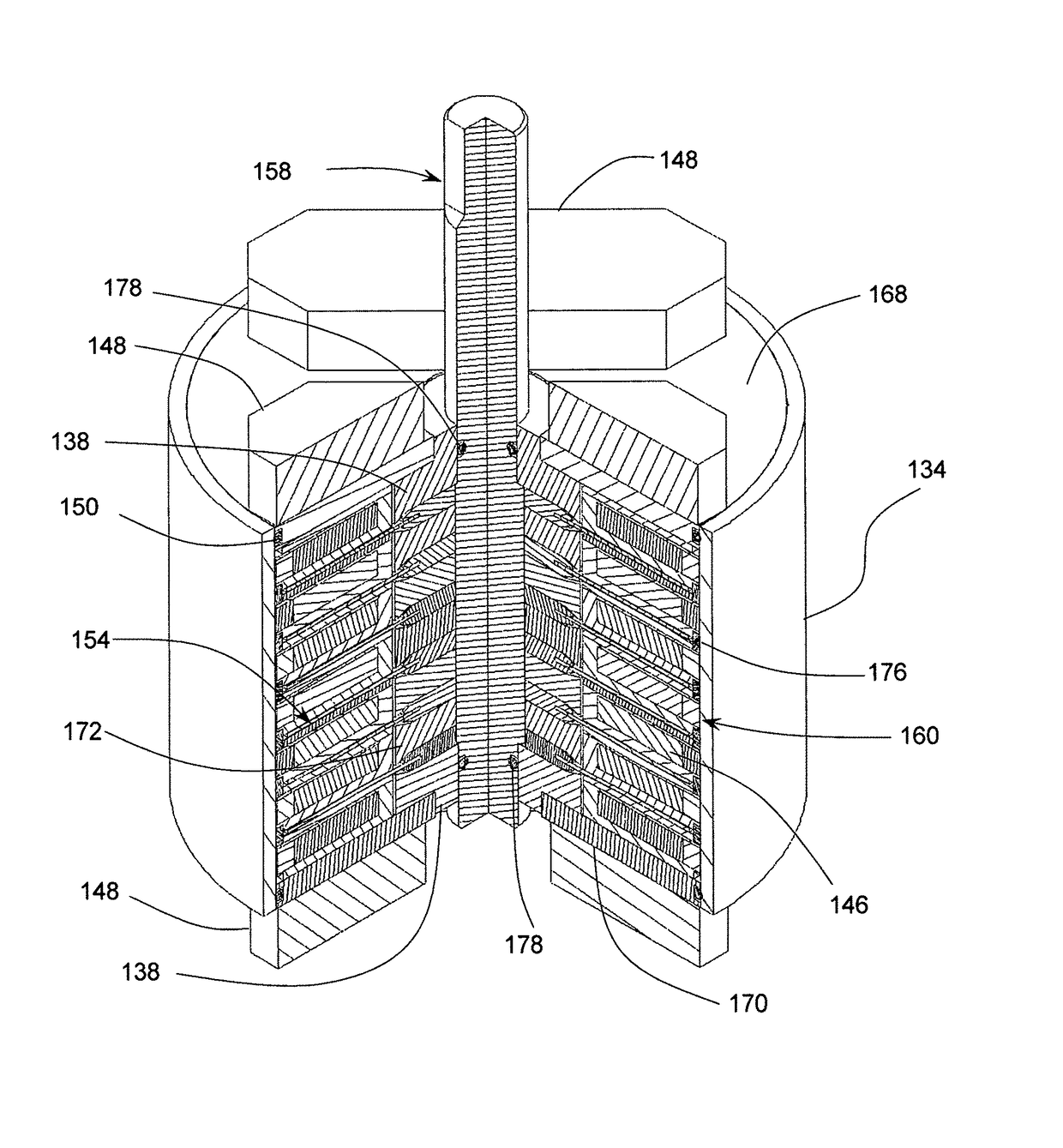

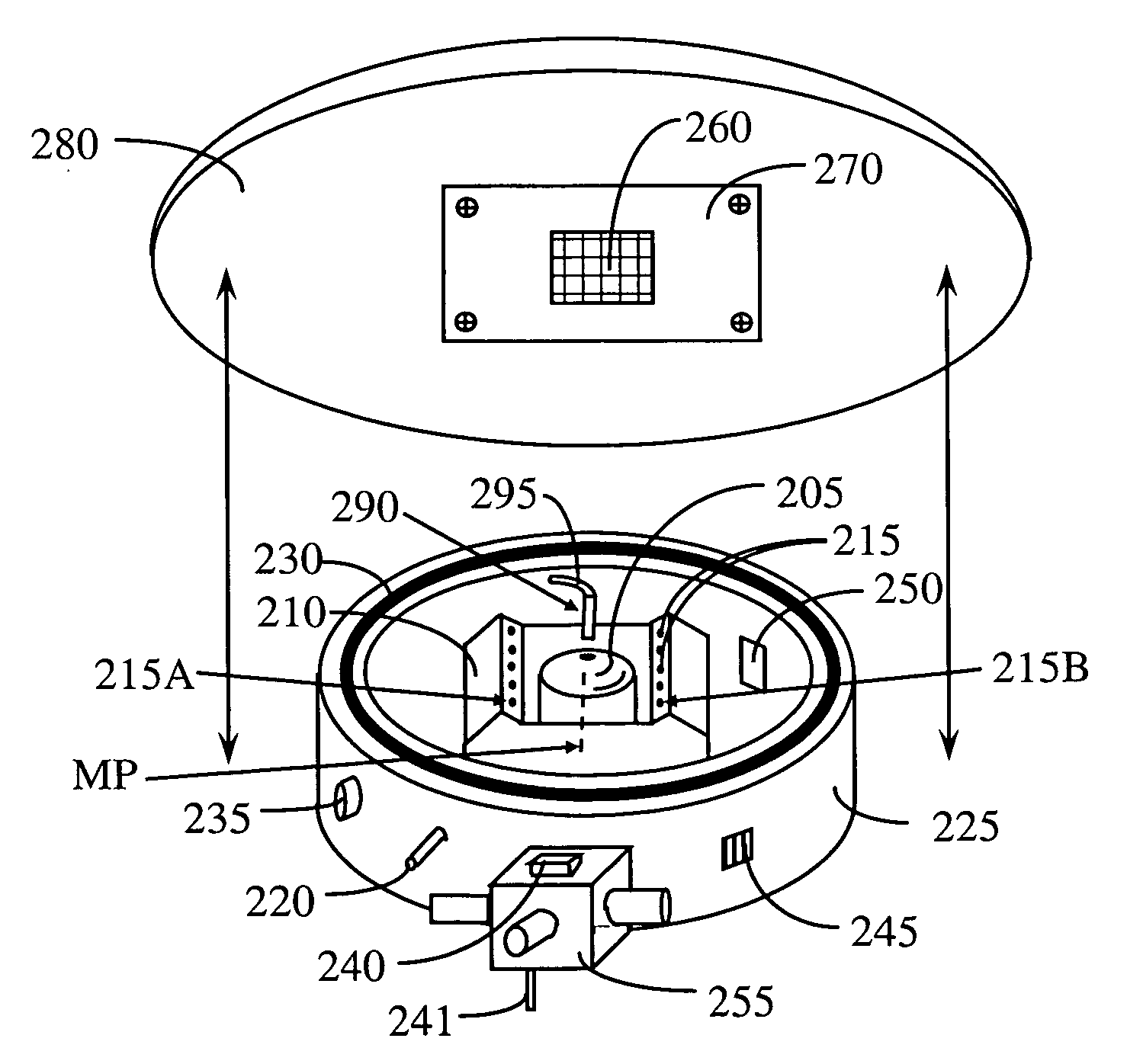

Magnetocaloric Refrigerator

ActiveUS20180045437A1Conducive to efficient heat transferImprove rendering capabilitiesIndirect heat exchangersMachines using electric/magnetic effectsCompression deviceMechanical energy

The invention is for an apparatus and method for a refrigerator and a heat pump based on the magnetocaloric effect (MCE) offering a simpler, lighter, robust, more compact, environmentally compatible, and energy efficient alternative to traditional vapor-compression devices. The subject magnetocaloric apparatus alternately exposes a magnetocaloric material to strong and weak magnetic field while switching heat to and from the material. Action of the heat switches is coordinated with the magnetic field strength to move heat up the thermal gradient. The invention may be practiced with multiple magnetocaloric stages to attain large differences in temperature. Key applications include thermal management of electronics, as well as industrial and home refrigeration, heating, and air conditioning. The invention offers a simpler, lighter, compact, and robust apparatus compared to magnetocaloric devices of prior art. Furthermore, the invention may be run in reverse as a thermodynamic engine, receiving low-level heat and producing mechanical energy.

Owner:VETROVEC JAN

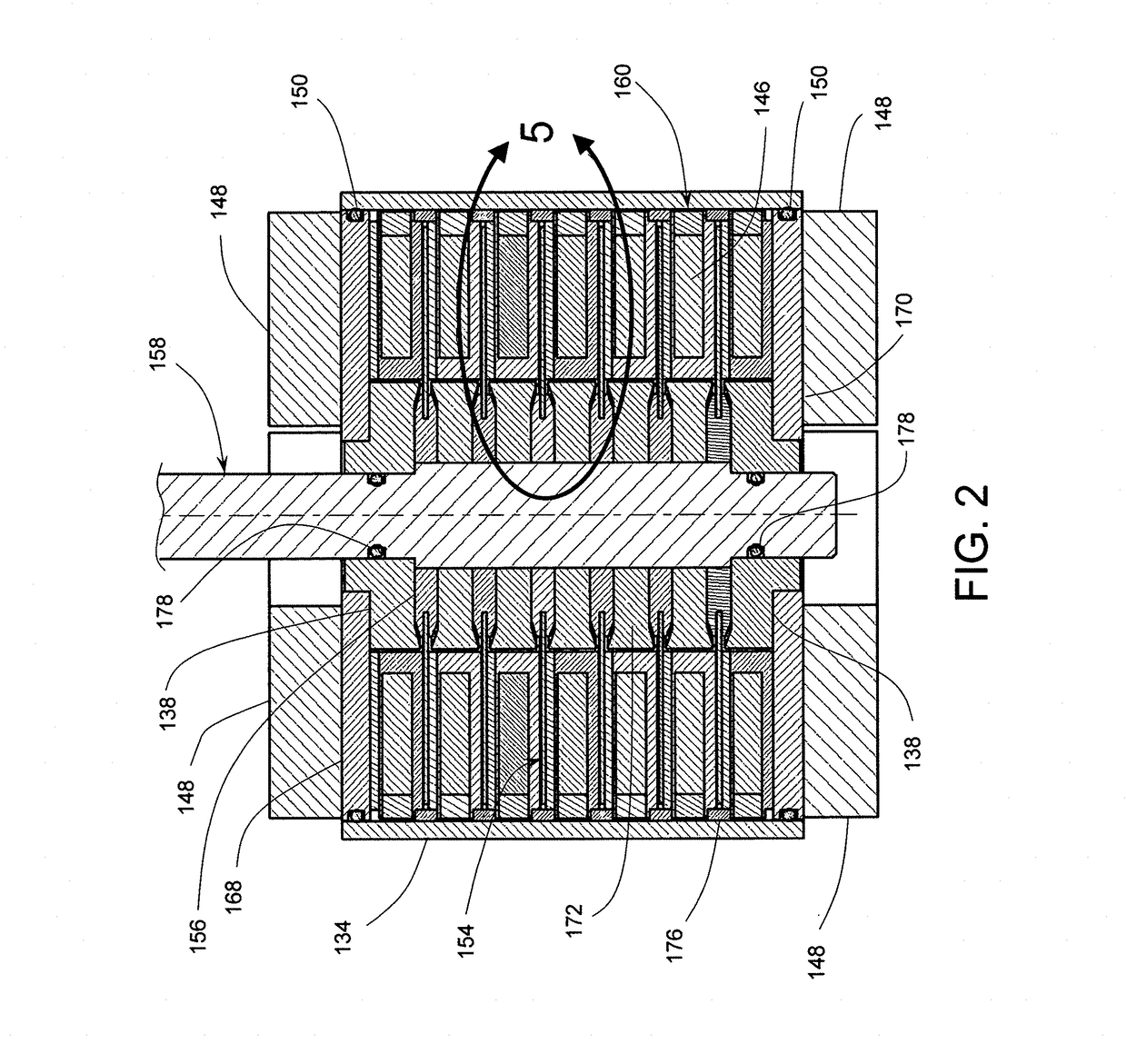

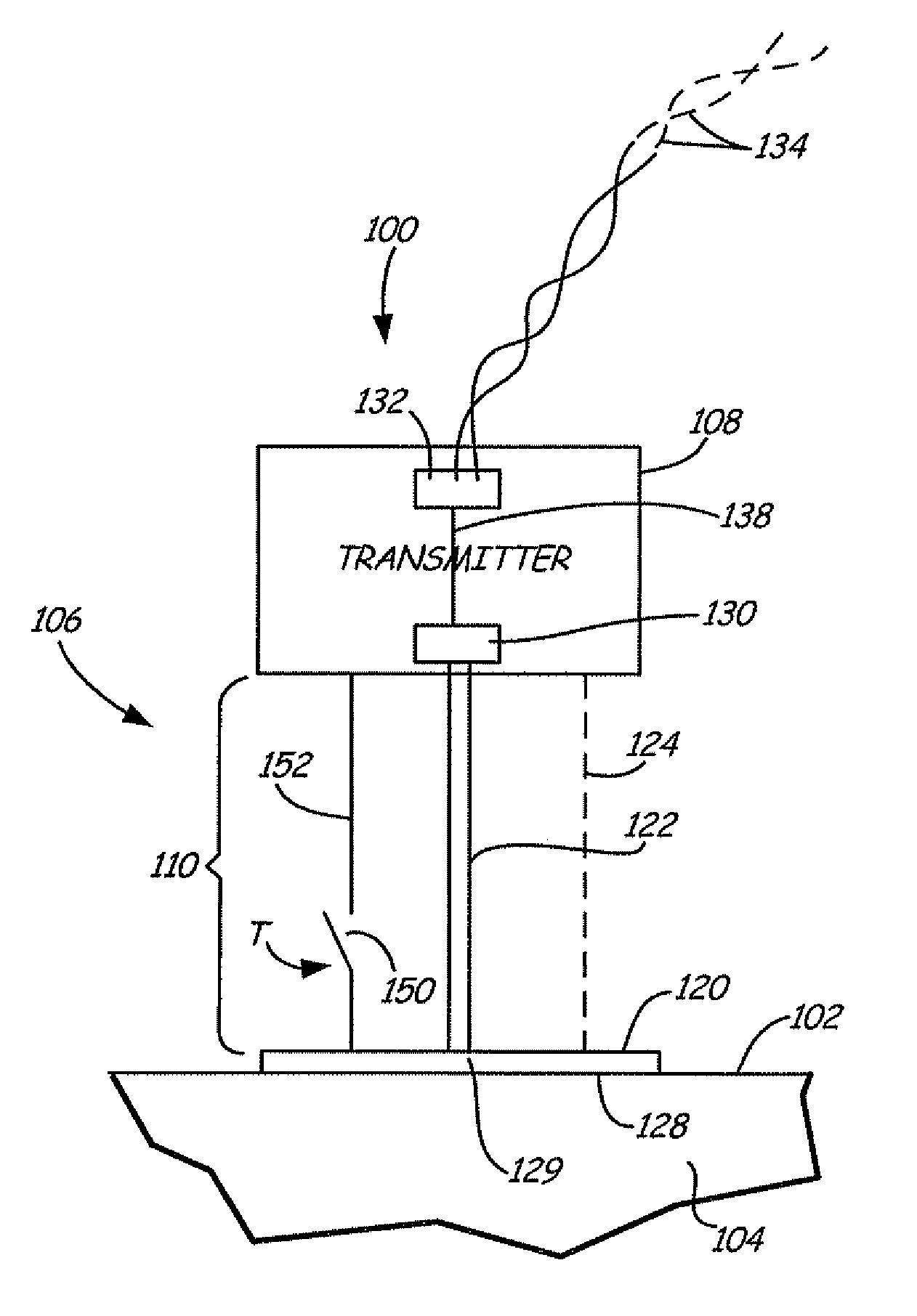

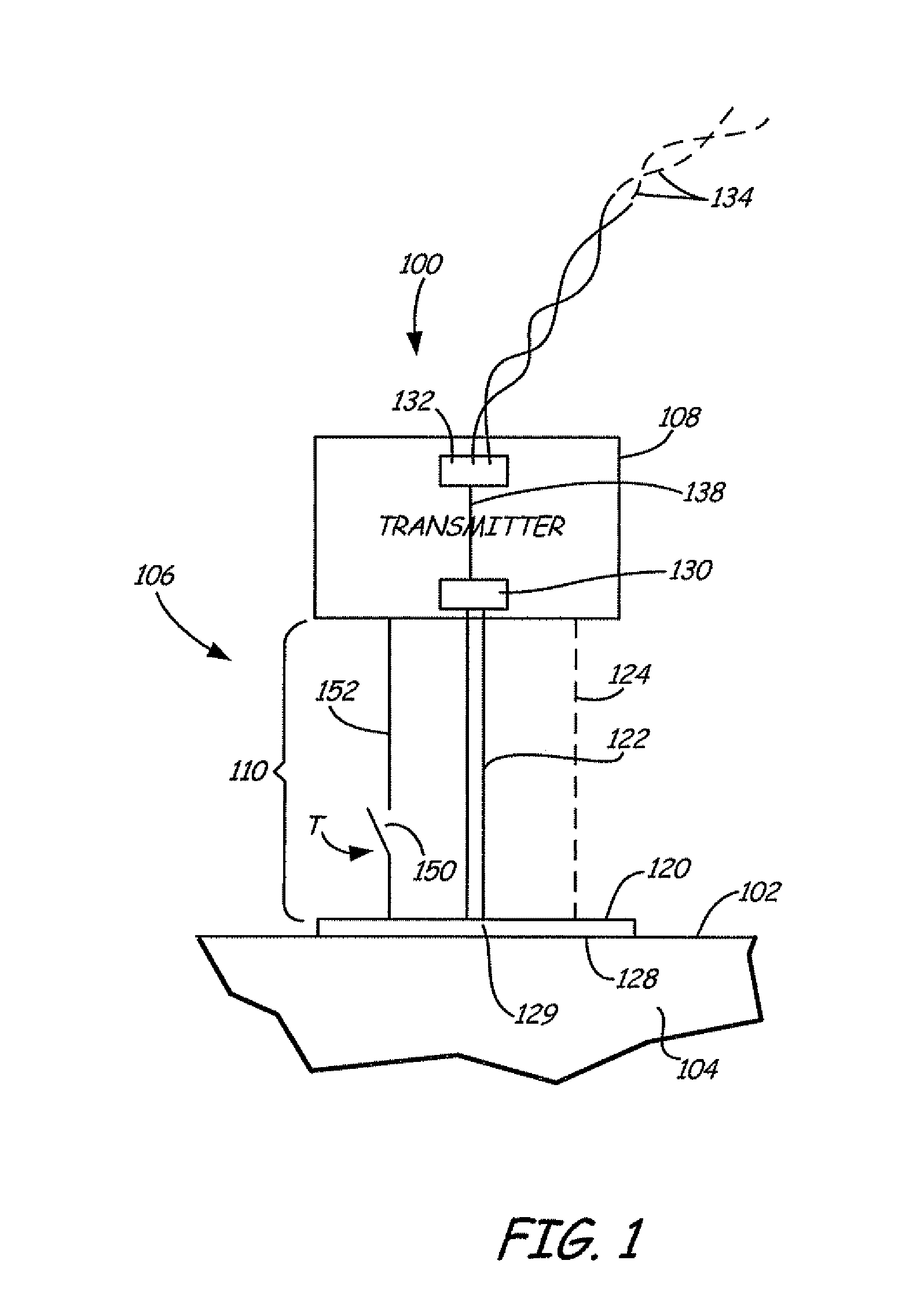

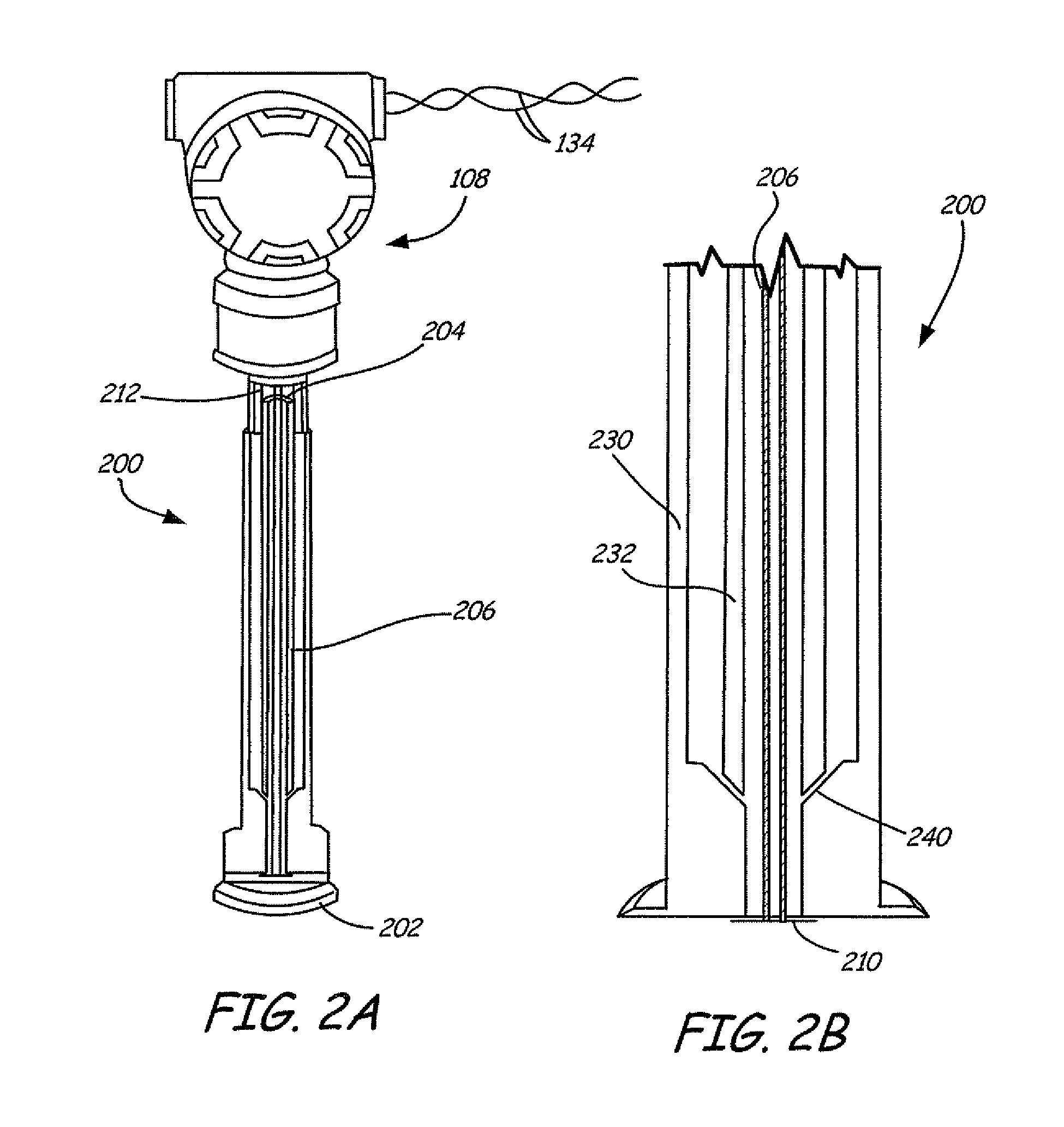

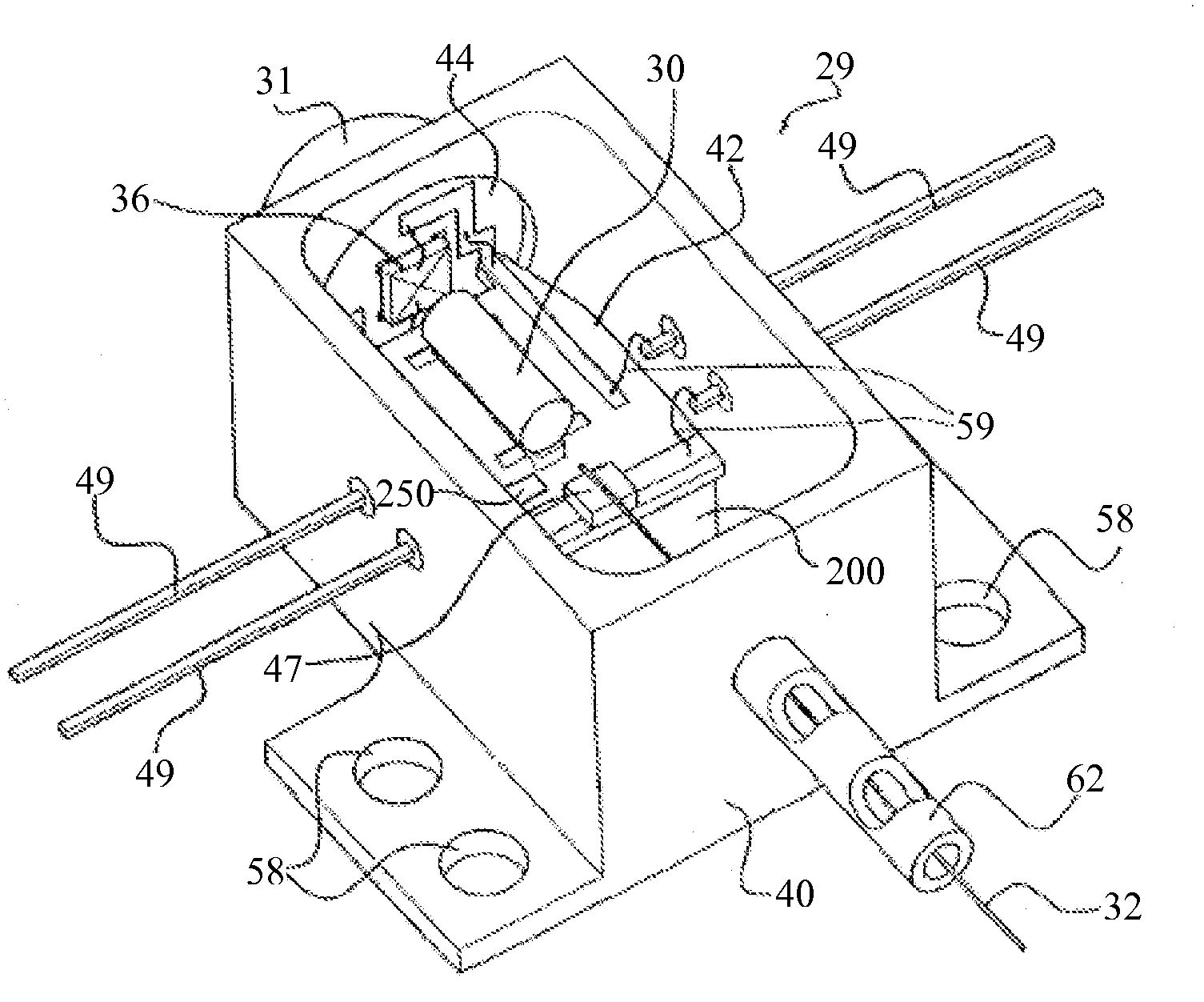

Direct mount for pressure transmitter with thermal management

ActiveUS7497123B1Improve thermal conductivityFluid pressure measurement by mechanical elementsHeat transfer modificationCouplingEngineering

A direct mount for coupling a pressure transmitter to a process fluid of an industrial process includes a transmitter coupling configured to couple to a pressure transmitter. A process coupling is configured to couple an industrial process. A capillary tube extends between the transmitter coupling and the process coupling. A thermally conductive path having relatively high thermal conductivity extends between the process coupling and the transmitter coupling. Preferably, a thermal switch selectively thermally connects the thermally conductive path between the process coupling and the transmitter coupling.

Owner:ROSEMOUNT INC

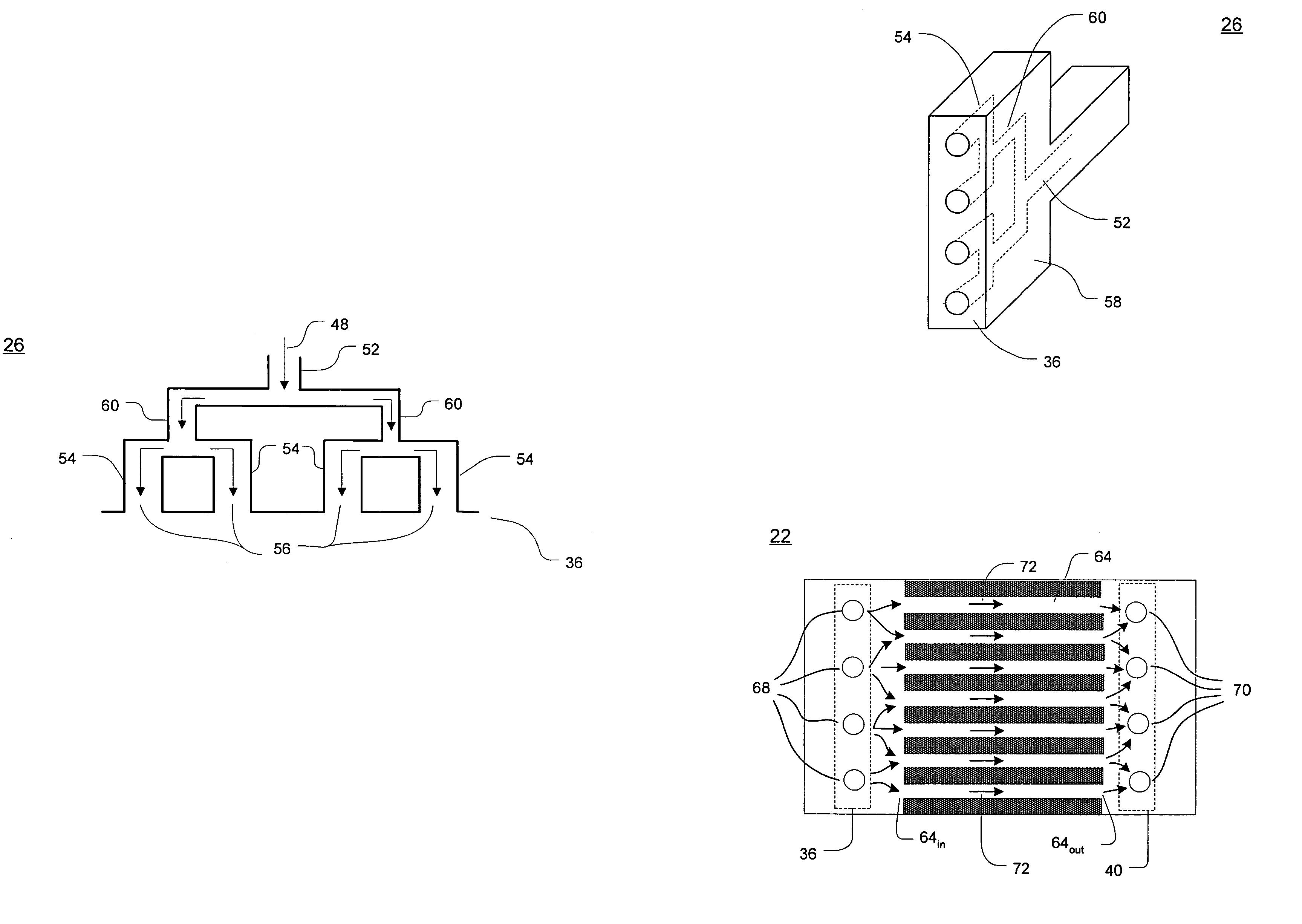

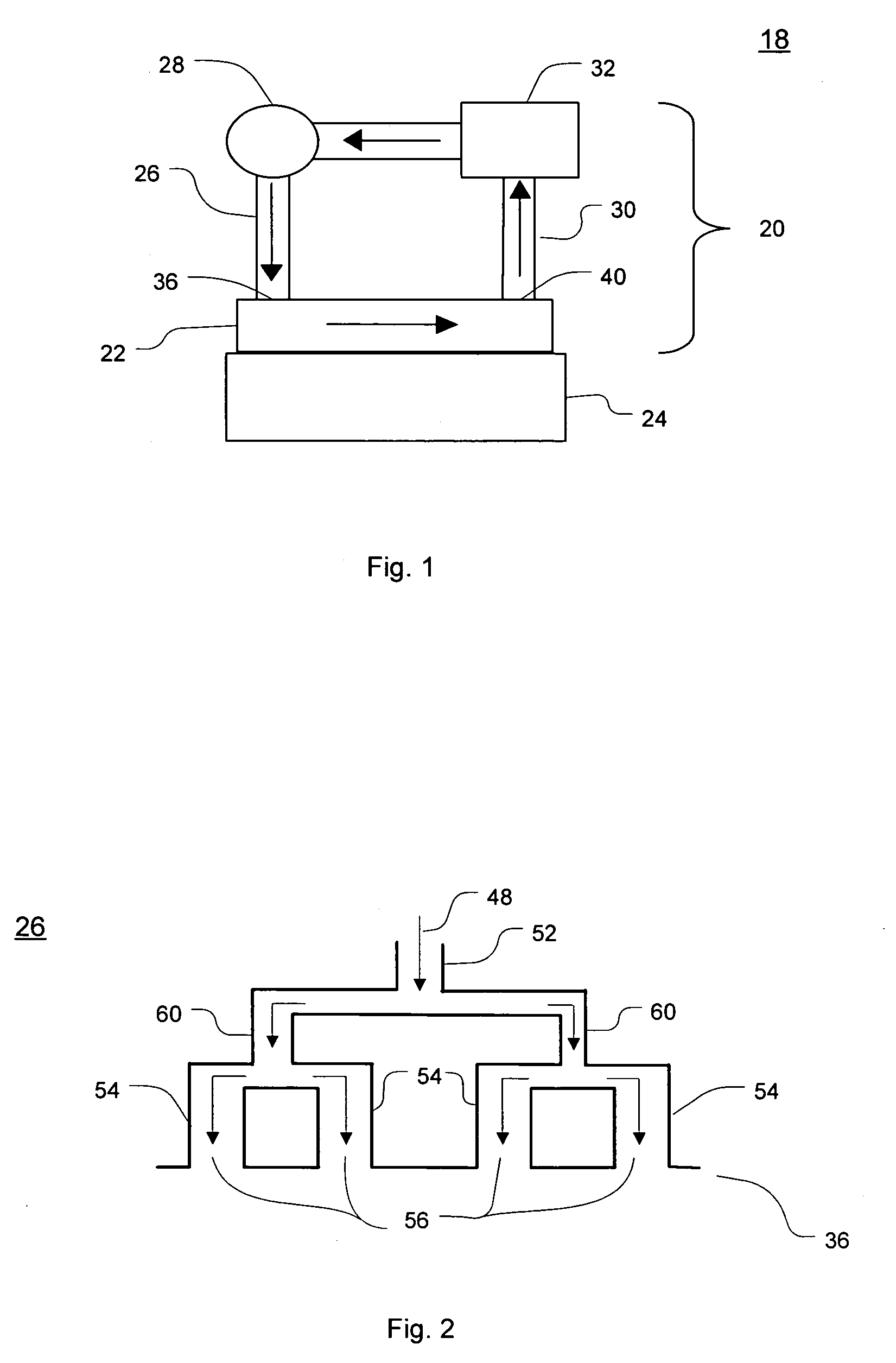

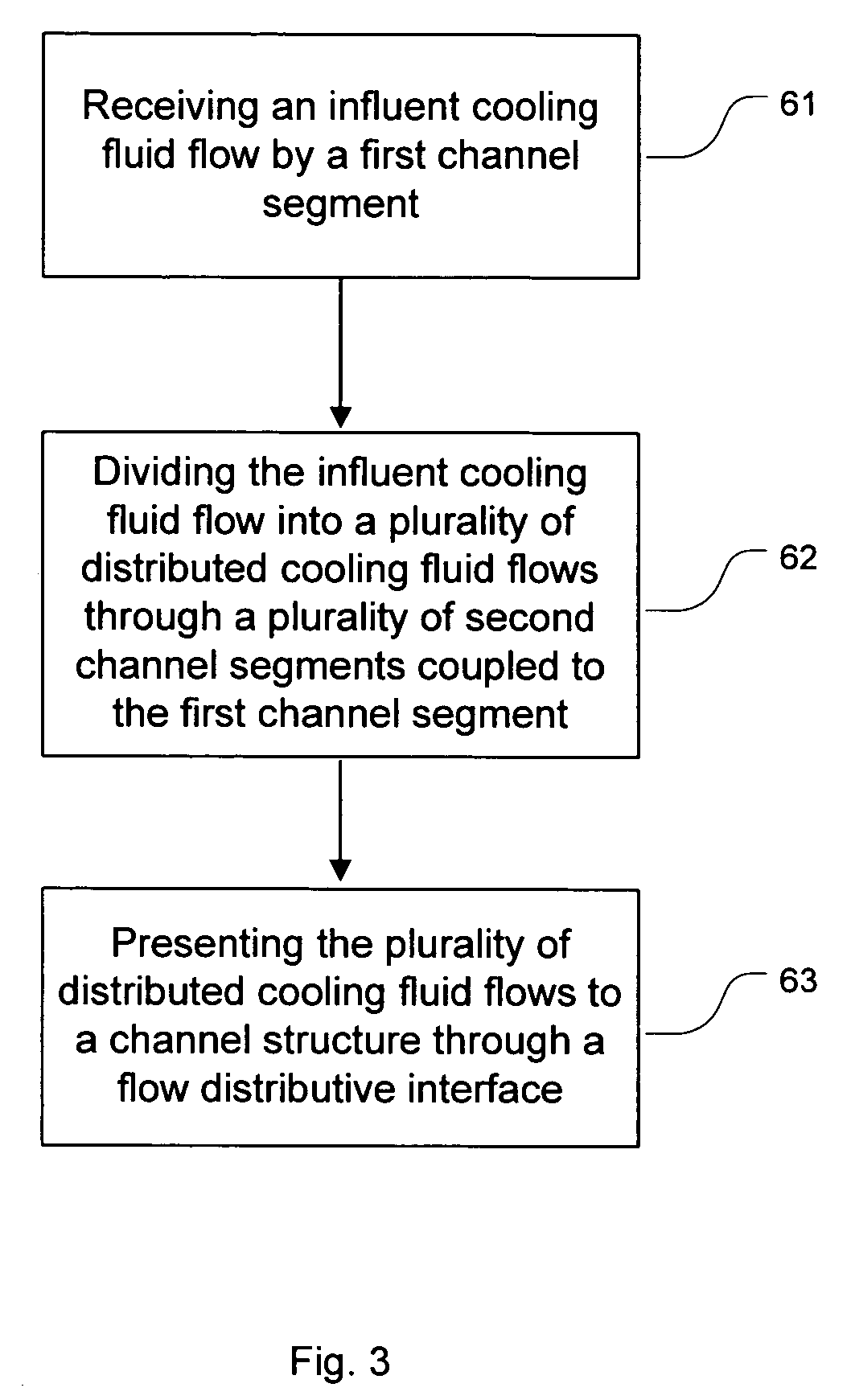

Method and apparatus for providing distributed fluid flows in a thermal management arrangement

InactiveUS7212405B2Semiconductor/solid-state device detailsHeat exhanger conduitsThermodynamicsHeat management

Embodiments of the present invention include an apparatus, method, and system for providing a flow distributive interface for a thermal management arrangement.

Owner:INTEL CORP

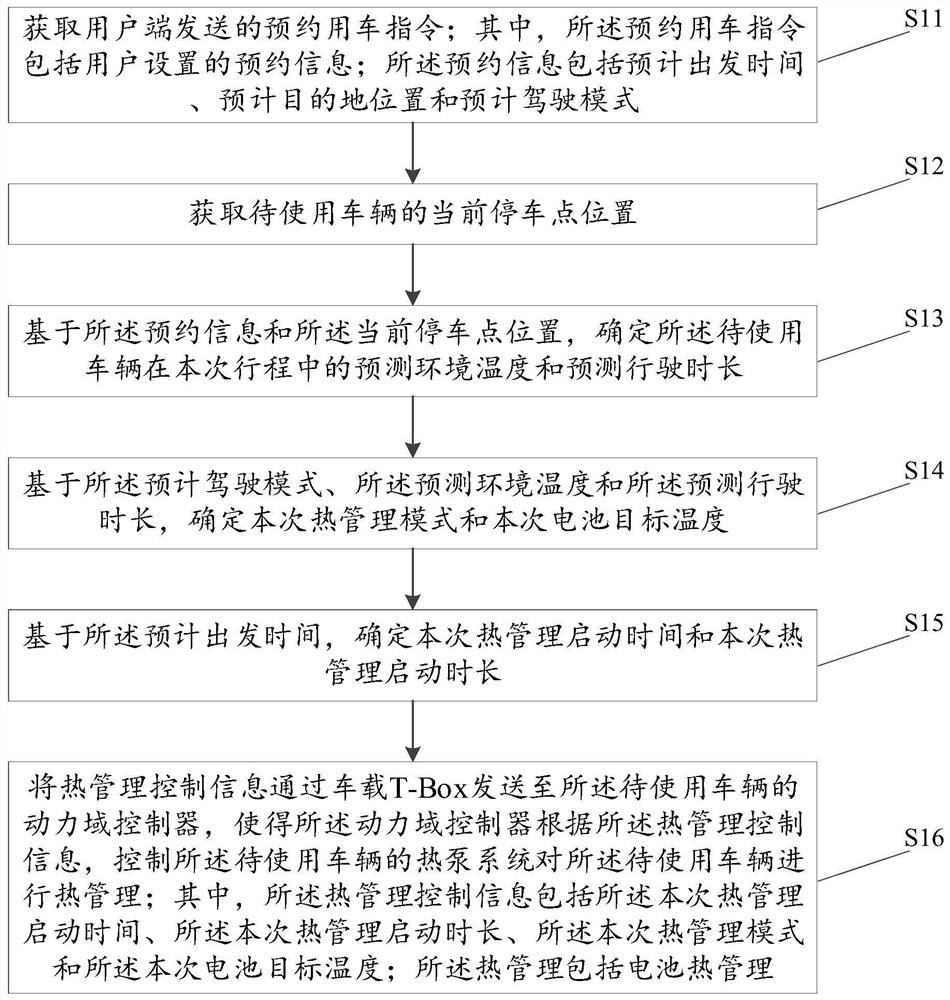

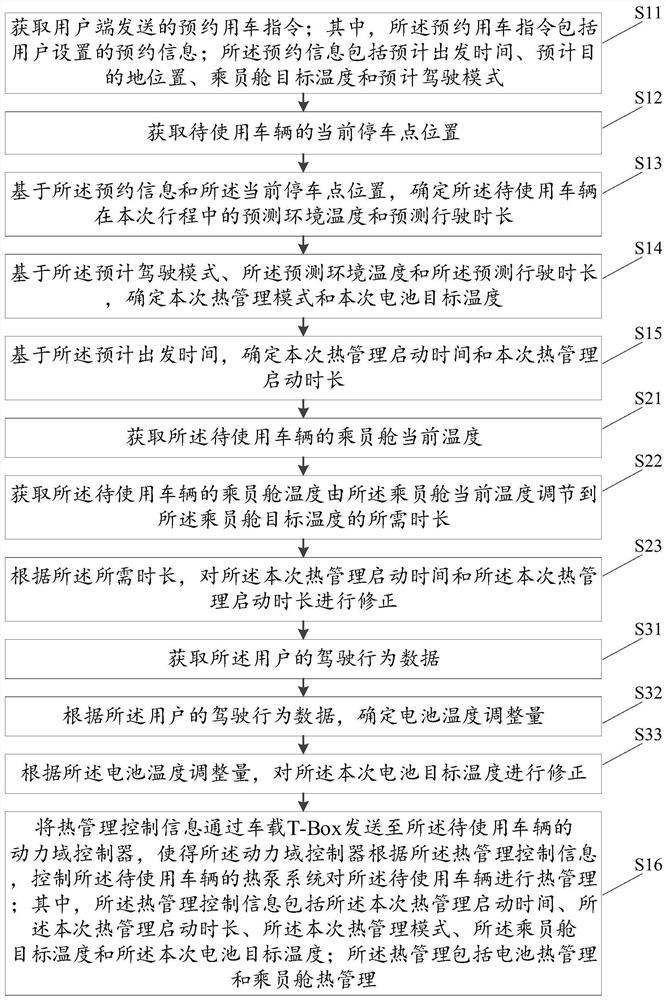

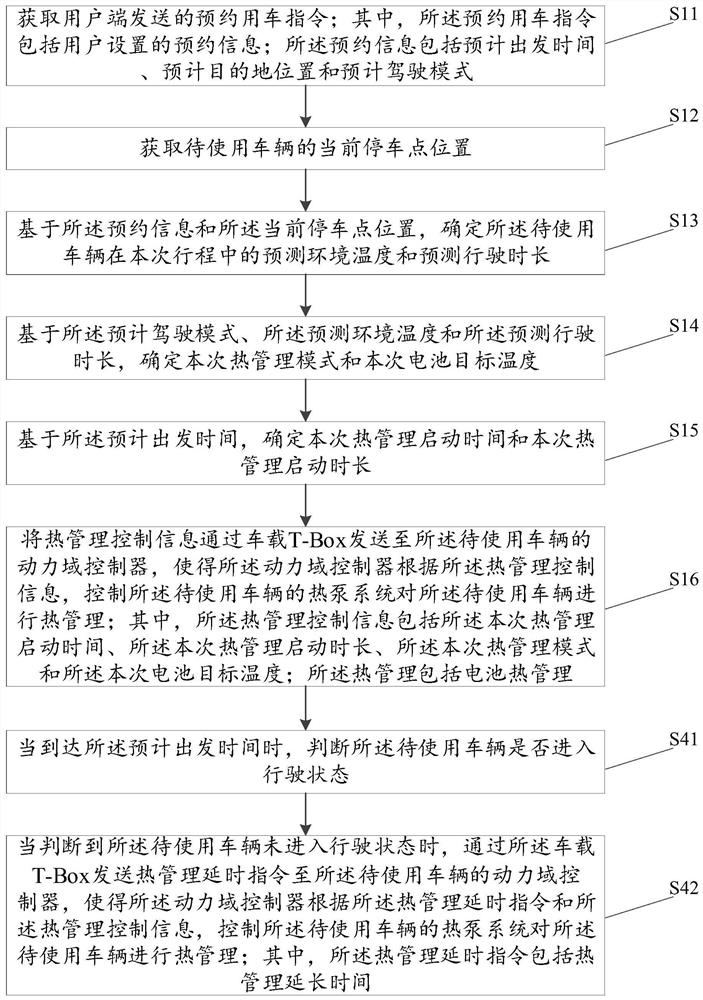

Electric vehicle remote thermal management control method, device and system and storage medium

ActiveCN111769240AAvoid heatingImprove comfortAir-treating devicesBatteries circuit arrangementsInformation controlThermodynamics

The invention discloses an electric vehicle remote thermal management control method, device and system and a storage medium. The method comprises: acquiring a vehicle reservation instruction which issent by a user side and comprises reservation information such as estimated departure time, an estimated destination position and an estimated driving mode; based on the reservation information and the obtained current parking point position, determining a predicted environment temperature and a predicted driving duration of the to-be-used vehicle in the travel; determining a current thermal management mode and a current battery target temperature based on the predicted driving mode, the predicted environment temperature and the predicted driving duration; determining current thermal management starting time and current thermal management starting duration based on the estimated departure time; and controlling a heat pump system of the to-be-used vehicle to perform heat management on theto-be-used vehicle through the power domain controller according to the determined heat management control information. By adopting the embodiment of the invention, unnecessary energy waste can be reduced while the use comfort of the vehicle is improved and the cruising ability of the vehicle is increased.

Owner:HUMAN HORIZONS (JIANGSU) TECH CO LTD

System and method for thermal management and gradient reduction

InactiveUS20070290702A1Reduce and prevent stagnation pointAvoid intersectionIndividual semiconductor device testingContactless circuit testingStagnation pointJet flow

A micro-spray cooling system beneficial for use in testers of electrically stimulated integrated circuit chips is disclosed. The system includes micro-spray heads disposed about a probe head, which provide a coolant flow onto the IC. A flow inducing injector is provided that directs a fluid jet onto zones where stagnation of the coolant flow is present. This reduces or eliminates any stagnation points and enhance temperature uniformity over the area of the IC.

Owner:DCG SYST

System and method of monitoring with temperature stabilization

ActiveUS20090101823A1Accurate measurementRadiation pyrometryWave based measurement systemsFiberEngineering

A system and method of monitoring with temperature stabilization. The system can include a housing operably connected to a fiber optic cable that provides a light wave thereto, a relay optic for receiving the light wave and being positioned in the housing, a radiation device for processing or producing radiation in the frequency range of 10 GHz to 100 THz from the light wave and being positioned in the housing, a temperature sensor in thermal communication with the housing, and a thermal management device in thermal communication with the housing where the thermal management device adjusts a temperature within the housing based on temperature conditions measured by the temperature sensor. Other embodiments are disclosed.

Owner:HONEYWELL INT INC

Method For Implementing Thermal Management In A Processor And/Or Apparatus And/Or System Employing The Same

A method for detecting temperature associated with a processor, results of the detecting being used for controlling power dissipation associated with the processor and / or apparatus and / or system employing the same.

Owner:TEXAS INSTR INC

System and method for estimating ambient temperaure from portable computing device

InactiveCN104838330AAmbient temperature estimationDoes not significantly affect the degree of experienceEnergy efficient ICTThermometers using electric/magnetic elementsThermal energyEngineering

Various embodiments of methods and systems for estimating environmental ambient temperature of a portable computing device (“PCD”) from temperature measurements taken within the PCD are disclosed. In an exemplary embodiment, it may be recognized that the PCD is in an idle state, thus producing little or no thermal energy. Temperature measurements are then taken from temperature sensors within the PCD and used to estimate the environmental ambient temperature to which the PCD is exposed. Certain embodiments may simply render the estimated ambient temperature for the benefit of the user or use the estimated ambient temperature as an input to a program or application running on the PCD. It is envisioned that certain embodiments of the systems and methods may use the estimated ambient temperature to adjust temperature thresholds in the PCD against which thermal management policies govern thermally aggressive processing components.

Owner:QUALCOMM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com