Novel middle waste absorbing punching roller

A punching roller, a new type of technology, applied in metal processing and other directions, can solve the problems of scraps falling outside the workstation, slow punching rollers, reduced work efficiency, etc., to achieve low noise, improve work efficiency, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

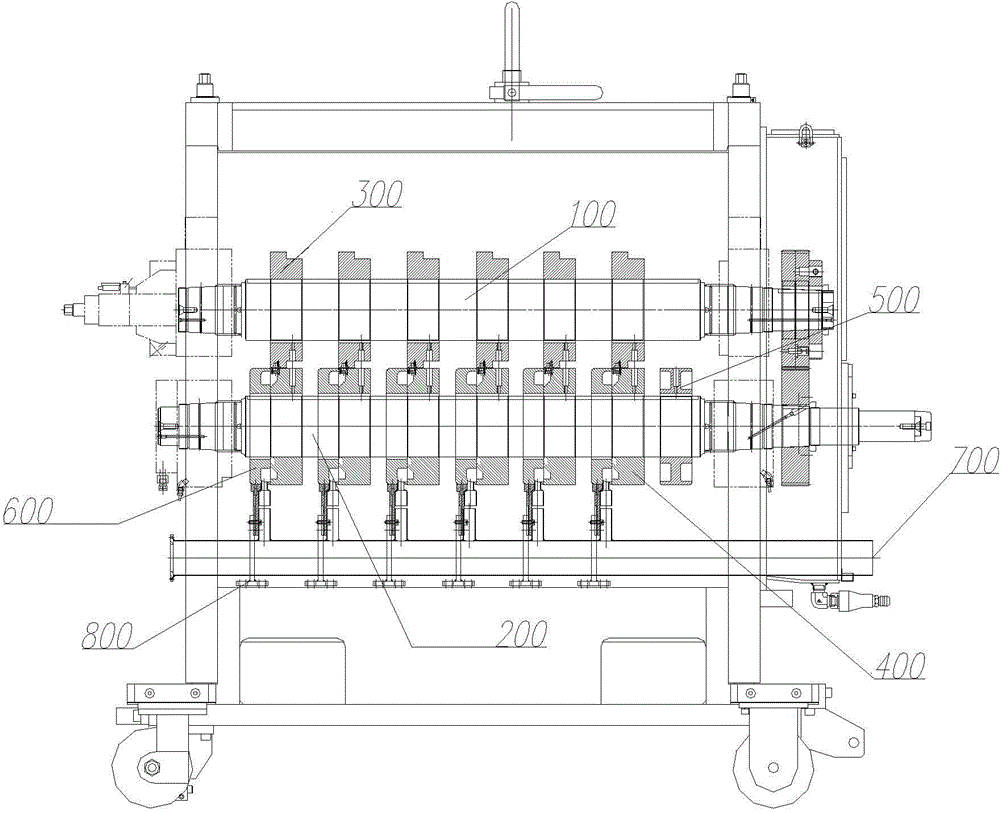

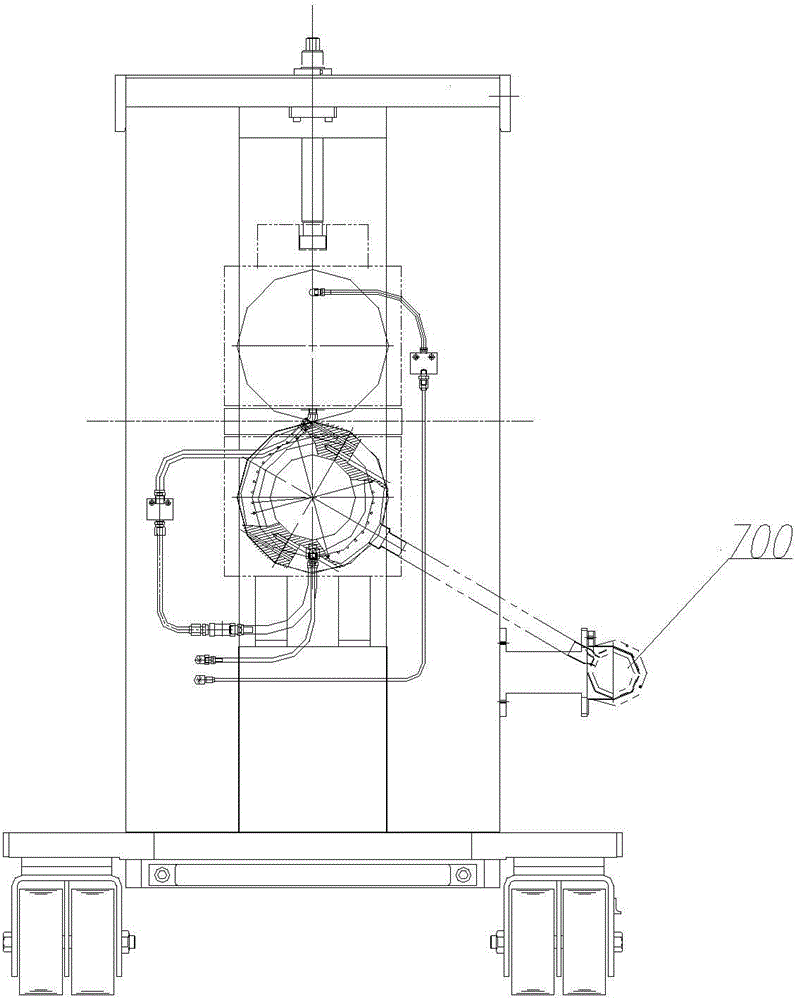

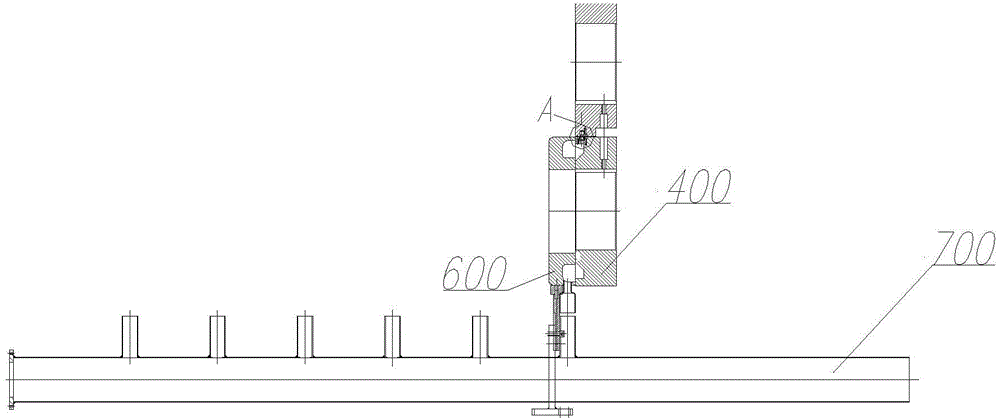

[0018] refer to Figure 5 Figure 6 , a new type of intermediate waste-absorbing punching roller, which is designed and modified using the principle of vacuum waste suction, and realizes complete separation of products and waste under high-speed operation. It includes a frame, and an upper punching roller 1 and a lower punch placed on the frame Hole roller 2 and waste material outlet 3, the upper punching roller 1 and the lower punching roller 2 are both hollow rollers, the upper punching roller 1 and the lower punching roller 2 are bridged on the frame, and the relative arrangement has a certain distance; The waste material outlet 3 communicates with the hollow part of the lower punching roller 3, and an upper punching die 11 and a lower punching die 21 are respectively arranged on the upper punching roller 1 and the lower punching roller 2, and the upper punching die 11 and the lower punching die 21 interlock; Universal wheels are set at the lower part of the frame for movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com