Grindstone

A grinding stone and grinding technology, applied in the direction of abrasives, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of hindering grinding/polishing, clogging, short grinding/polishing life, etc., and achieve improved grinding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

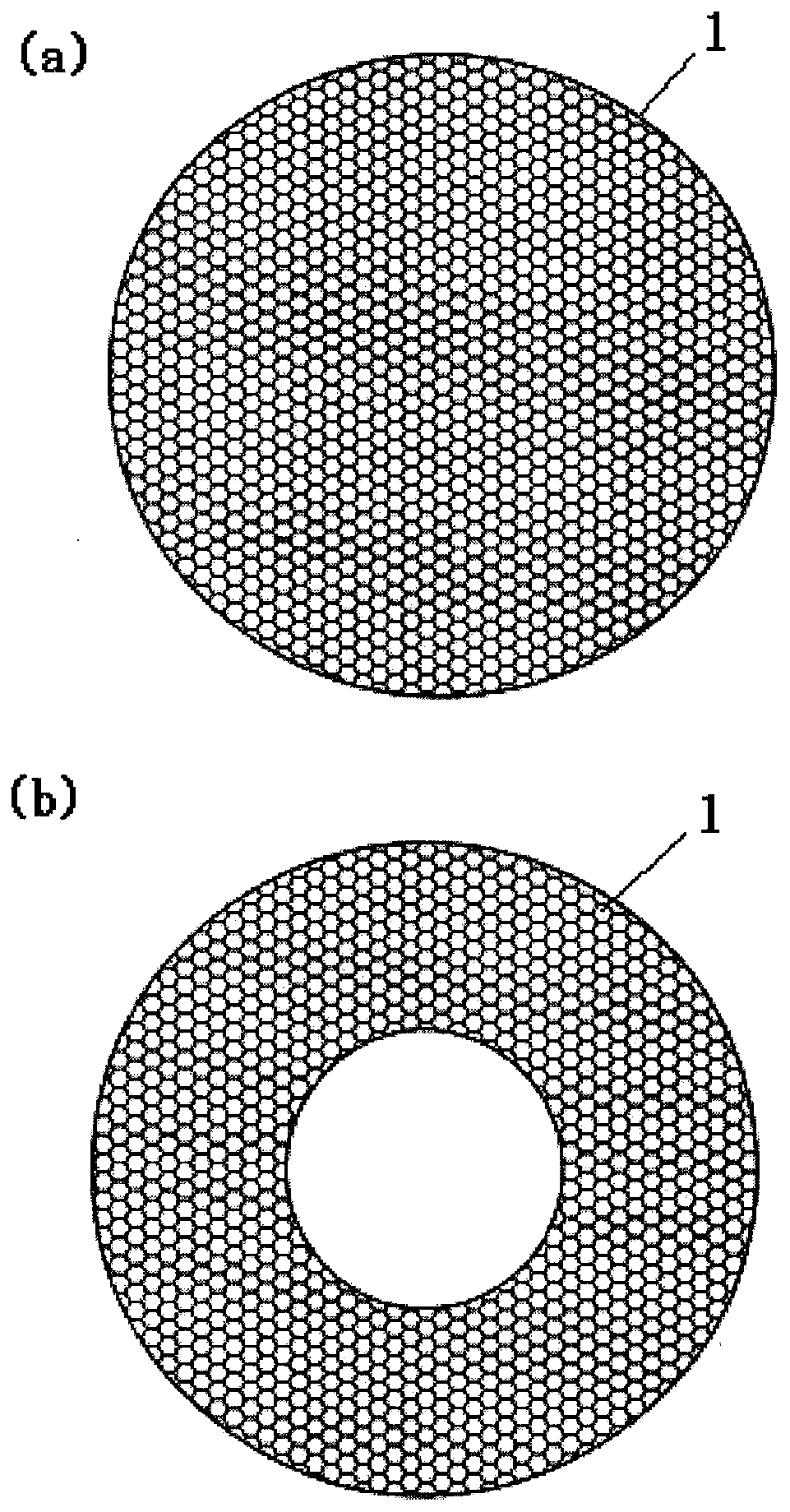

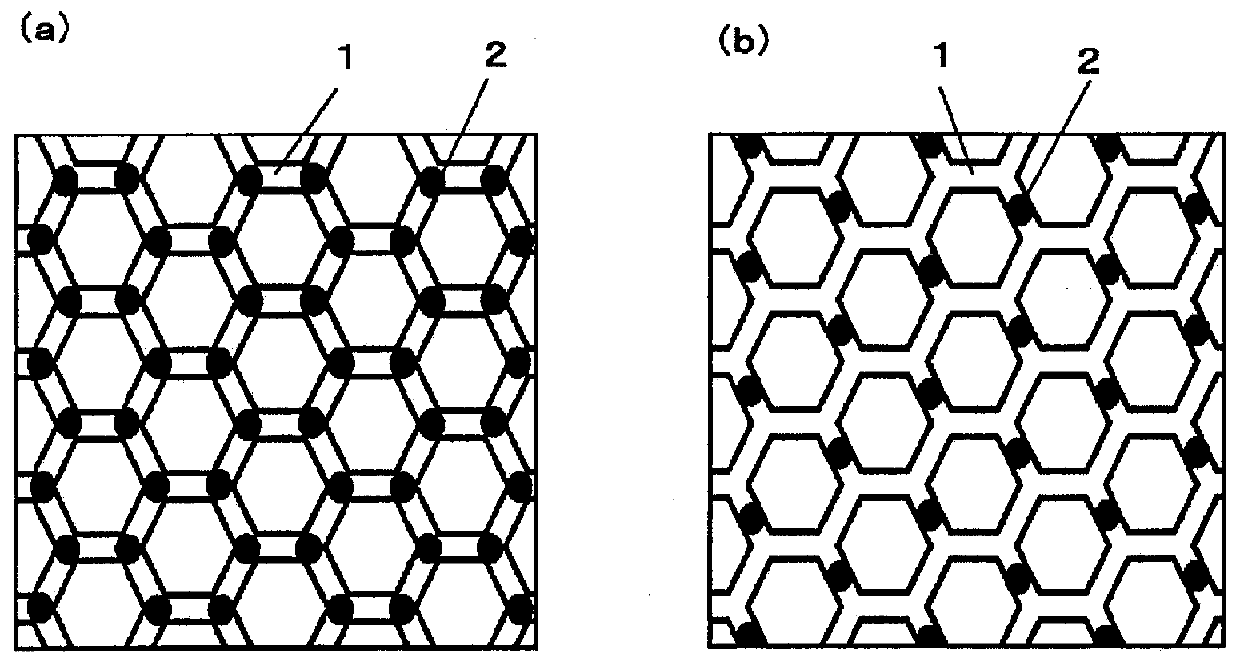

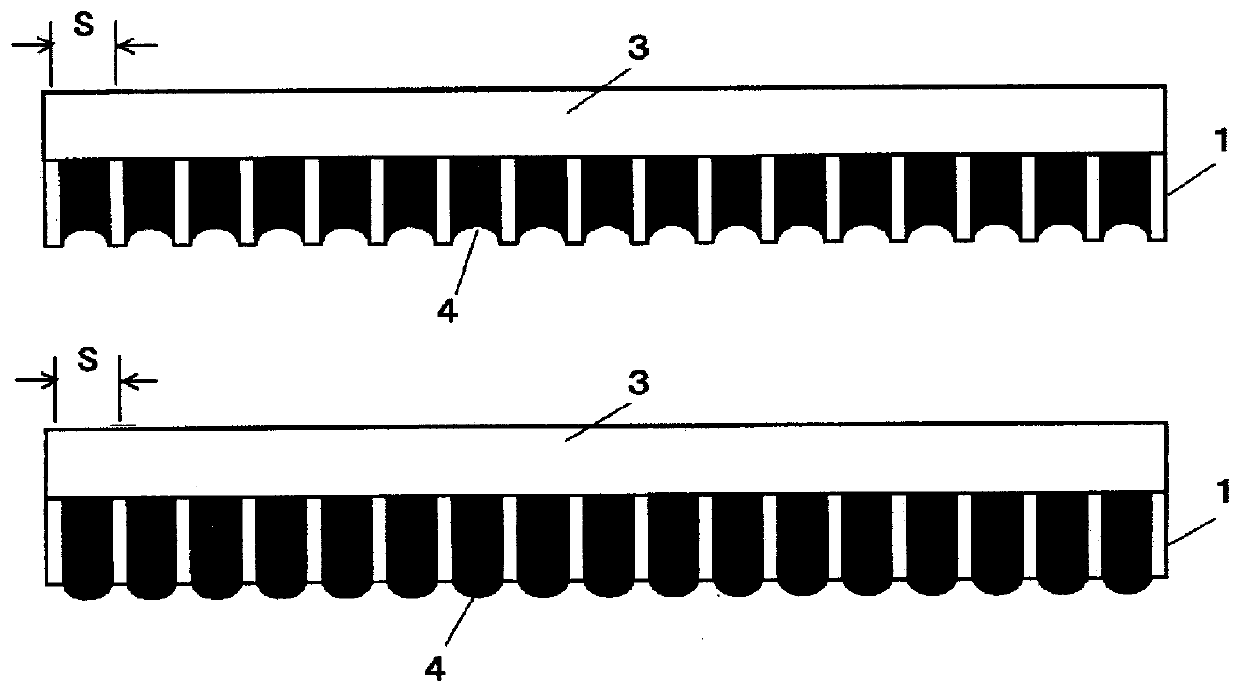

[0099] use Figure 1-6 The flat grindstone of the present invention shown in and Picture 9 The thickness of the linear grindstone or the cup-shaped grindstone corresponding to the diameter D of the grindstone column within the scope of the present invention is 1-2 mm which is 1-100 times the average particle size of the abrasive grains 5. The distance S between adjacent grindstone pillars is 10-20 mm, which is equivalent to 10-1000 times the thickness of the diameter D of the grindstone pillar. And the porosity of the grindstone column and the grindstone base 3 is 30-60%. The total ratio of the cross-sectional area of the grindstone column to the area of the grinding / polishing surface of the grindstone is 0.4-7.0%, which is a lower value than before. In addition, the abrasive grains used diamond with an average particle diameter of 20 μm.

[0100] The effect of the embodiment when the abrasive grain of the present invention is made of diamond and when the workpiece W is sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com