Silver fine particles and processes and equipment for the production thereof

A preparation device and technology of silver particles, applied in transportation and packaging, metal processing equipment, cable/conductor manufacturing, etc., can solve the problems of low preparation efficiency, falling off of silver flakes, narrowing of flow path, etc., and achieve high preparation efficiency and easy The effect of the maintenance of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

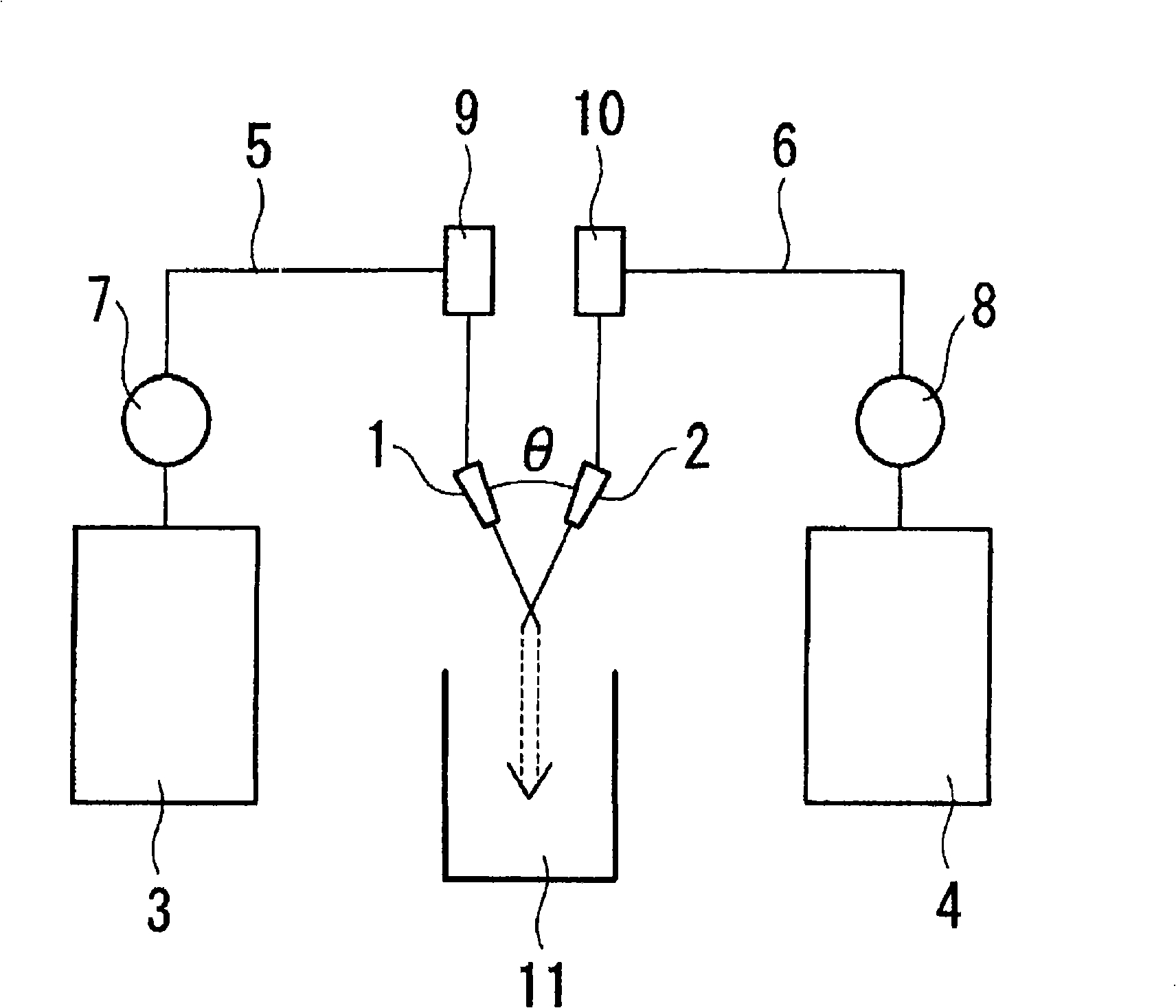

[0045] The first aspect of the preparation method of the present invention is a method for preparing silver microparticles by reducing the silver ammonia complex, wherein, by making the silver ammonia complex aqueous solution and the reducing agent solution merge on the outside of their infusion lines, and in the The open space reduces the silver ammonium complex and precipitates silver particles.

[0046] In the first aspect of the preparation method of the present invention, since the silver particles are deposited in the open space outside the infusion line, the silver particles will not adhere to the surroundings of the deposition site, and there will be no generation of coarse falling particles. Therefore, silver fine particles containing no coarse particles having a particle size of 5 μm or more can be obtained.

[0047] In the first scheme of the preparation method of the present invention, since the silver ammonia complex aqueous solution and the reducing agent solutio...

experiment example 1

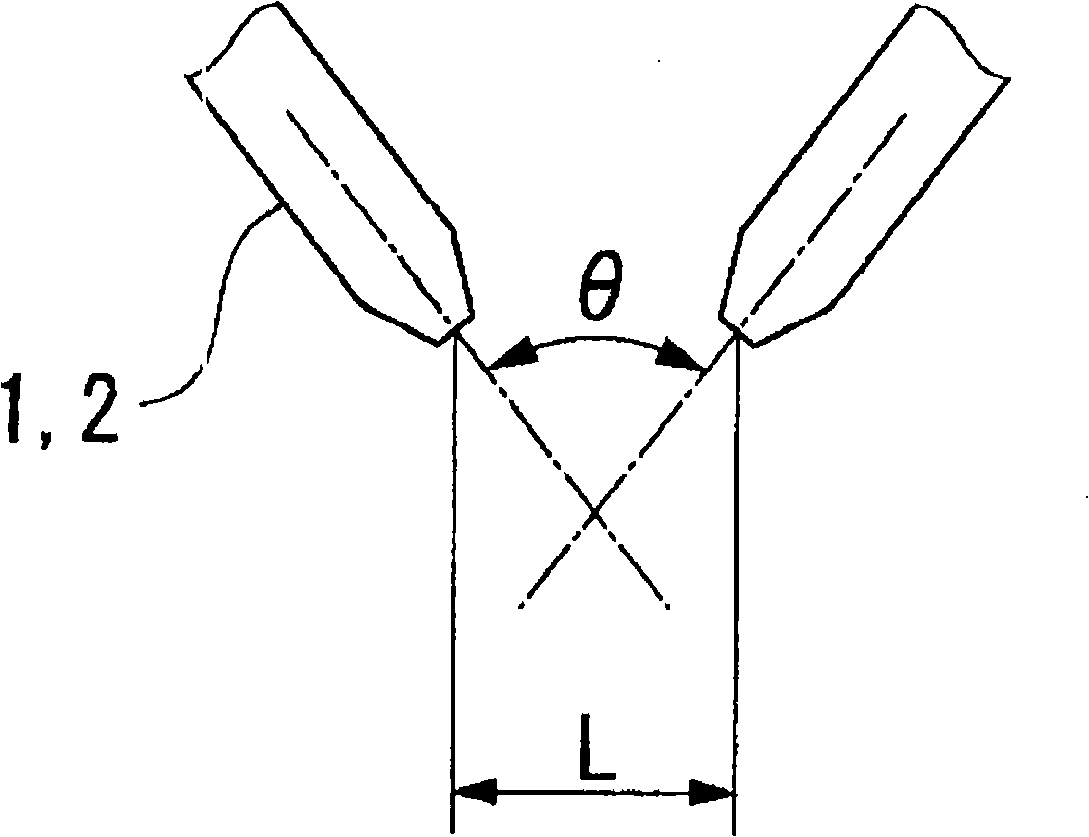

[0079] Silver particles were prepared by spray synthesis. Select the spray pressure and nozzle caliber that can form the spray amount shown in Table 1, spray the silver ammonium complex aqueous solution and the reducing agent solution with the same spray amount from the nozzles facing each other at an angle of about 90 °, and make its confluence. Synthesis conditions and results are shown in Table 1. In addition, the electron micrograph (multiplier 7500) of the silver particle of sample A6 is shown in Figure 4 .

experiment example 2

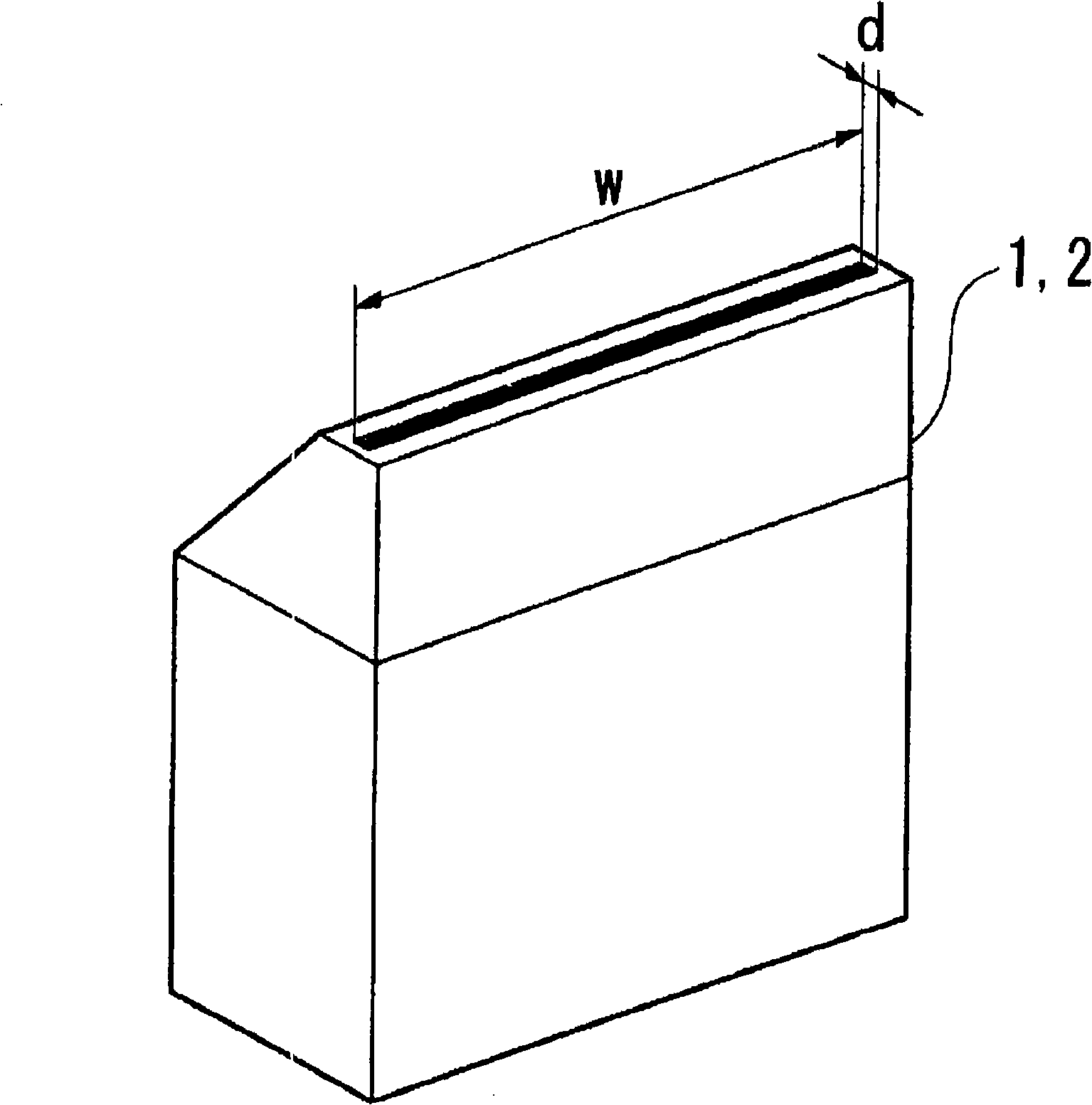

[0081] Silver fine particles were prepared by the outflow synthesis method using a nozzle having a cylindrical outlet. The silver ammonium complex aqueous solution and the reducing agent solution with the concentrations shown in Table 2 flowed out at the same flow rate from the nozzles facing each other at the nozzle angles and distances between the nozzles shown in Table 2, and merged. Synthesis conditions and results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com