Super-clean treatment process system for flue gas

A process system and flue gas technology, applied in the direction of gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems that performance is greatly affected by load fluctuations, high resistance, and low dust removal efficiency of pre-dust collectors, etc., to achieve low overall resistance, The effect of long equipment life and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

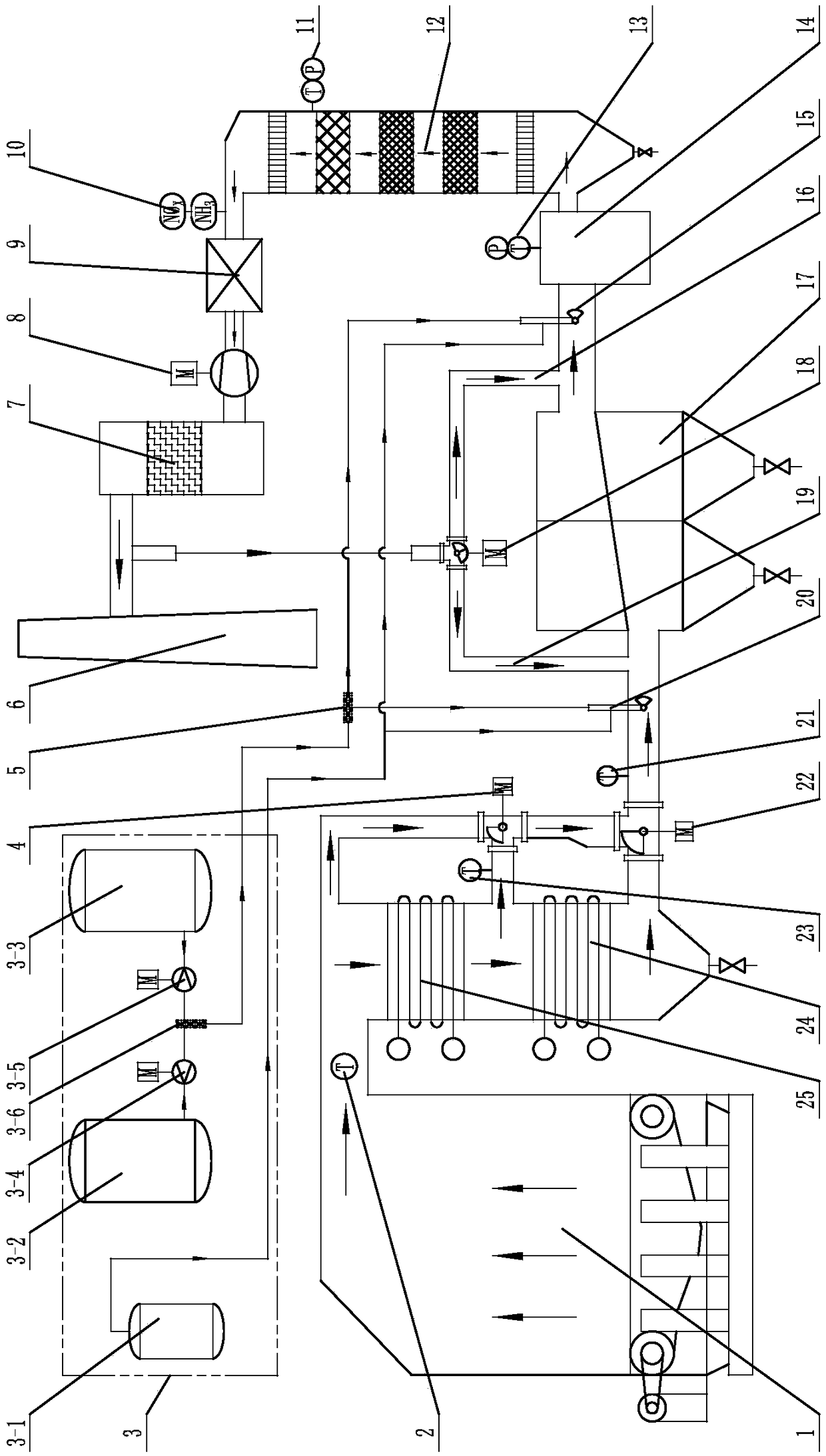

[0026] Specific implementation mode one: combine figure 1 Describe this embodiment, a flue gas ultra-clean treatment process system of this embodiment, which includes a flue temperature adjustment system, a dust collector 17, a disturbance device 14, an SCR reactor 12, a waste heat recovery system, an induced draft fan 8, an ultra-clean desulfurization Dust removal equipment 7, reducing agent system and automatic control system, flue temperature adjustment system, dust collector 17, SCR reactor 12, waste heat recovery system, induced draft fan 8 and ultra-clean desulfurization and dust removal equipment 7 are connected in sequence from front to back, reducing agent One end of the system is connected to the inlet of the dust collector 17, the other end of the reducing agent system is connected to the inlet of the SCR reactor 12, and the disturbance device 14 is set at the inlet of the SCR reactor 12;

[0027] The smoke temperature regulating system includes a high-temperature h...

specific Embodiment approach 2

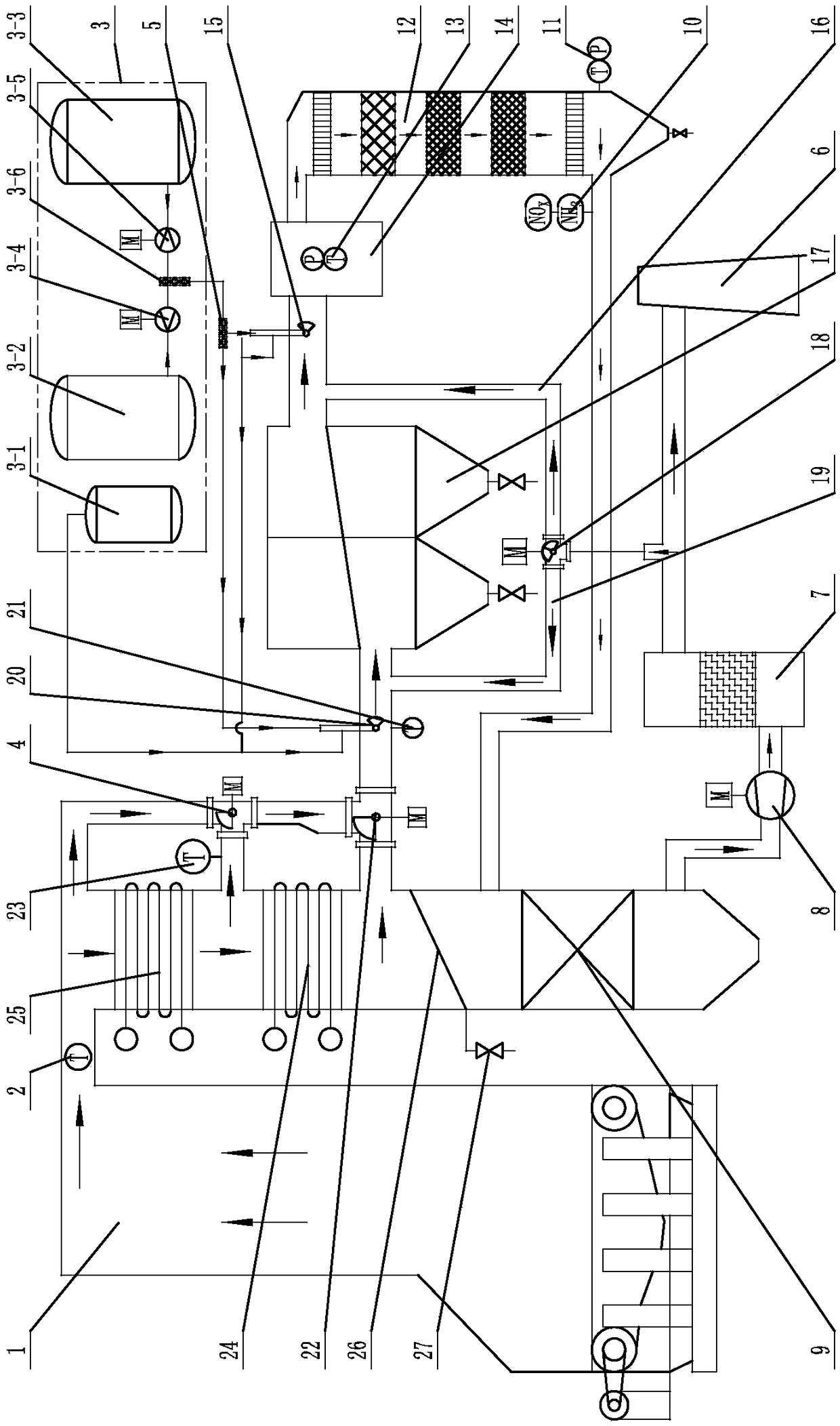

[0029] Specific implementation mode two: combination figure 2Describe this embodiment. This embodiment also includes an anti-dust system. The medium-temperature heat exchange surface 24 communicates with the waste heat recovery system through a flue, and the anti-dust system is arranged between the medium-temperature heat exchange surface 24 and the waste heat recovery system. The low-temperature flue (the first low-temperature bypass 19 and the second low-temperature bypass 16) is drawn from the outlet of the ultra-clean desulfurization and dust removal equipment 7, and there is no need to install a fan. When the temperature is too high, open the low-temperature three-way valve 18 to mix the low-temperature flue gas into the high-temperature flue gas. The mixing position is controlled by the second thermocouple 23. It is mixed before the agitator 14 through the second low-temperature bypass 16 , otherwise, it is mixed before the dust collector 17 through the first low-temper...

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. The anti-ash system of this embodiment includes ash discharge partition 26, ash discharge pipeline 27 and ash cooling equipment. The ash discharge partition 26 is arranged obliquely between the medium-temperature heat exchange surface 24 and the waste heat recovery system. On the flue wall of the flue, a through hole is opened on the flue wall at the lower end of the ash discharge partition 26, and one end of the ash discharge pipeline 27 communicates with the through hole on the flue wall, and the other end of the ash discharge pipeline 27 is connected to the ash discharge pipeline. The slag cooling equipment or kiln 1 is connected. In this way, the anti-dust system is mainly used for the transformation of the original boiler economizer or the waste heat boiler of the kiln. An inclined wear-resistant and heat-resistant insulation is installed between the upper and lower he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com