Edible ink for ink-jet printing on surface of eggshell and preparation method thereof

An inkjet printing and ink technology, which is applied to the field of edible ink and its preparation, can solve the problems of inkjet printer drainage tank failure, ink circulator pipeline blockage, high foaming, and achieves good market prospects, and the production method is simple. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

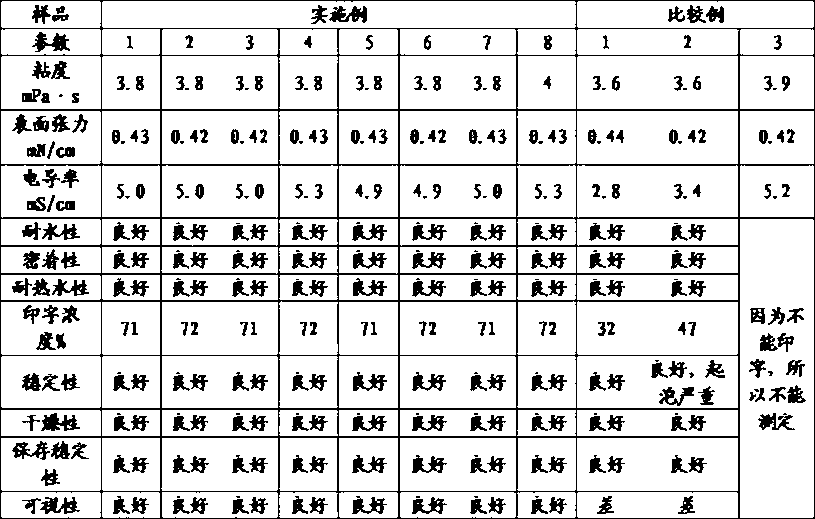

Examples

Embodiment 1

[0029] (a) Preparation of hydroxypropyl cellulose solution: 0.1 kg of hydroxypropyl cellulose and 99.9 kg of water were continuously stirred for 3 hours to obtain a hydroxypropyl cellulose solution;

[0030] (b) Preparation of ink lubricant: Stir and heat 85kg of polydimethylsiloxane and 15kg of silicon dioxide at 150°C for 1 hour to obtain a pasty ink lubricant;

[0031] (c) Emulsified ink lubricant and dispersant: Mix and stir 0.01kg of the above-mentioned ink lubricant, 0.0033kg of sorbitan fatty acid ester, 0.0033kg of glycerin fatty acid ester, 0.0033kg of sucrose fatty acid ester and 99.98kg of water for 30 minutes , adding 10 times the volume of water to dilute to obtain an emulsion;

[0032] (d) Preparation of ink: In a stainless steel container, stir and dissolve 3kg of sodium ferric chlorophyllin and 77kg of water, then add 10kg of the hydroxypropyl cellulose solution prepared in step (a), mix well and add the emulsion prepared in step (c) 10kg, continue to stir eve...

Embodiment 2

[0034] (a) Preparation of hydroxypropyl cellulose solution: 5 kg of hydroxypropyl cellulose and 95 kg of water were continuously stirred for 3 hours to obtain a hydroxypropyl cellulose solution;

[0035] (b) Preparation of ink lubricant: Stir and heat 90kg of polydimethylsiloxane and 10kg of silicon dioxide at 150°C for 1 hour to obtain a pasty ink lubricant;

[0036] (c) Emulsified ink lubricant and dispersant: Mix and stir 10kg of the above-mentioned ink lubricant, 2kg of sorbitan fatty acid ester, 1kg of glycerin fatty acid ester, 2kg of sucrose fatty acid ester and 85kg of water for 30 minutes, then add 10 times the volume diluted with water to obtain an emulsion;

[0037] (d) Preparation of ink: In a stainless steel container, stir and dissolve 6 kg of sodium copper chlorophyllin, 20 kg of propylene glycol and 54 kg of water, then add 10 kg of the hydroxypropyl cellulose solution prepared in step (a), mix well and add to step (c) to obtain 10kg of the emulsion, continue ...

Embodiment 3

[0039] (a) Preparation of hydroxypropyl cellulose solution: 0.5 kg of hydroxypropyl cellulose and 99.5 kg of water were continuously stirred for 3 hours to obtain a hydroxypropyl cellulose solution;

[0040] (b) Preparation of ink lubricant: Stir and heat 86kg of polydimethylsiloxane and 14kg of silicon dioxide at 150°C for 1 hour to obtain a pasty ink lubricant;

[0041](c) Emulsified ink lubricant and dispersant: Mix and stir 0.5kg of the above-mentioned ink lubricant, 0.03kg of sorbitan fatty acid ester, 0.04kg of glycerin fatty acid ester, 0.05kg of sucrose fatty acid ester and 99.4kg of water for 30 minutes , adding 10 times the volume of water to dilute to obtain an emulsion;

[0042] (d) Prepare ink: In a stainless steel container, stir and dissolve water-soluble annatto pigment 2kg, chlorophyll 2kg, propylene glycol 10kg and water 66kg, then add 10kg of hydroxypropyl cellulose solution prepared in step (a), mix well and add Take 10kg of the emulsion prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com