Operation device

An operating device and operating surface technology, applied in mechanical control devices, instruments, sliding contact resistors, etc., can solve the problems of damaged operating touch, wrong operation, easy bending and deformation, and achieve good operability and continuous smooth operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

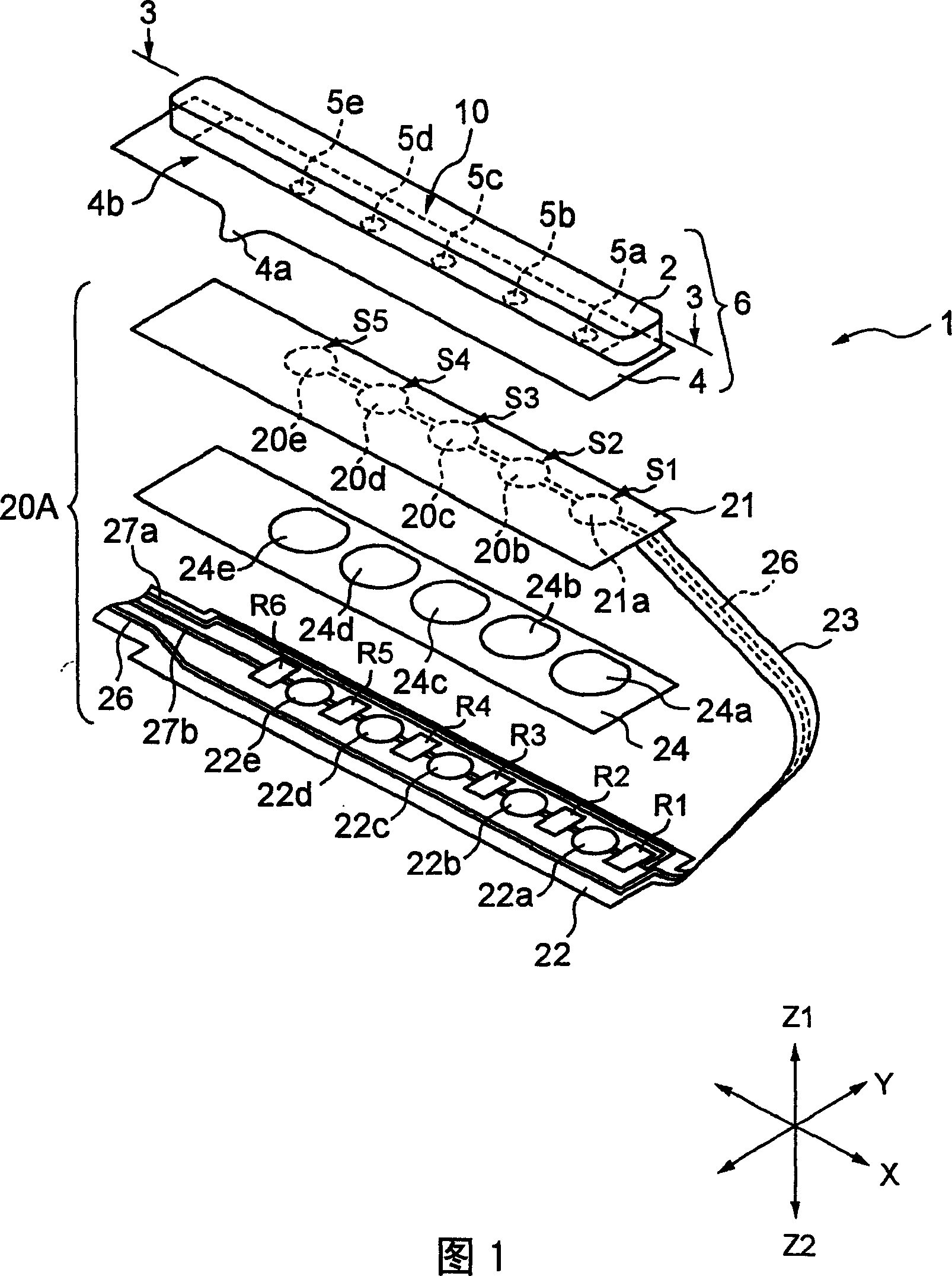

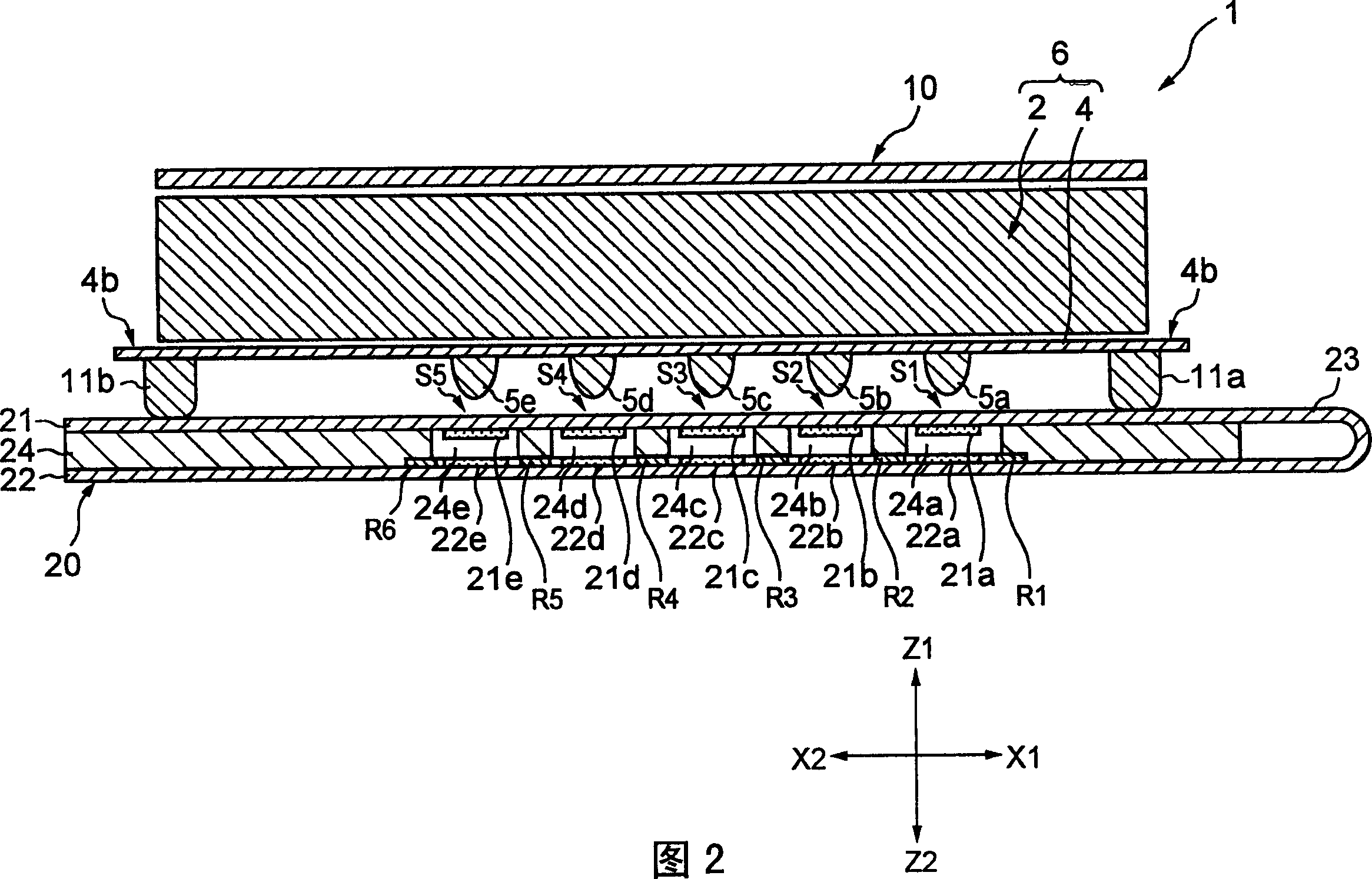

[0051] Next, as Example 1, the specific structure of the upper sheet 21 and the lower sheet 22 constituting the detection means 20A will be described.

[0052] As shown in FIG. 1, the first conductive portions 21a to 22e of the upper sheet 21 are connected in series with wires, and the lead pattern 26 is connected to 21a of the first conductive portion at the tip. The above-mentioned drawing pattern 26 is drawn to the outside of the detection mechanism 20A through the above-mentioned flexible sheet 23 and the lower side sheet 22.

[0053] Resistors R1, R2, R3, R4, R5, and R6 are printed on both ends of the second conductive portions 22a-22e provided on the lower sheet 22, respectively. The number of the resistors R1 to R6 is one more than the number of the switch parts S1 to S5. Thus, in accordance with the resistor R1, the second conductive portion 22a, the resistor R2, the second conductive portion 22b, the resistor R3, the second conductive portion 22c, the resistor R4, the sec...

Embodiment 2

[0079] Figure 5 It is a perspective view showing the detection mechanism 20B of the second embodiment of the present invention. among them, Figure 5 The spacer is omitted in the.

[0080] Figure 5 The detection mechanism 20B shown is different in that a band-shaped resistor 22B extending in the X direction in the figure is formed on the lower sheet (second sheet) 22. The strip resistor 22B described above is a resistor whose resistance value changes in proportion to the length in the X direction.

[0081] In the second embodiment, the switch parts S1, S2, S3, S4, and S5 are formed between the strip resistor 22B and the first conductive parts 21a to 21e, respectively.

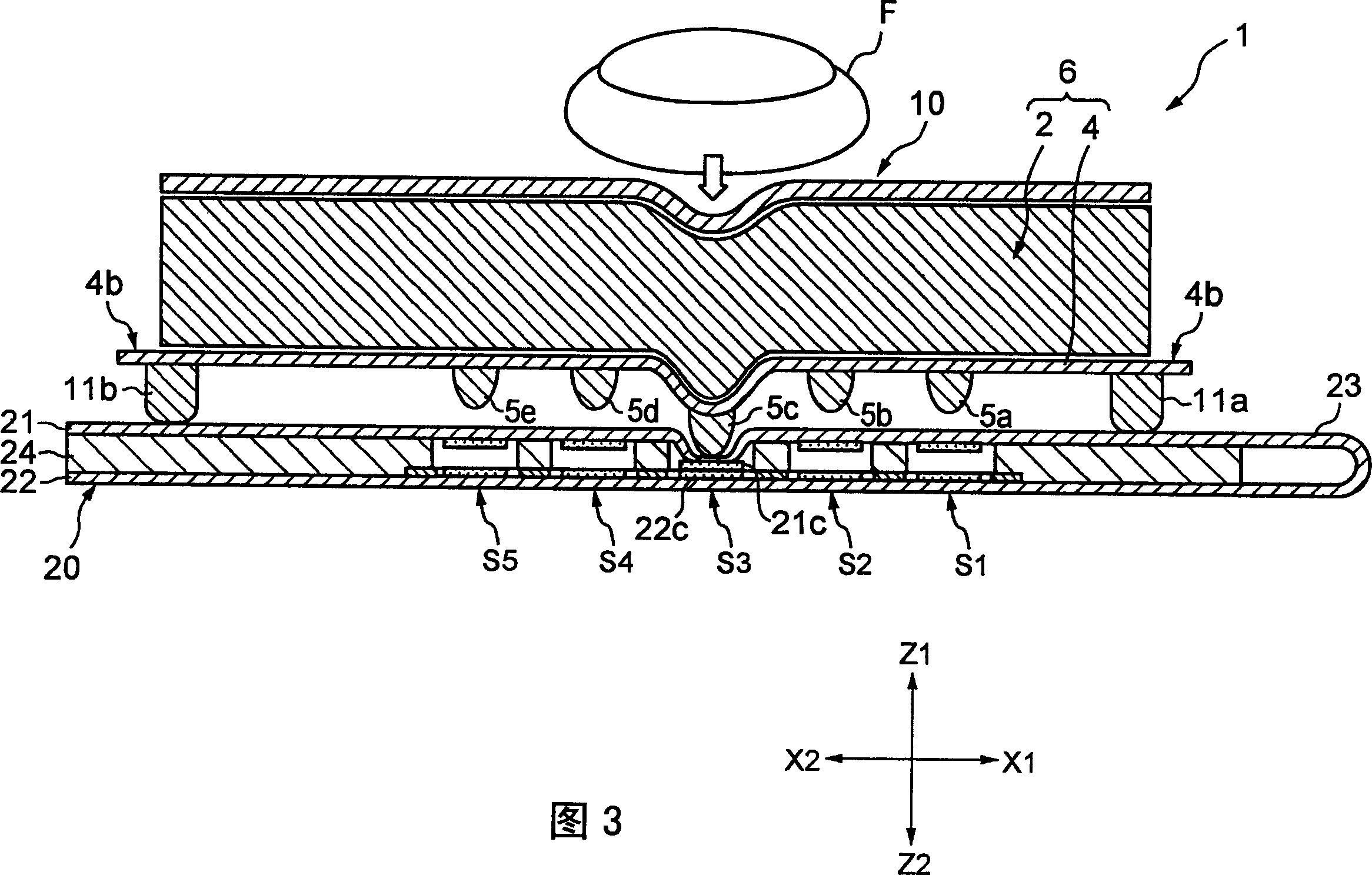

[0082] Even when using Figure 5 In the operating device of the detection mechanism 20B shown, if the finger F is lightly pressed in the Z2 direction while being pressed against any one of the switch parts S1 to S5, the reinforcing member 4 is bent and deformed, and the protrusions are also pressed in the Z2 dir...

Embodiment 3

[0090] Figure 6 Is a perspective view showing the detection mechanism 20C of the third embodiment of the present invention, Figure 7 It is an equivalent circuit diagram showing the circuit configuration equivalent to the operation device adopted in the third embodiment. Table 3 shows the output current I corresponding to the operation of each switch section.

[0091] Figure 6 The illustrated embodiment 3 has substantially the same structure as the foregoing embodiment 1 shown in FIG. 1, but the difference lies in the structure that the lead pattern 27b and the resistor R6 are removed from the lower sheet 22 described above.

[0092] In Example 3, each of the first conductive portions 21a to 21e and the second conductive portions 22a to 22 constitutes the switch portions S1, S2, S3, S4, and S5, respectively. Furthermore, the lead pattern 27a of the detection mechanism 20C is connected to the power supply Vcc, and the lead pattern 26 is grounded, and the detection mechanism 20C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com