Precise determination method of extreme working conditions of external heat flow of orbit of remote sensor in whole life cycle

A technology with full life cycle and extreme working conditions, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., to achieve the effect of improving calculation accuracy and comprehensive analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

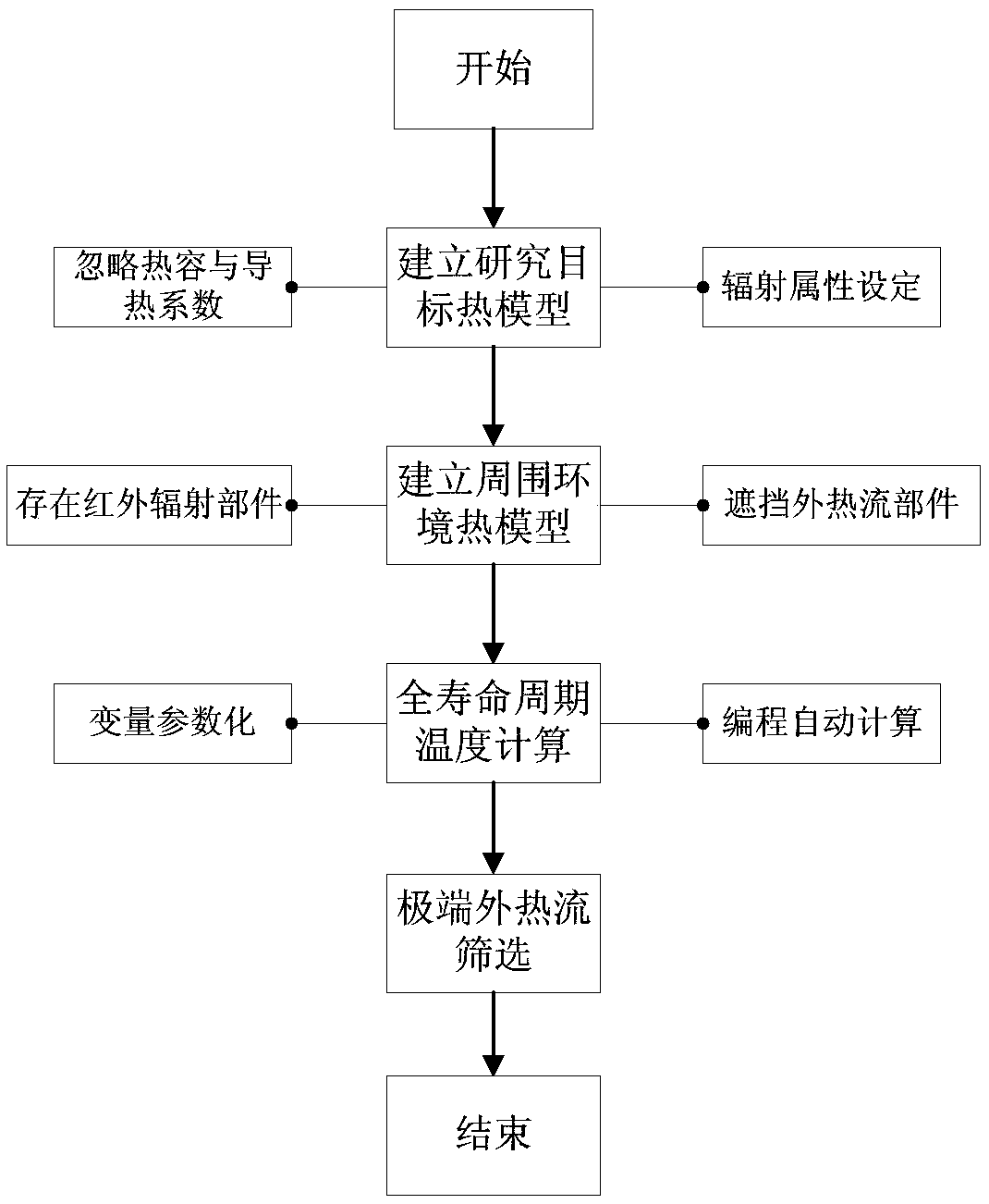

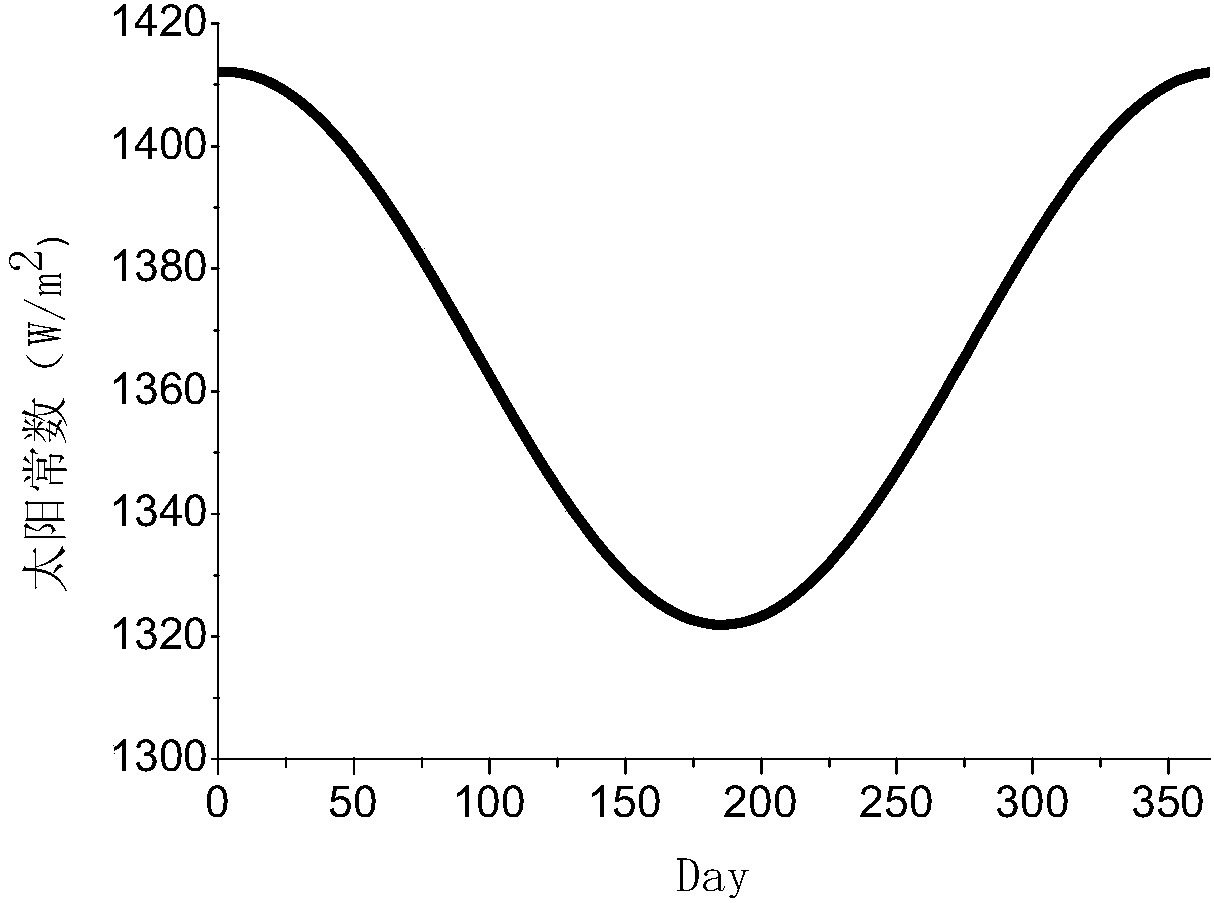

[0029] The invention considers that the temperature stability of the optical lens is very critical to the imaging quality of the remote sensor, and takes the extreme working condition of the outer heat flow of the optical lens as the extreme working condition of the outer heat flow of the orbit of the remote sensor in its full life cycle, and proposes a full life cycle orbit of the remote sensor. Precise screening method for extreme external heat flow conditions. like figure 1 As shown, the specific steps of the method are:

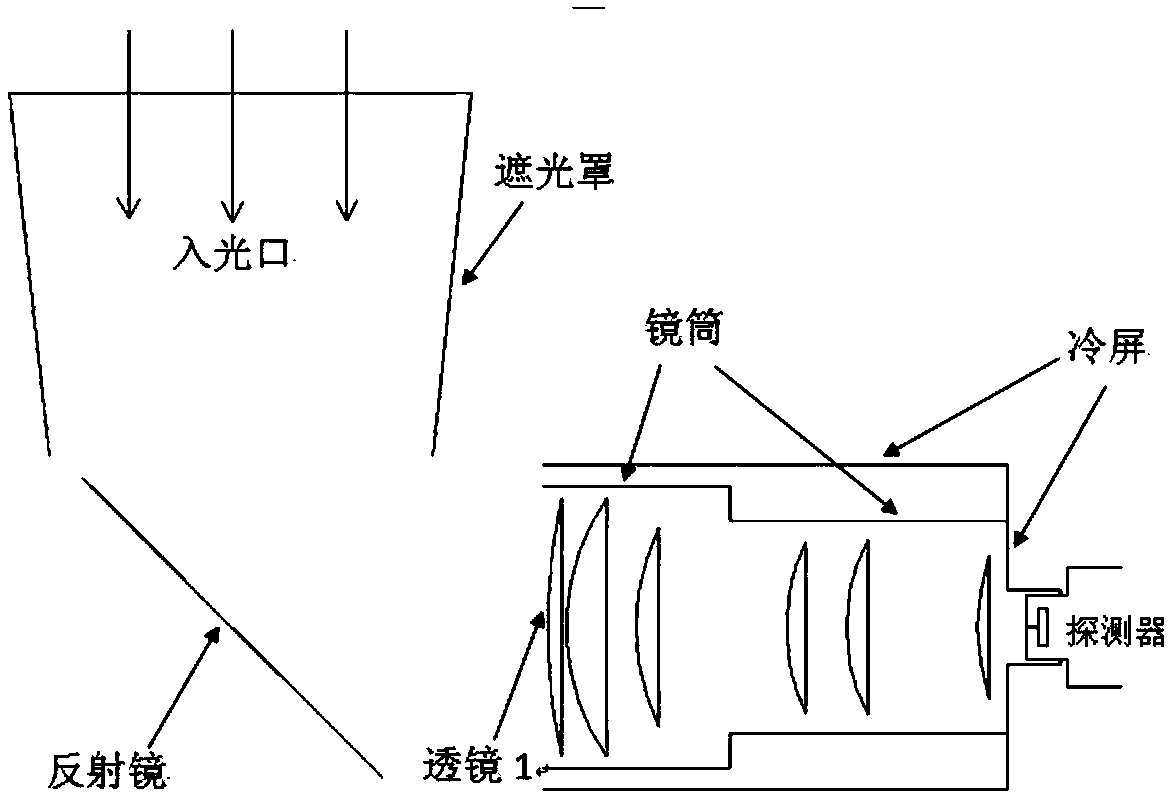

[0030] (1) Select the components on the satellite that block the heat flow outside the light entrance of the remote sensor, and the components that have radiation heat exchange between the remote sensor and the optical lens. According to the geometric position relationship and contact relationship between the selected com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com