Method for analyzing aluminum alloy oxidization solution

An oxidation solution and analysis method technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of large error in analysis results, complicated operations, and difficult judgment of the end point. , to achieve the effect of high accuracy, simple and effective analysis method, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 The analysis results of the original analysis method to the triacid oxidation system

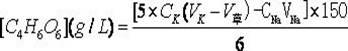

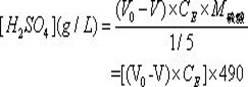

[0034] (1) Analysis of sulfuric acid content

[0035] In the original analysis method, chrome black T was used as the indicator, and the titration with zinc sulfate standard solution until the solution was reddish-purple was the end point. Calculation formula

[0036]

[0037] In the formula:

[0038] C E —concentration of EDTA standard solution;

[0039] C Zn - concentration of zinc sulfate standard solution;

[0040] V Zn - the number of milliliters of zinc sulfate standard solution consumed;

[0041] 50 - the number of milliliters of EDTA standard solution consumed;

[0042]98 - M sulfuric acid.

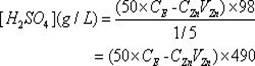

[0043] (2) Analysis of oxalic acid content

[0044] In the original analysis method, phenolphthalein was used as indicator, and the titration with zinc sulfate standard solution until the solution was reddish-purple was the end point. The calculation formula is th...

Embodiment 2

[0049] Embodiment 2 According to the analysis result of the present invention to the triacid oxidation system

[0050] Analysis method of the present invention to the analysis result of three acid oxidation system

[0051]

Embodiment 3

[0052] Example 3 Analytical results of the adjusted tri-acid oxidation working solution according to the present invention

[0053] If the three-acid oxidation working solution is supplemented with a sulfuric acid concentration of 125.80 g / L, an oxalic acid concentration of 20 g / L, and a tartaric acid concentration of 25 g / L, the supplementary formula is as follows:

[0054] C 0 V 0 =CV+m x

[0055] In the formula:

[0056] C 0 ——Concentration of working solution to be prepared

[0057] V 0 ——The volume of the working solution planned to be prepared

[0058] C - the concentration of a certain component of the bath solution after a period of use

[0059] V——The volume of the tank solution after a period of use

[0060] m x - the mass of a certain component that needs to be added

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com