Method for measuring ethanolamine substance residual quantity in cosmetics

A technology for ethanolamines and cosmetics, which is applied in the field of cosmetics detection, can solve the problems of high detection limit of monoethanolamine, high analysis precision, fast work efficiency, etc., and achieves the effects of high sensitivity, high extraction recovery rate and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

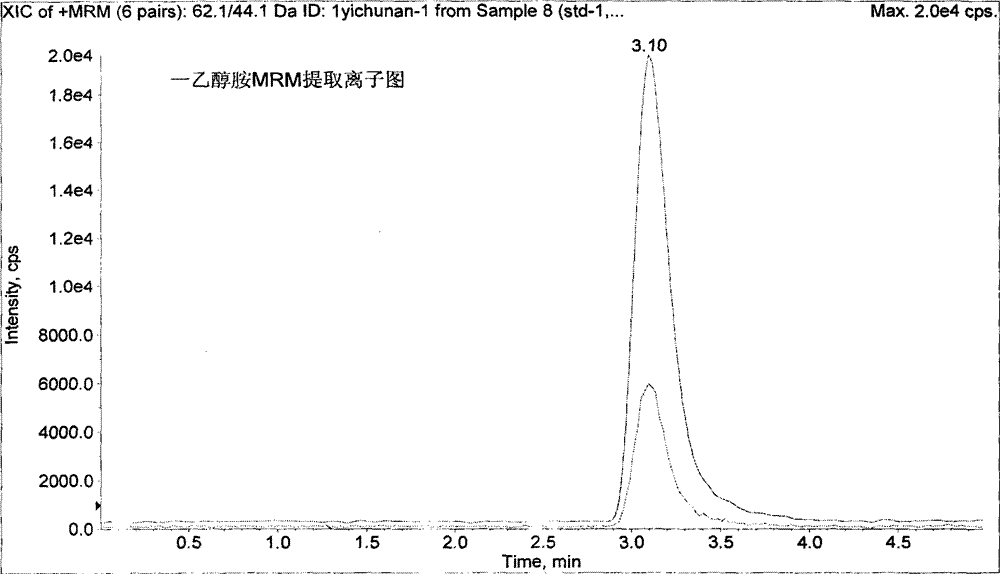

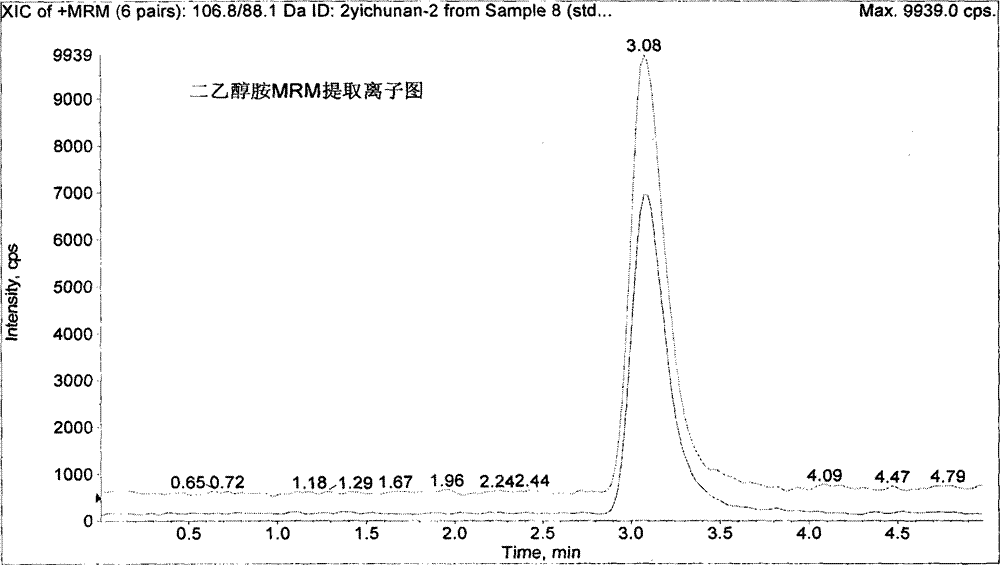

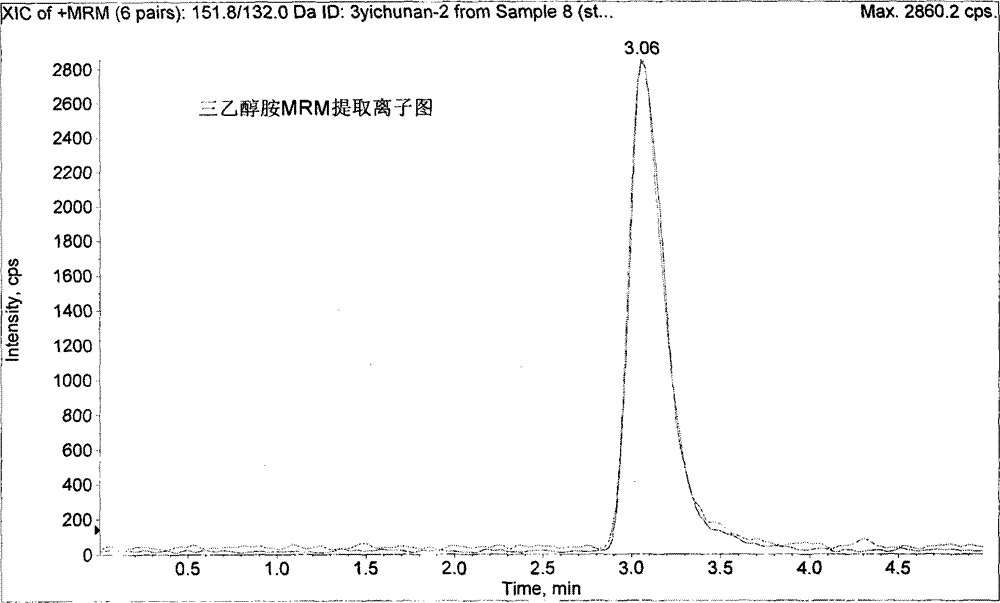

[0037] Using water as a solvent, prepare stock solutions of monoethanolamine, diethanolamine, and triethanolamine respectively according to Table 1, and prepare mixed standard solutions, and perform LC-MS / MS analysis and detection according to the above experimental conditions. figure 1 , figure 2 , image 3 The chromatograms in the figure are the extracted ion mass spectrograms of the three ethanolamines detected, respectively. The ordinate in the mass spectrogram represents the relative instrument corresponding value of the peak, and the abscissa is the retention time, and the unit is min. Make a graph with peak area to concentration, according to the measurement result of standard solution, set up the standard curve of three kinds of ethanolamines, such as Figure 4 As shown in the standard curve diagram, the abscissa in the standard curve diagram is the concentration of the target substance, and the ordinate is the response value of the liquid chromatography peak area. ...

Embodiment 2

[0048] Add the standard test solution among the example 1 with the emollient cream sample extraction solution of 0.2% (v / v) formic acid ethanol, wherein the concentration that contains standard solution is monoethanolamine, diethanolamine and triethanolamine is 1.0 μ g / mL, the test system For the precision, the measurement was repeated 6 times, and the analysis results are shown in Table 4. The relative standard deviation RSD of the repeated test was 2.2-3.4%, indicating that the stability of the instrument system was very good.

[0049] Table 4 Precision Test

[0050]

Embodiment 3

[0052] Blank test: Accurately weigh 2.00g of body cream samples into three 50mL plastic centrifuge tubes, add 20mL of 0.2% (v / v) formic acid ethanol solution into 50mL centrifuge tubes, first vortex and mix for 1min, then put into ultrasonic In the instrument, sonicate at room temperature for 5 minutes. Then refrigerate and centrifuge at 8000r / min at 4°C for 5min. After passing through a 0.22 μm filter membrane, it was tested by high-performance liquid chromatography-tandem mass spectrometry. Make three parallel samples of this sample, such as Figure 5 As shown, the target substance was not detected in the sample.

[0053] The recovery rate of standard addition of table 5 moisturizer cream sample

[0054]

[0055]

[0056] Spike recovery rate test: Accurately weigh 2.00g of moisturizer in parallel into three 50mL plastic centrifuge tubes, numbered Spike A, Spike B, and Spike C. Carry out the standard addition experiment of 3 concentration gradients to this sample, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com