Dilution extraction process capable of improving copper recovery rate

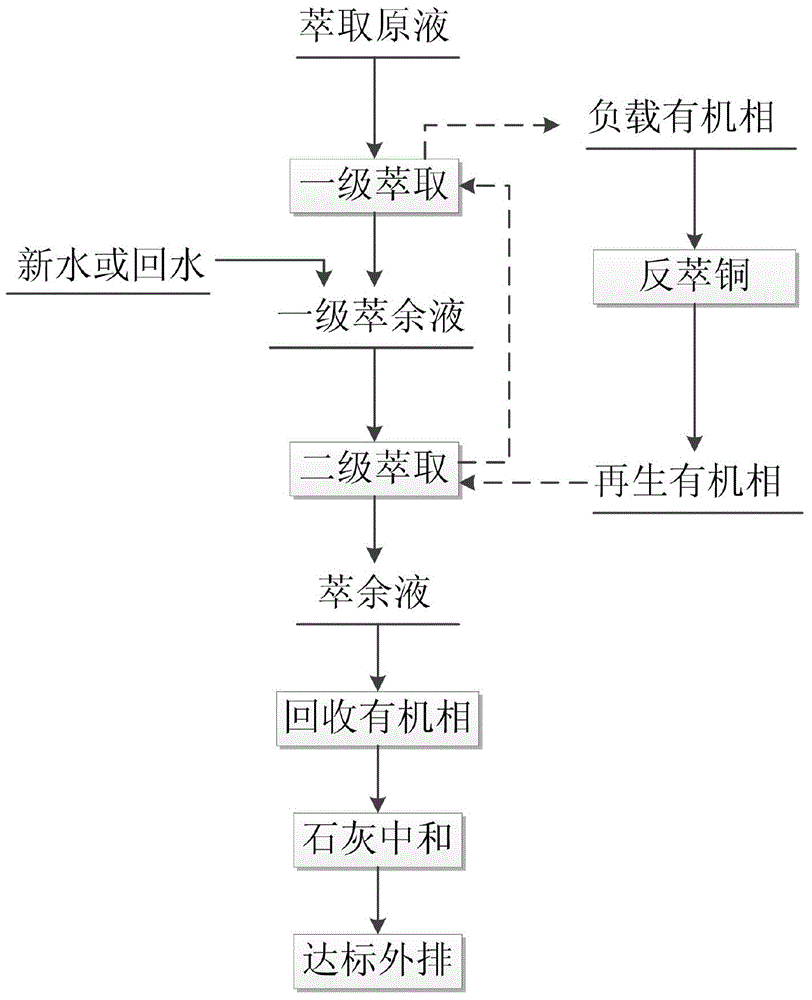

A recovery and extraction technology, which is applied in the dilution extraction process to improve copper recovery, and the dilution extraction process field, can solve the problems of increased three-phase volume in the extraction system and unfavorable oil-water mixed phase separation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

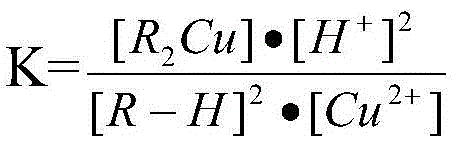

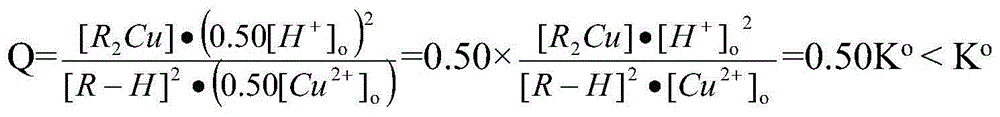

[0056] Copper-containing extraction stock solution (Cu 2g / L, H 2 SO 4 8g / L), using a two-stage countercurrent extraction process to recover copper, adding 30% fresh water to the first-stage raffinate to dilute, and then carrying out the second-stage extraction, the raffinate copper concentration is reduced to 50mg / L , copper extraction rate 96.75%.

Embodiment 2

[0058] Copper-containing extraction stock solution (Cu 2g / L, H 2 SO 4 8g / L), using a two-stage countercurrent extraction process to recover copper, adding 50% fresh water to the first-stage raffinate to dilute, and then carrying out the second-stage extraction, the raffinate copper concentration is reduced to 30mg / L , copper extraction rate 97.75%.

Embodiment 3

[0060] Copper-containing extraction stock solution (Cu 2g / L, H 2 SO 4 8g / L), using a two-stage countercurrent extraction process to recover copper, the first-stage raffinate is diluted with new water with 100% raffinate volume, and then the second-stage extraction is carried out, and the copper concentration of the raffinate is reduced to 20mg / L , copper extraction rate 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com