Catalyst screening method during preparation of sulphuric acid

A catalyst and catalyst particle technology, applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems affecting the conversion rate of sulfuric acid conversion process, the total sulfur utilization rate of system output, increasing the frequency of device maintenance, and poor catalyst screening effect, etc., to achieve Promote clean and civilized production, reduce equipment energy consumption, and protect human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

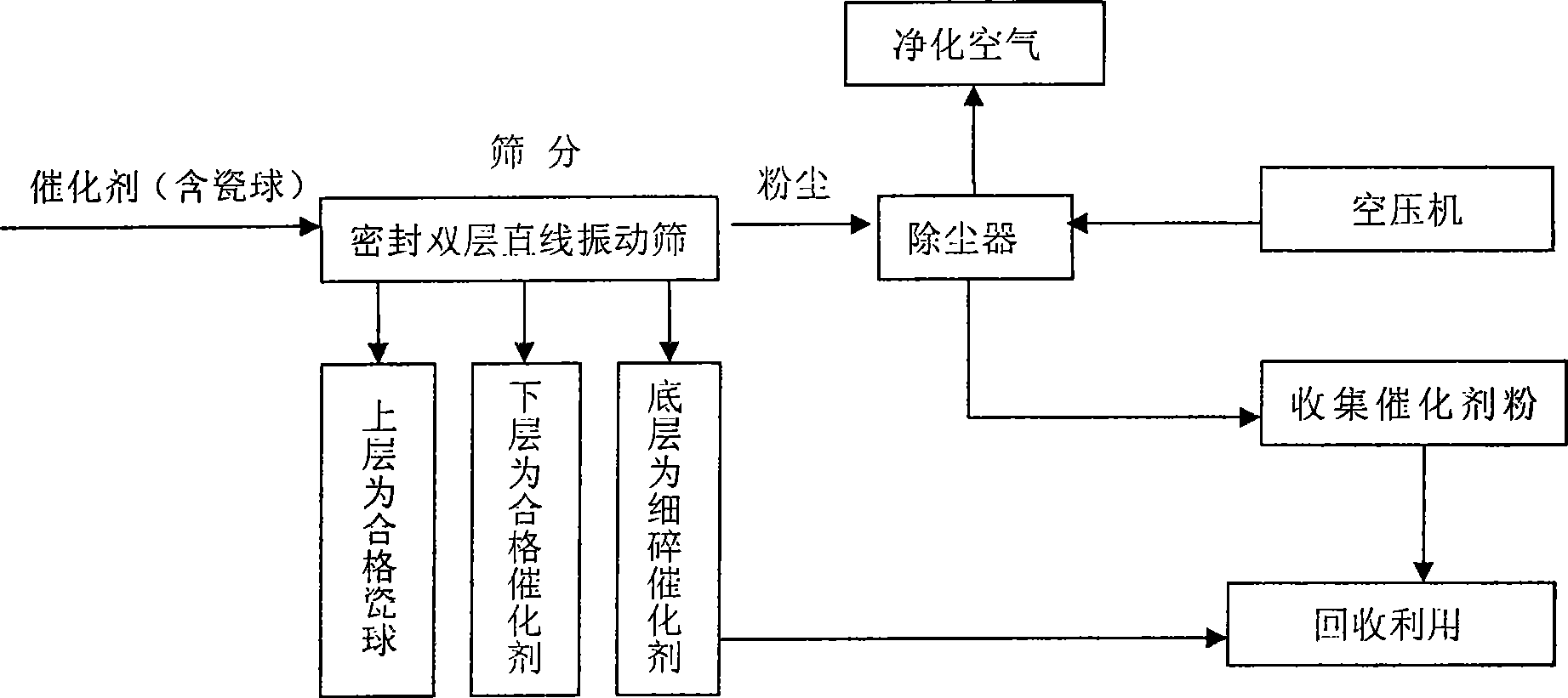

[0020] Such as image 3 As shown, the catalyst to be screened in the converter of the sulfuric acid plant enters the sealed vibrating screen together with the ceramic balls for grading and screening. After sieving, the upper layer is ceramic balls, the lower layer is qualified catalyst, and the bottom layer is finely divided catalyst particles. The dust generated during the screening process directly passes through the dust collection pipe on the top of the vibrating screen, and is sucked into the dust collector by the fan, filtered and removed, and the clean air is discharged directly. The catalyst dust collected by the dust collector and the finely divided catalyst particles at the bottom of the sealed vibrating screen are bagged separately for recycling.

Embodiment 2

[0022] Repeat Example 1, with the following differences: the dust remover adopted is a pulse-jet stand-alone bag filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com