Nesting device used in nesting process for high-vacuum multilayer heat-insulating LNG tank for ship

A multi-layer thermal insulation and high vacuum technology, which is applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of unfavorable quantitative control, deviation from the shell 2, accurate observation and evaluation, etc. There is a risk of scratching, the effect of continuous and smooth operation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

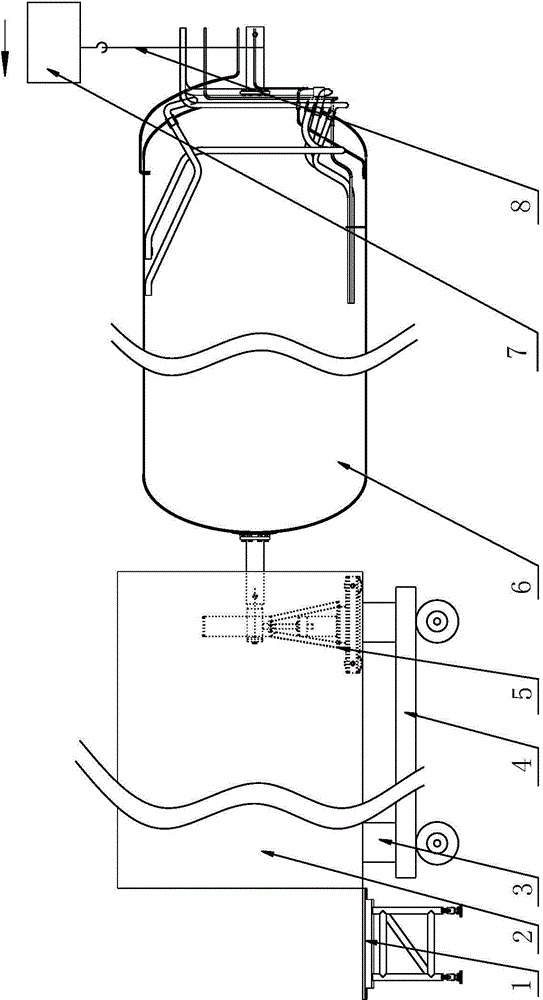

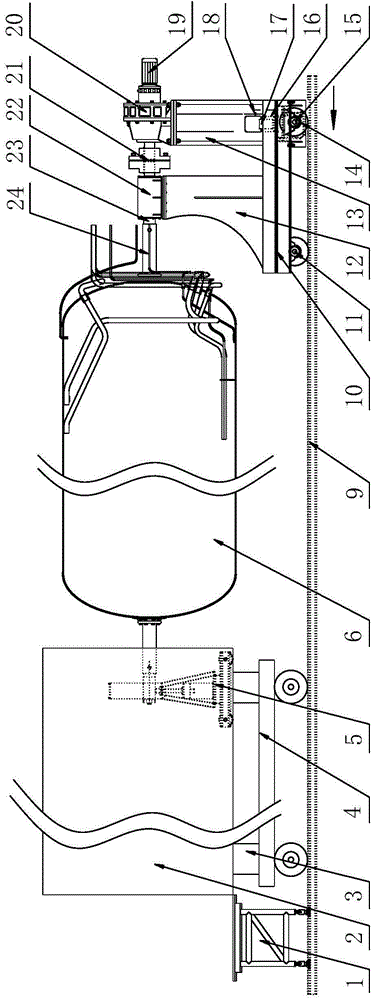

[0025] see figure 2 As shown, the embodiment of the present invention provides a fitting device used in the fitting process of a marine high-vacuum multi-layer heat-insulated LNG gas tank. There is a guiding trolley 5, and the fitting device includes an adapter frame 1, a flatbed cart 4, a tractor with its own power, and a track 9. The rail 9 is located on the ground of the factory building, and the adapter frame 1 is located on one side of the flatbed cart 4. The powered tractor is located on the other side of the flatbed truck 4, and the flatbed truck 4 is fixed with a rolling tire frame 3, and the shell 2 of the marine high-vacuum multi-layer heat-insulated LNG gas tank is fixed on the rolling tire frame 3, and the guide trolley 5 in the shell 2 is connected to the One end of the inner bag 6 is connected, and the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com