High-voltage power source device for electric dust collector

A high-voltage power supply and dust collector technology, applied in power supply technology, electrostatic separation, etc., can solve the problems of reduced dust collection efficiency, failure to consider the fire safety of dust collection objects, and inability to ensure the suspension time, so as to prevent the generation of discharge sparks, The effect of suppressing the generation of continuous sparks and ensuring ignition safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

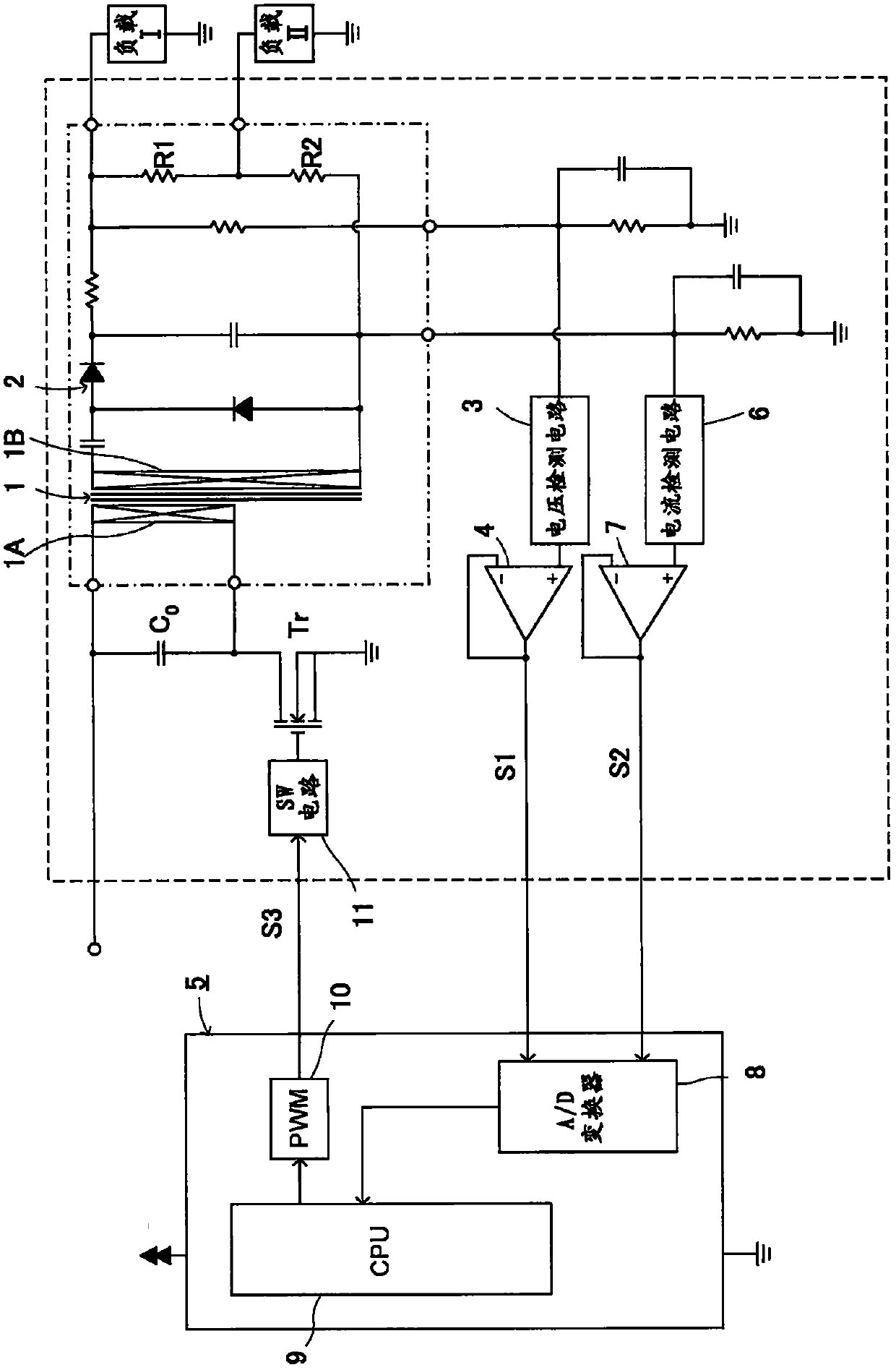

Method used

Image

Examples

no. 1 example

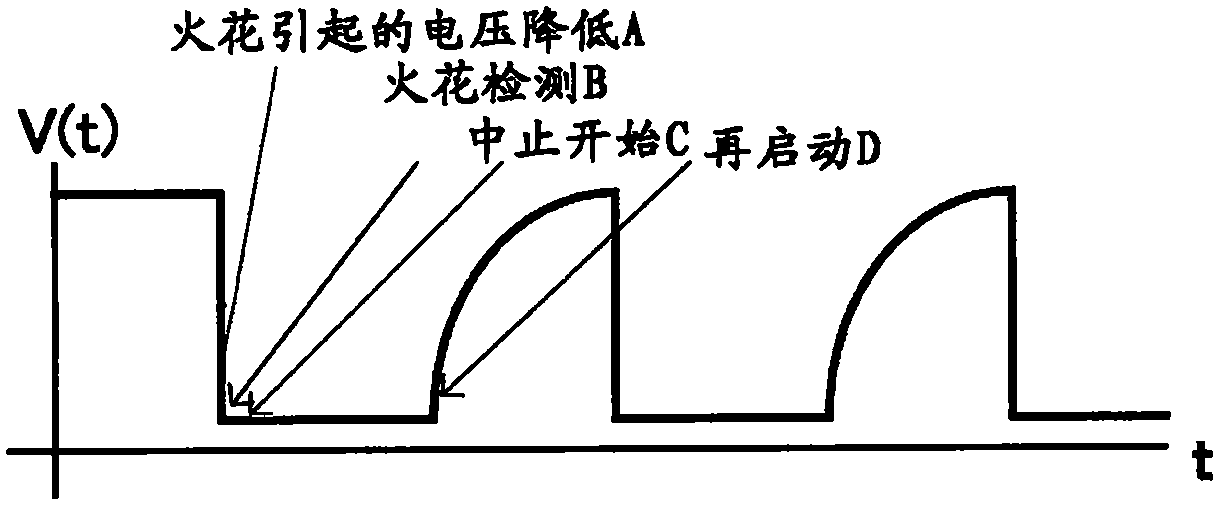

[0053] This example is control aimed at ensuring safety by stopping time. Specifically, as figure 2 As shown, when a spark is generated, the load is momentarily short-circuited, and a voltage drop A caused by the spark occurs. As a result, the output voltage V becomes substantially zero. The drop of the output voltage V causes the spark detection B to be performed by the voltage detection circuit 3, and the start C mode is stopped. As a result, the discharge was temporarily suspended, but due to the suspension, the high-voltage power supply device for an electric dust collector released from the load short-circuit recovers. If the cause of the discharge spark is not removed, it is easy to switch to a continuous discharge spark. However, even if a discharge spark occurs, if it occurs once, it will not threaten safety, and there is no need to stop the operation. Therefore, in order not to switch to continuous discharge, even if it occurs once, the spark should be detected im...

no. 2 example

[0057] The purpose of this example is spark suppression in constant current mode. When the generation of the discharge spark does not end in the process described in the first embodiment, the output characteristic of the power supply is switched in order to suppress the generation of the discharge spark and continue the operation of the dust collector.

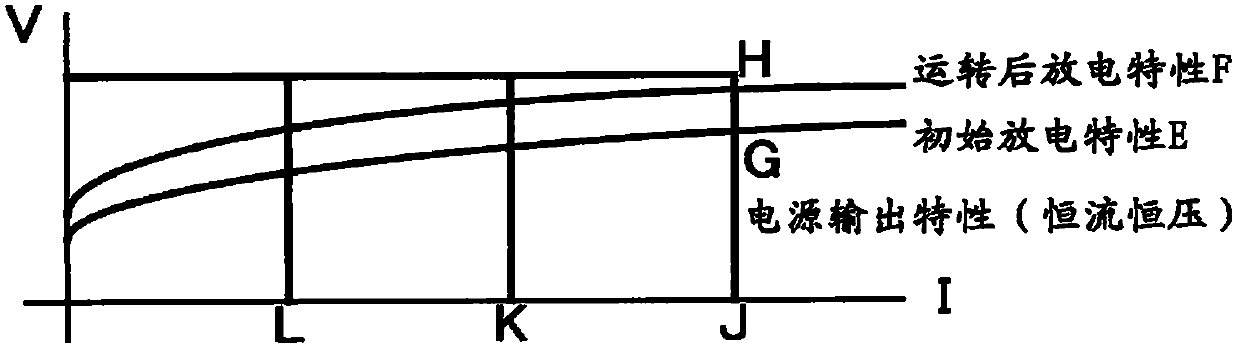

[0058] image 3 It is a graph showing an example of constant current / constant voltage operation, that is, box-type constant voltage / constant current output characteristics, in which initial discharge characteristics E and post-operation discharge characteristics F are superimposed. Initially, the operation starts from operating point G, but due to contamination of electrodes, etc., in order to continue constant current / constant voltage operation, it switches to operating point H, and gradually reduces the output current I through the intersection of constant current characteristics and constant voltage characteristics, thereby...

no. 3 example

[0073] In the above-mentioned second embodiment, the manner of gradually reducing the current of the constant current / constant current control has been described, but the same method can also be described in detail in the spark suppression in the constant voltage mode. That is, if Figure 4 As shown, it is also possible to reduce the constant voltage characteristic M to the constant voltage characteristic N without changing the constant current characteristic, and further decrease from the constant voltage characteristic N to the constant voltage characteristic O stepwise.

[0074] In spite of the processing of Example 1, if the number of discharge sparks generated within a certain period exceeds a predetermined threshold, the discharge sparks can be reliably stopped by changing the value of the constant voltage on the software, but the discharge current value The range of change is relatively large, therefore, compared with the second embodiment, it is inferior in terms of en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com