Ore-dressing method for recovering nickel from ore-washing slurry of copper-nickel sulfide ore

A copper-nickel sulfide and mineral processing technology, which is applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of low metal recovery rate, uneven particle size, low pulp concentration, etc., and achieves high comprehensive recovery rate, high The effect of low production cost and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below using the accompanying drawings and specific examples.

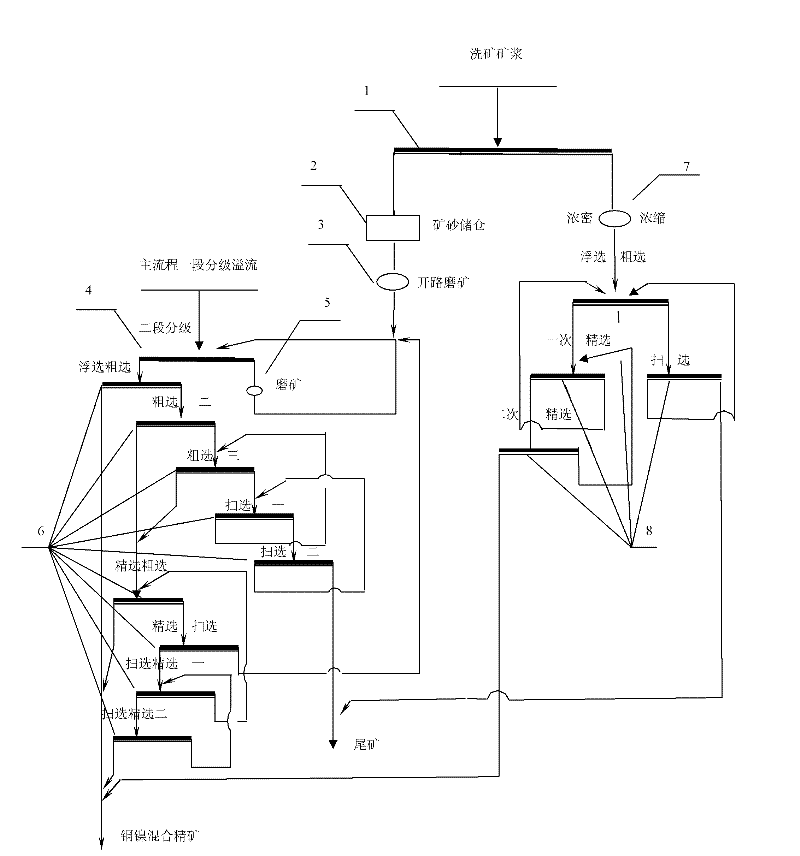

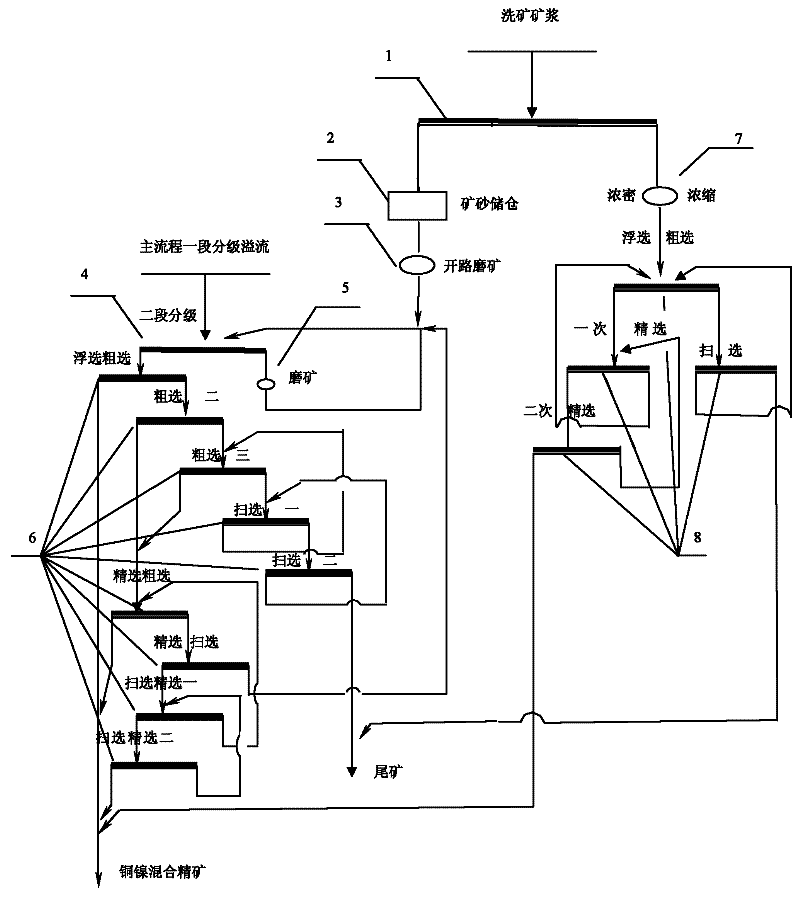

[0020] refer to figure 1 , a kind of beneficiation method that recovers metal from non-ferrous metal washing ore pulp comprises the following steps in sequence:

[0021] Ore washing pulp re-election process 1, through the φ219mm pipeline, the ore washing pulp in the crushing workshop is transported to 11 BL-1500B spiral chutes by gravity, and the nickel minerals in the ore washing pulp in the crushing workshop are classified according to density by using the spiral chute , carry out desliming and dehydration, so that the ore in the slurry is separated from the ore, and the obtained gravity concentrate is the ore product, the nickel grade is ≥ 1%, and the copper grade is ≥ 0.3%;

[0022] Ore storage and dehydration process 2, the ore fed in process 1 is naturally dehydrated and stored in the stacked ore storage bin, the purpose is to store a sufficient amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com