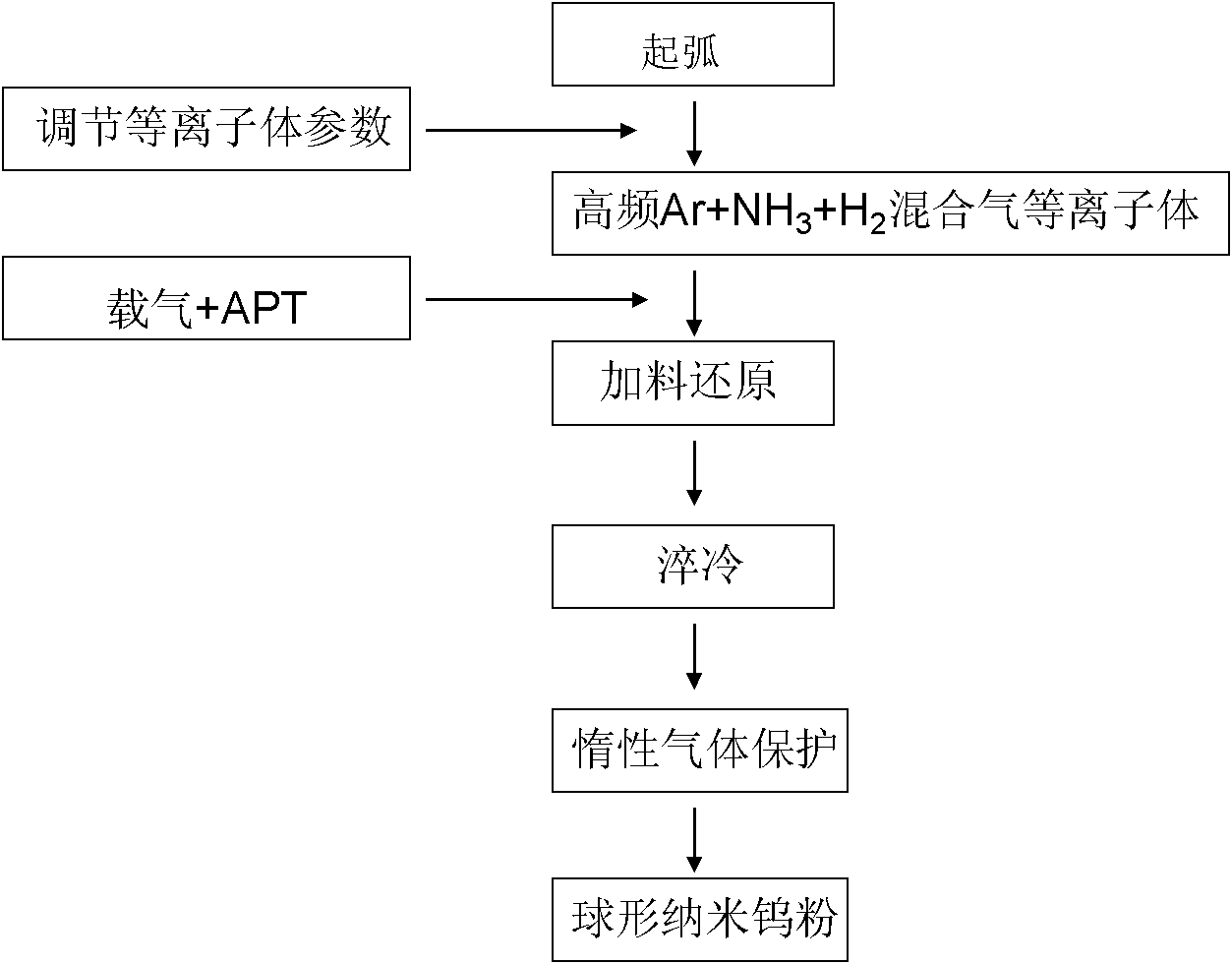

Method for preparing spherical nano tungsten powder

A nano-tungsten powder, spherical technology, applied in the field of powder metallurgy powder making, can solve the problems of arc extinguishing and plasma arc reduction, and achieve the effect of full cylinder, improved production efficiency and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

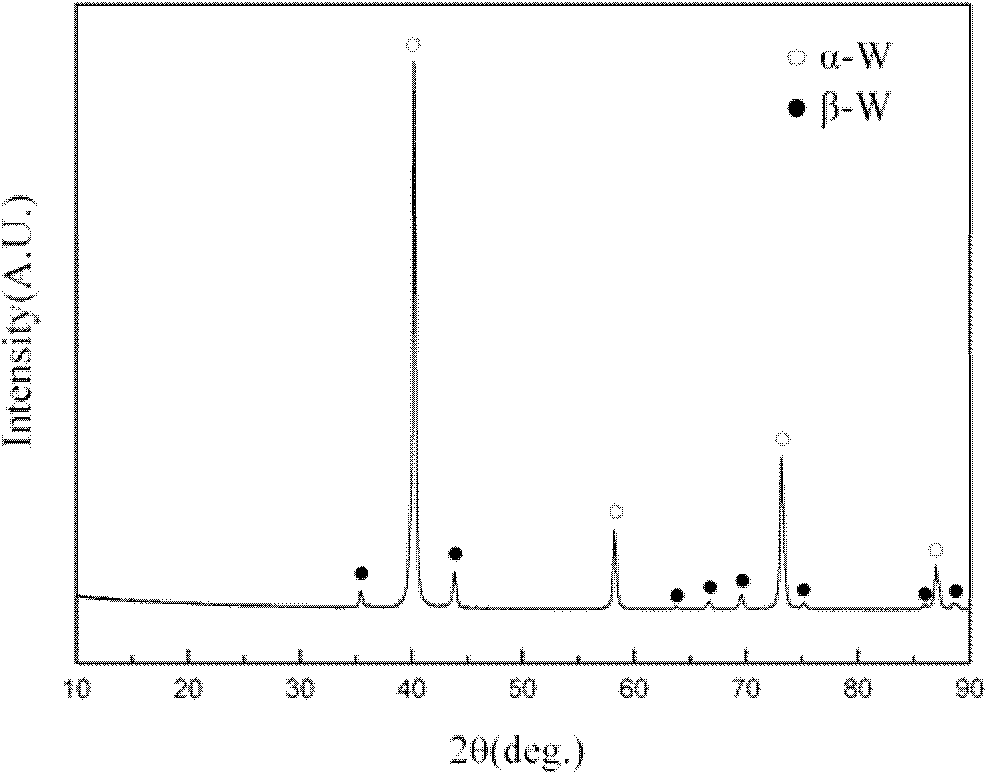

Embodiment 1

[0022] By adjusting the plasma parameters, the output power of the high-frequency machine is 30KW, both the middle gas and the side gas use Ar, and the flow rate of the middle gas is 1m 3 / h, the edge air flow is 4m 3 / h, H 2 The flow rate is 0.3m 3 / h, NH 3 The flow rate is 1.2m 3 / h, to establish a stable high frequency Ar+NH 3 +H 2 Mixed gas plasma, using NH 3 and H 2 As the carrier gas, the raw material APT is added to the plasma arc in stable operation. The particle size of APT is 10μm, and the feeding amount is 3g / min. The stainless steel casing of the cooling chamber is passed through reverse cooling water, and the upper part of the cooling chamber is cooled by tangential cooling through the ventilation flange. Gas, the cooling water inlet temperature is 10°C, the cooling gas is inert gas Ar, and the flow rate is 2m 3 / h. The reaction time is 2 hours. After the reduction, pass Ar for half an hour to protect the product. After the reactor is cooled, the material...

Embodiment 2

[0024] By adjusting the plasma parameters, the output power of the high-frequency machine is 33KW, both the middle gas and the edge gas use Ar, and the flow rate of the middle gas is 2m 3 / h, edge air flow is 5m 3 / h, H 2 The flow rate is 0.8m 3 / h, NH 3 The flow rate is 0.8m 3 / h, to establish a stable high frequency Ar+NH 3 +H 2 Mixed gas plasma, using NH 3 and H 2 As the carrier gas, the raw material APT is added to the plasma arc in stable operation. The particle size of APT is 100μm, and the feeding amount is 20g / min. The stainless steel casing of the cooling chamber is passed through reverse cooling water, and the upper part of the cooling chamber is cooled by tangential cooling through the ventilation flange. Gas, the cooling water inlet temperature is 15°C, the cooling gas is inert gas Ar, and the flow rate is 6m 3 / h. The reaction time was 3 hours, and the product was protected by passing Ar for half an hour after the reduction. After the reactor is cooled, ...

Embodiment 3

[0026] By adjusting the plasma parameters, the output power of the high-frequency machine is 35KW, both the middle gas and the edge gas use Ar, and the flow rate of the middle gas is 4m 3 / h, the edge air flow rate is 6m 3 / h, H 2 The flow rate is 1.2m 3 / h, NH 3 The flow rate is 0.3m 3 / h, to establish a stable high frequency Ar+NH 3 +H 2 Mixed gas plasma, using NH 3 and H 2 As the carrier gas, the raw material APT is added to the plasma arc in stable operation. The particle size of APT is 150μm, and the feeding amount is 50g / min. The stainless steel casing of the cooling chamber is passed through reverse cooling water, and the upper part of the cooling chamber is cooled by tangential cooling through the ventilation flange. Gas, the cooling water inlet temperature is 15°C, the cooling gas is inert gas Ar, and the flow rate is 8m 3 / h. After the reduction, pass Ar for half an hour to protect the product. After the reactor is cooled, the material is collected in the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com