Patents

Literature

117 results about "Plasma parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma parameters define various characteristics of a plasma, an electrically conductive collection of charged particles that responds collectively to electromagnetic forces. Plasma typically takes the form of neutral gas-like clouds or charged ion beams, but may also include dust and grains. The behaviour of such particle systems can be studied statistically.

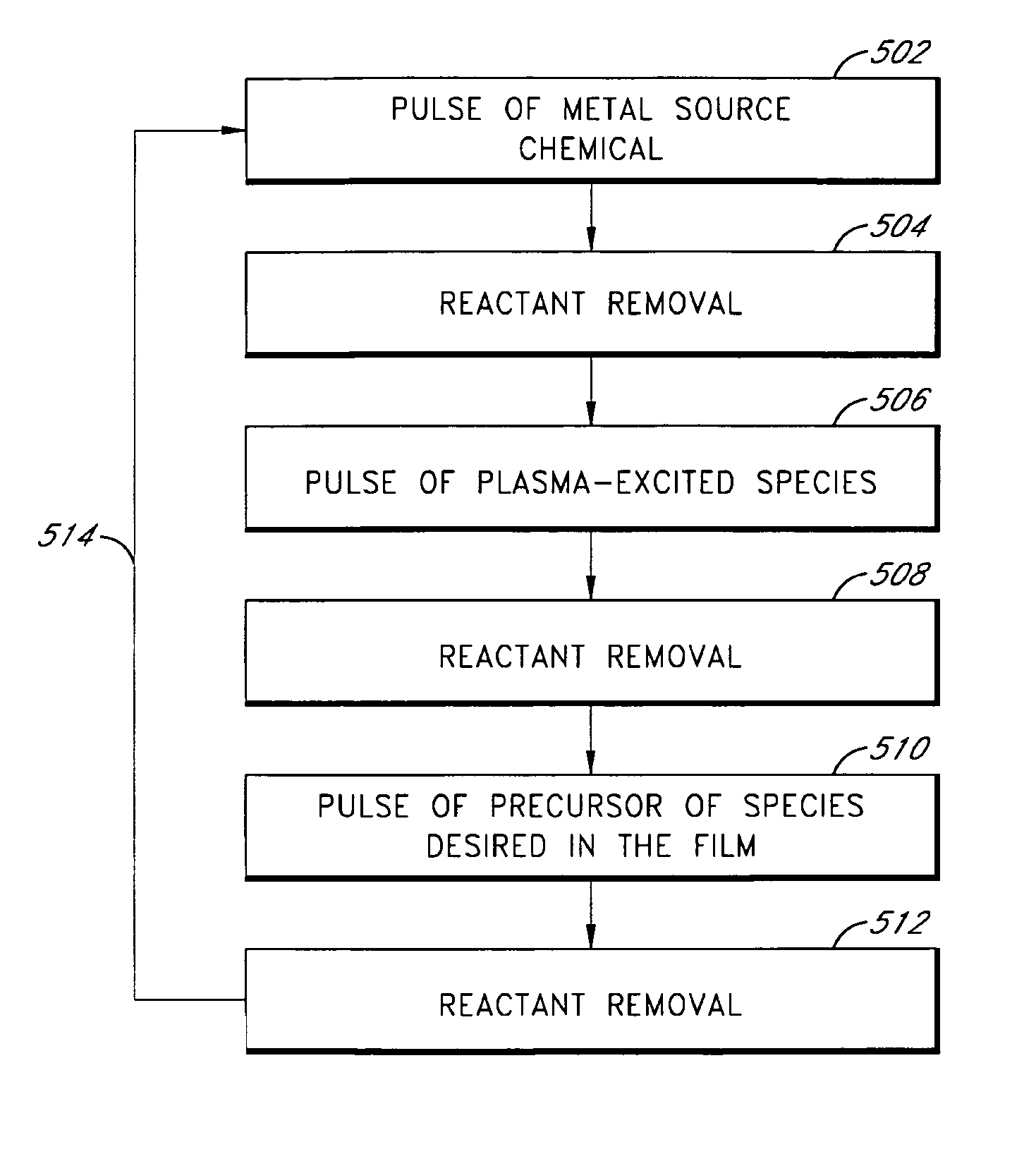

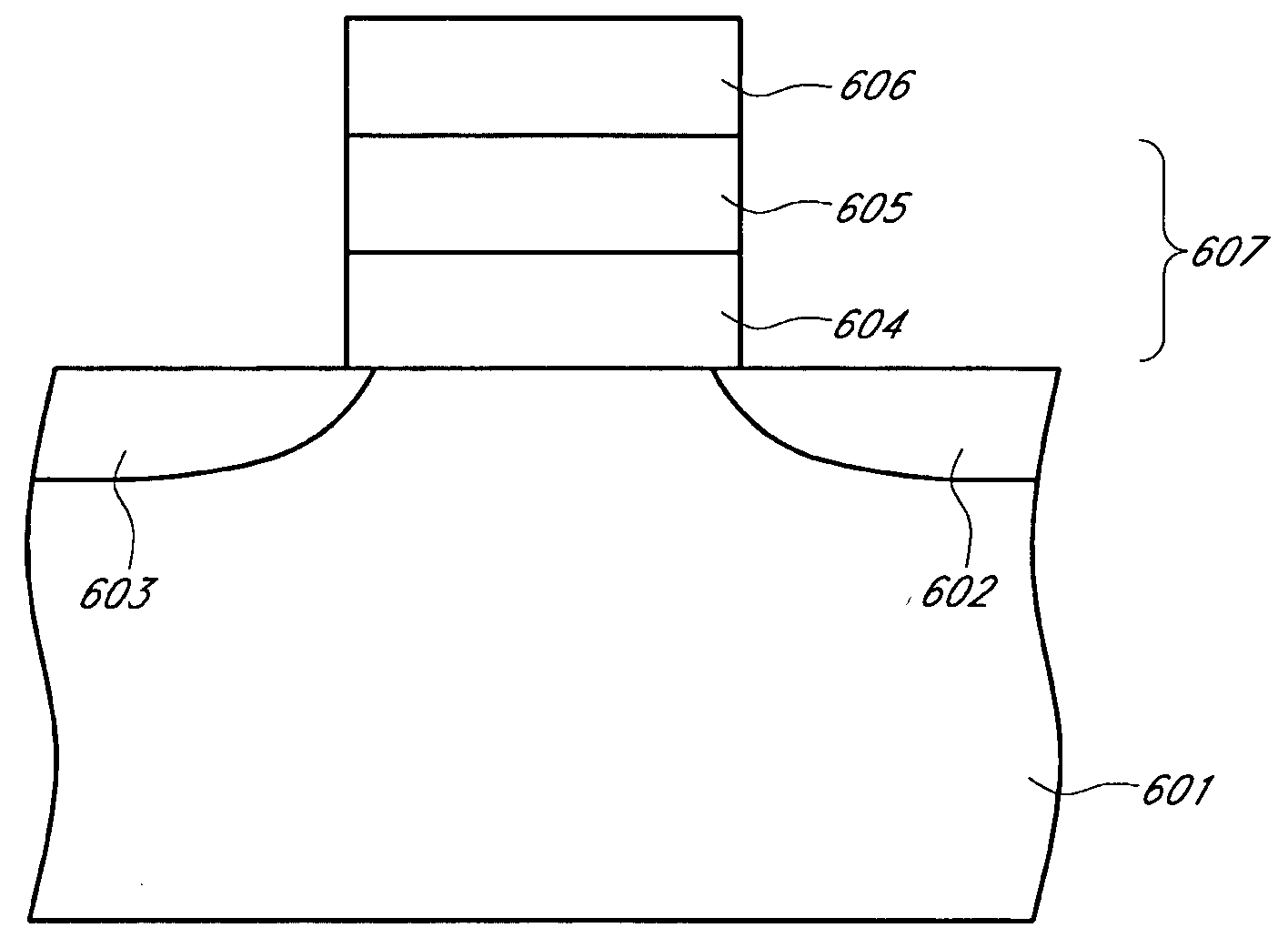

Controlled composition using plasma-enhanced atomic layer deposition

ActiveUS7727864B2Easily and accurately adjusted to a desired valueSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxidation stateWork function

Metallic-compound films are formed by plasma-enhanced atomic layer deposition (PEALD). According to preferred methods, film or thin film composition is controlled by selecting plasma parameters to tune the oxidation state of a metal (or plurality of metals) in the film. In some embodiments, plasma parameters are selected to achieve metal-rich metallic-compound films. The metallic-compound films can be components of gate stacks, such as gate electrodes. Plasma parameters can be selected to achieve a gate stack with a predetermined work function.

Owner:ASM IP HLDG BV

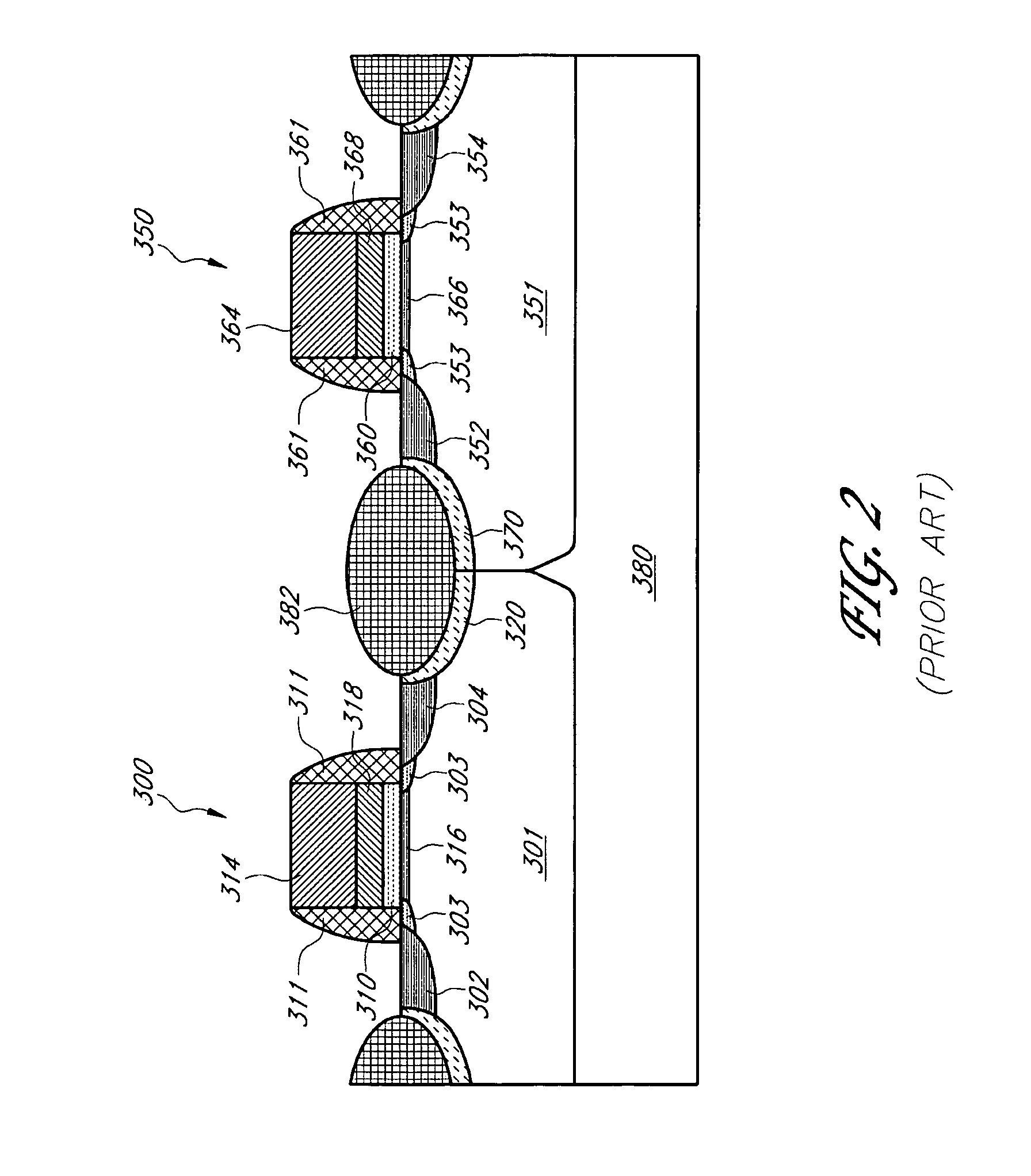

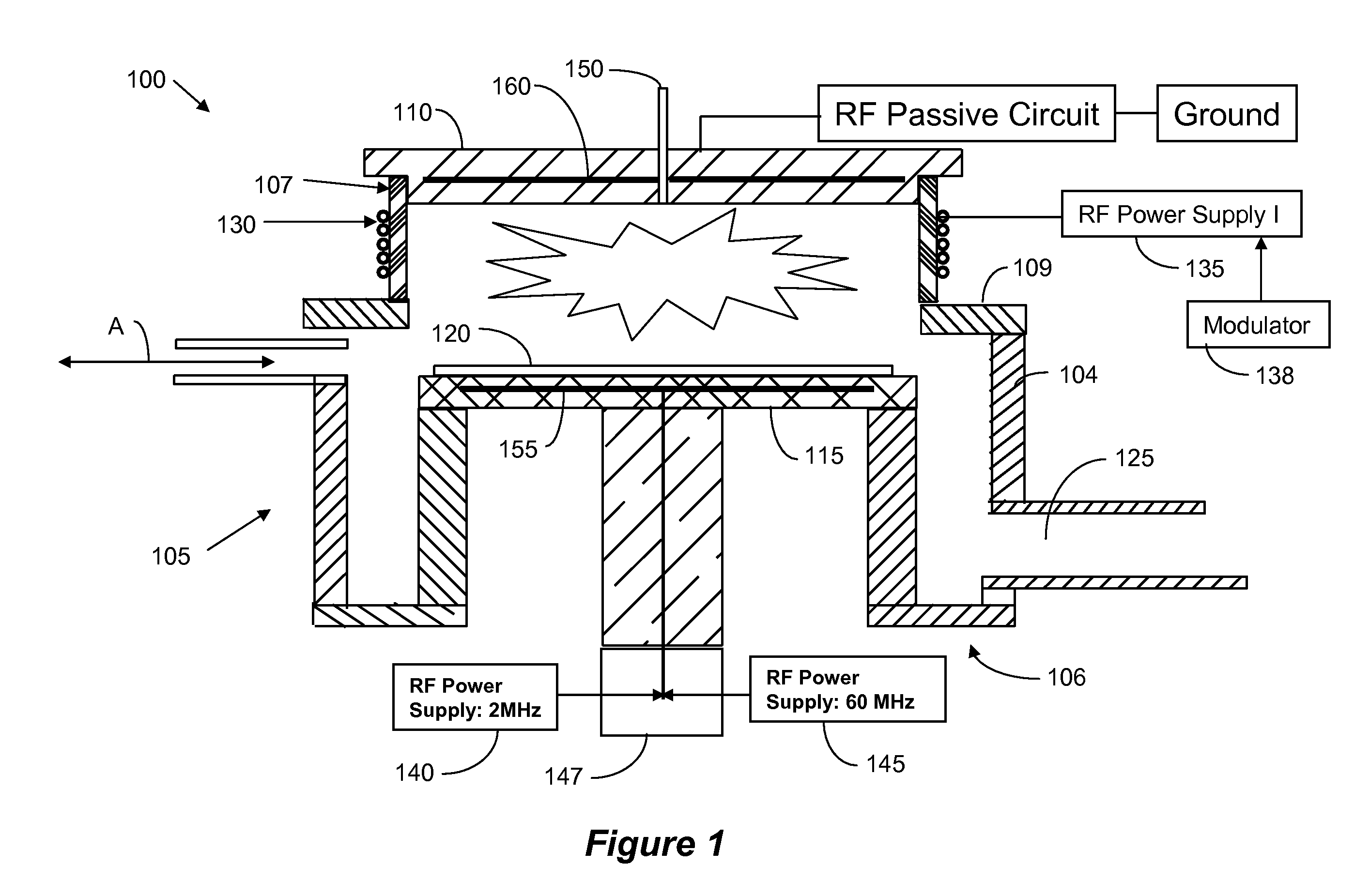

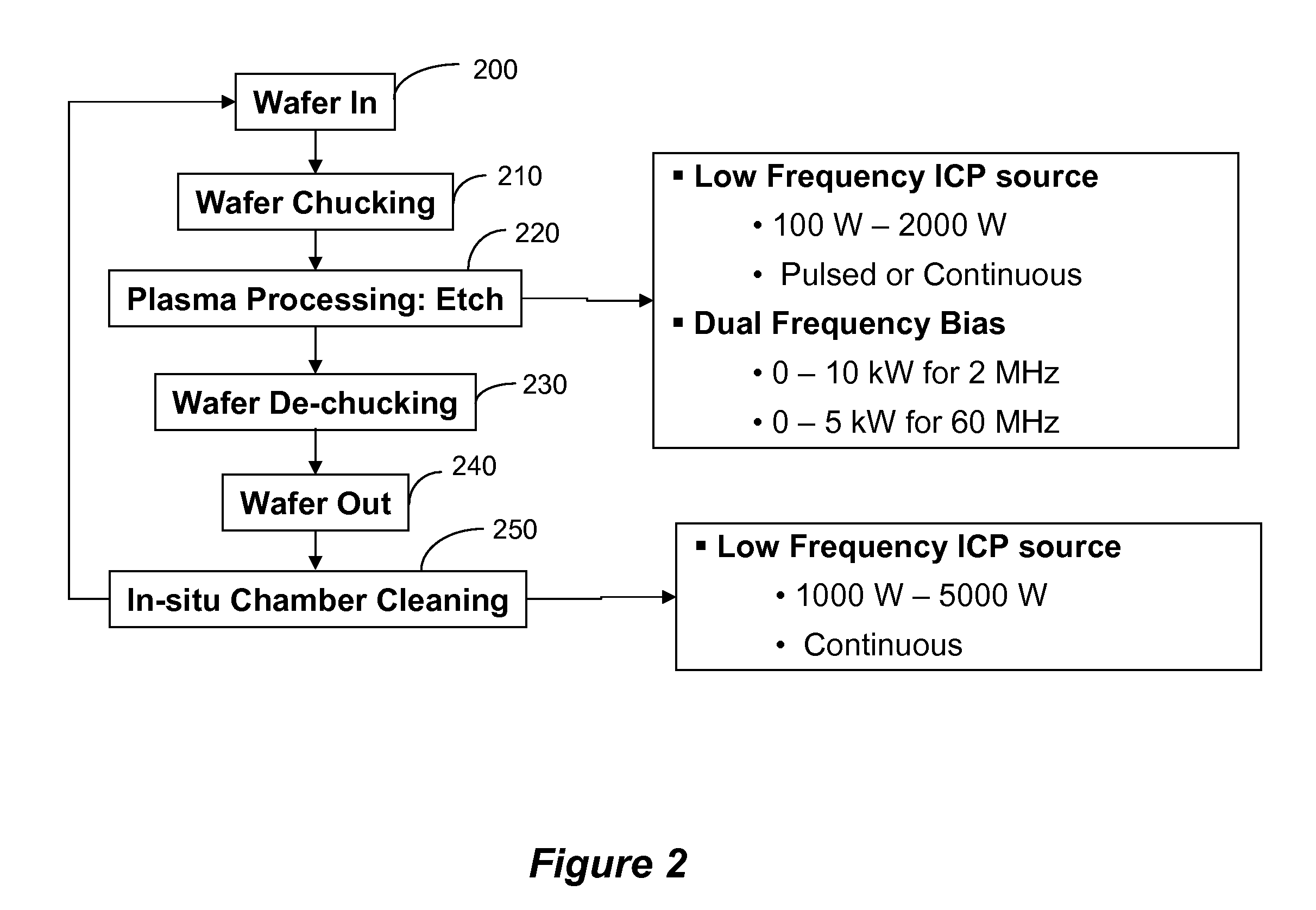

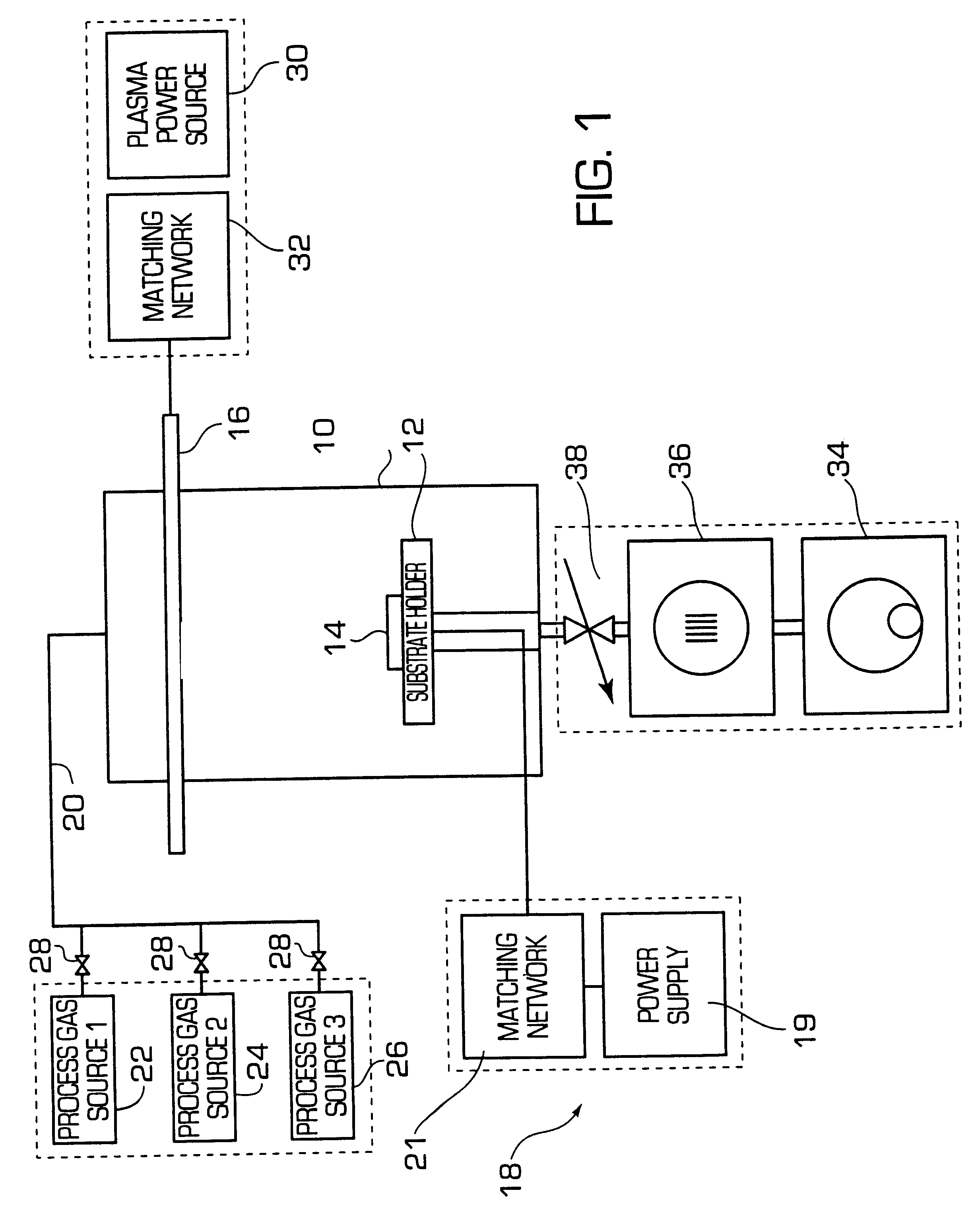

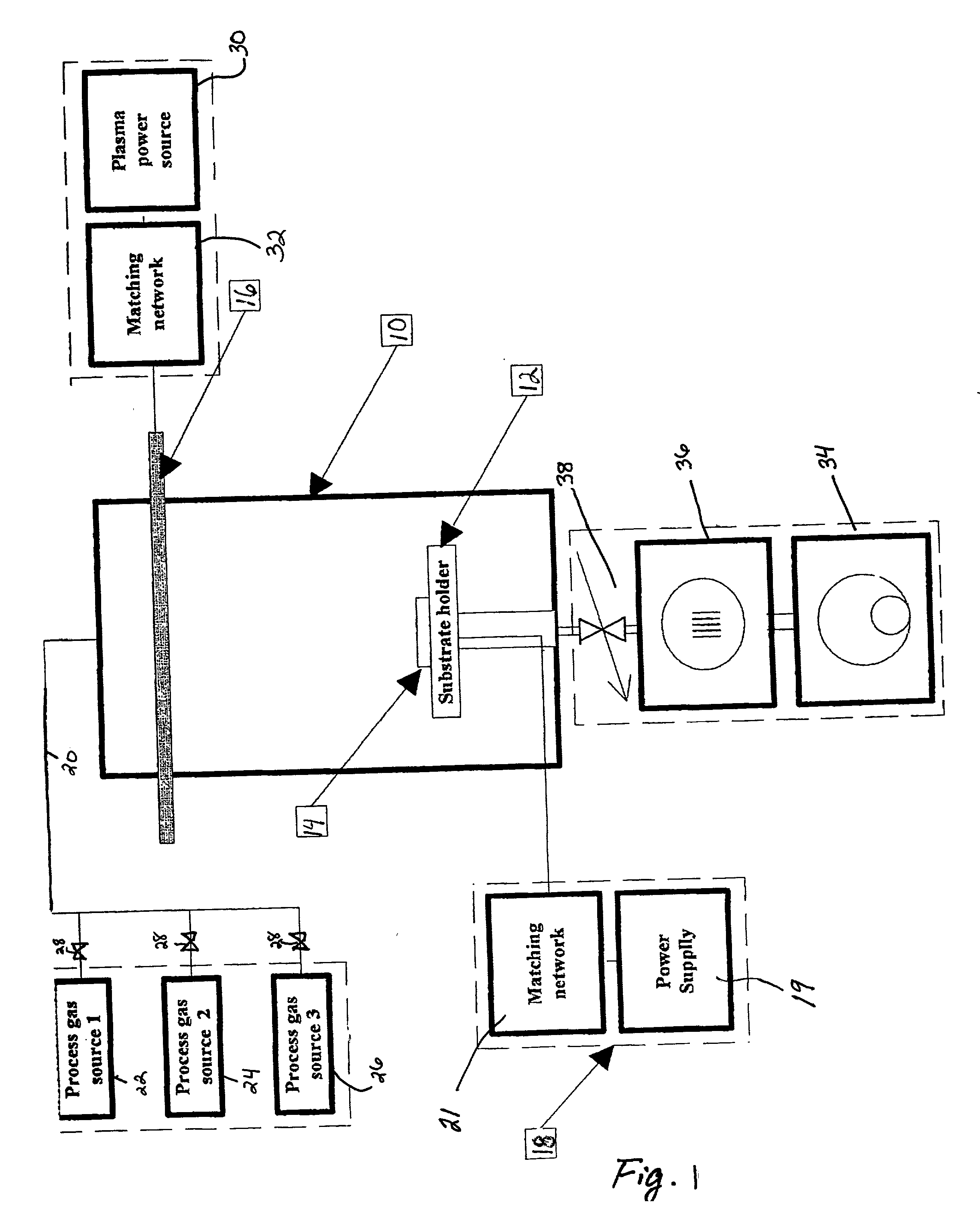

Hybrid etch chamber with decoupled plasma controls

InactiveUS20090004873A1Electric discharge tubesSemiconductor/solid-state device manufacturingDual frequencyCapacitance

A dielectric etch chamber and method for improved control of plasma parameters. The plasma chamber comprises dual-frequency bias source that capacitively couples the RF energy to the plasma, and a single or dual frequency source that inductively couples the RF energy to the plasma. The inductive source may be modulated for improved etch uniformity.

Owner:INTEVAC

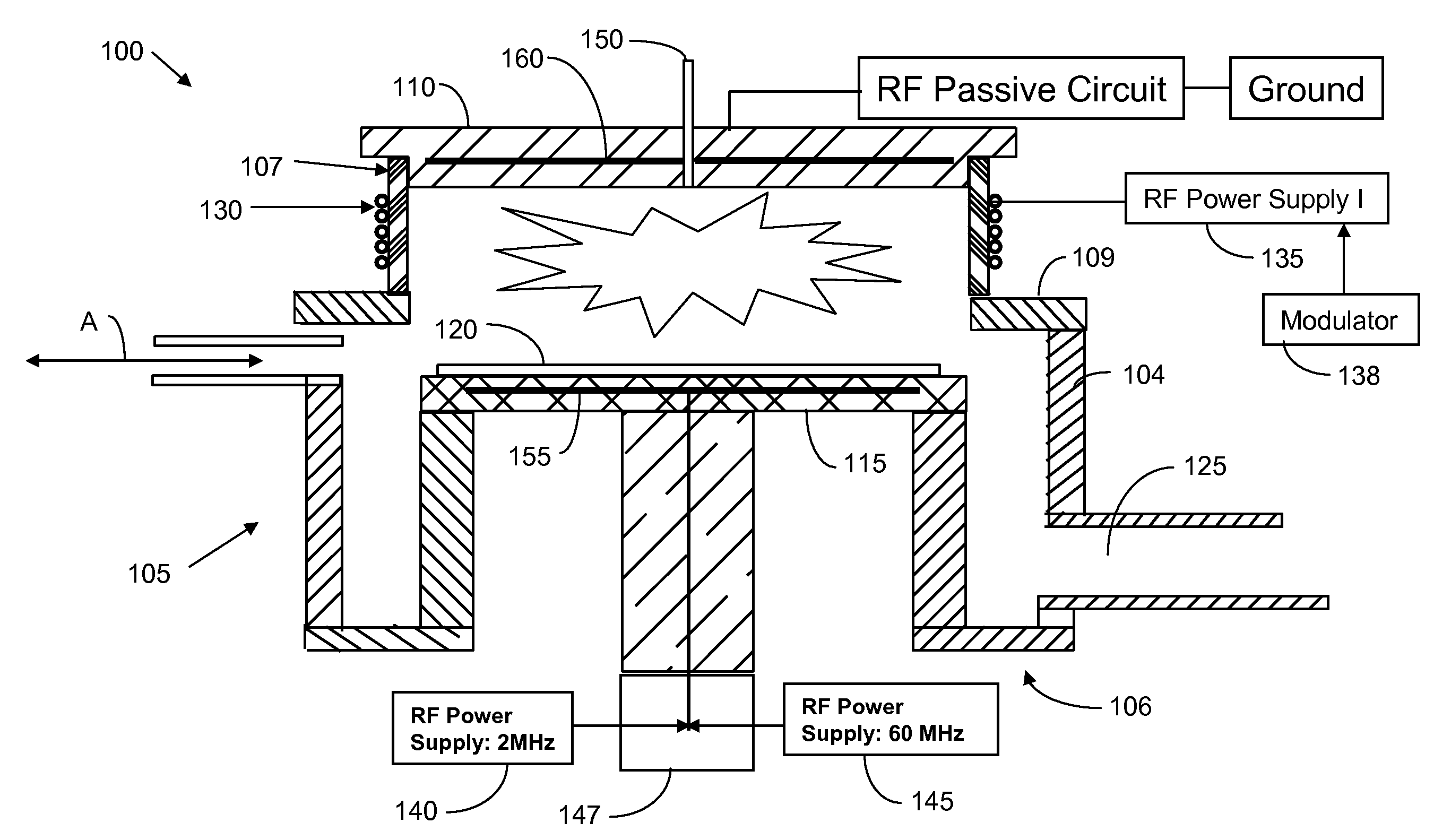

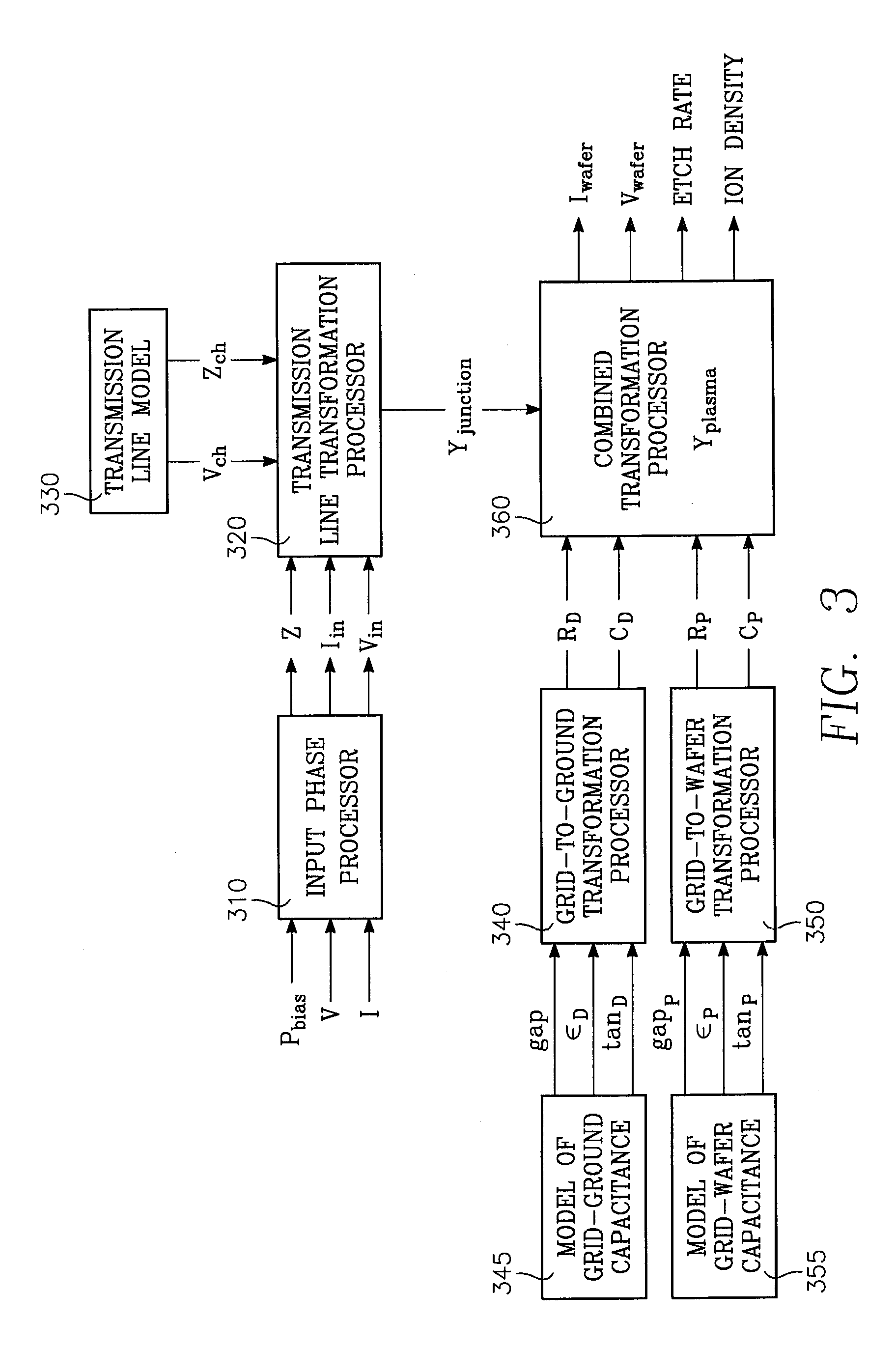

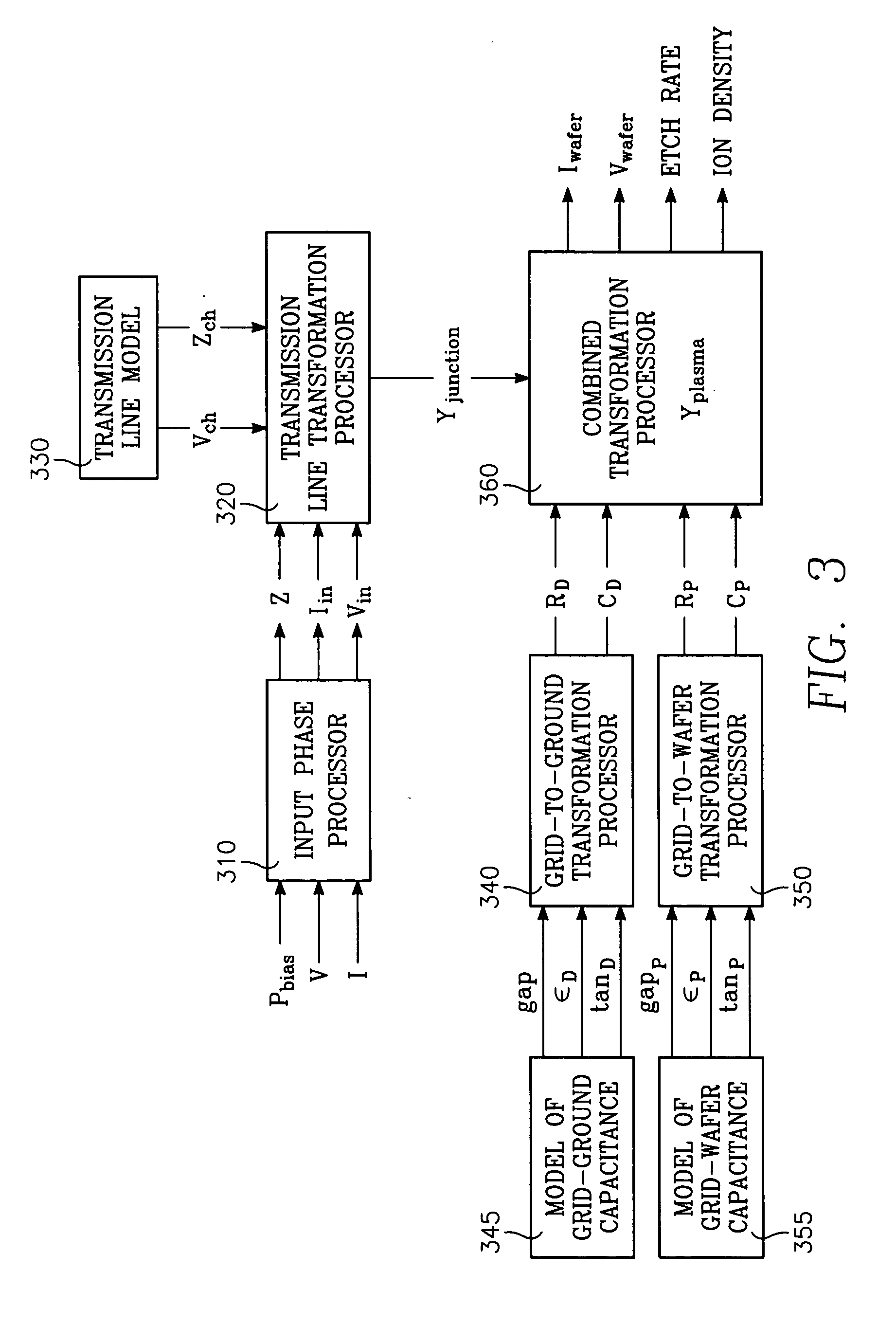

Method of controlling a chamber based upon predetermined concurrent behavoir of selected plasma parameters as a function of selected chamber paramenters

InactiveUS20070095788A1Electric discharge tubesVacuum gauge using ionisation effectsIon densityEngineering

The invention involves a method of processing a workpiece on workpiece support pedestal in a plasma reactor chamber in accordance with user-selected values of plural (i.e., N) plasma parameters by controlling plural chamber parameters. The plasma parameters may be selected from of a group including ion density, wafer voltage, etch rate, wafer current and possibly other plasma parameters. The chamber parameters may be selected from a group including source power, bias power, chamber pressure, magnet coil current of different coils, gas flow rate in different gas injection zones, gas species composition in different gas injection zones, and possibly other chamber parameters. The method begins with a first step carried out for each one of the selected plasma parameters. This first step consists of fetching from a memory a relevant surface of constant value corresponding to the user-selected value of the one plasma parameter, the surface being defined in a N-dimensional space of which each of the N chamber parameters is a dimension. This step further includes determining an intersection of these relevant surfaces, the intersection corresponding to a target value of each of the N chamber parameter. The method further includes setting each of the N chamber parameters to the corresponding target value.

Owner:APPLIED MATERIALS INC

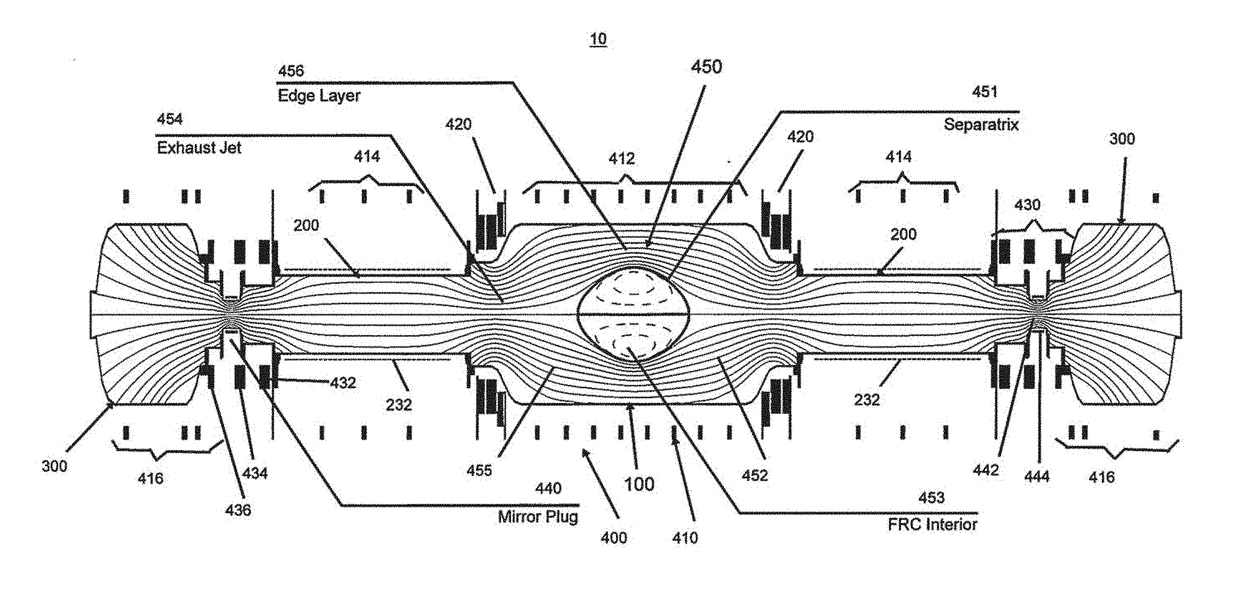

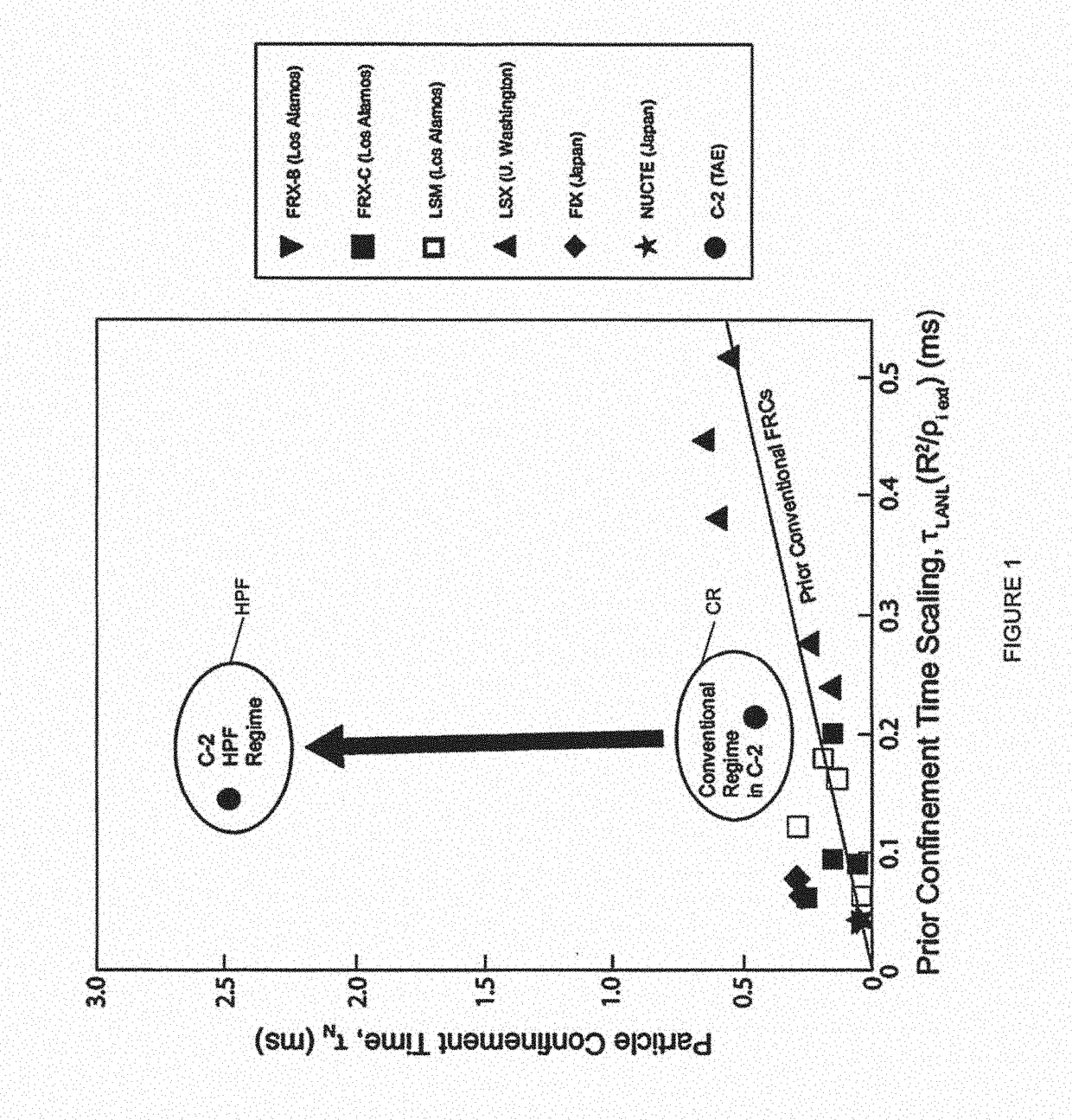

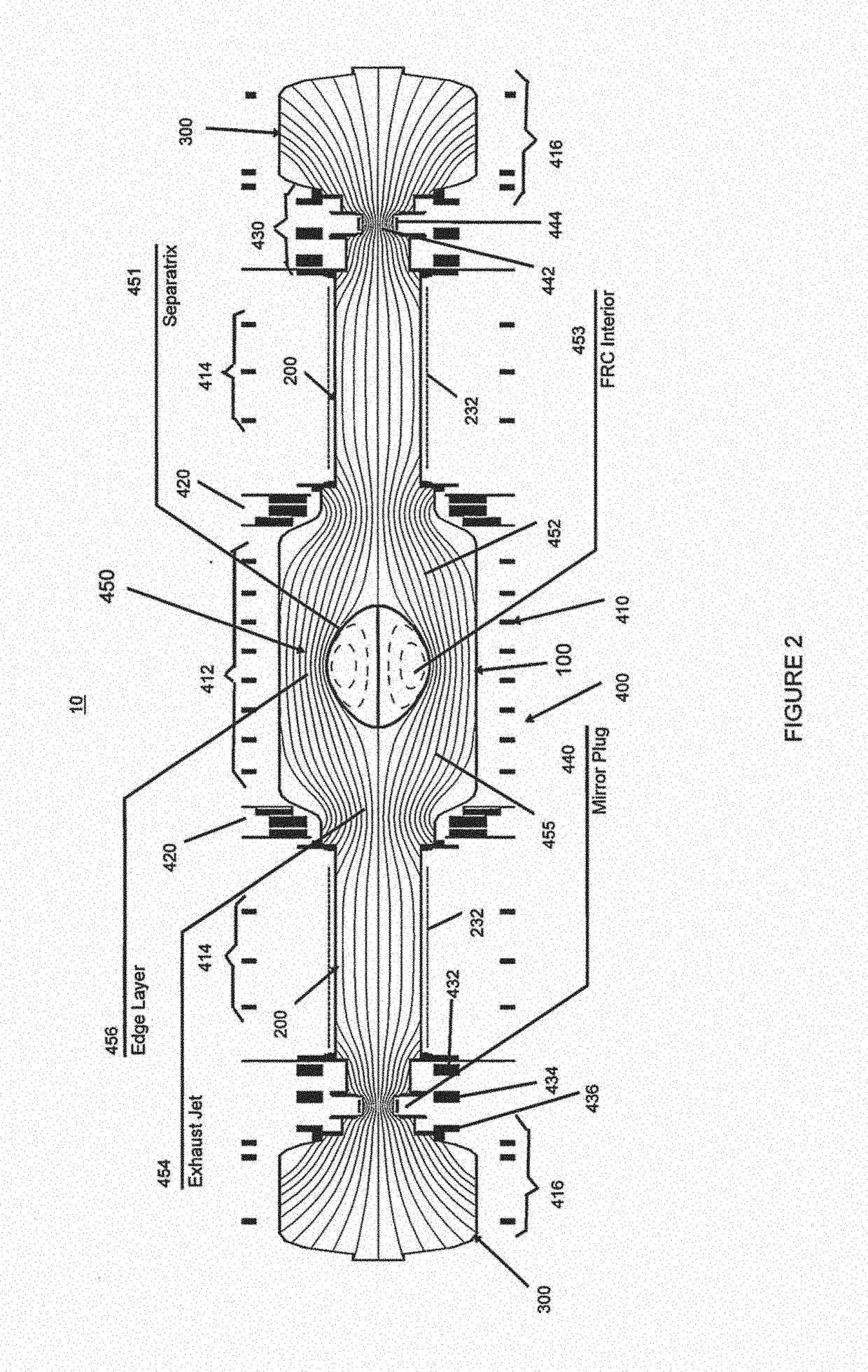

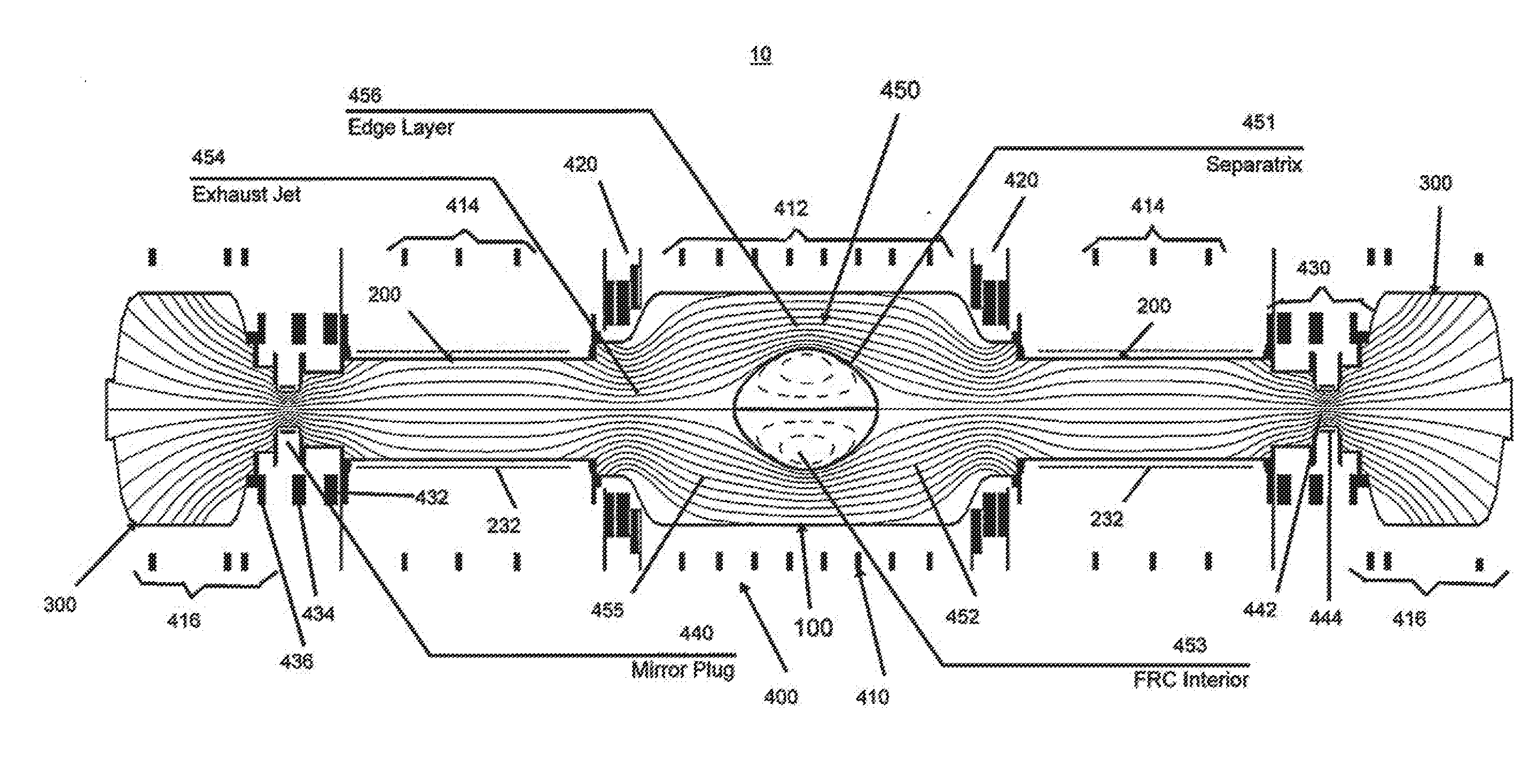

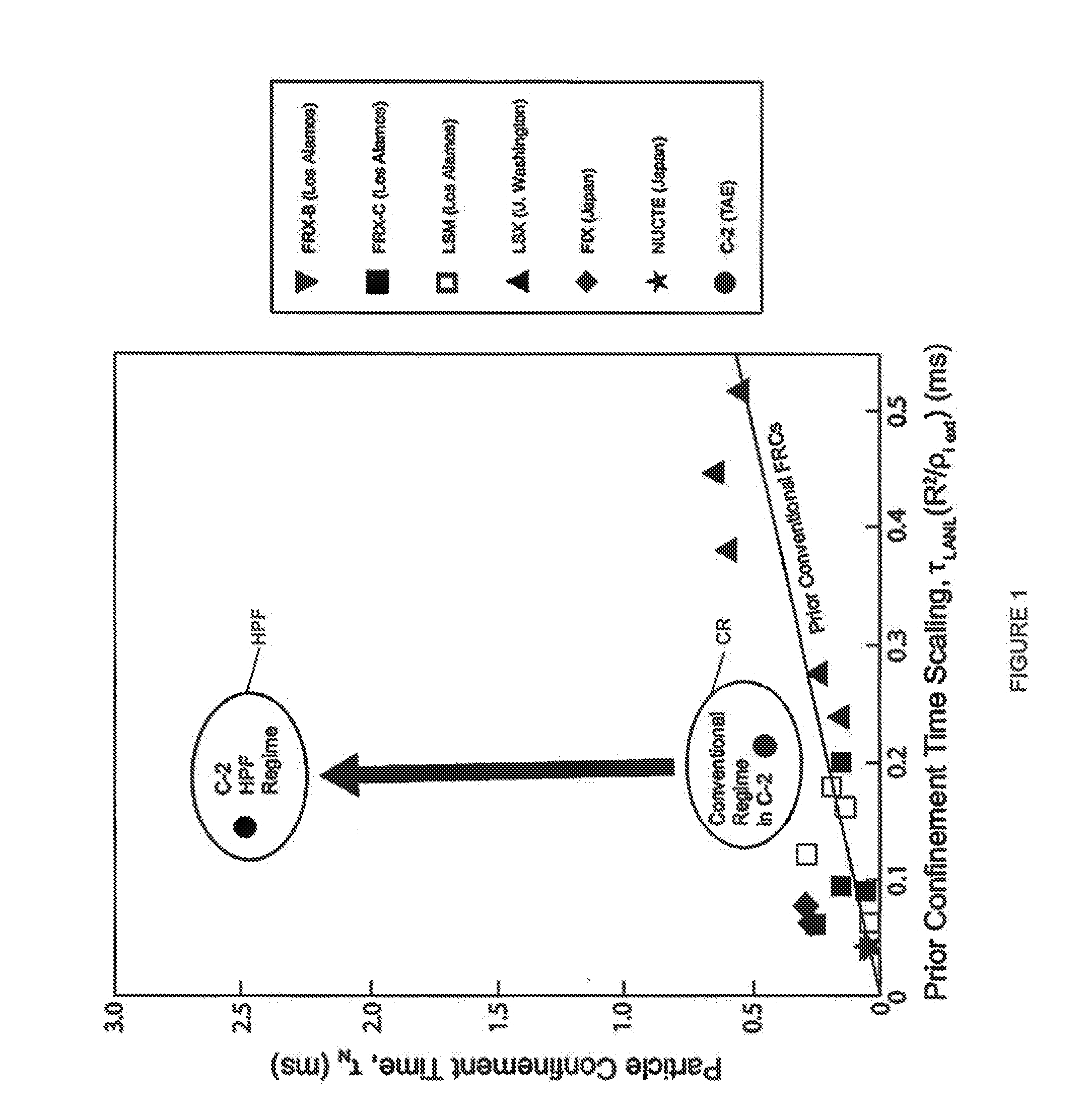

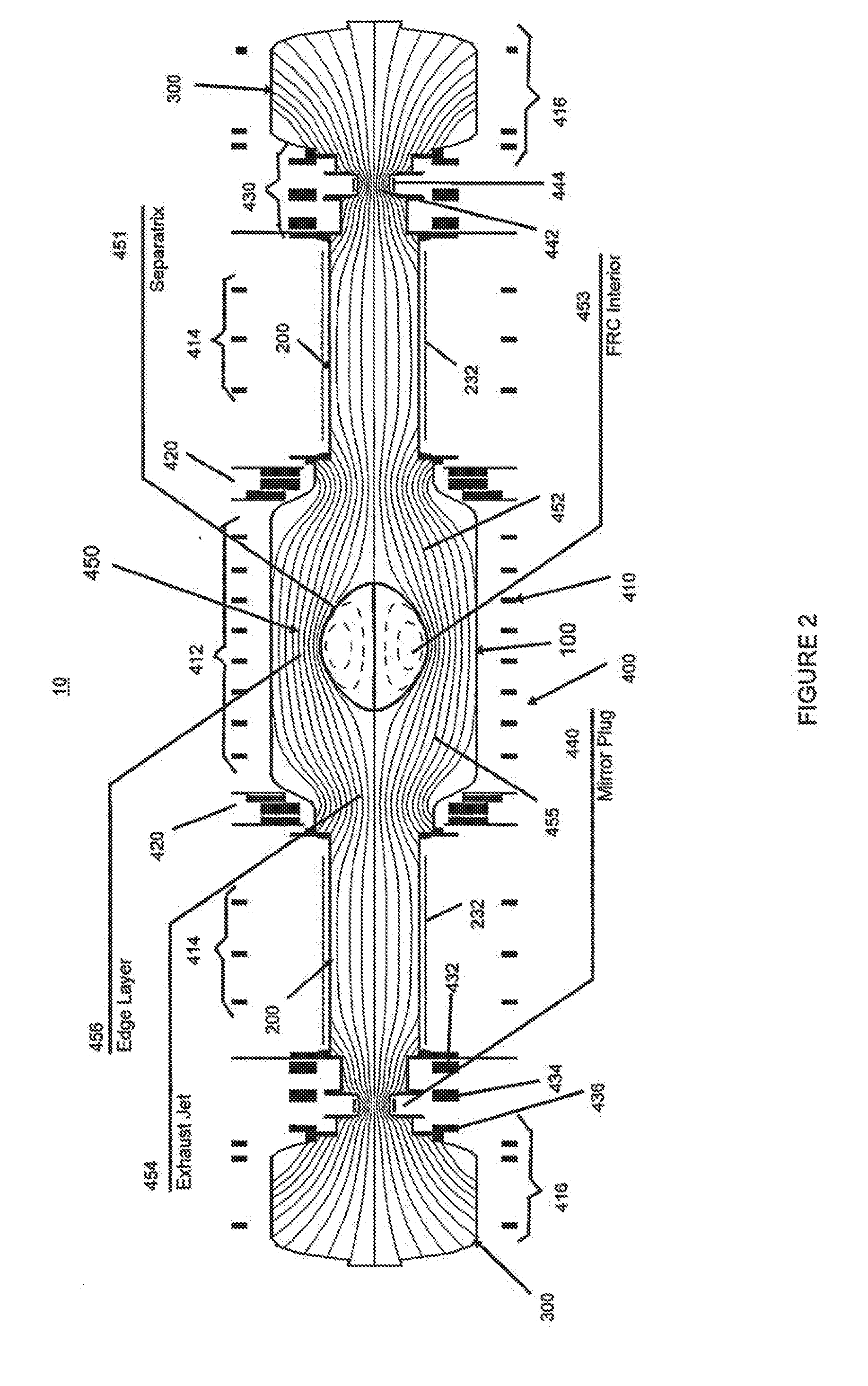

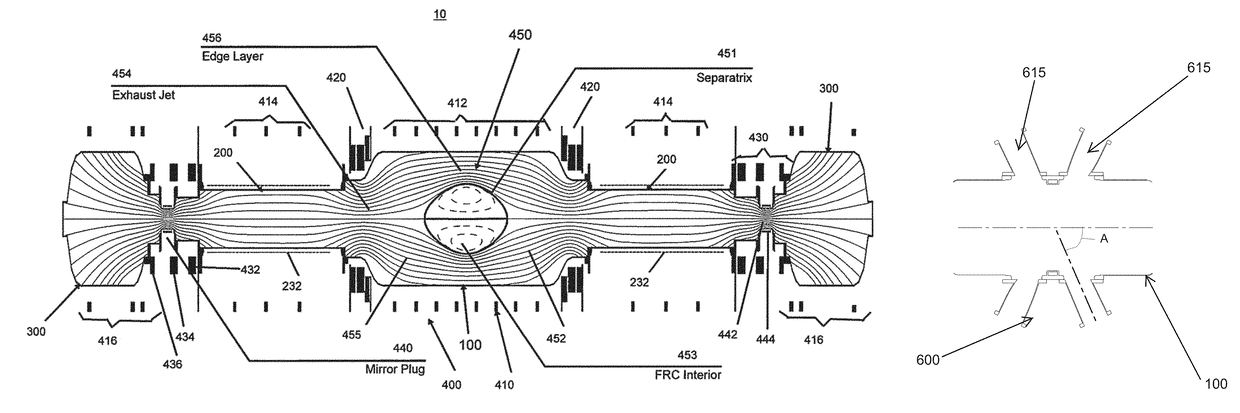

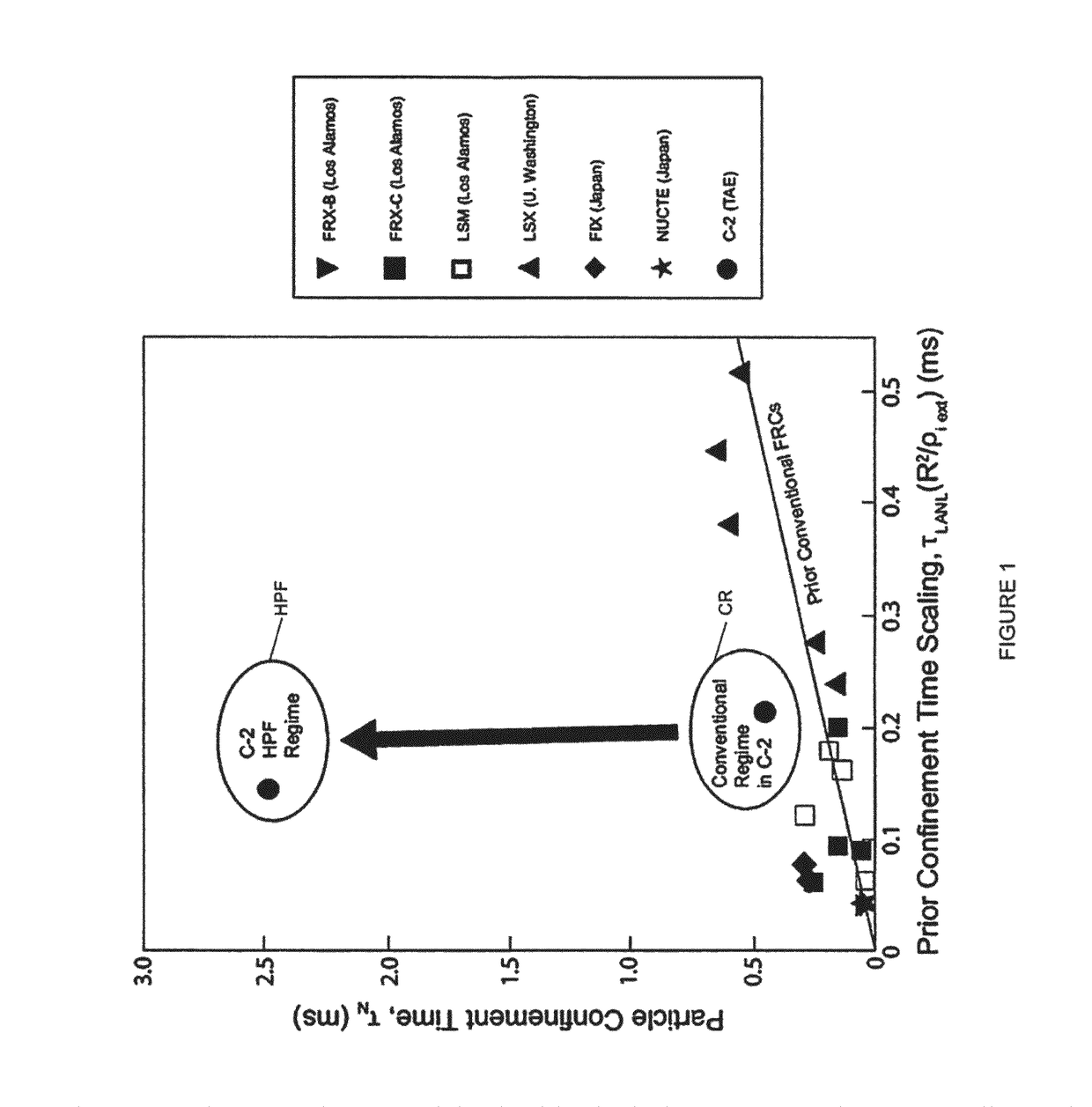

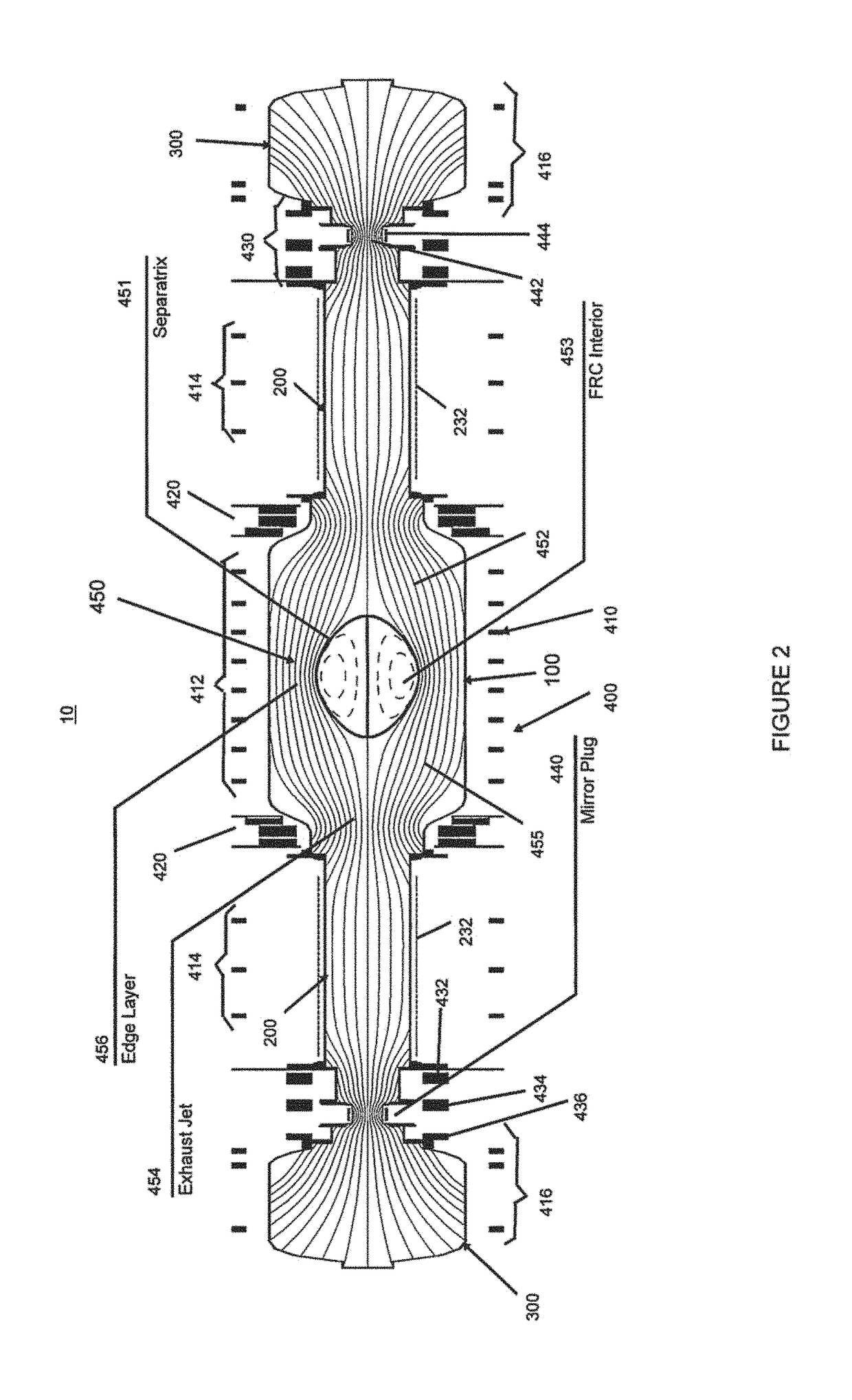

Systems and methods for forming and maintaining a high performance frc

ActiveUS20170359886A1Improve FRC confinementStability control without negative side-effectsNuclear energy generationAcceleratorsThermal energyDivertor

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet or CT injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Controlled composition using plasma-enhanced atomic layer deposition

ActiveUS20080102613A1Easily and accurately adjusted to a desired valueSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOxidation stateWork function

Metallic-compound films are formed by plasma-enhanced atomic layer deposition (PEALD). According to preferred methods, film or thin film composition is controlled by selecting plasma parameters to tune the oxidation state of a metal (or plurality of metals) in the film. In some embodiments, plasma parameters are selected to achieve metal-rich metallic-compound films. The metallic-compound films can be components of gate stacks, such as gate electrodes. Plasma parameters can be selected to achieve a gate stack with a predetermined work function.

Owner:ASM IP HLDG BV

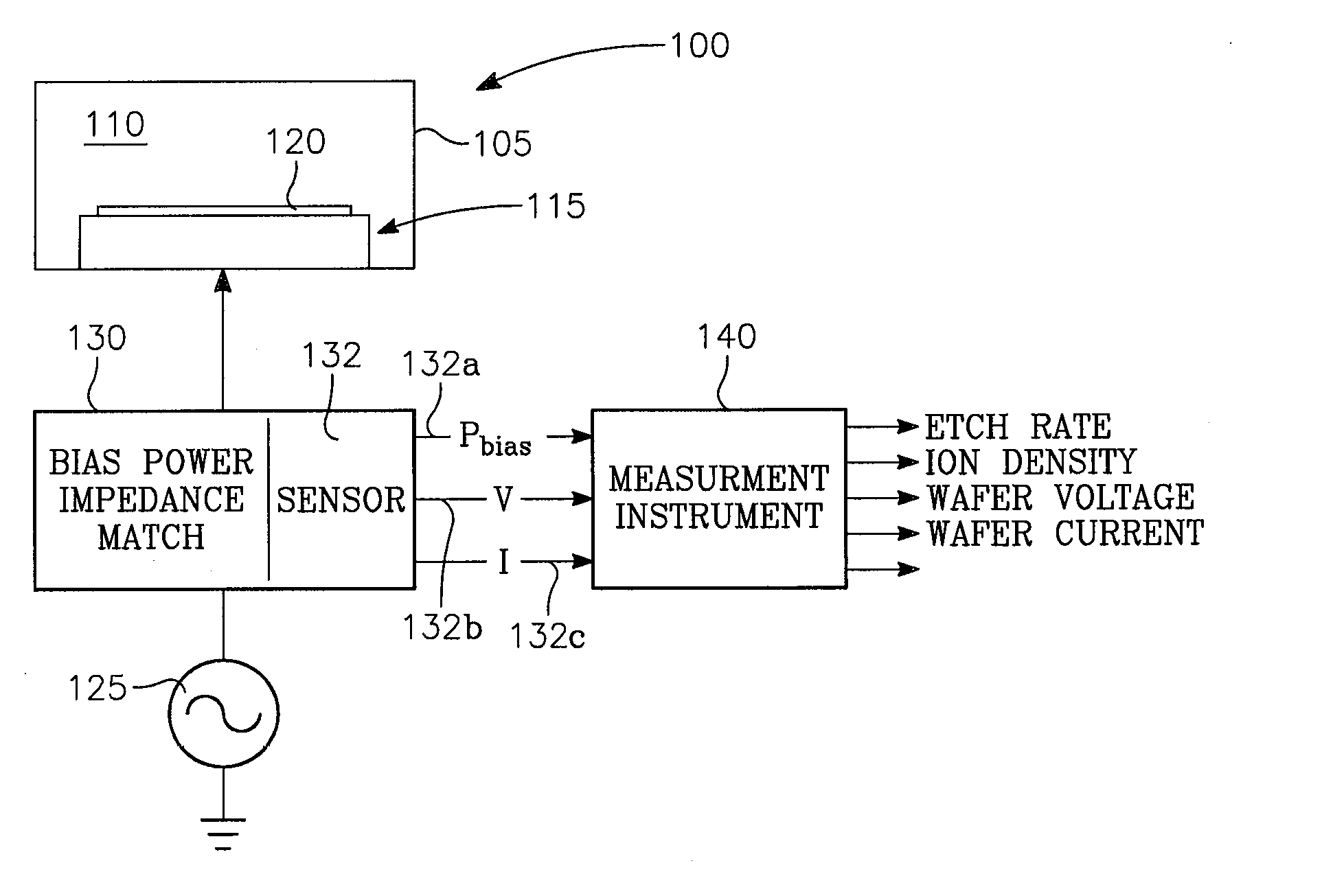

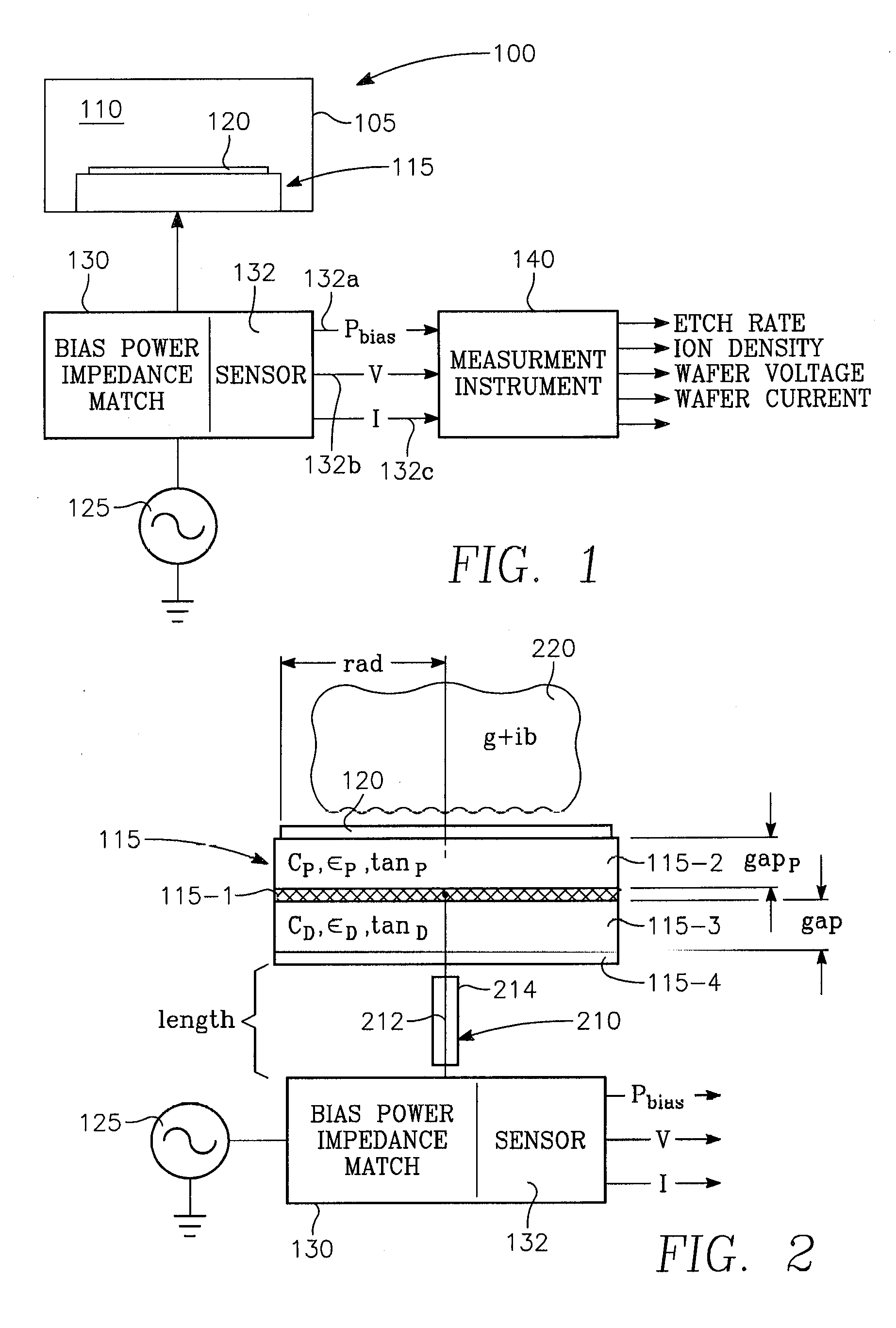

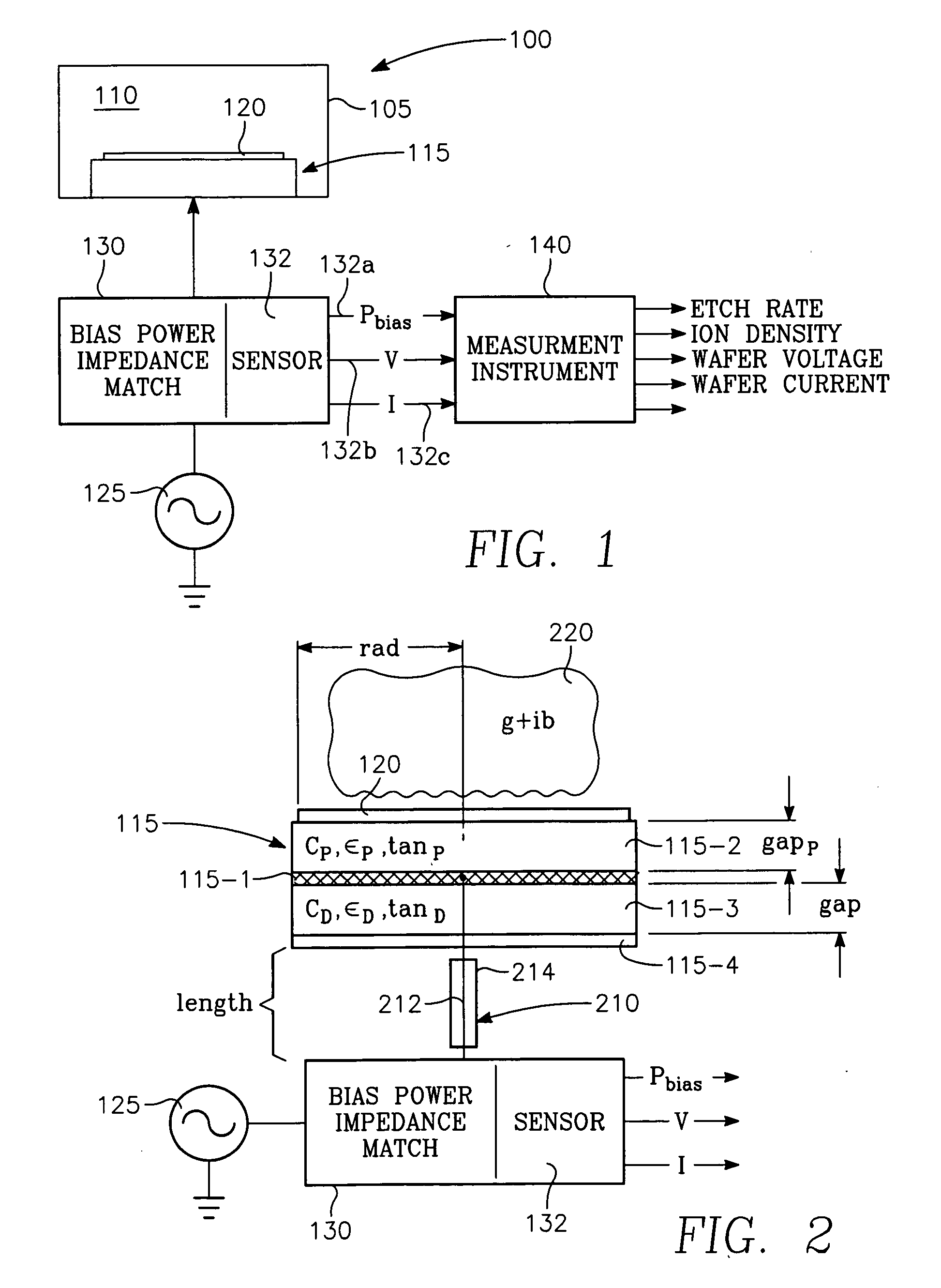

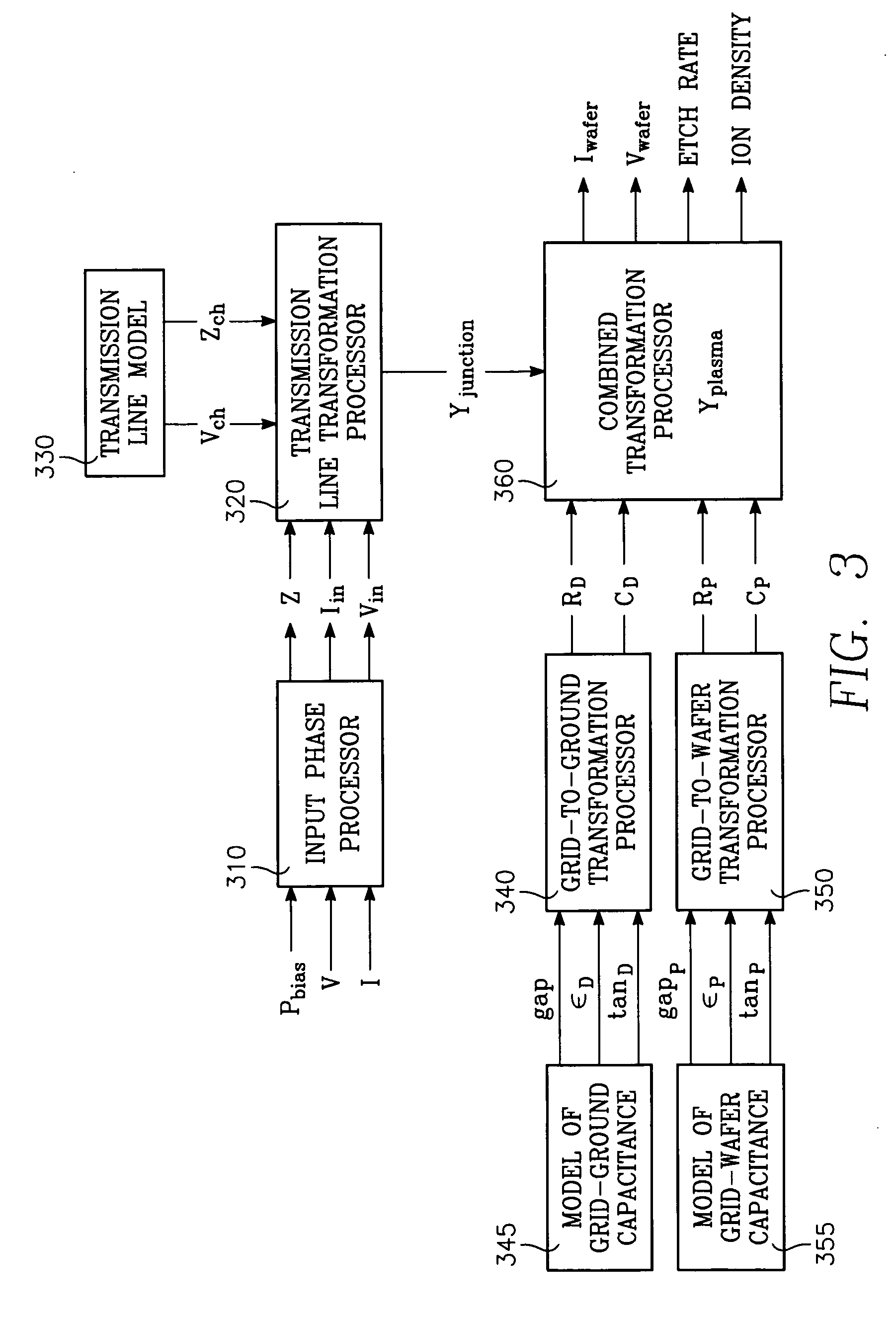

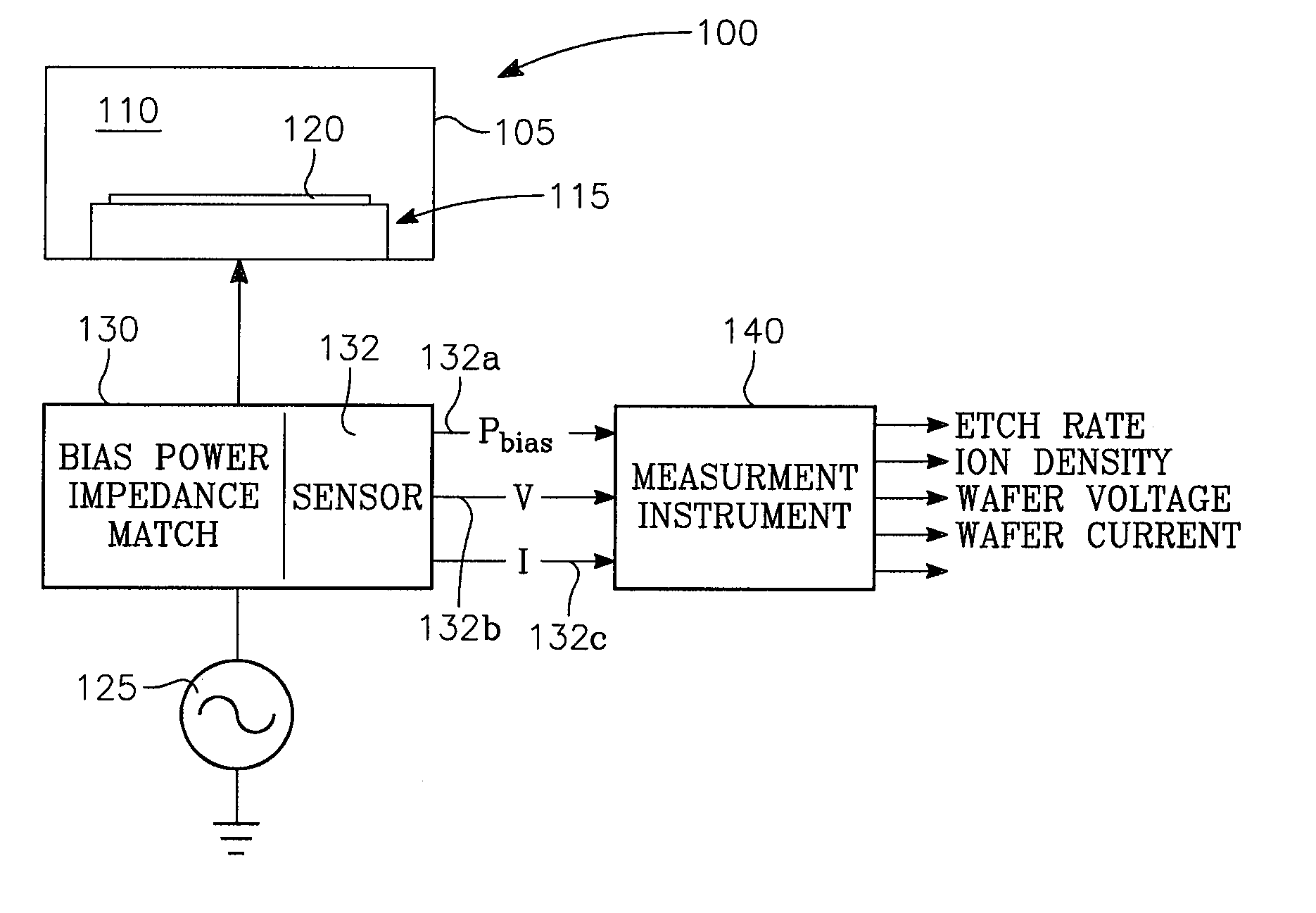

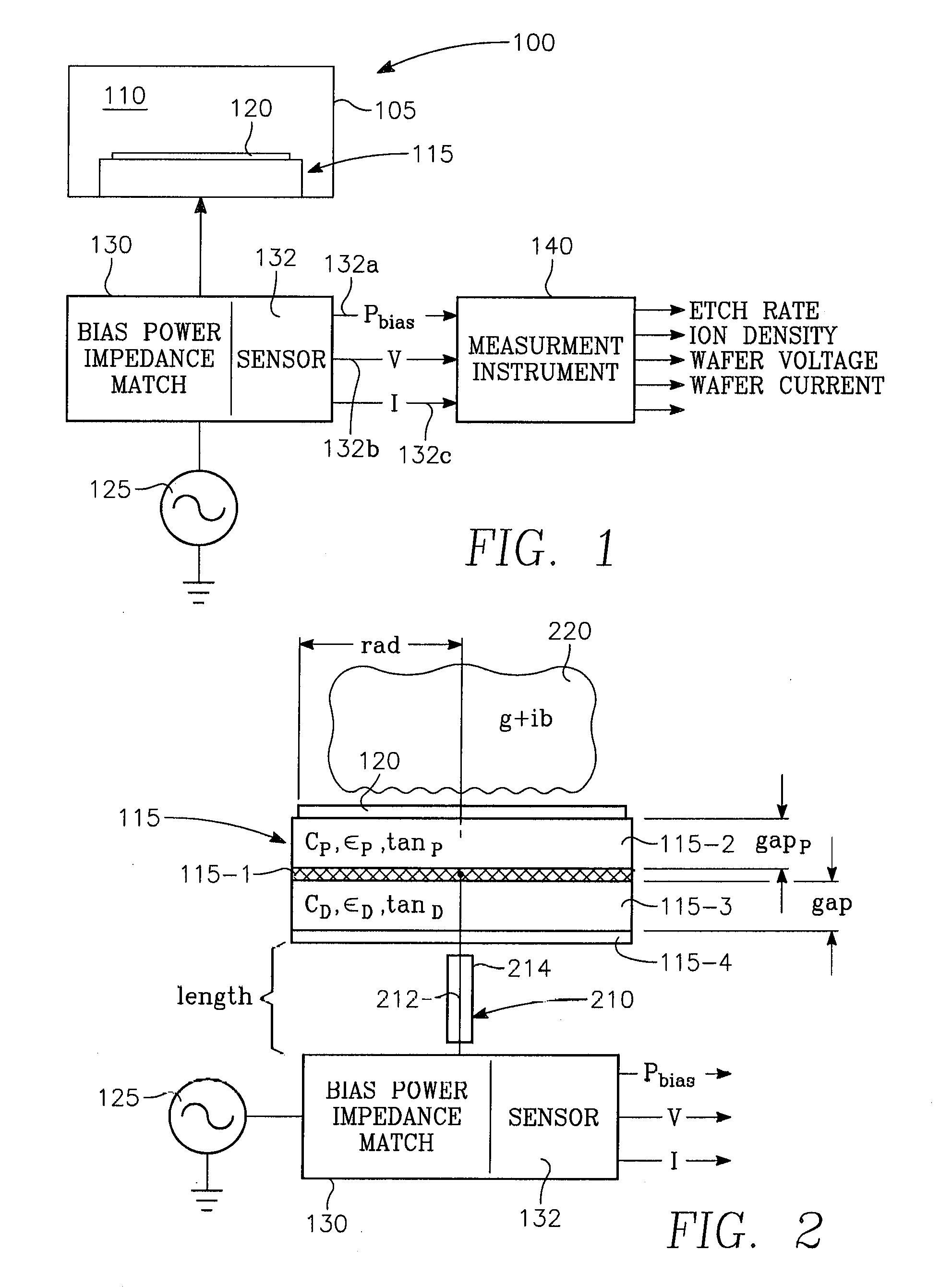

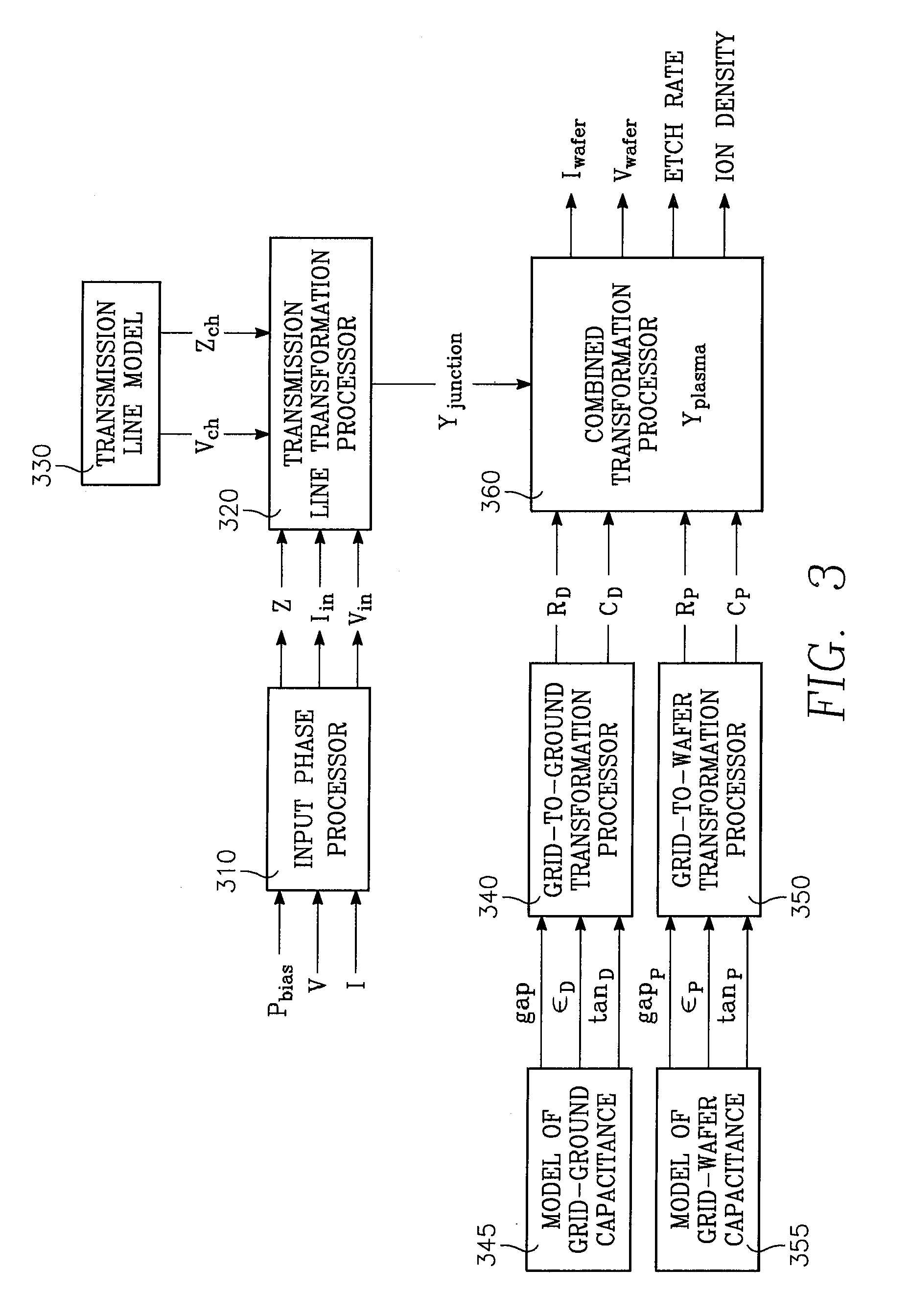

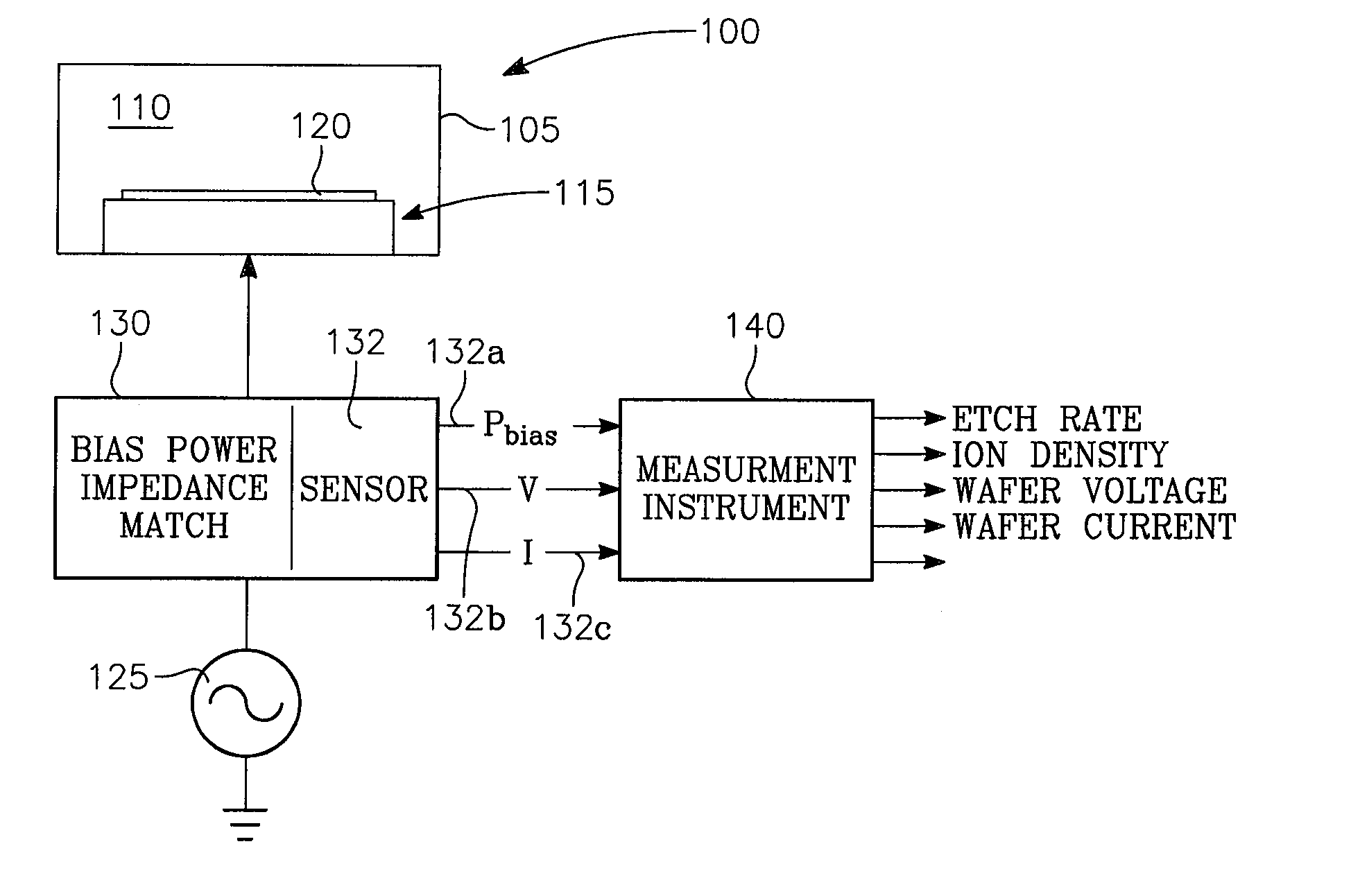

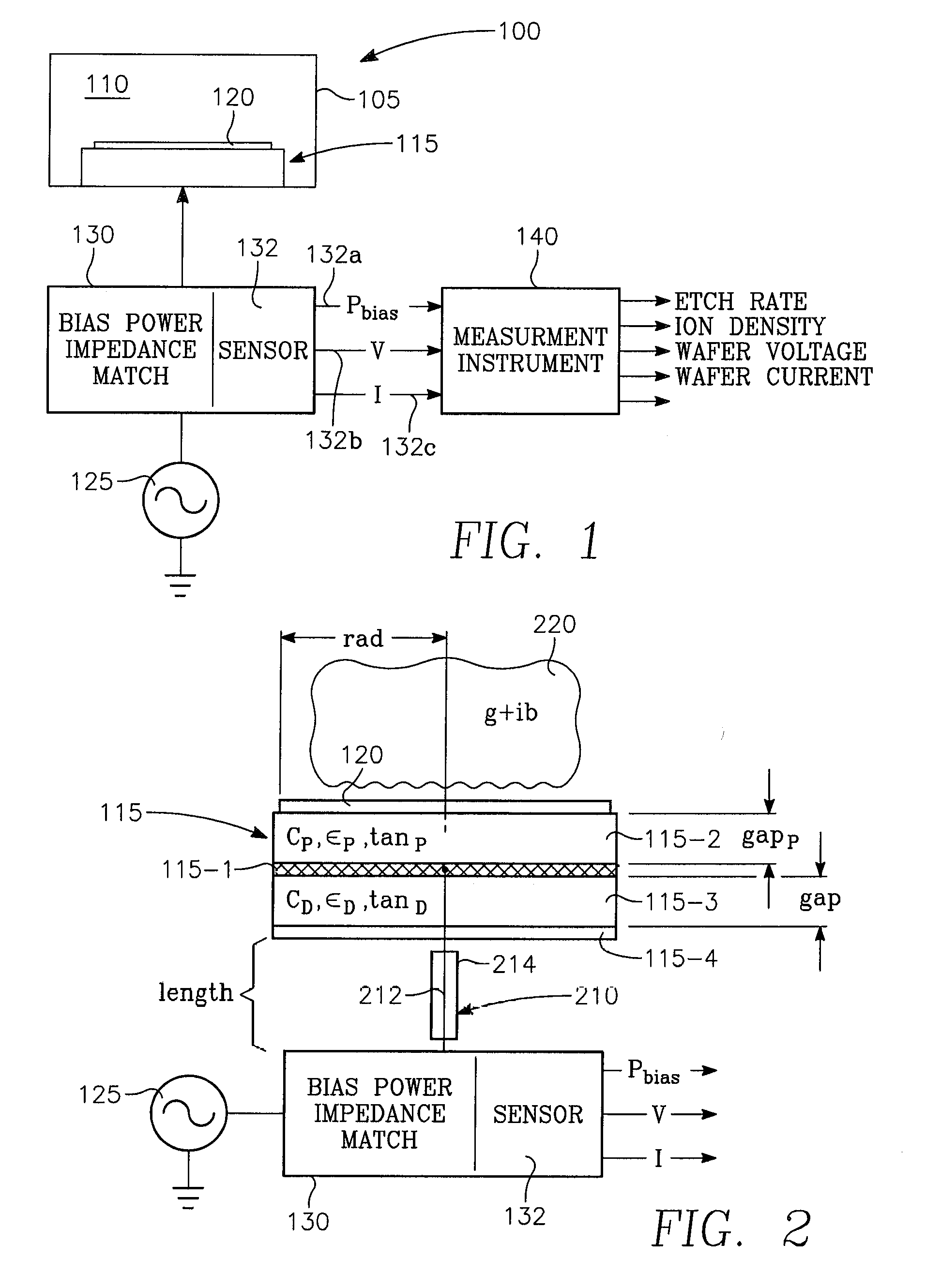

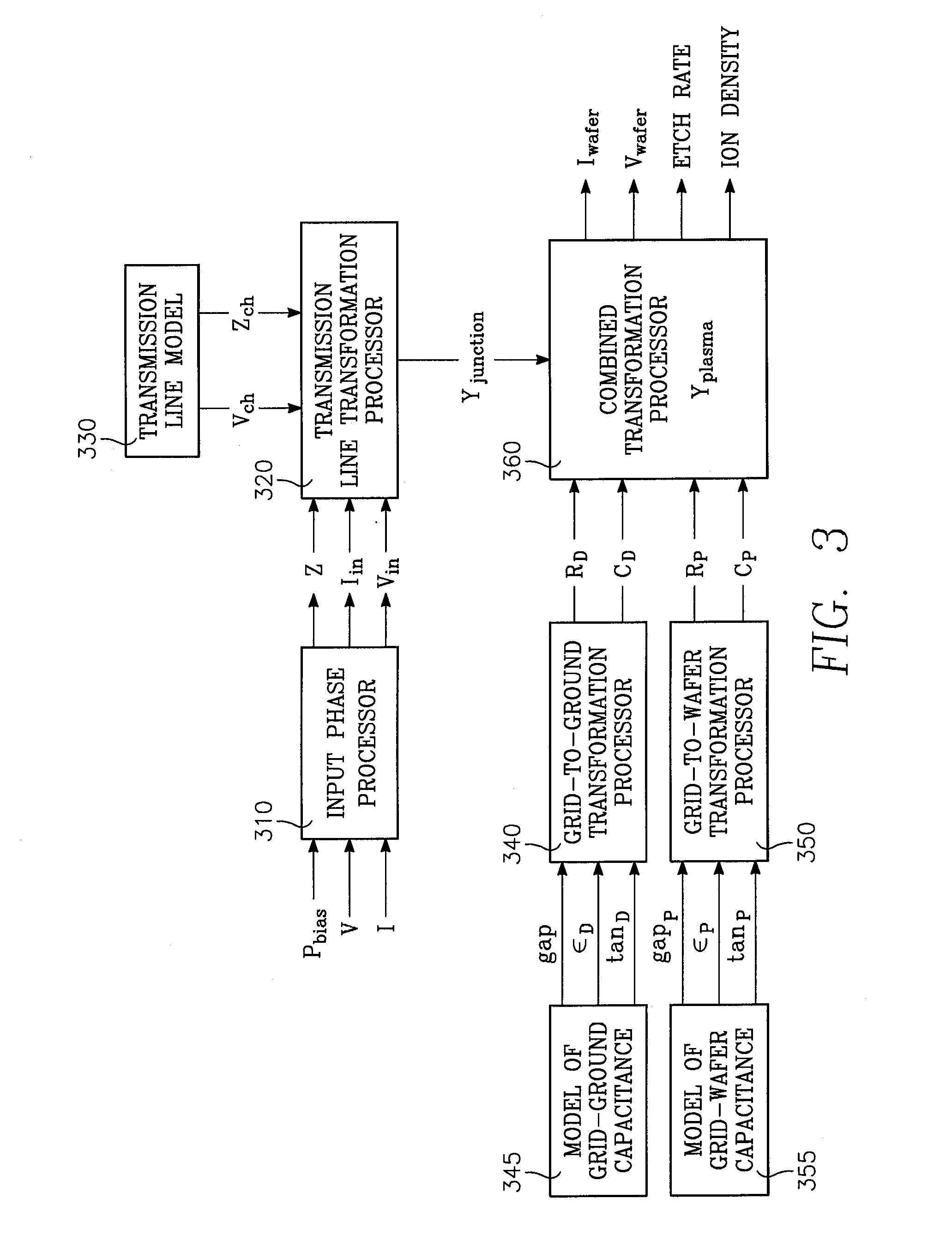

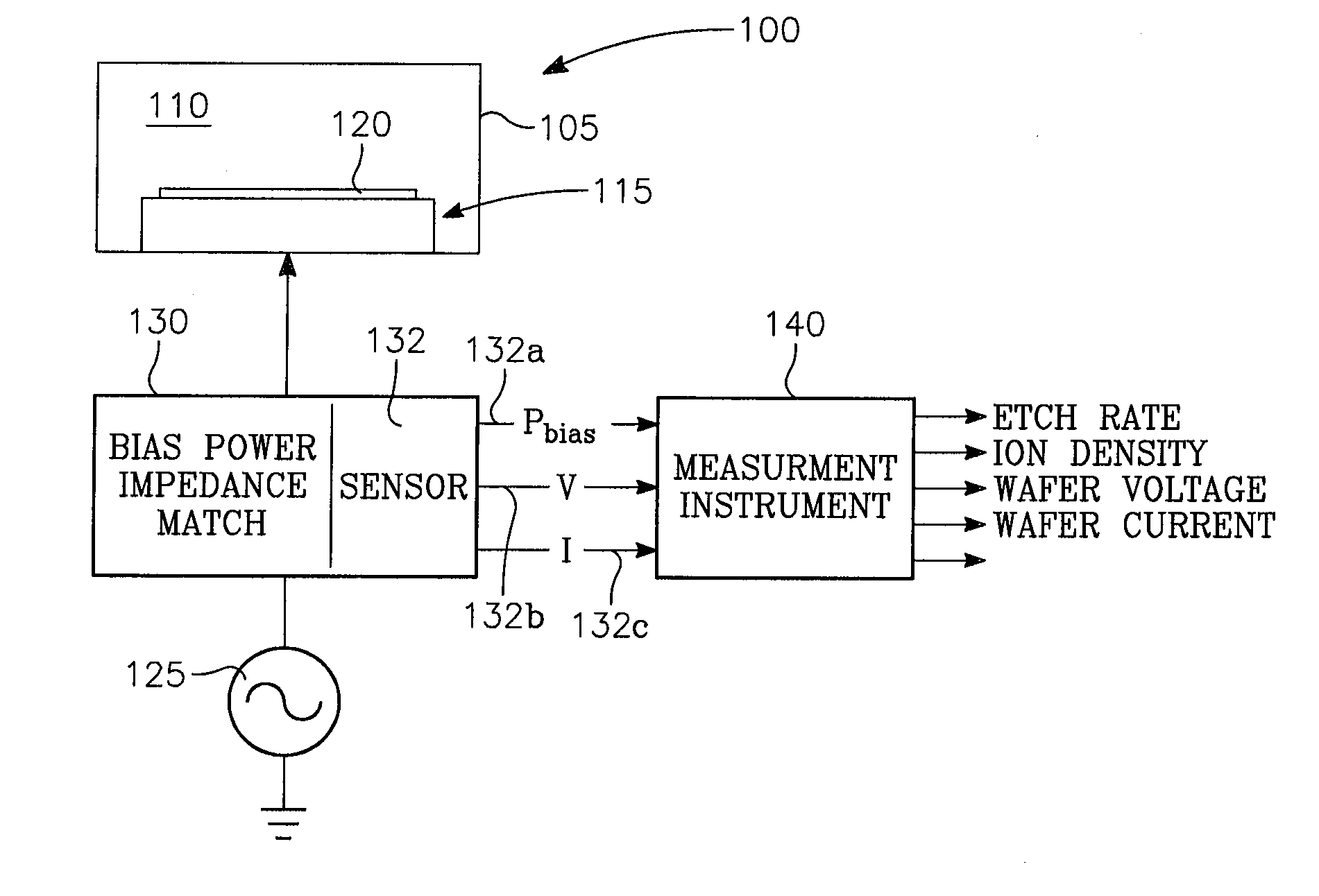

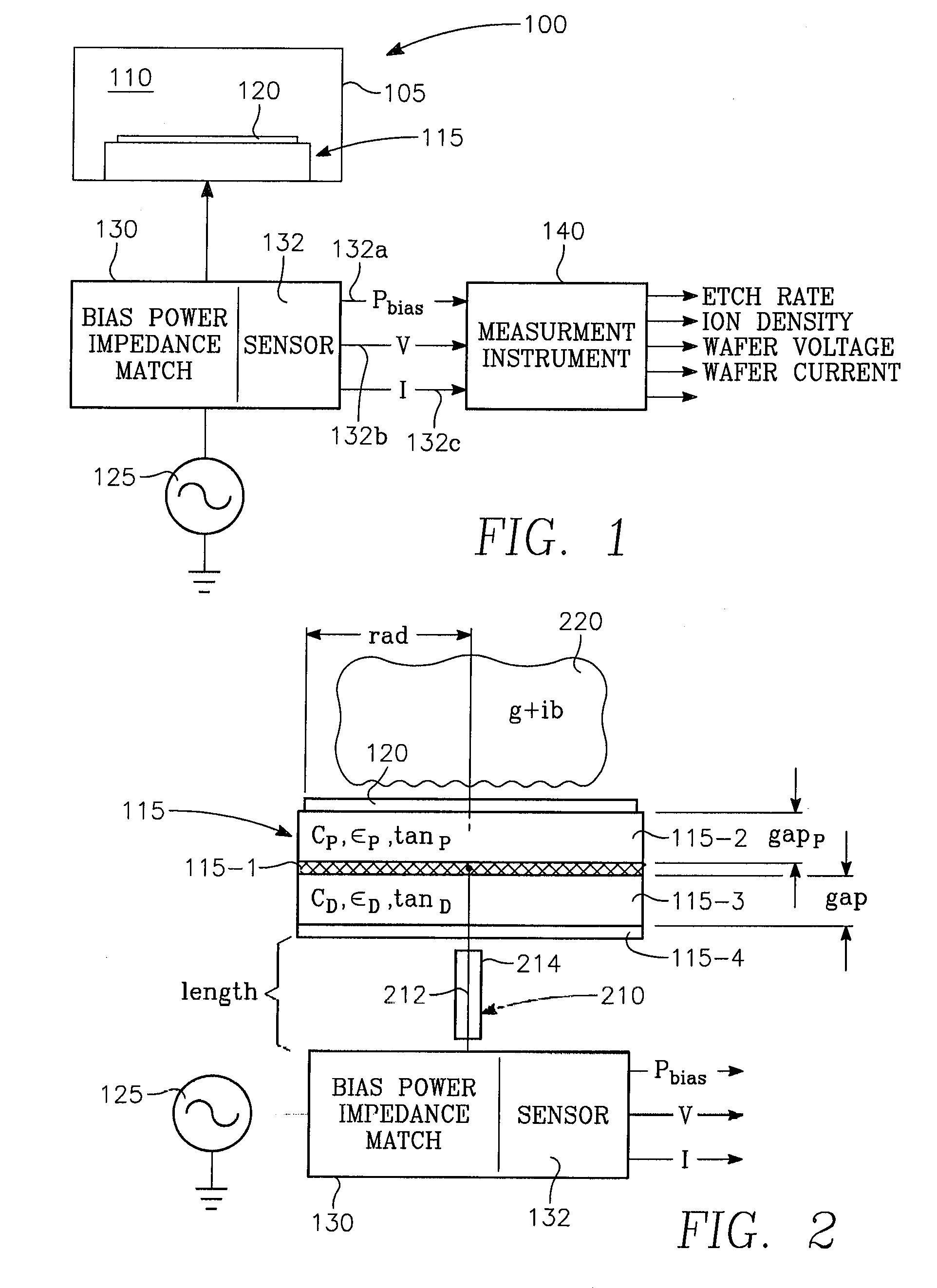

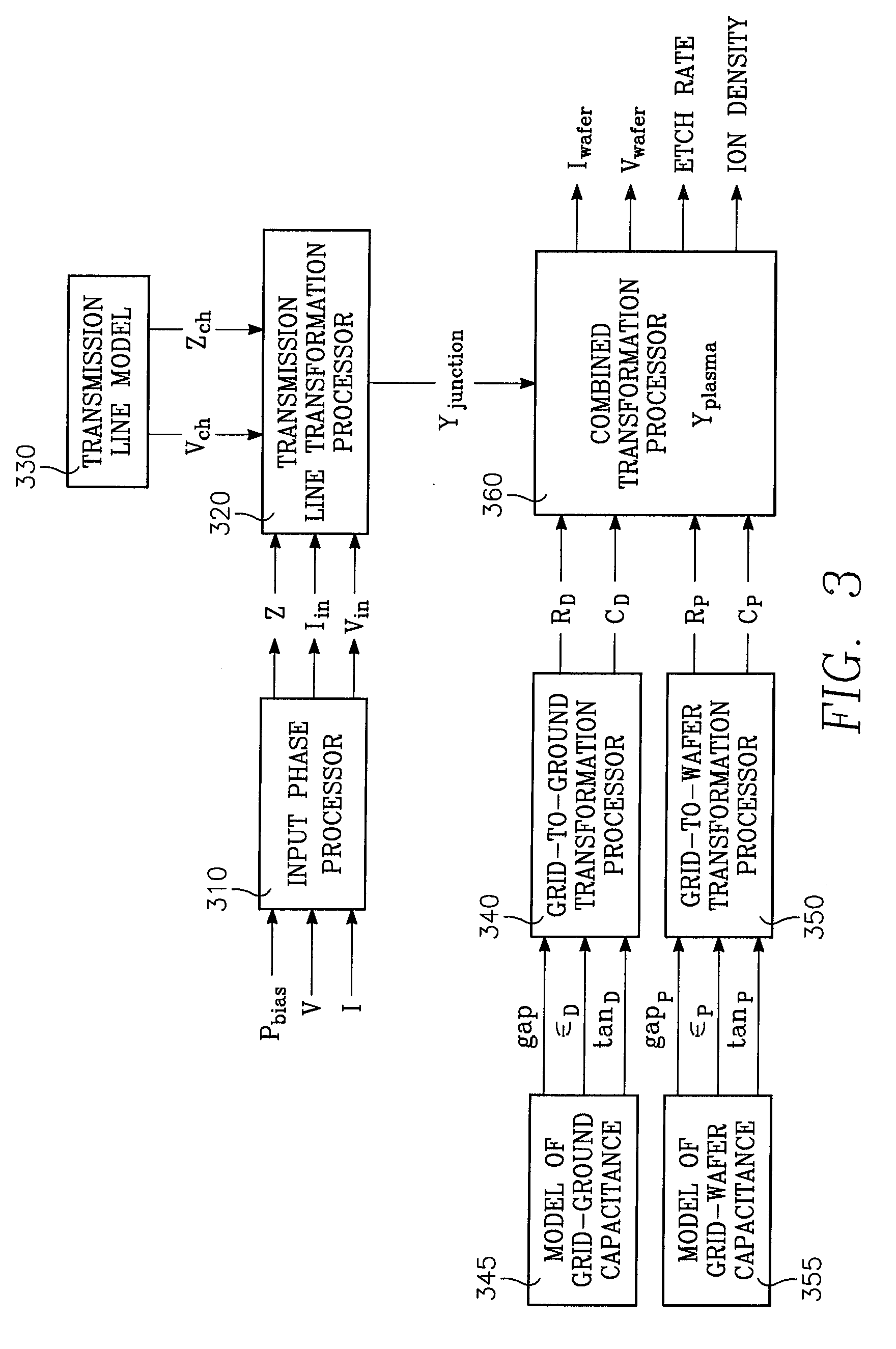

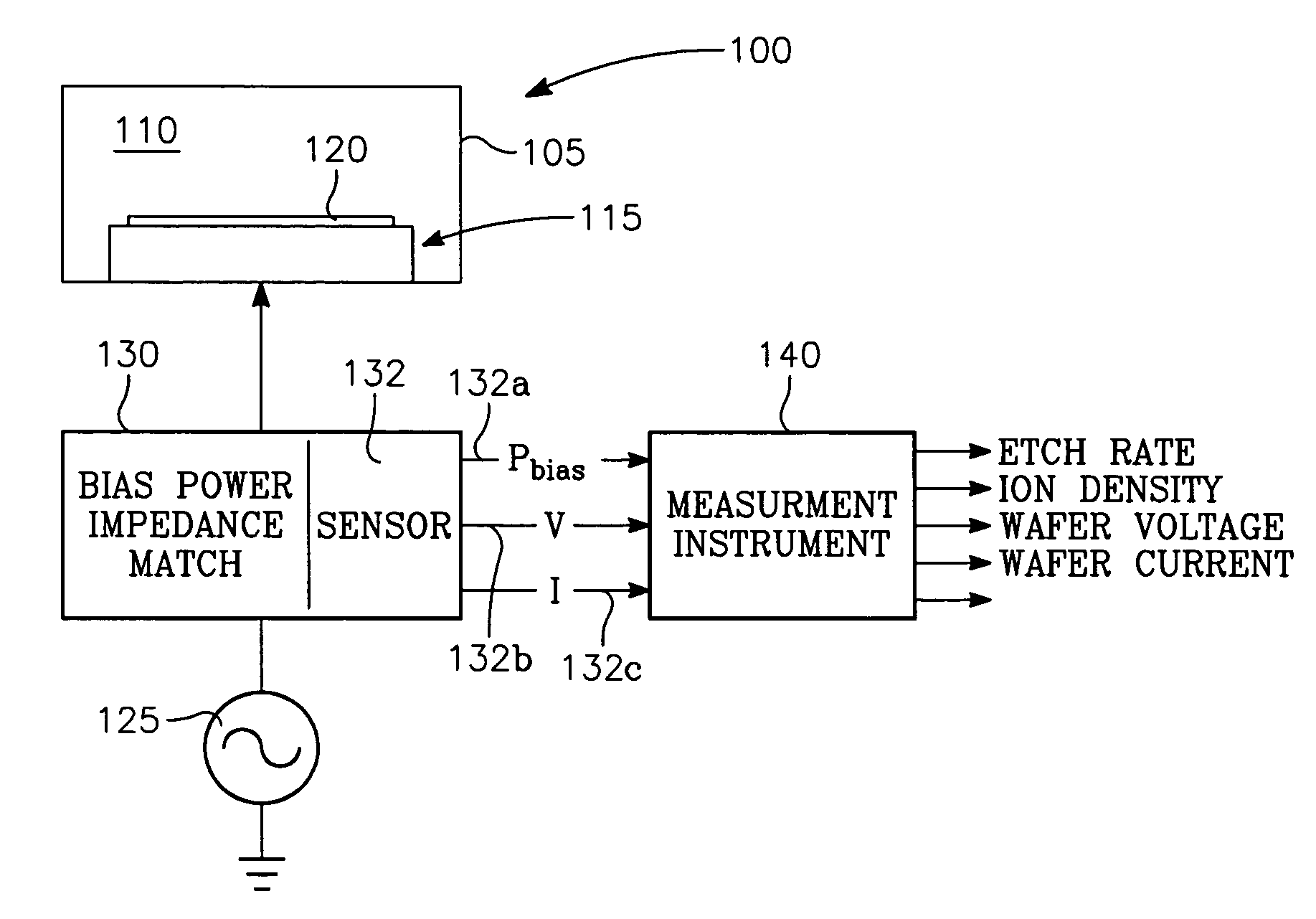

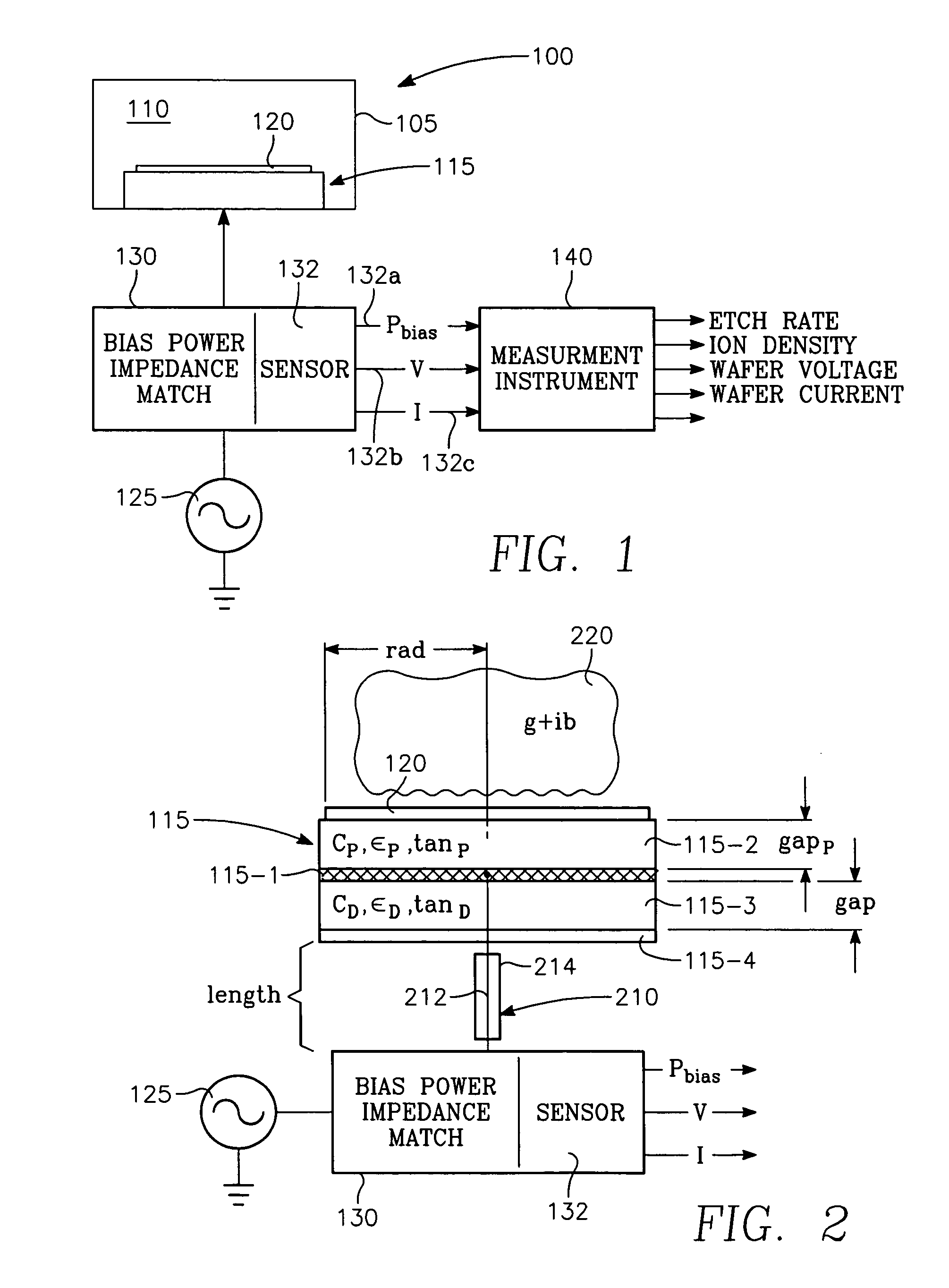

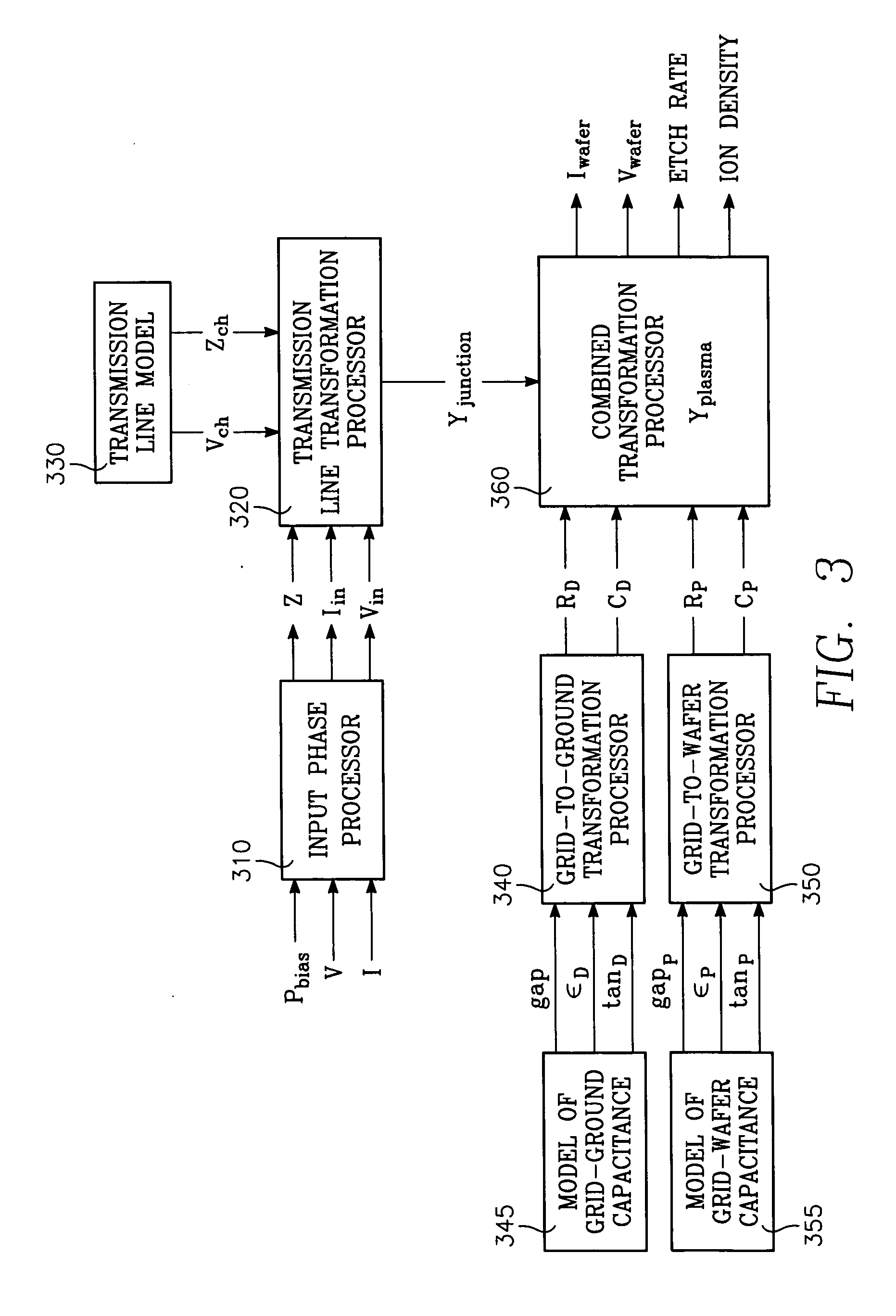

Method of determining plasma ion density, wafer voltage, etch rate and wafer current from applied bias voltage and current

ActiveUS20060278608A1Semiconductor/solid-state device testing/measurementElectric discharge tubesImpedance matchingShunt capacitance

Plasma parameters such as plasma ion density, wafer voltage, etch rate and wafer current in the chamber are determined from external measurements on the applied RF bias electrical parameters such as voltage and current. The method includes sensing RF parameters corresponding to an input impedance, an input current and an input voltage at the input of the impedance match element to a transmission line coupled between the bias generator and the wafer pedestal. The method continues by computing a junction admittance of a junction between the transmission line and the electrode within the wafer pedestal from the input impedance, input current and input voltage and from parameters of the transmission line. The method further includes providing shunt electrical quantities of a shunt capacitance between the electrode and a ground plane, and providing load electrical quantities of a load capacitance between the electrode and a wafer on the pedestal. The method further includes computing at least one of the plasma parameters from the junction admittance, the shunt electrical quantities, the load electrical quantities and a frequency of RF bias power applied to the electrode.

Owner:APPLIED MATERIALS INC

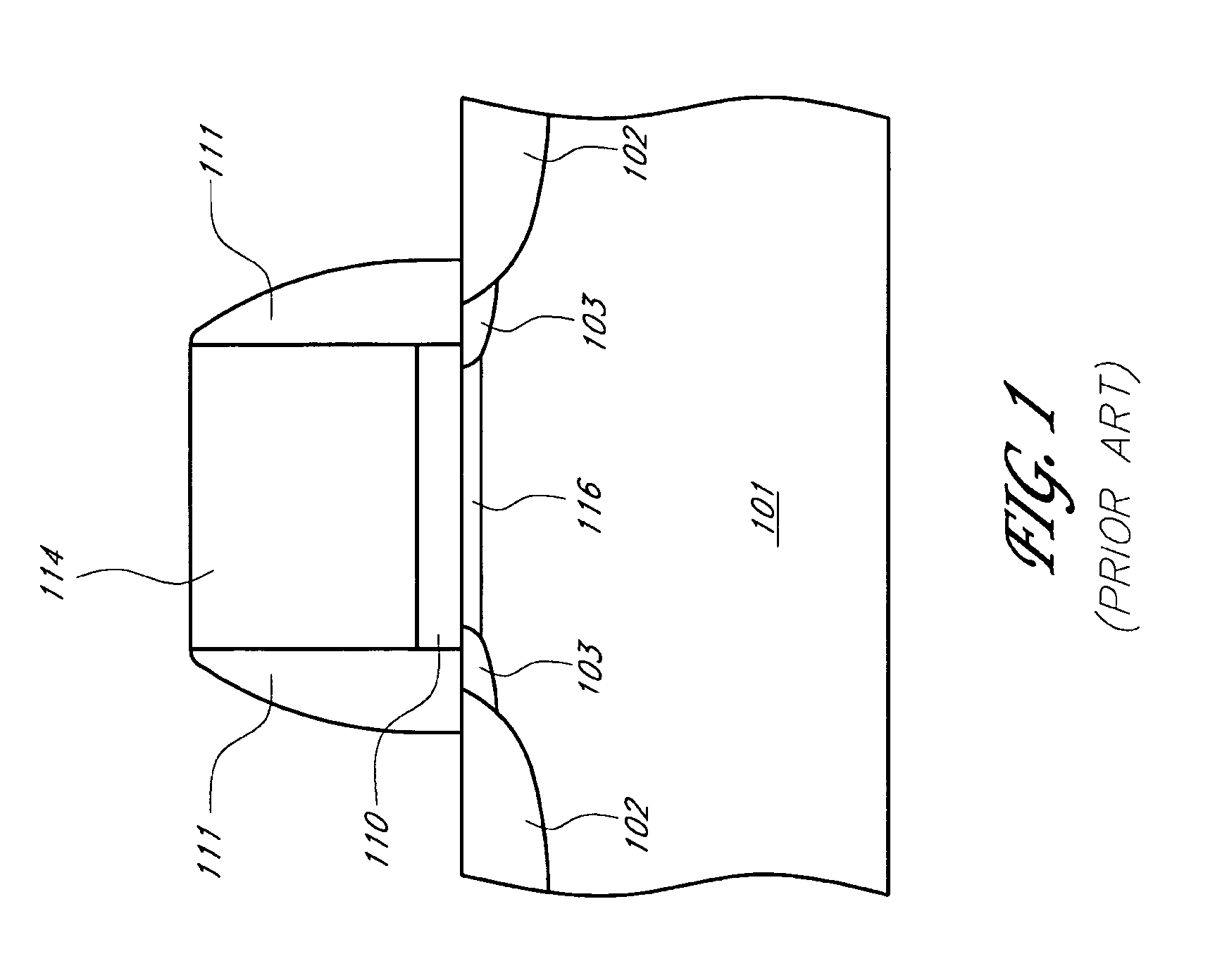

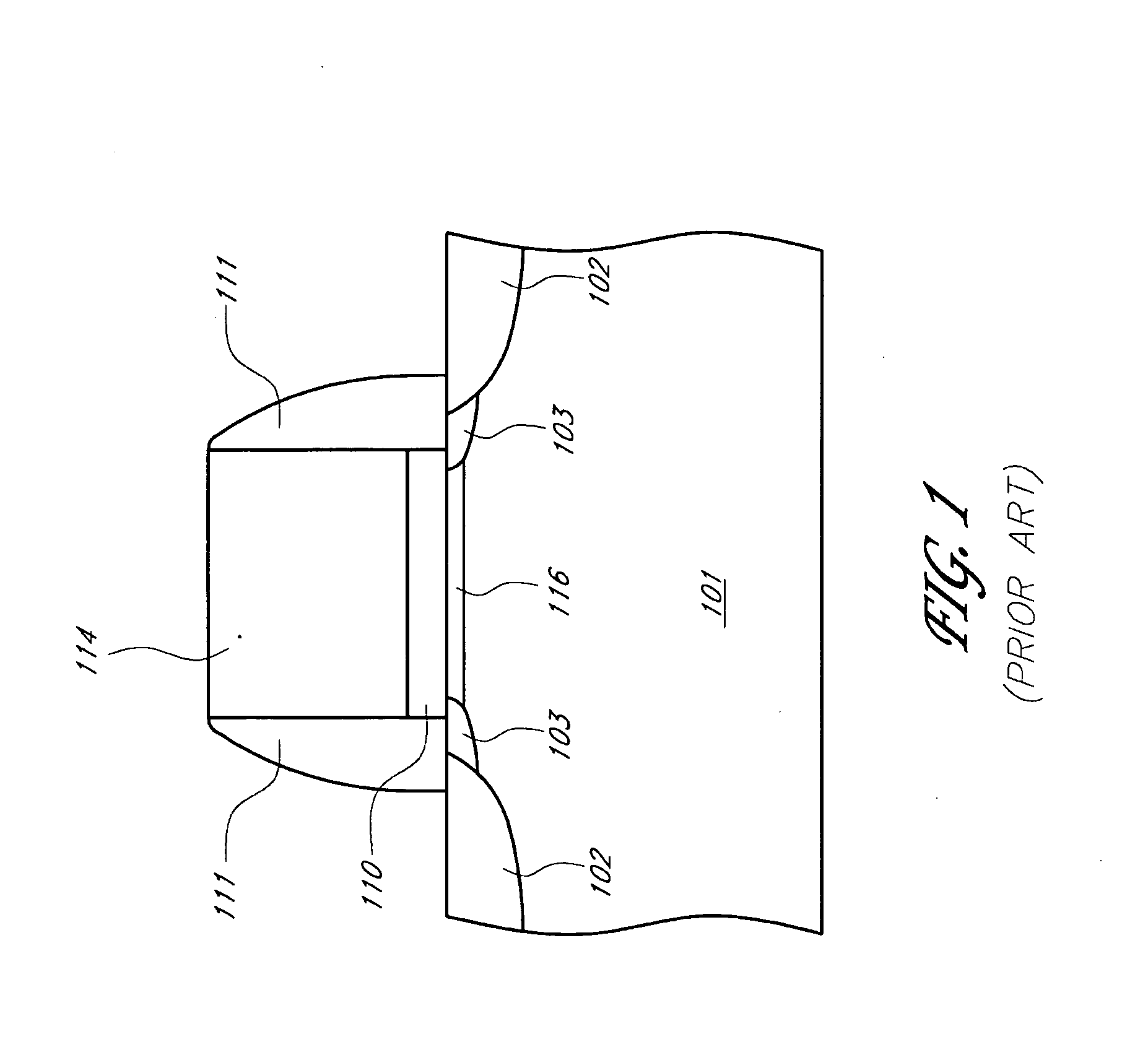

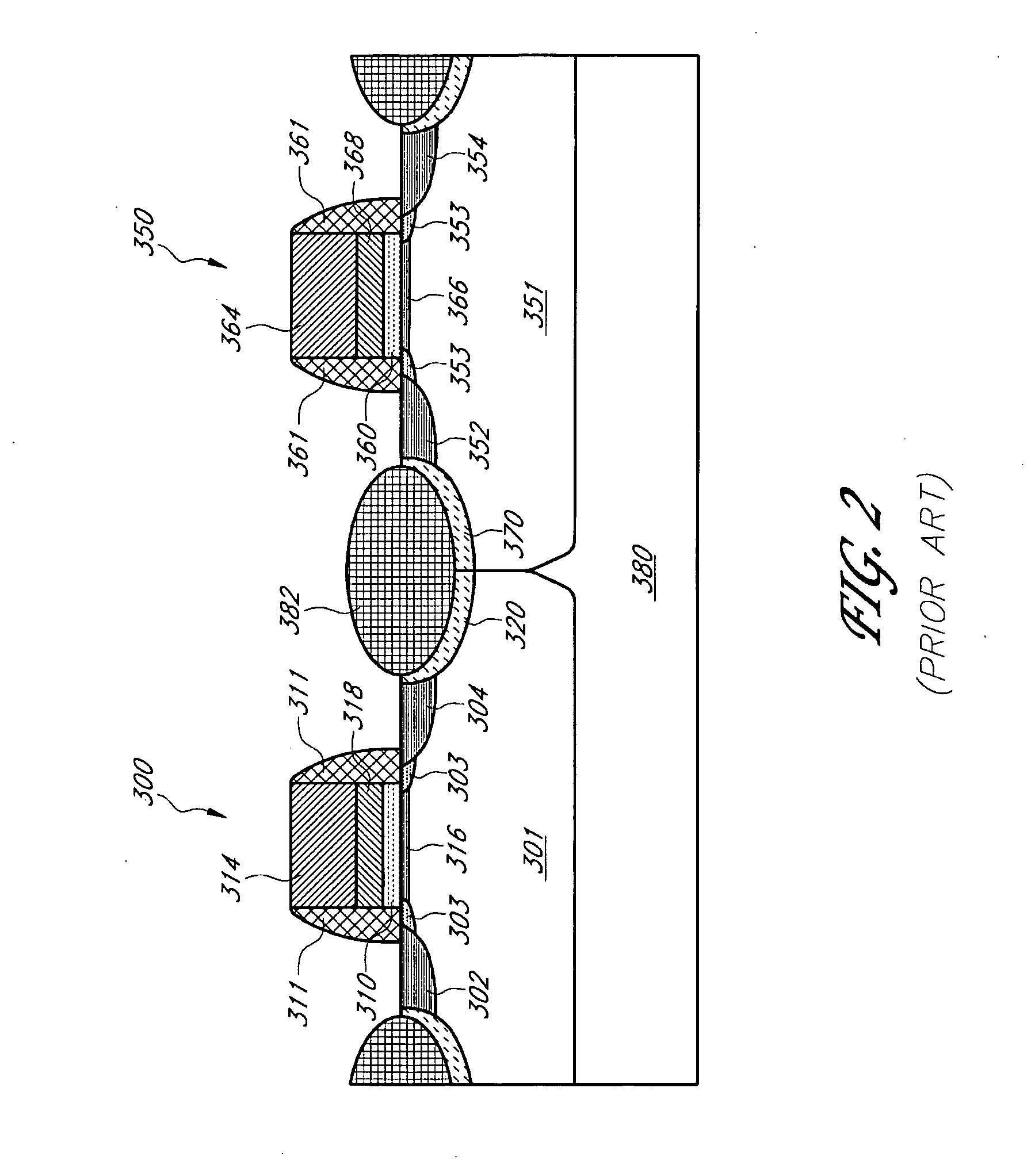

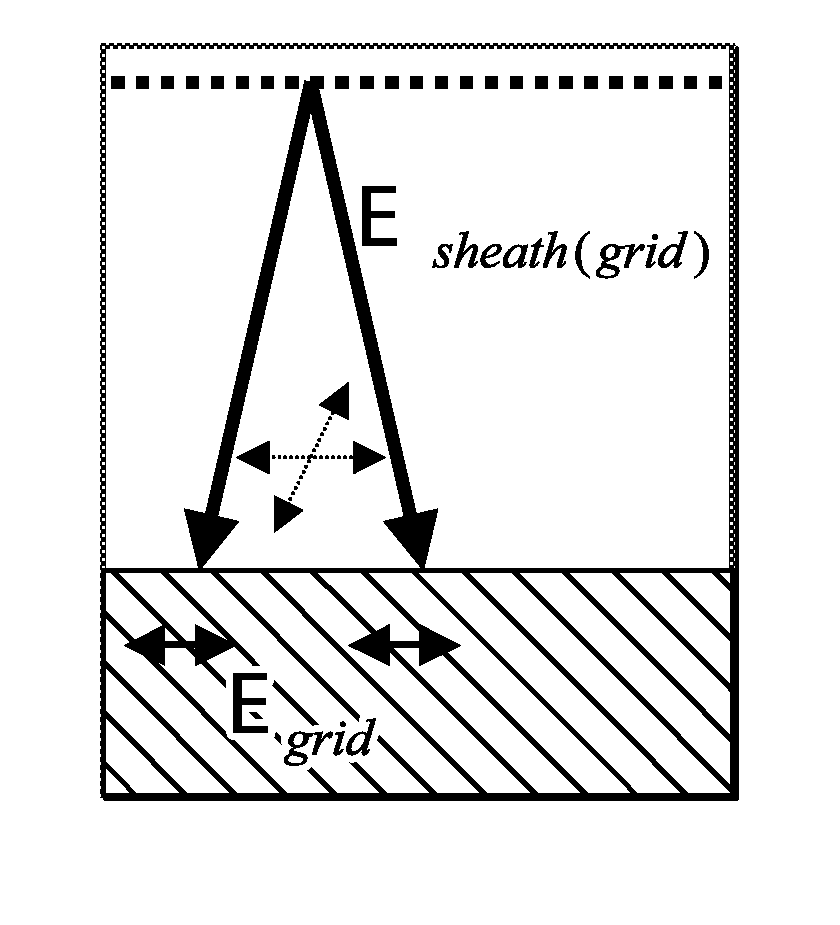

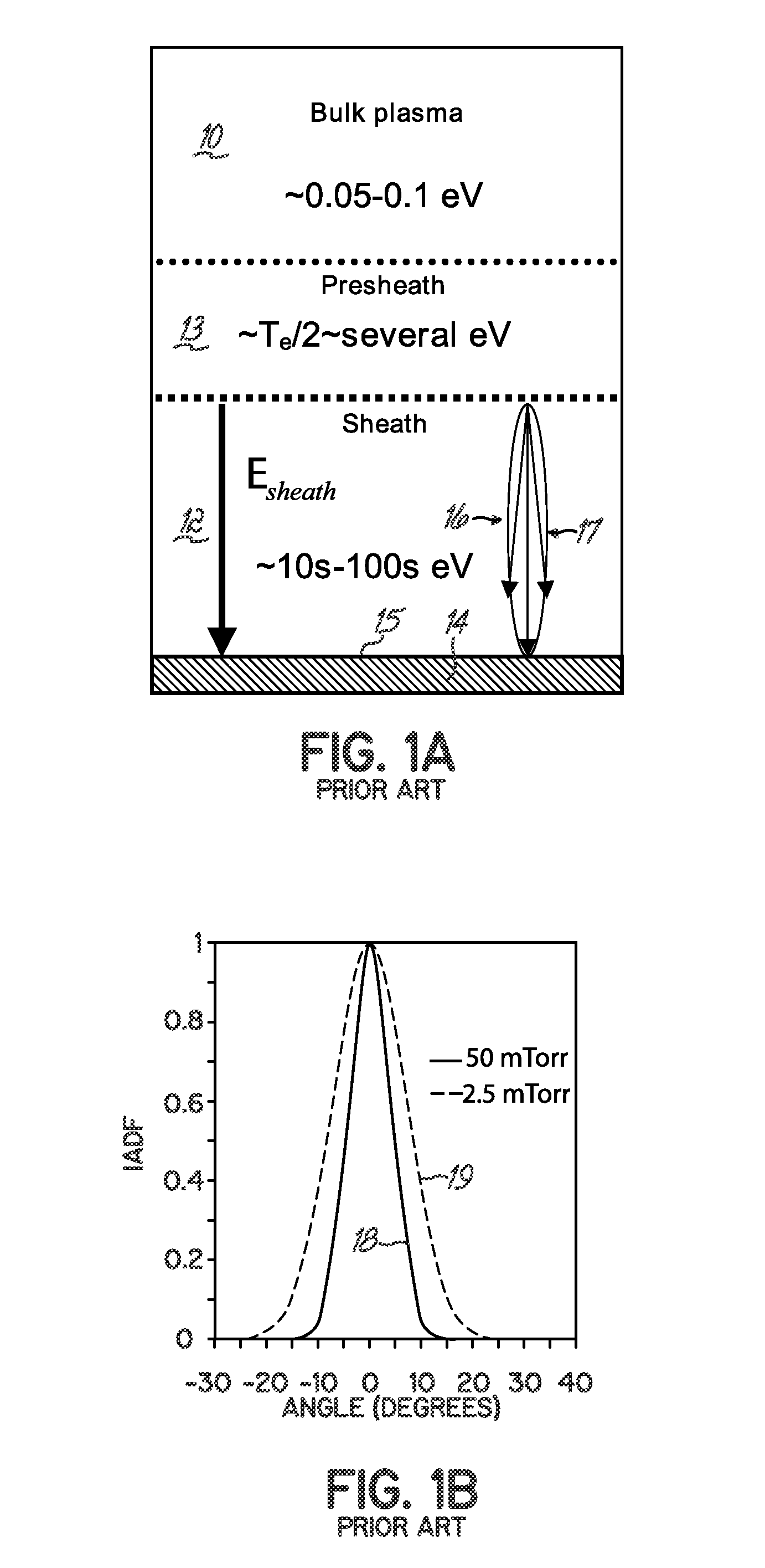

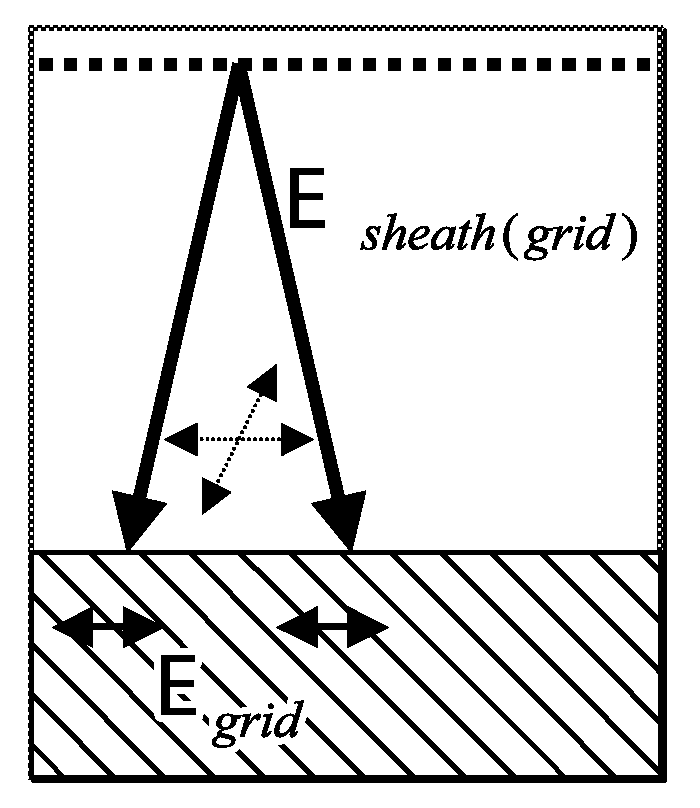

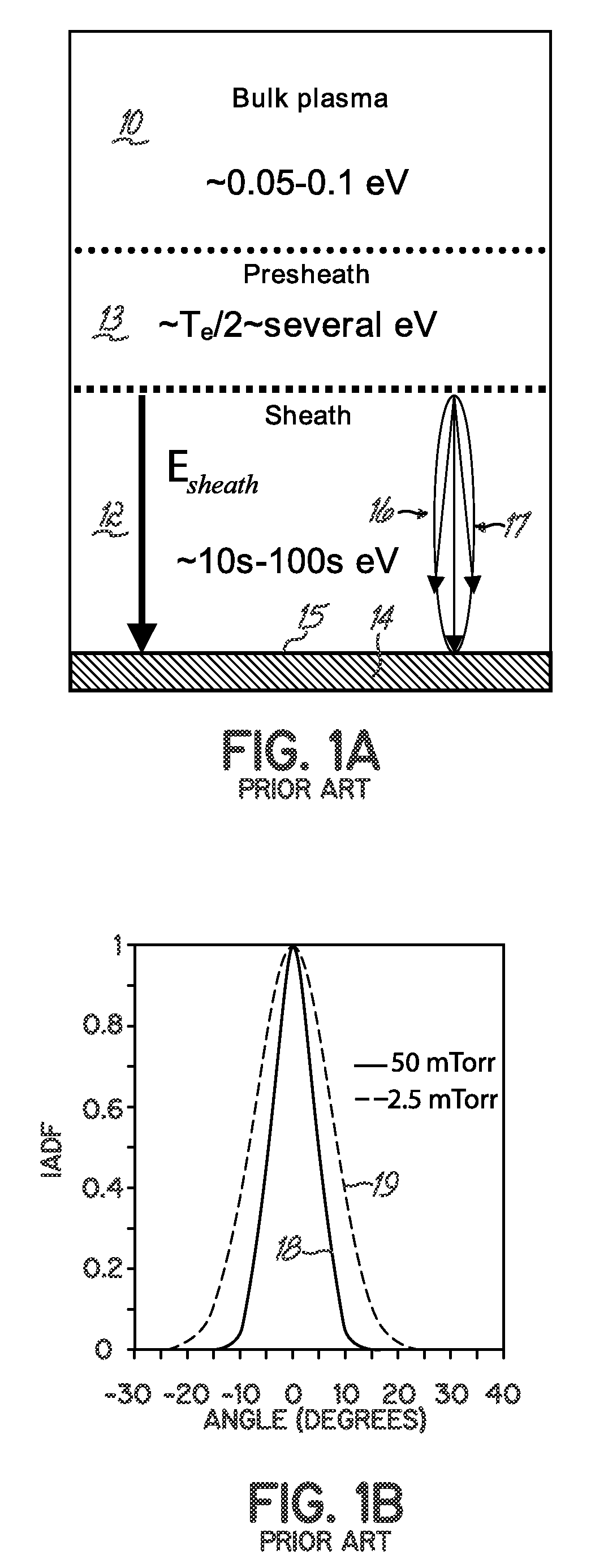

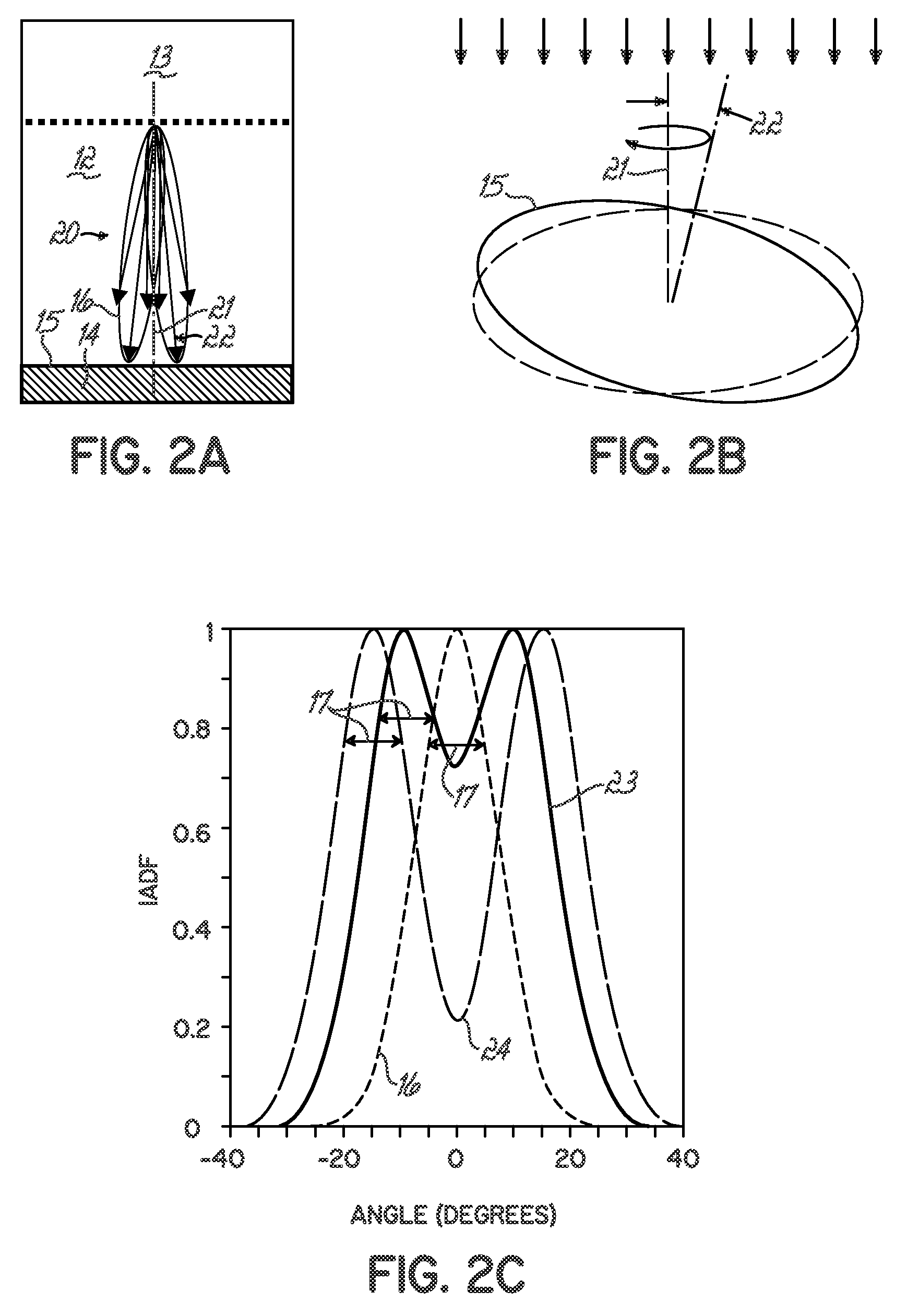

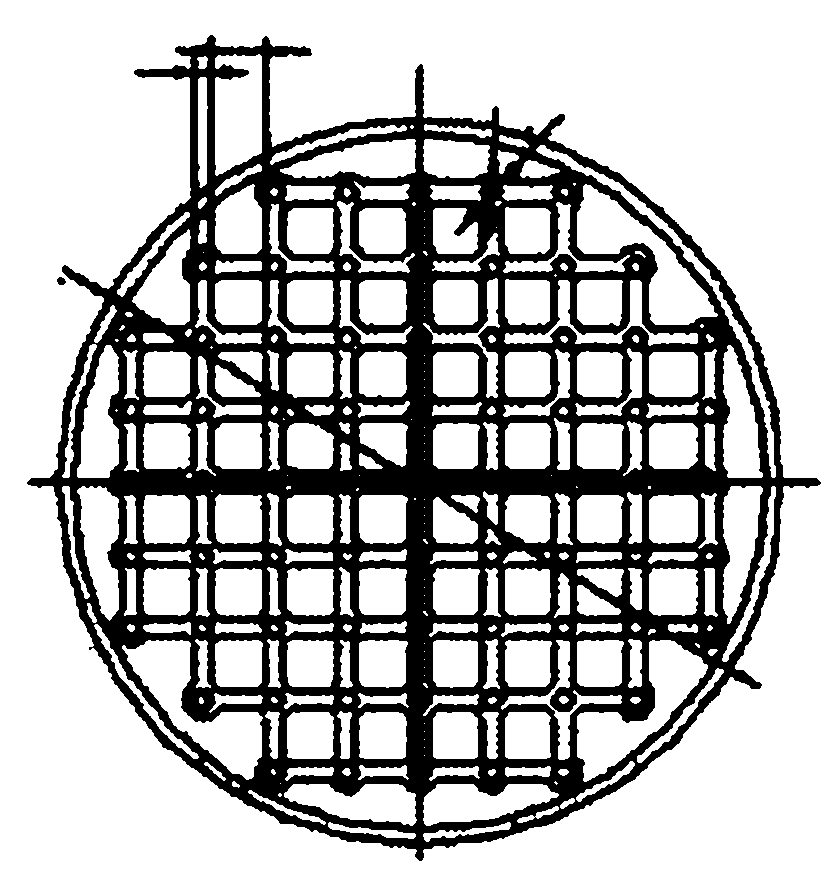

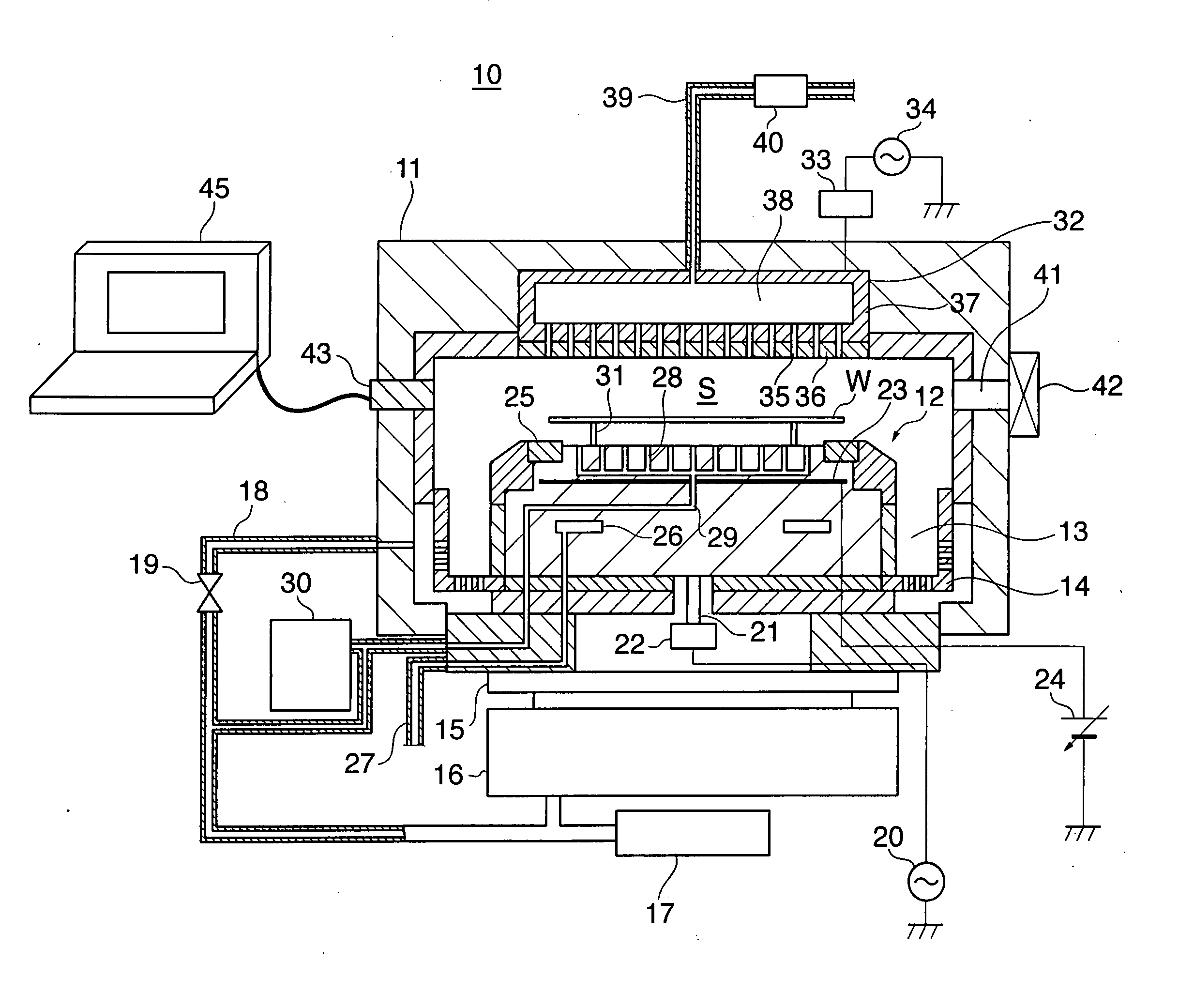

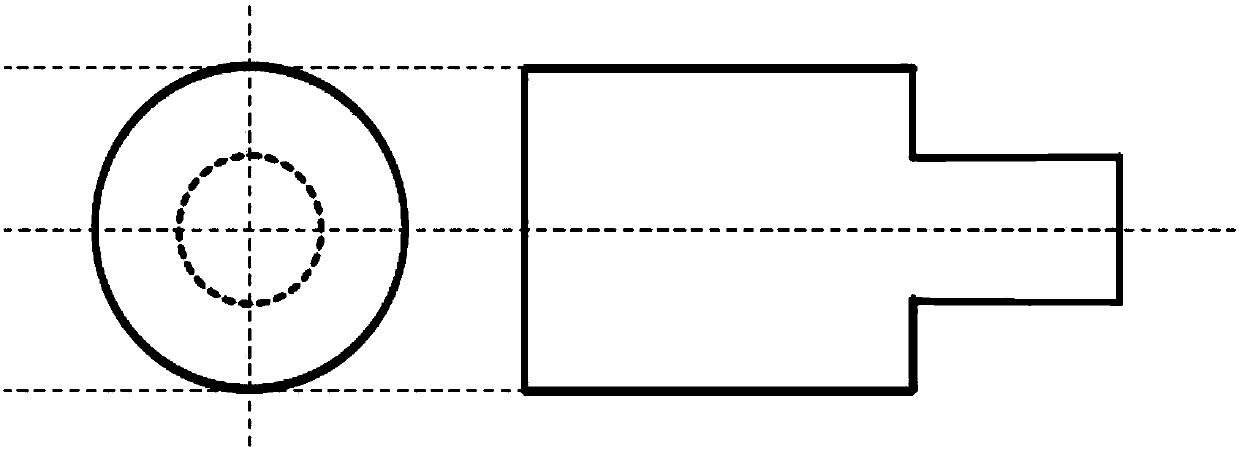

Control of ion angular distribution function at wafer surface

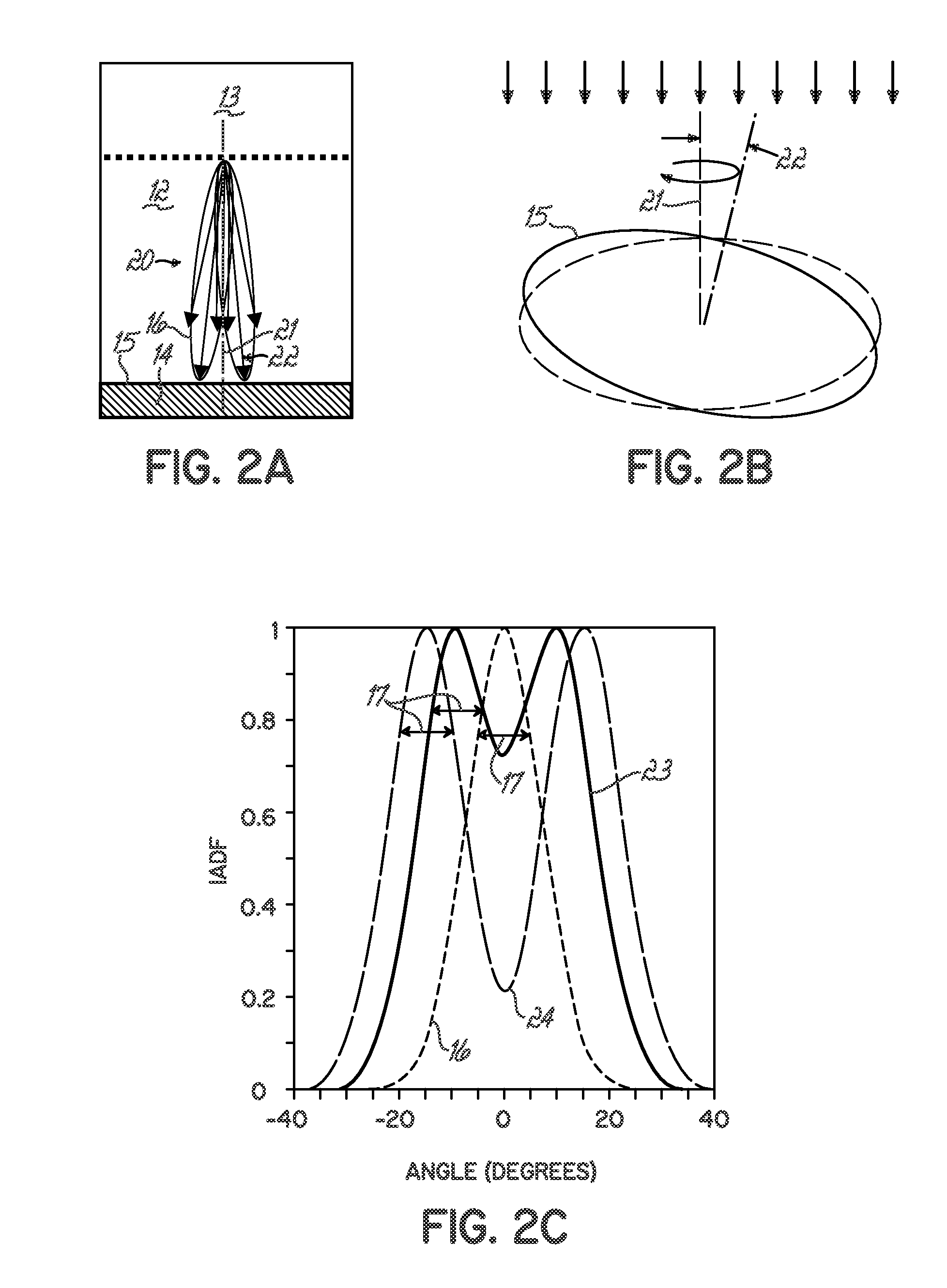

InactiveUS20080242065A1Suppress mutationCompensation effectElectric discharge tubesVacuum gauge using ionisation effectsEtchingPower grid

A manufacturing method and apparatus for IC fabrication controls the ion angular distribution at the surface of a wafer with electrodes in a wafer support that produce electric fields parallel to the wafer surface without disturbing plasma parameters beyond the wafer surface. The ion angular distribution function (IADF) at the wafer surface is controlled for better feature coverage or etching. Grid structure is built into the substrate holder within the coating at the top of the holder. The grid components are electrically biased to provide electric fields that combine with the sheath field to distribute the ion incidence angles from the plasma sheath onto the wafer. The grid can be dynamically biased or phased to control uniformity of the effects.

Owner:TOKYO ELECTRON LTD

Method of characterizing a chamber based upon concurrent behavior of selected plasma parameters as a function of plural chamber parameters

InactiveUS20070080138A1Electric discharge tubesVacuum gauge using ionisation effectsIon densityEngineering

The invention involves a method of characterizing a plasma reactor chamber through the behavior of many selected plasma parameters as functions of many selected chamber parameters. The plasma parameters may be selected from a group including ion density, wafer voltage, etch rate and wafer current or other plasma parameters. The chamber parameters are selected from a group including source power, bias power, chamber pressure, magnetic coil current in different magnetic coils, gas flow rates in different gas injection zones and species composition of the gas in different gas injection zones.

Owner:APPLIED MATERIALS INC

Systems and methods for forming and maintaining a high performance frc

ActiveUS20160276044A1Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueThermal energyDivertor

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

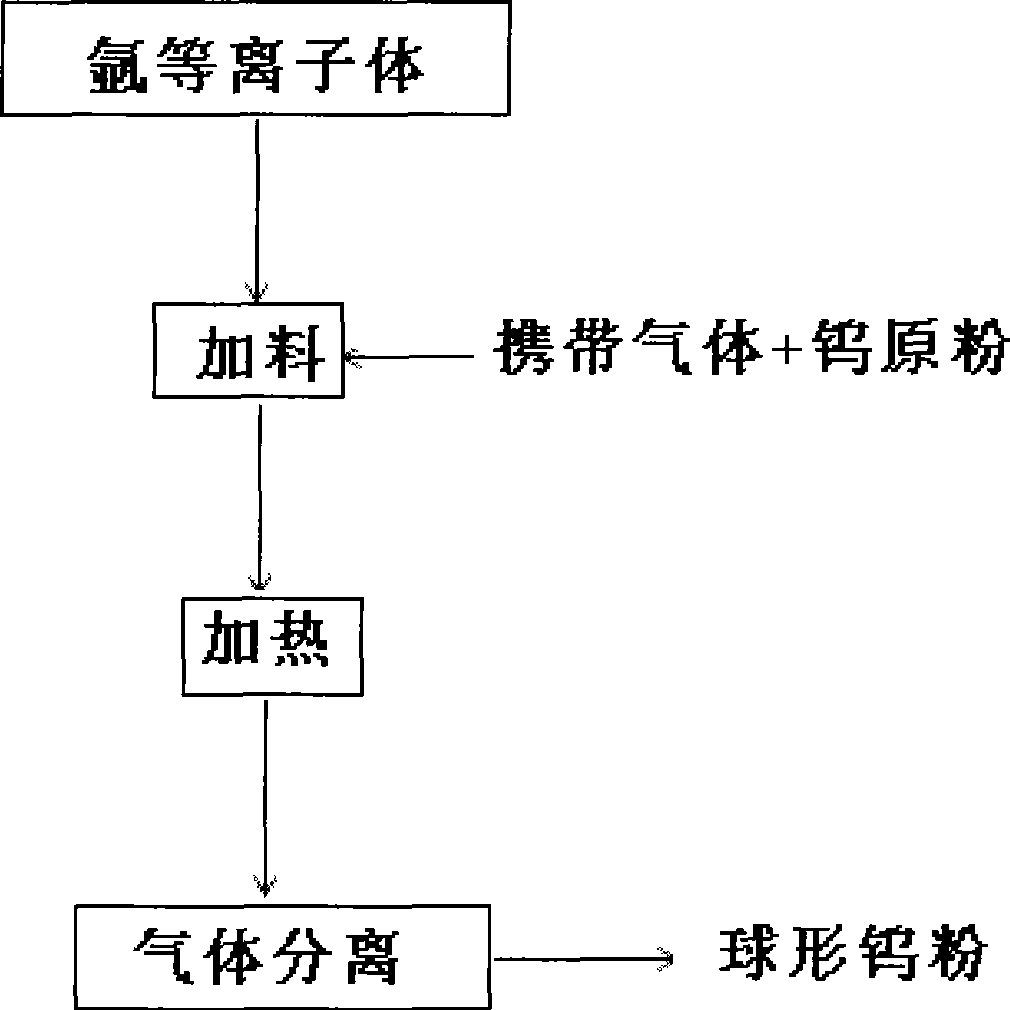

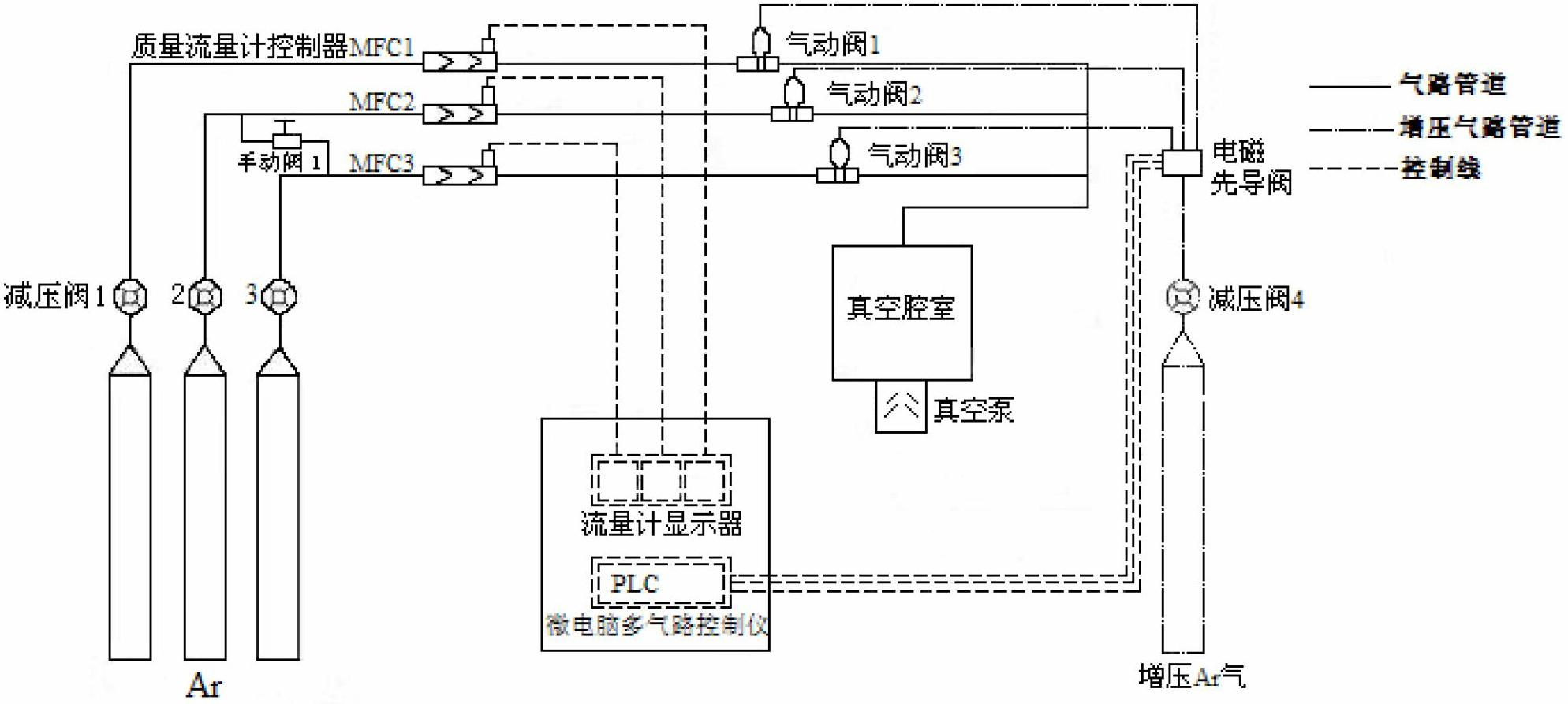

Preparation method of fine globular tungsten powder

The invention relates to a powder material preparation method, in particular to a method for preparing fine spherical tungsten powder. Plasma parameters are adjusted by building a stable argon plasma, thereby heating tungsten powder material and acquiring the fine spherical tungsten powder through the separation after cooling and solidification, and the obtained tungsten powder has better fluidity, higher density, purity and particle cleanliness of surface, and lower powder particle porosity compared with the tungsten original powder; and the method has advantages of changing shapes of tungsten powder particles, high sphericity, increasing the apparent density of powder, improving the tungsten powder fluidity and physical characteristics of the tungsten powder, and reducing costs.

Owner:SOUTHWESTERN INST OF PHYSICS

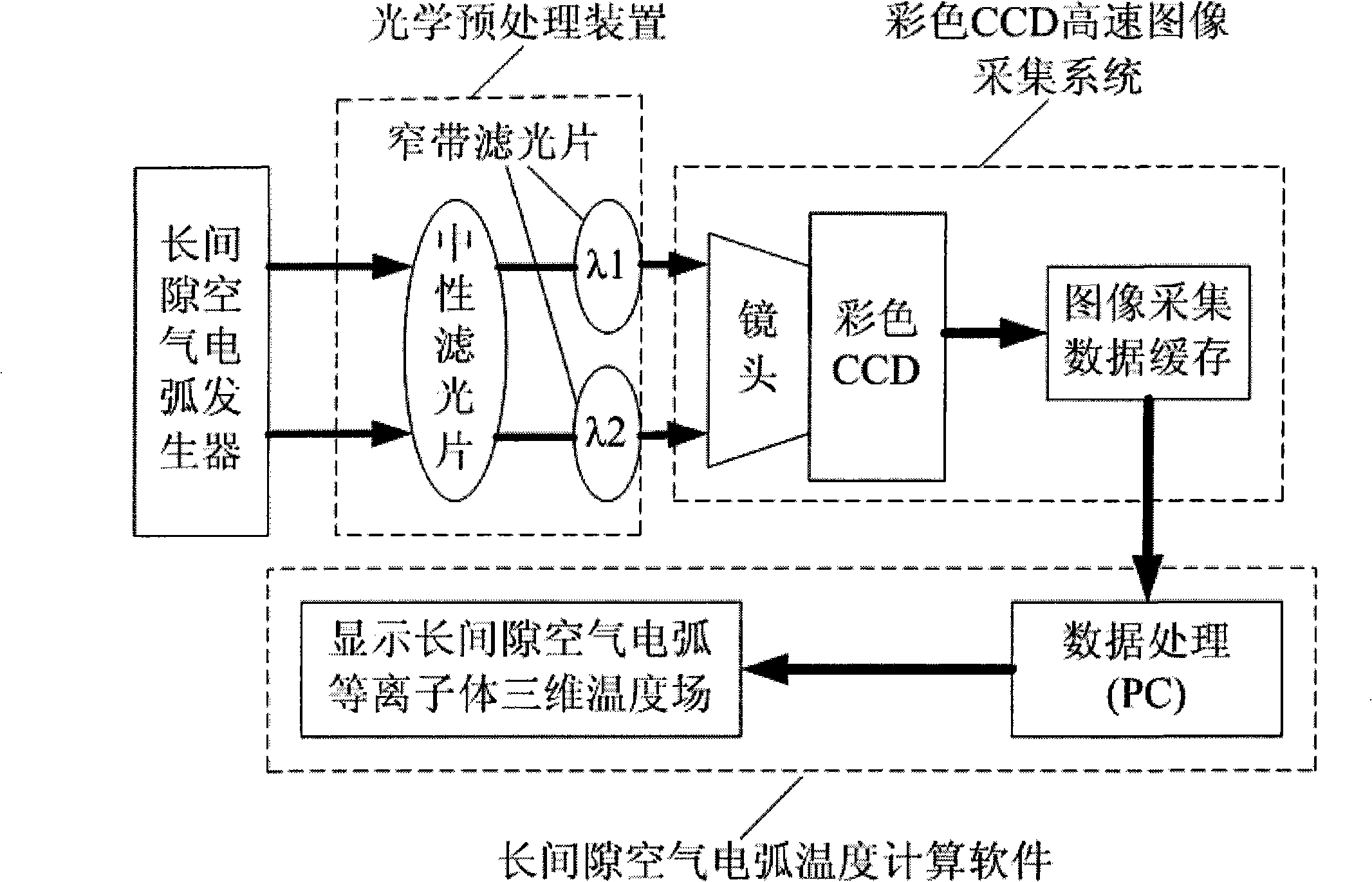

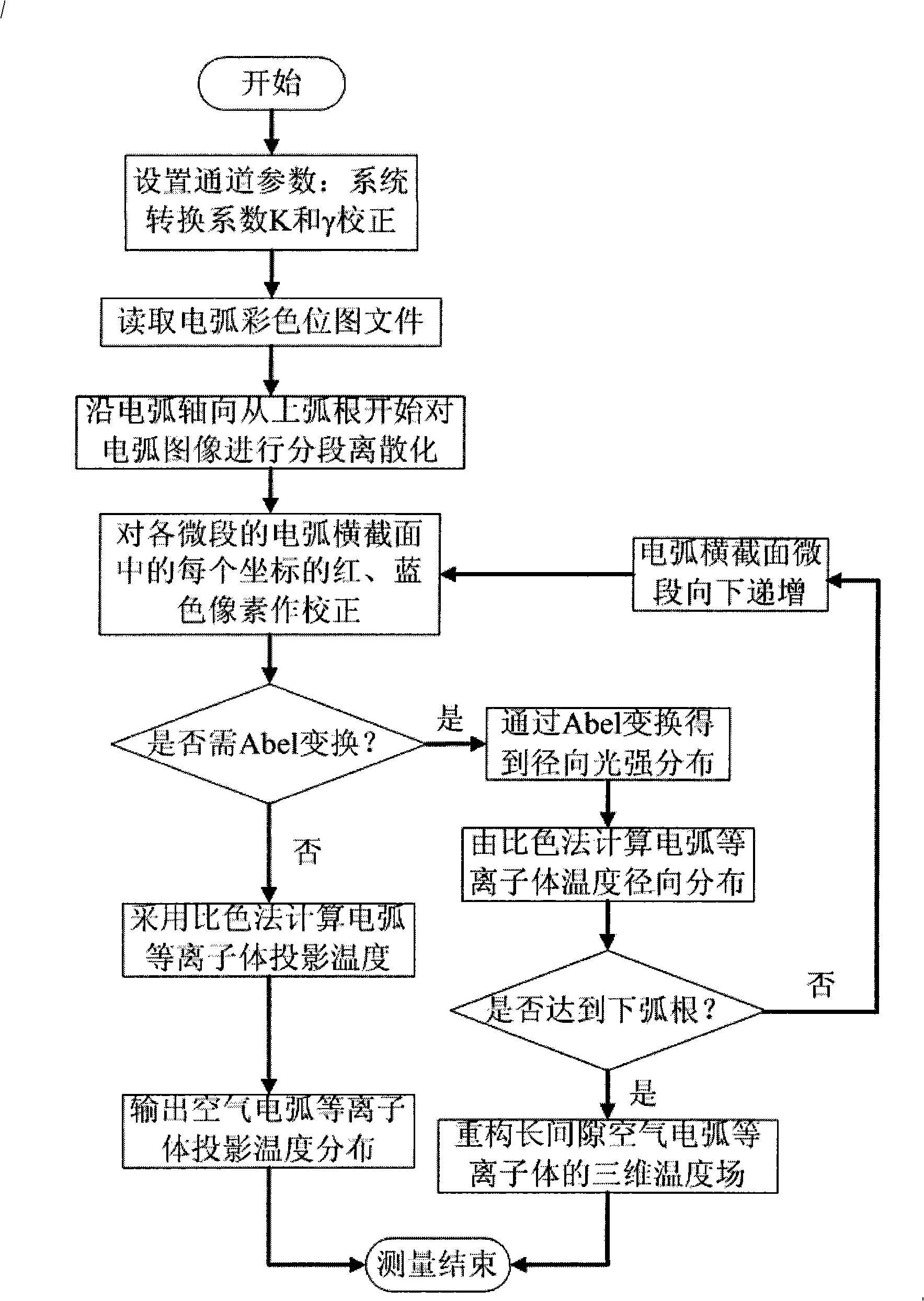

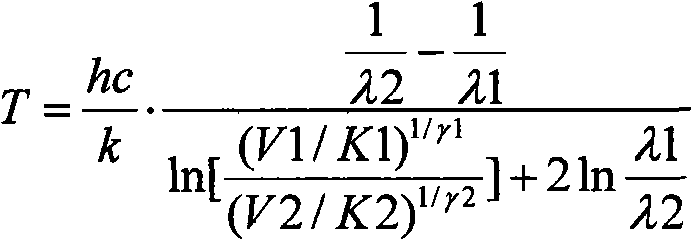

Method for measuring long clearance air arc-plasma temperature

ActiveCN101303257AEliminate Saturation DistortionMeet diagnostic requirementsRadiation pyrometryOriginal dataImage acquisition

Provided is a method for measuring temperature of long-gap air arc plasma, relating to heat plasma temperature measurement field. The method is based upon spectrum diagnosis principle of air arc plasma radiation, shooting long-gap air arc image through an attachment double-narrow-band-pass filter and a calibrated color CCD high speed image acquisition system, and storing in BMP format which data is not compressed; correcting pixel value of arc color bitmap file responded with two feature center wavelengths to original data of arc radiation intensity; obtaining arc radial light intensity distribution through Abel transformation, then calculating arc plasma projection temperature distribution or arc plasma temperature radial distribution by a colorimetry of spectrum relative intensity, and rebuilding tridimensional temperature field. The method of the present invention can measure open arc plasma temperature in air of several meters accurately and provides an important plasma parameter for researching microcosmic mechanism of long-gap air arc.

Owner:CHINA ELECTRIC POWER RES INST +1

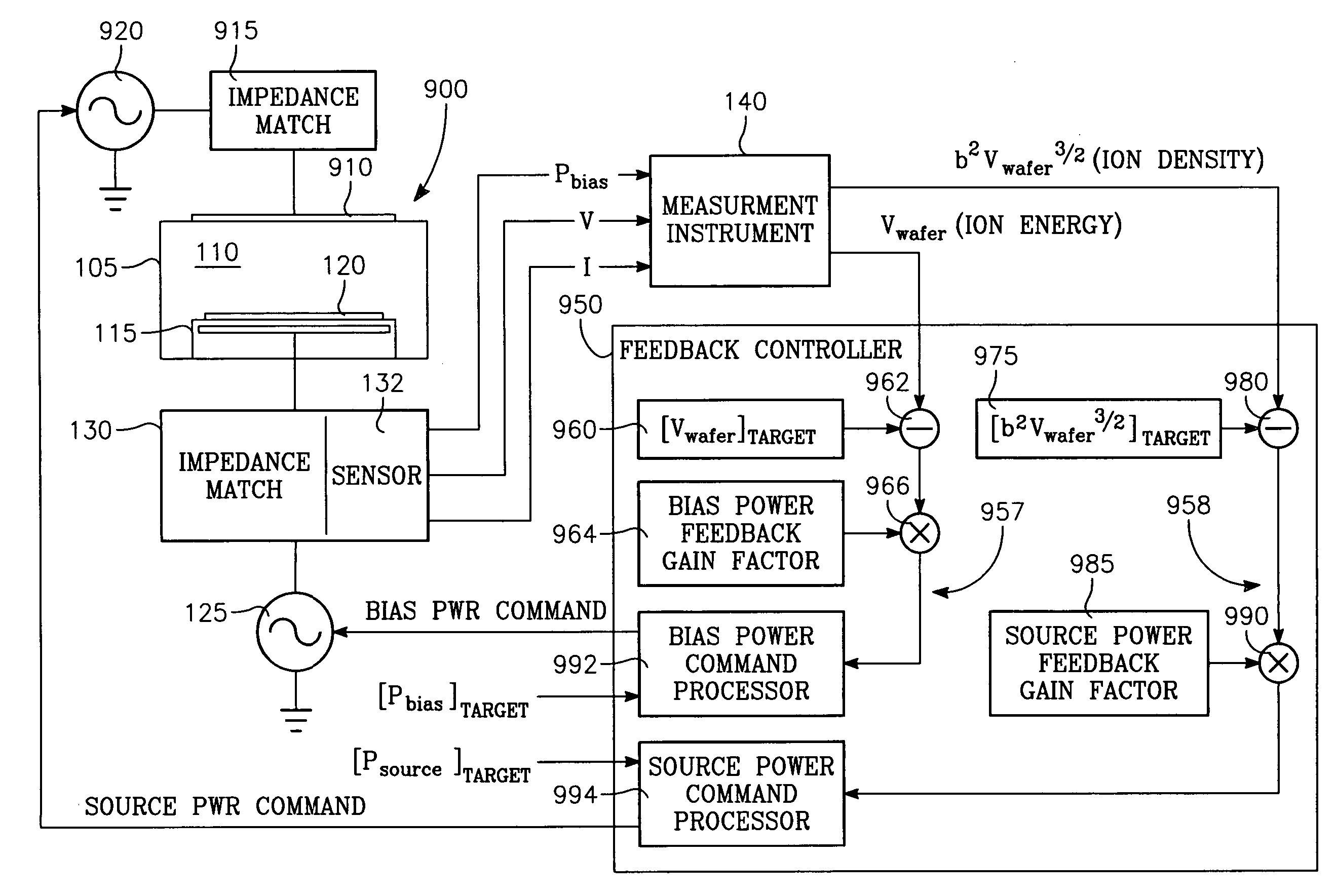

Plasma reactor control by translating desired values of m plasma parameters to values of n chamber parameters

InactiveUS20070080140A1Semiconductor/solid-state device testing/measurementElectric discharge tubesGas compositionIon density

The invention concerns a method of processing a wafer in a plasma reactor chamber by controlling plural chamber parameters in accordance with desired values of plural plasma parameters. The method includes concurrently translating a set of M desired values for M plasma parameters to a set of N values for respective N chamber parameters. The M plasma parameters are selected from a group including wafer voltage, ion density, etch rate, wafer current, etch selectivity, ion energy and ion mass. The N chamber parameters are selected from a group including source power, bias power, chamber pressure, inner magnet coil current, outer magnet coil current, inner zone gas flow rate, outer zone gas flow rate, inner zone gas composition, outer zone gas composition. The method further includes setting the N chamber parameters to the set of N values.

Owner:APPLIED MATERIALS INC

Control of ion angular distribution function at wafer surface

InactiveUS7867409B2Electric discharge tubesVacuum gauge using ionisation effectsEtchingElectric field

A manufacturing method and apparatus for IC fabrication controls the ion angular distribution at the surface of a wafer with electrodes in a wafer support that produce electric fields parallel to the wafer surface without disturbing plasma parameters beyond the wafer surface. The ion angular distribution function (IADF) at the wafer surface is controlled for better feature coverage or etching. Grid structure is built into the substrate holder within the coating at the top of the holder. The grid components are electrically biased to provide electric fields that combine with the sheath field to distribute the ion incidence angles from the plasma sheath onto the wafer. The grid can be dynamically biased or phased to control uniformity of the effects.

Owner:TOKYO ELECTRON LTD

Systems and methods for forming and maintaining a high performance FRC

ActiveUS10049774B2Improve FRC confinementStability control without negative side-effectsNuclear energy generationPlasma techniqueThermal energyDivertor

A high performance field reversed configuration (FRC) system includes a central confinement vessel, two diametrically opposed reversed-field-theta-pinch formation sections coupled to the vessel, and two divertor chambers coupled to the formation sections. A magnetic system includes quasi-dc coils axially positioned along the FRC system components, quasi-dc mirror coils between the confinement chamber and the formation sections, and mirror plugs between the formation sections and the divertors. The formation sections include modular pulsed power formation systems enabling static and dynamic formation and acceleration of the FRCs. The FRC system further includes neutral atom beam injectors, pellet injectors, gettering systems, axial plasma guns and flux surface biasing electrodes. The beam injectors are preferably angled toward the midplane of the chamber. In operation, FRC plasma parameters including plasma thermal energy, total particle numbers, radius and trapped magnetic flux, are sustainable at or about a constant value without decay during neutral beam injection.

Owner:TAE TECH INC

Method of controlling a chamber based upon predetermined concurrent behavior of selected plasma parameters as a function of source power, bias power and chamber pressure

InactiveUS20070080139A1Semiconductor/solid-state device testing/measurementElectric discharge tubesIon densityEngineering

The invention involves a method of processing a workpiece on workpiece support pedestal in a plasma reactor chamber in accordance with user-selected values of plural plasma parameters by controlling chamber parameters of source power, bias power and chamber pressure. The plasma parameters may be selected from of a group including ion density, wafer voltage, etch rate, wafer current and possibly other plasma parameters. The method begins with a first step carried out for each one of the plural plasma parameters. This first step consists of fetching from a memory a relevant surface of constant value corresponding to the user-selected value of the one plasma parameter, the surface being defined in a 3-dimensional space of which each of the chamber parameters is dimension. This step further includes determining an intersection of these relevant surfaces, the intersection corresponding to a target value of source power, bias power and chamber pressure. The method further includes setting the source power, the bias power and the chamber, respectively, to the corresponding target value.

Owner:APPLIED MATERIALS INC

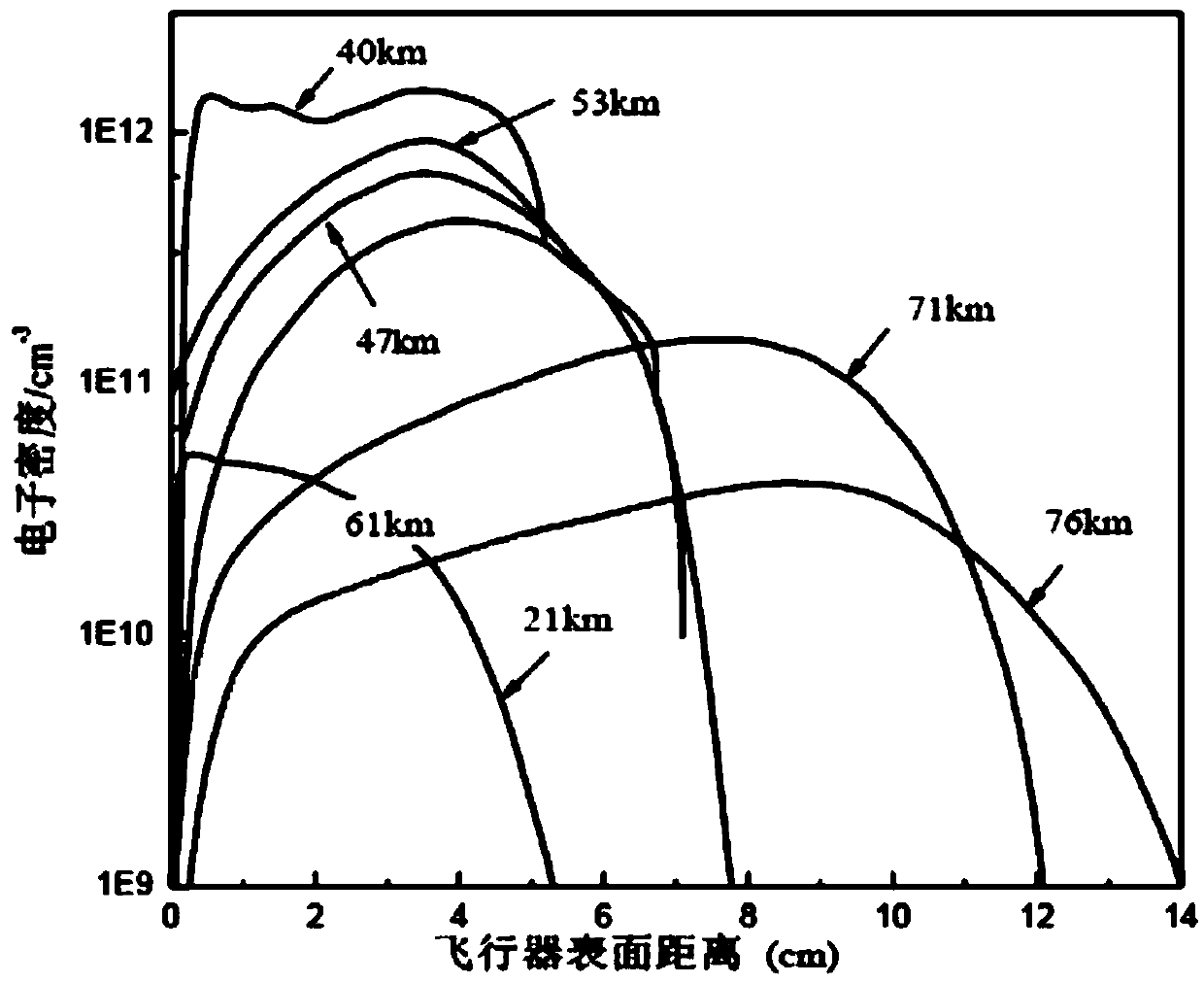

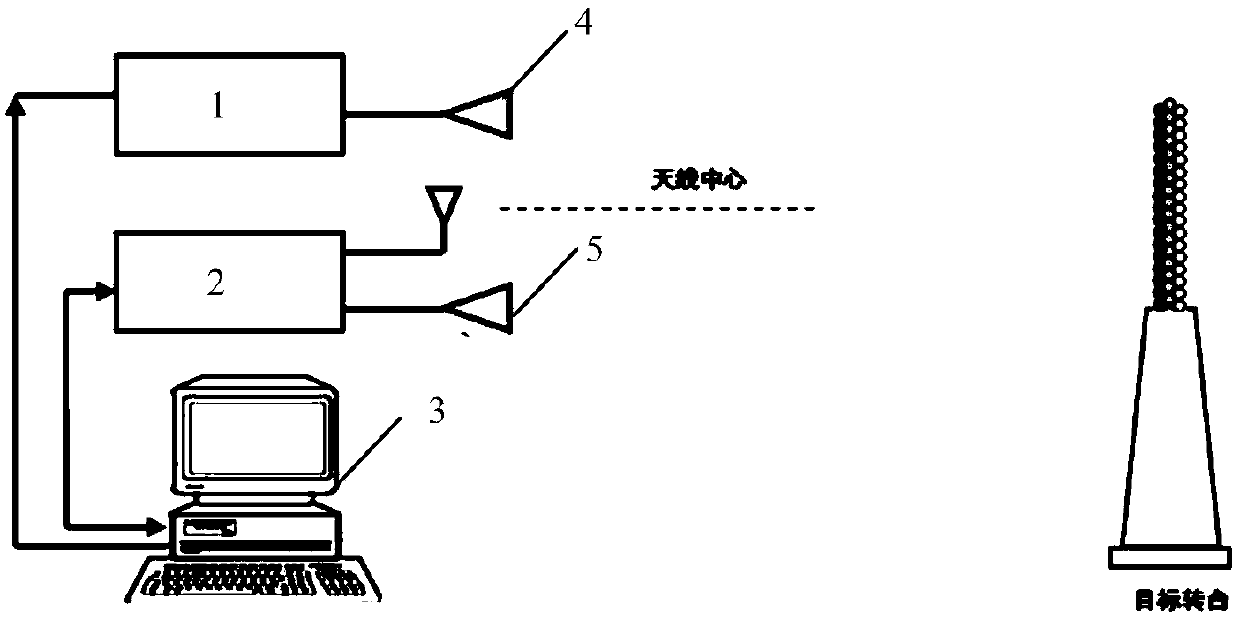

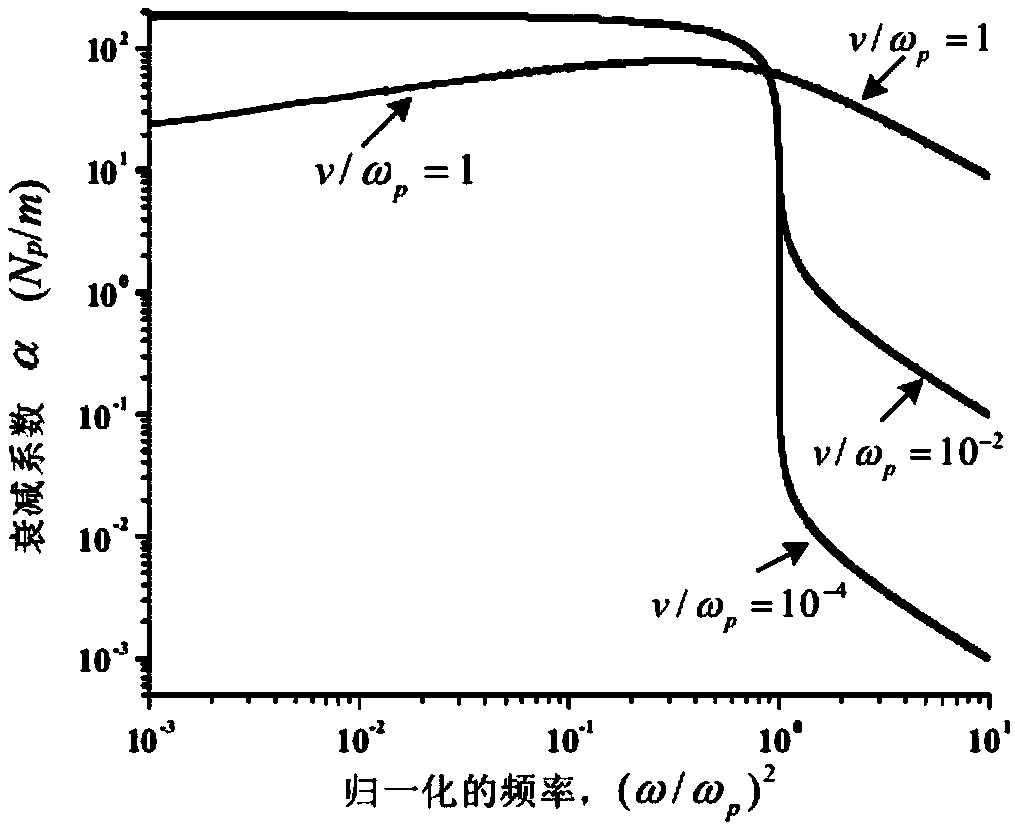

Diagnostic system and method for non-uniform plasma electron density

ActiveCN109640501AEffective diagnostic electron densityAvoid direct contactPlasma techniqueUltra-widebandPlasma electron

The invention provides a diagnostic system for non-uniform plasma electron density, including the following parts: a plasma generator, disposed in front of the calibrator; an ultra-wideband antenna, including a receiving antenna and a transmitting antenna disposed on the same side of the plasma generator; a time domain narrow-pulse source, connected to the transmitting antenna; a high-speed sampling digital oscilloscope, connected to the transmitting antenna and the receiving antenna, and used for recording and processing a transmitting signal of the transmitting antenna and a receiving signalof the receiving antenna; and a programmable power supply system, respectively connected to the time domain narrow-pulse source, the high-speed sampling digital oscilloscope and the plasma generator,and used to trigger the time domain narrow-pulse source, control the discharge power of the plasma generator, and record different discharge power states of the plasma to obtain basic plasma parameters under different discharge states. The system provided by the invention has the advantage of simulating a more accurate environment of super-sonic target surface plasma sheath, and having high testefficiency and low test cost.

Owner:SHANGHAI RADIO EQUIP RES INST

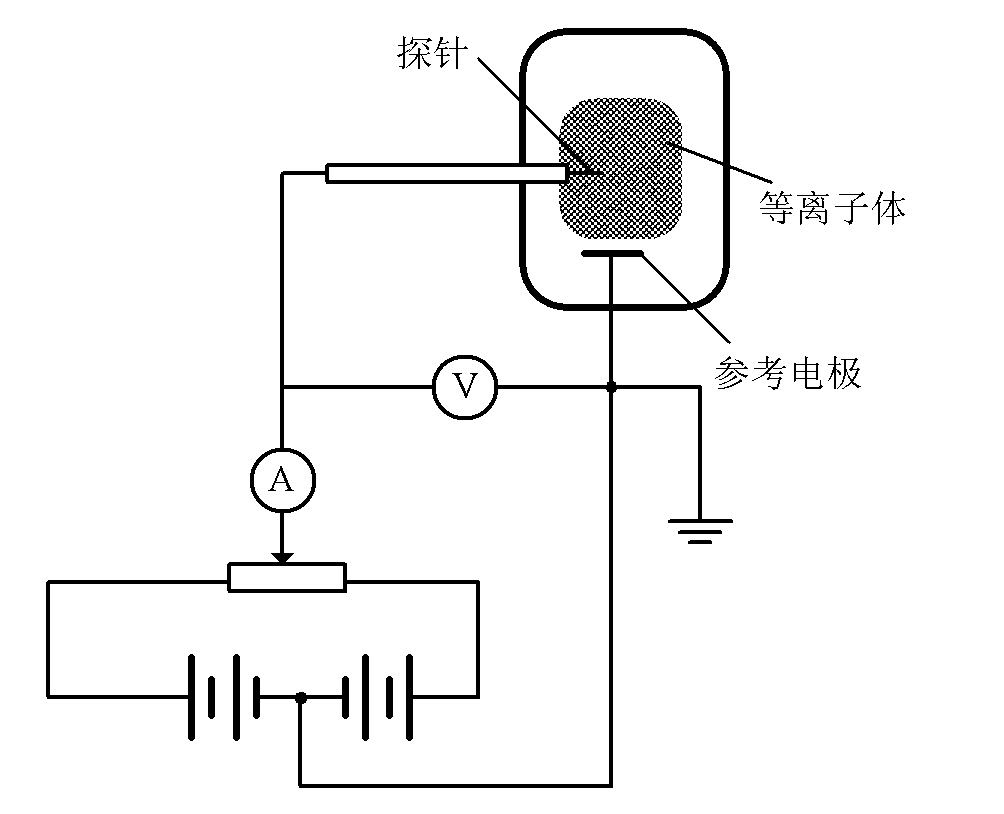

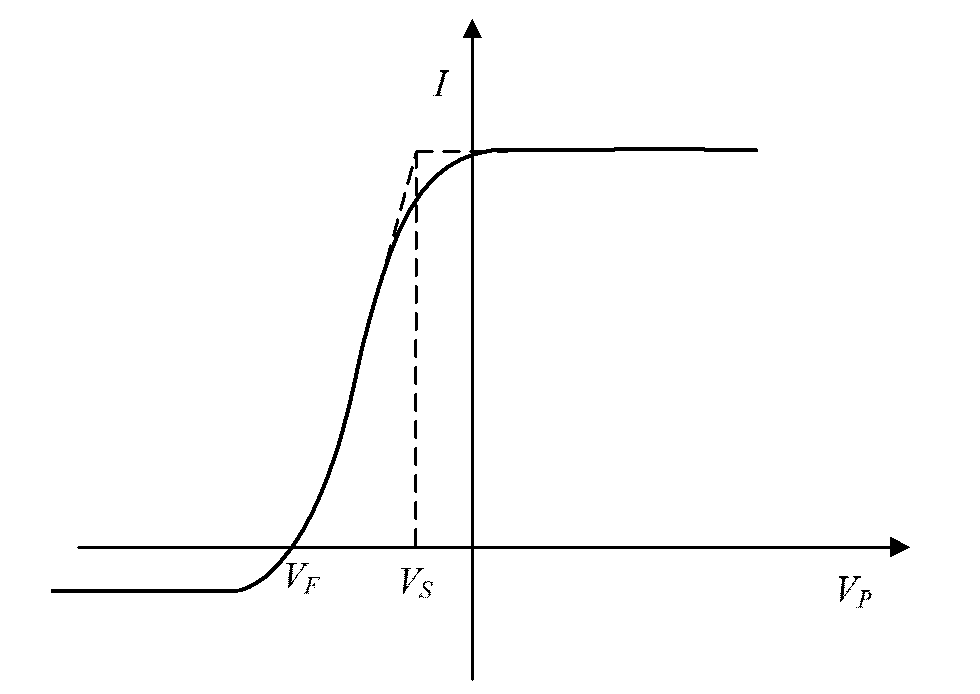

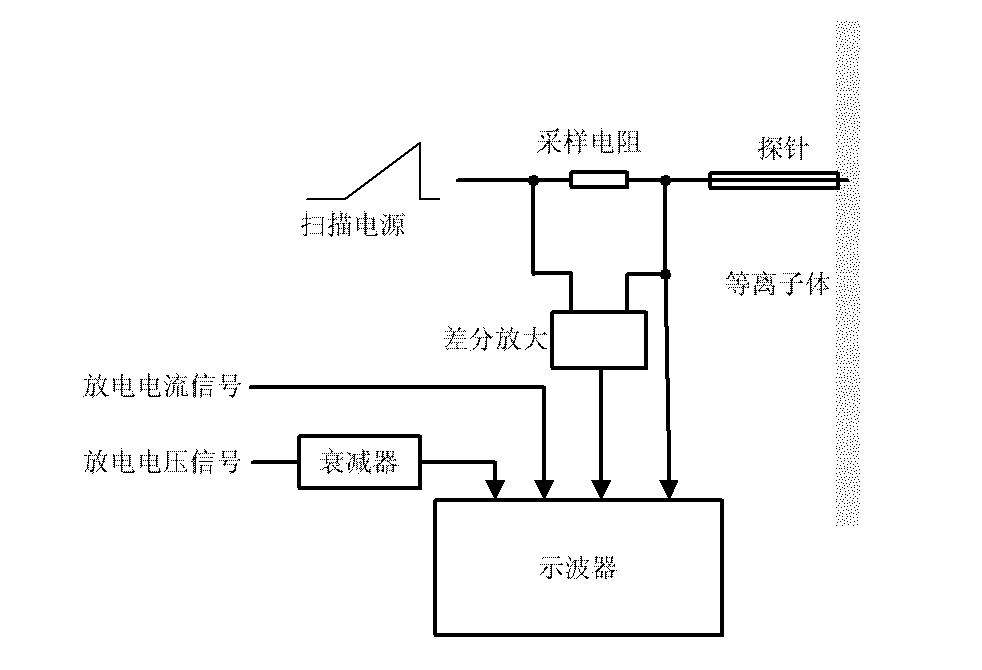

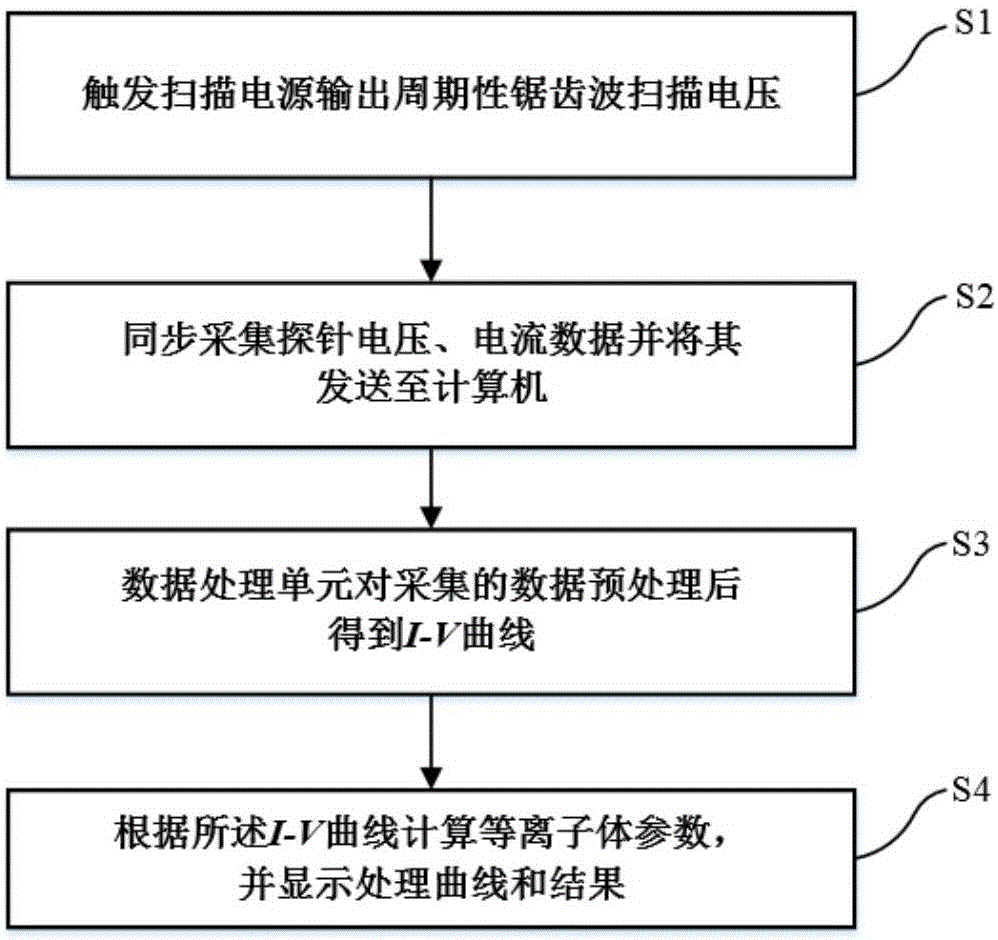

Method for acquiring voltage-current characteristic curve of plasma

The invention relates to a method for acquiring a voltage-current characteristic curve of plasma. The method is characterized in that plasma parameters are probed by using a Langmuir probe under the condition of radio-frequency discharge mode; a point to be probed is probed by the Langmuir probe under the control of a scanning voltage to acquire sampling values of the parameters, thereby, the voltage-current characteristic curve of the plasma is acquired, wherein one-time probe working time comprises a plurality of discharge cycles; the stable scanning voltage is applied to the Langmuir probe during the same discharge cycle; and each discharge cycle corresponds to one different scanning voltage.

Owner:NAT SPACE SCI CENT CAS

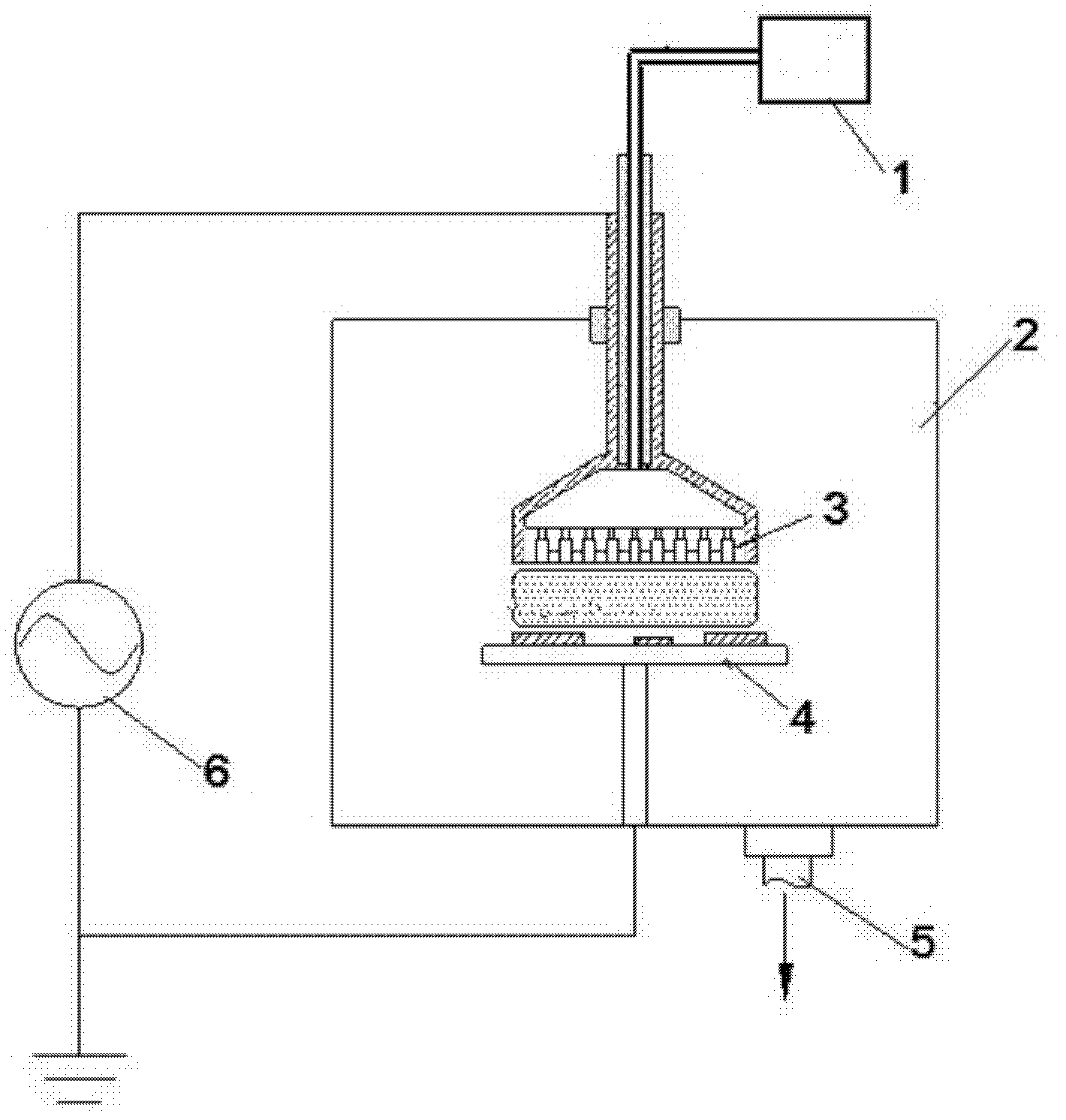

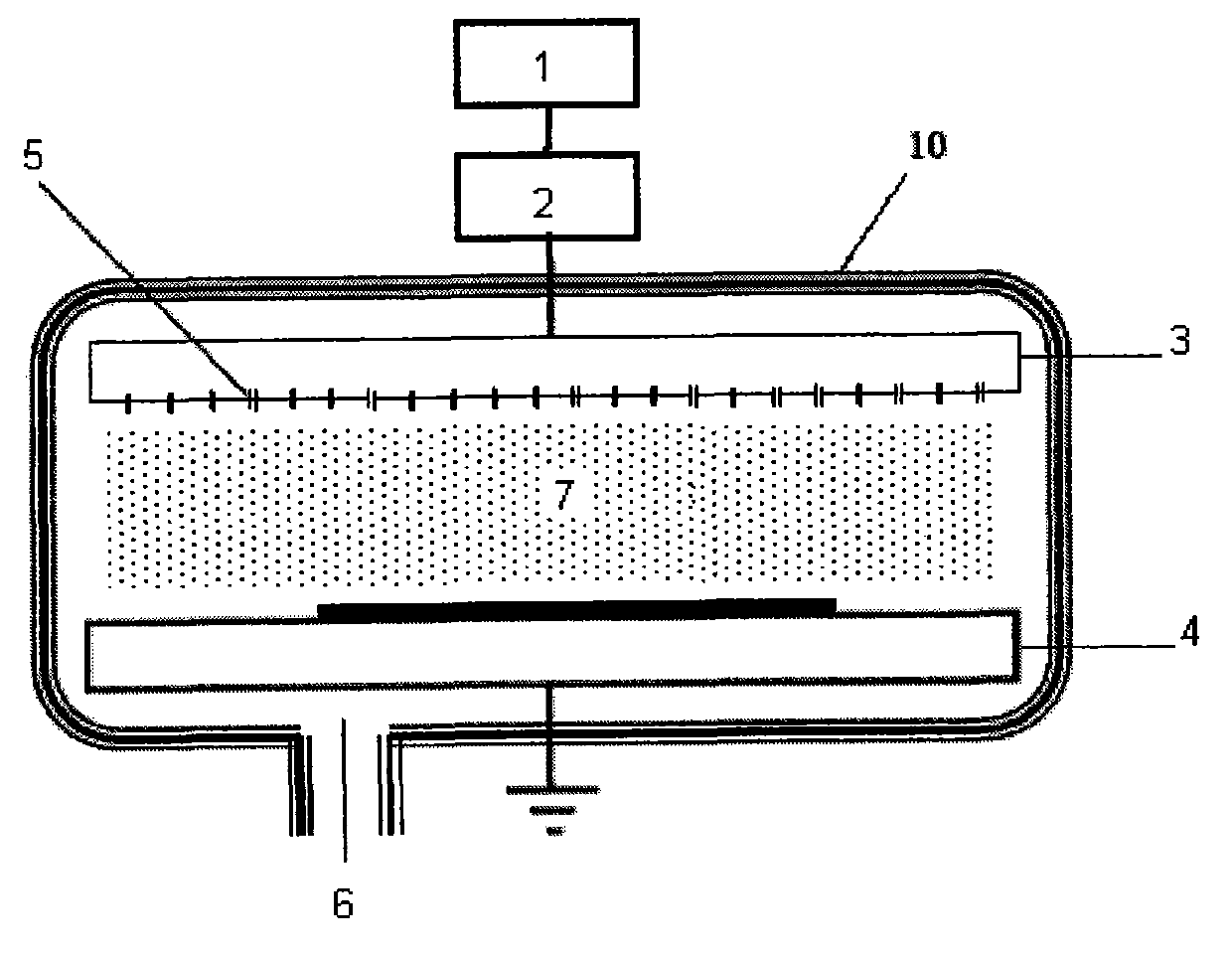

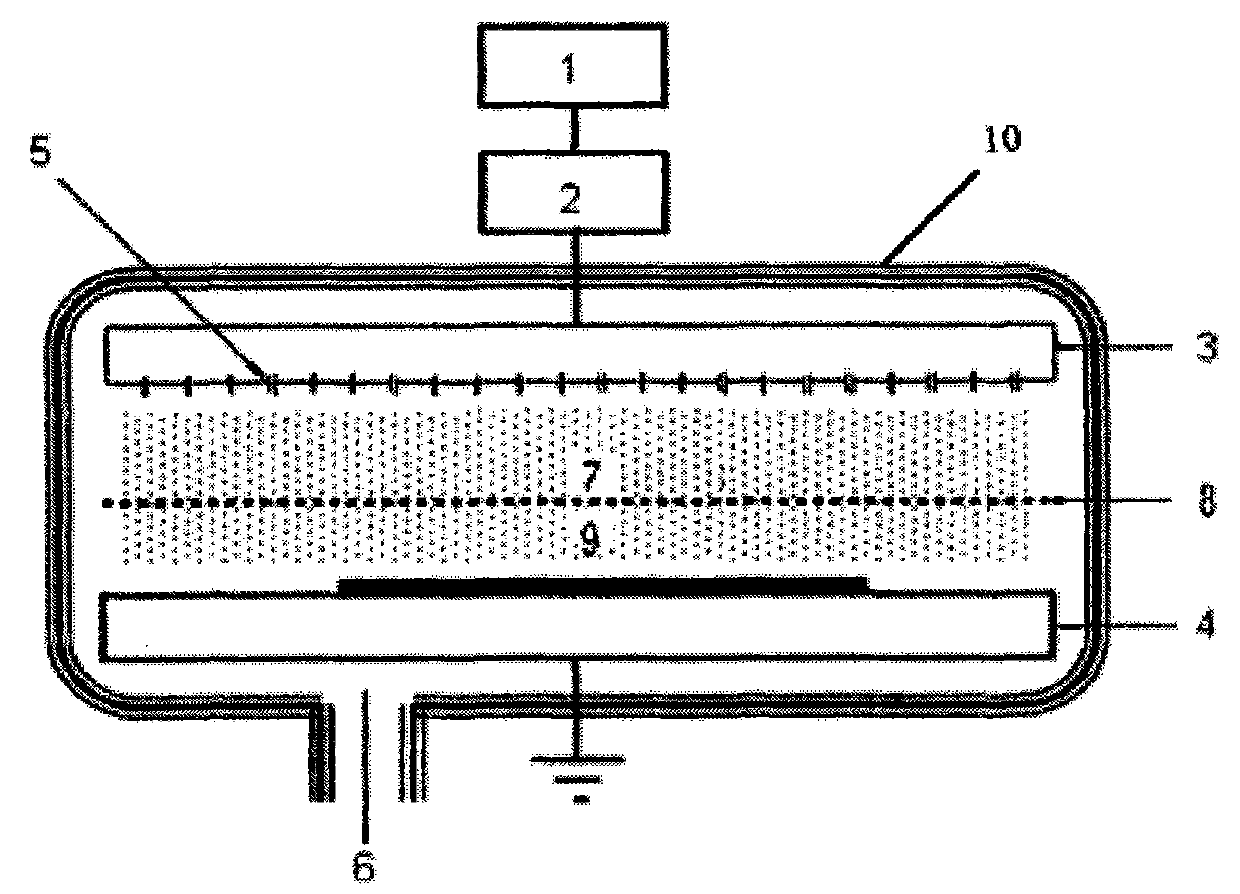

Atomic layer deposition device

The invention discloses an atomic layer deposition device, belongs to the technical field of plasma application, and relates to a plasma generator with an array hollow cathode structure. The device comprises a gas distribution system (1), a vacuum chamber (2), an array hollow cathode upper electrode (3), a flat plate grounding lower electrode (4), a vacuum-pumping system (5) and a power system (6), wherein the array hollow cathode upper electrode (3) is provided with a plurality of uniformly distributed through holes with diameter ranging from 1 to 3 mm, and a space between adjacent through holes is 2-4mm; a space between the array hollow cathode upper electrode (3) and the flat plate grounding lower electrode (4) is 5-20mm; and the array hollow cathode upper electrode (3) is connected with a gas supply pipeline of the gas distribution system (1). By the device, the plasma temperature is reduced, and other plasma parameters are improved, so that the deposition efficiency is improved and the microstructure and performance of the deposited material are optimized.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

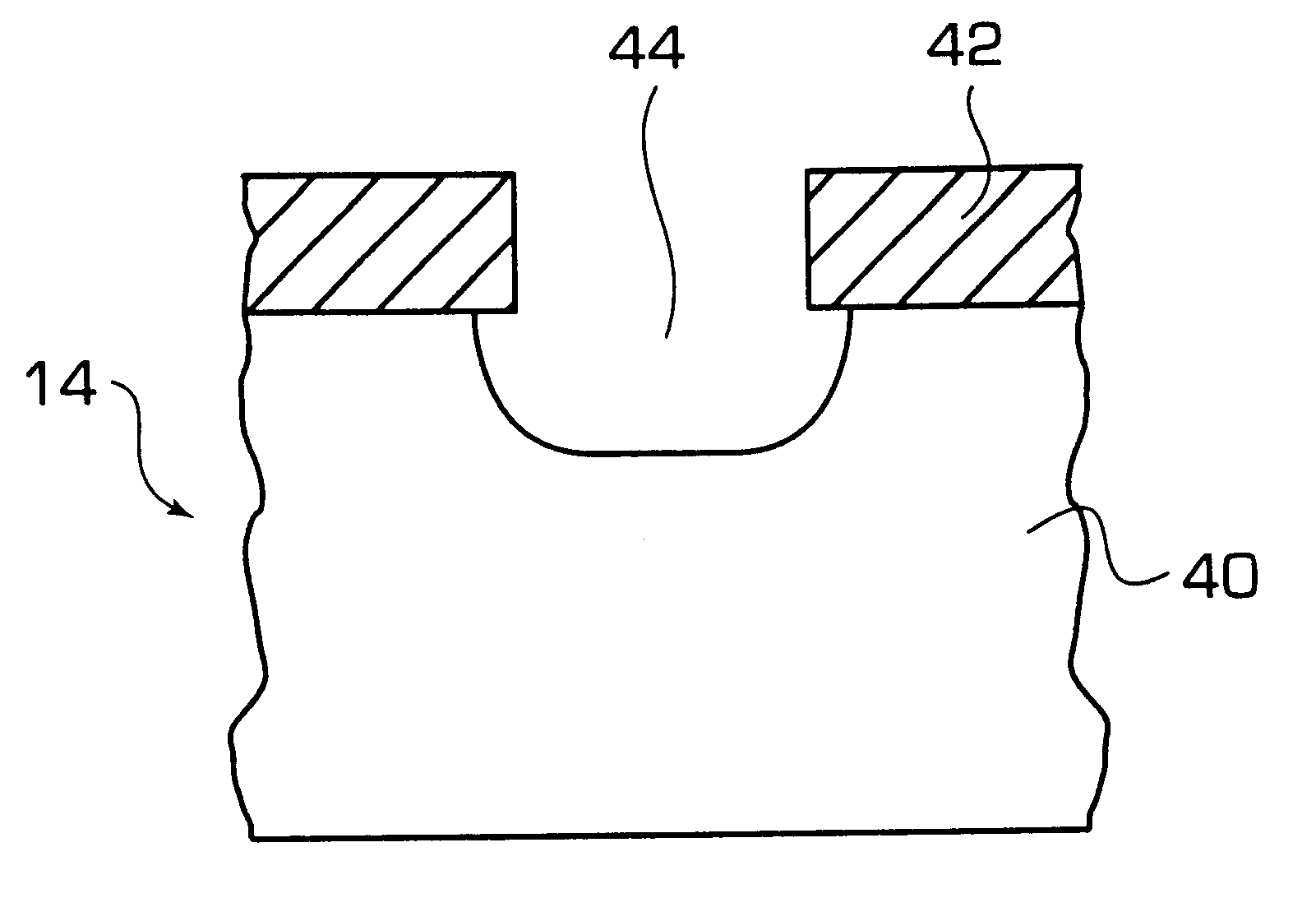

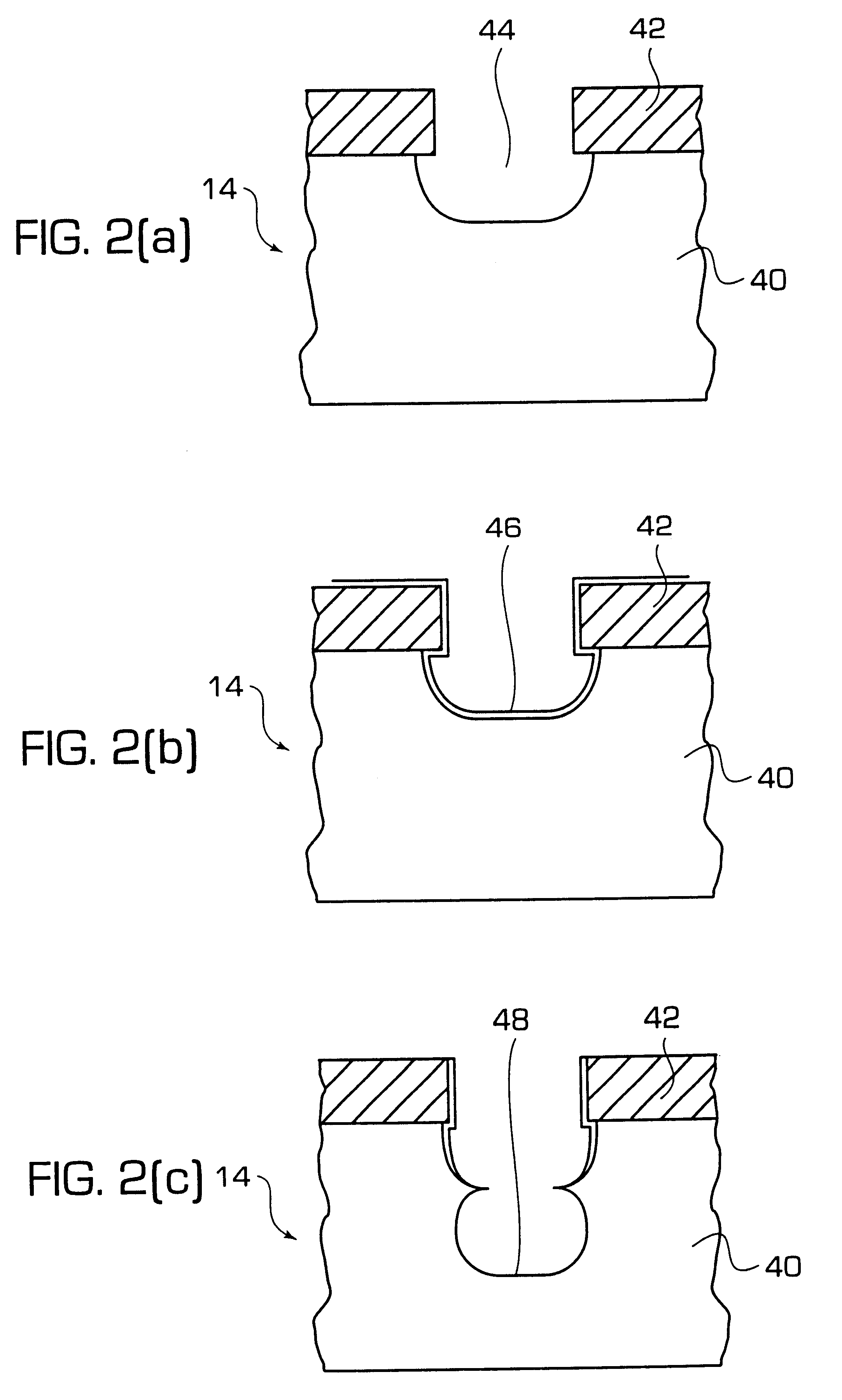

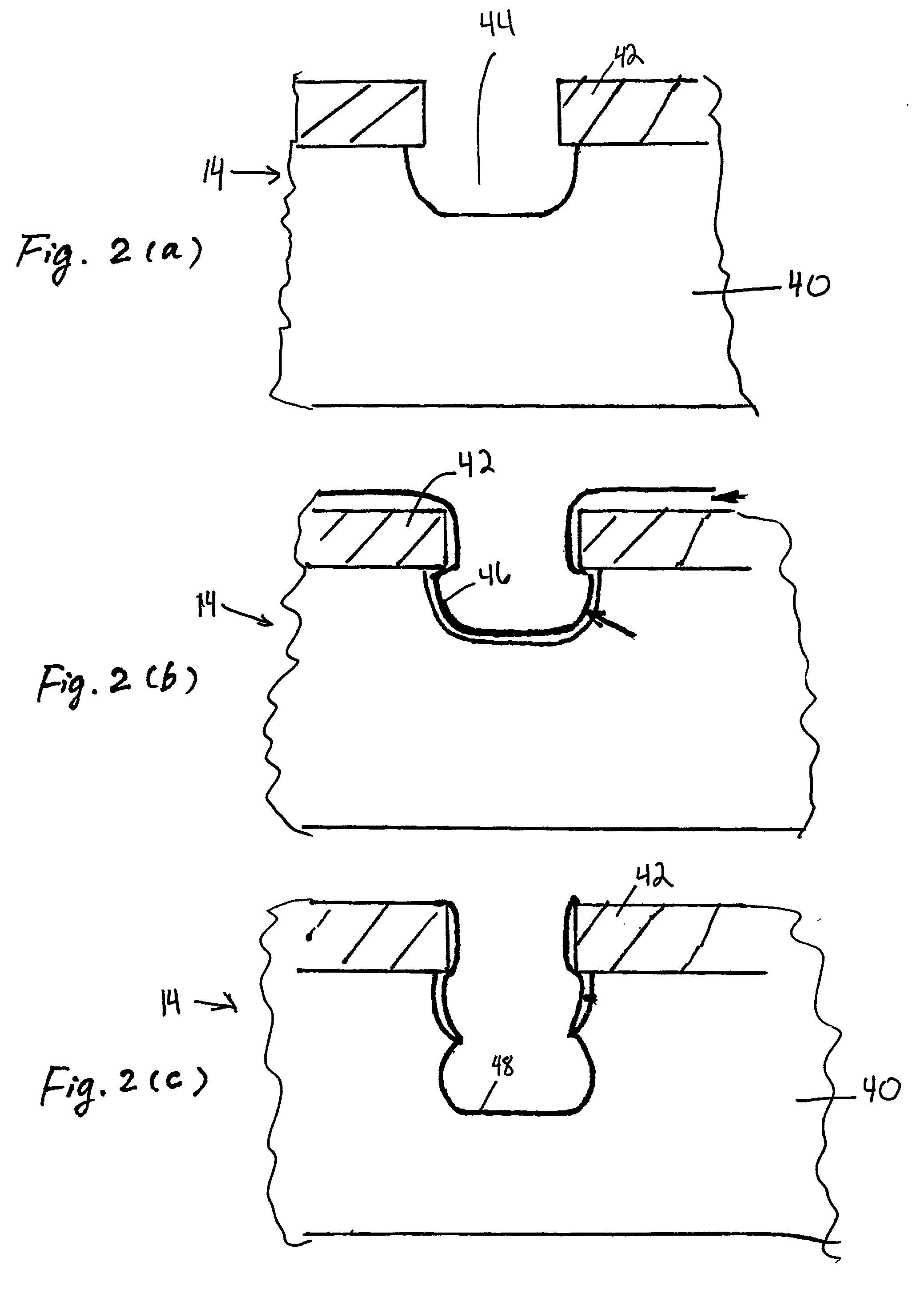

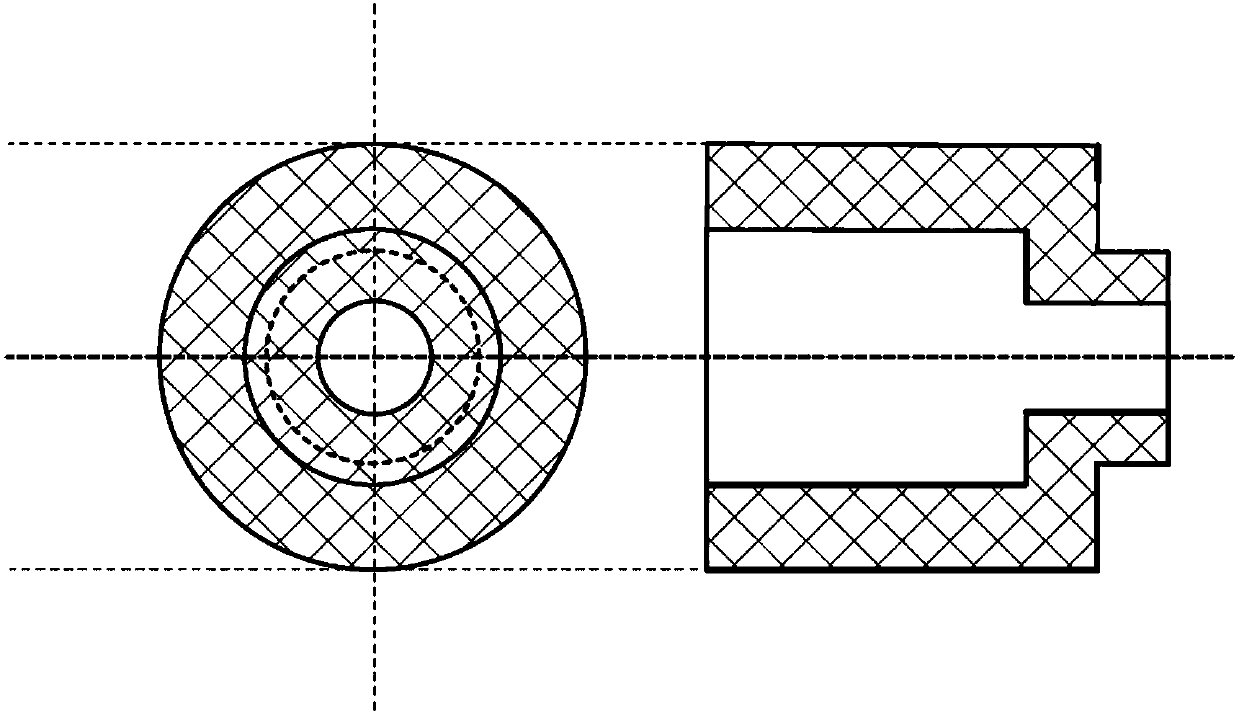

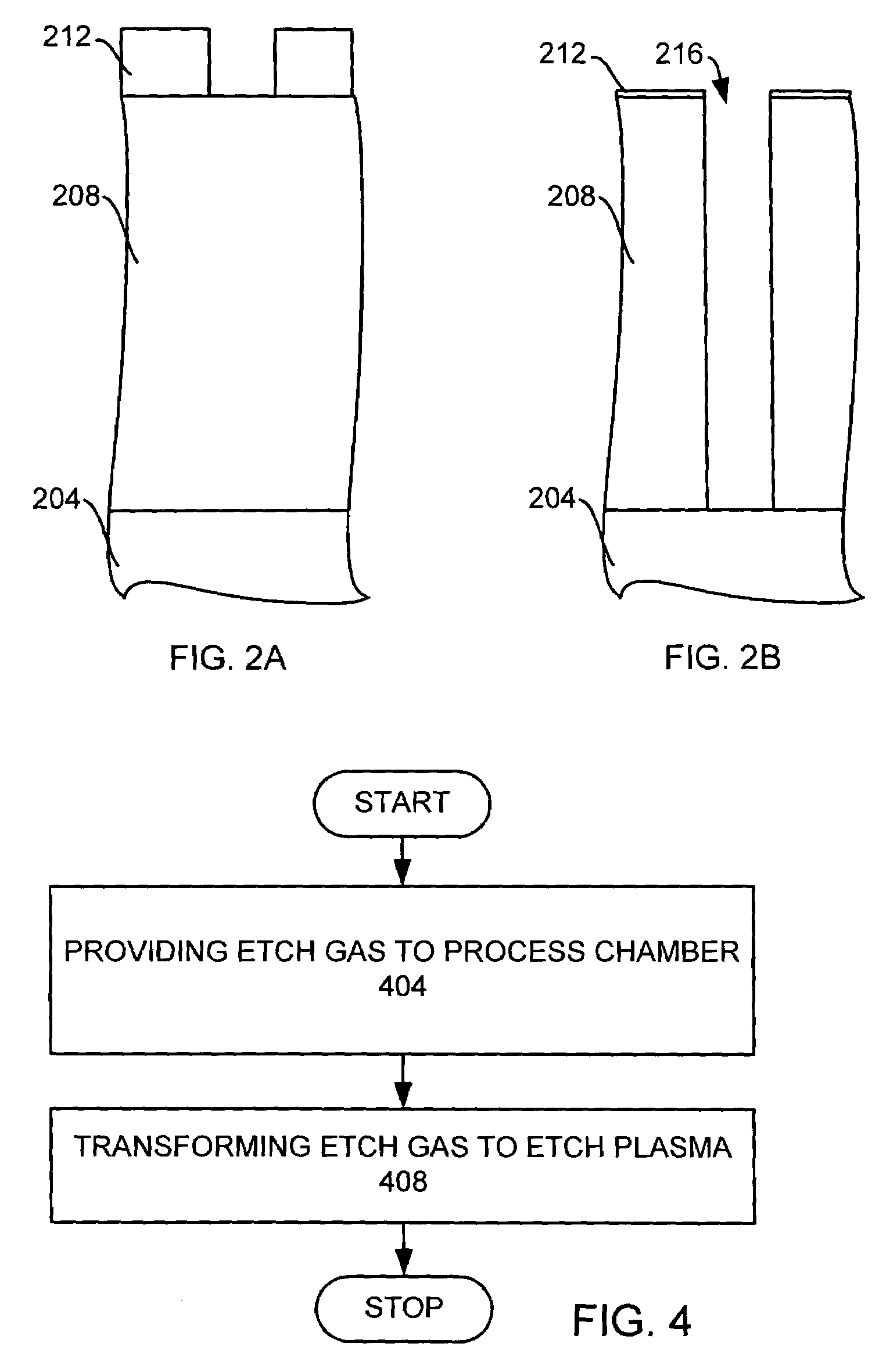

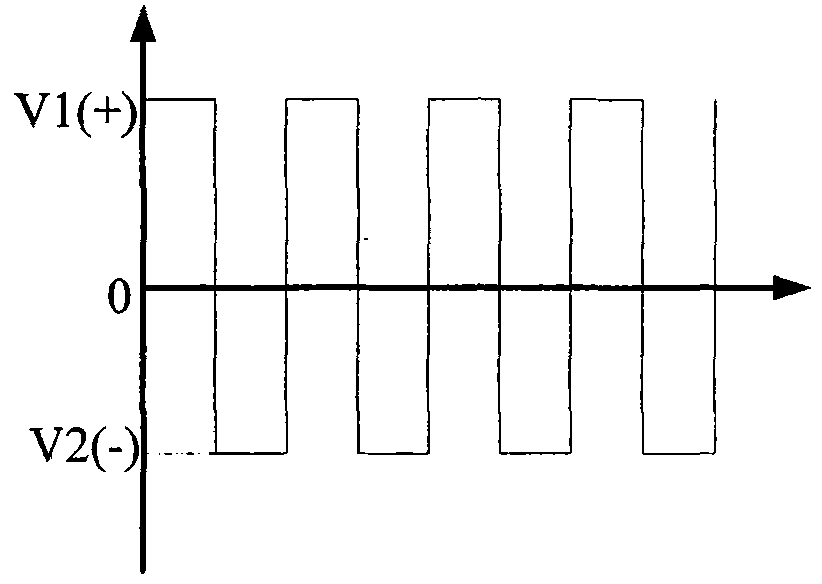

Method of anisotropic etching of substrates

InactiveUS6383938B2Convenient treatmentIncrease chanceSemiconductor/solid-state device manufacturingVacuum chamberMixed gas

A method of plasma etching of silicon that utilizes the plasma to provide laterally defined recess structures through a mask. The method is based on the variation of the plasma parameters to provide a well-controlled anisotropic etch, while achieving a very high etch rate, and a high selectivity with respect to a mask. A mixed gas is introduced into the vacuum chamber after the chamber is evacuated, and plasma is generated within the chamber. The substrate's surface is exposed to the plasma. Power sources are used for formation of the plasma discharge. An integrated control system is used to modulate the plasma discharge power and substrate polarization voltage levels.

Owner:WSOU INVESTMENTS LLC

Method of anisotropic etching of substrates

InactiveUS20010044213A1Less heatStable and repeatableSemiconductor/solid-state device manufacturingVacuum chamberMixed gas

A method of plasma etching of silicon that utilizes the plasma to provide laterally defined recess structures through a mask. The method is based on the variation of the plasma parameters to provide a well-controlled anisotropic etch, while achieving a very high etch rate, and a high selectivity with respect to a mask. A mixed gas is introduced into the vacuum chamber after the chamber is evacuated, and plasma is generated within the chamber. The substrate's surface is exposed to the plasma. Power sources are used for formation of the plasma discharge. An integrated control system is used to modulate the plasma discharge power and substrate polarization voltage levels.

Owner:WSOU INVESTMENTS LLC

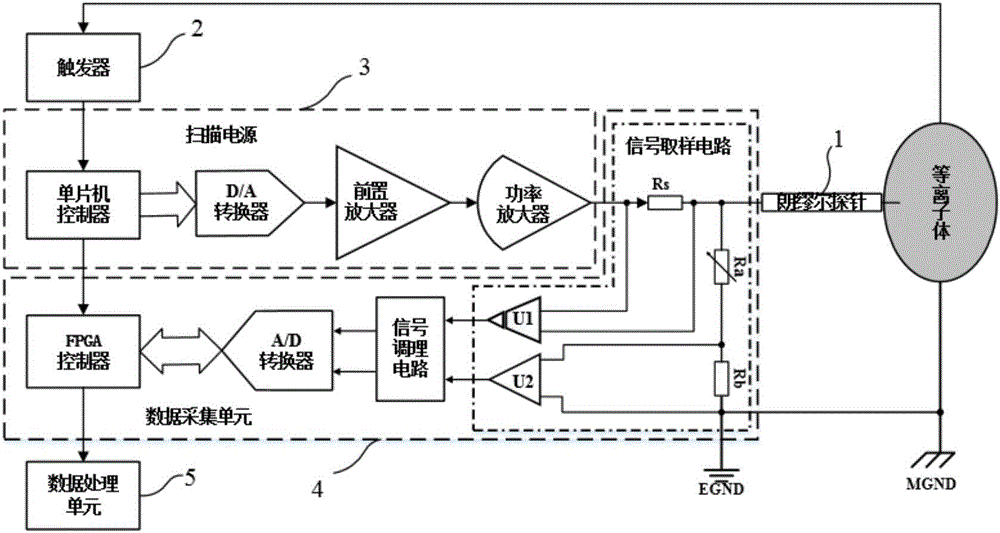

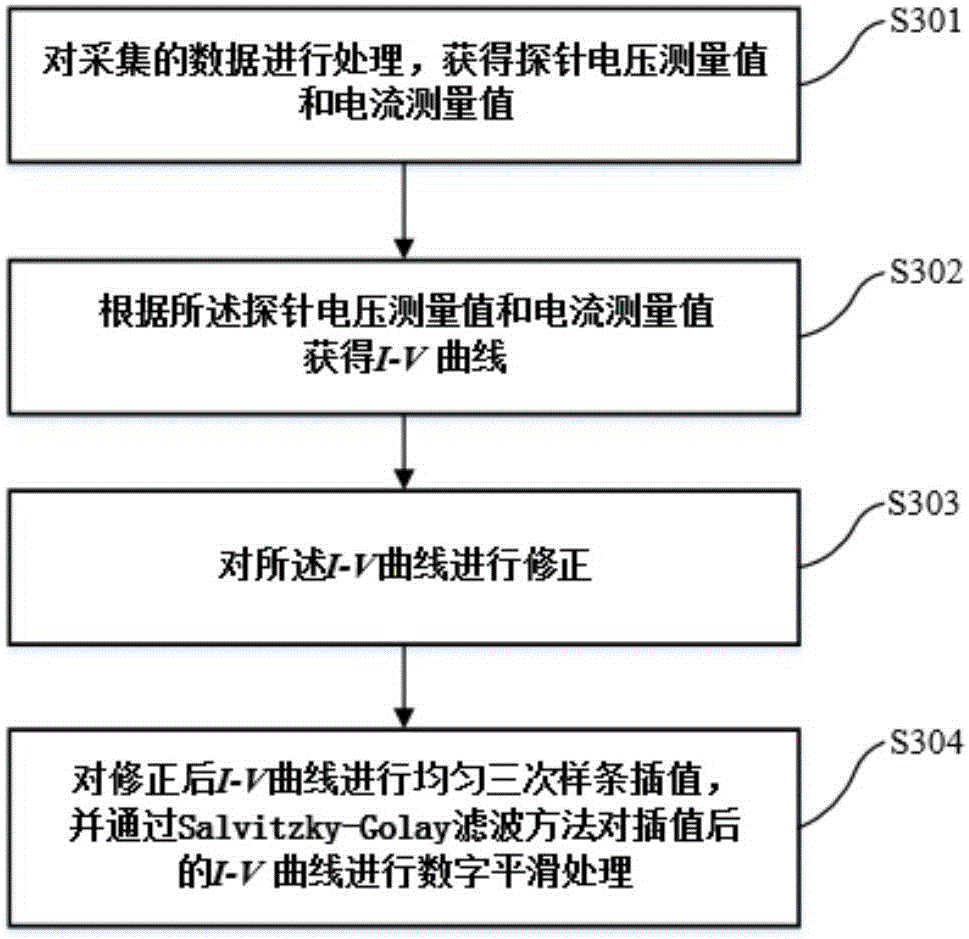

Highly-integrated Langmuir probe diagnosis system and method

InactiveCN106568805AHighly integratedHigh degree of automationMaterial analysis by electric/magnetic meansData acquisitionEngineering

The invention discloses a highly-integrated Langmuir probe diagnosis system and method. The highly-integrated Langmuir probe diagnosis system comprises a Langmuir probe, a trigger, a scanning power supply, a data acquisition unit and a data processing unit. The trigger transmits a pulse trigger signal to the scanning power supply via an optical fiber to trigger generation of sawtooth voltage with designated amplitude, period and repeat account, and the sawtooth voltage is loaded onto the Langmuir probe; the data acquisition unit carries out rapid, multiple and synchronous acquisition and storage on the voltage and current data of the Langmuir probe; and after completion of data acquisition, all the results are sent to the data processing unit in one shot, a data processing program on a computer is employed for automatic processing and analysis, and an acquired volt-ampere characteristic curve and acquired plasma parameters are displayed. The highly-integrated Langmuir probe diagnosis system has high automation degree and integrated level, can realize high-speed synchronous data acquisition and large-quantity data storage and communication, employs data processing for automatic processing and analysis of acquired data and provides a good man-machine interaction interface for displaying and recording of processing results.

Owner:HUAZHONG UNIV OF SCI & TECH

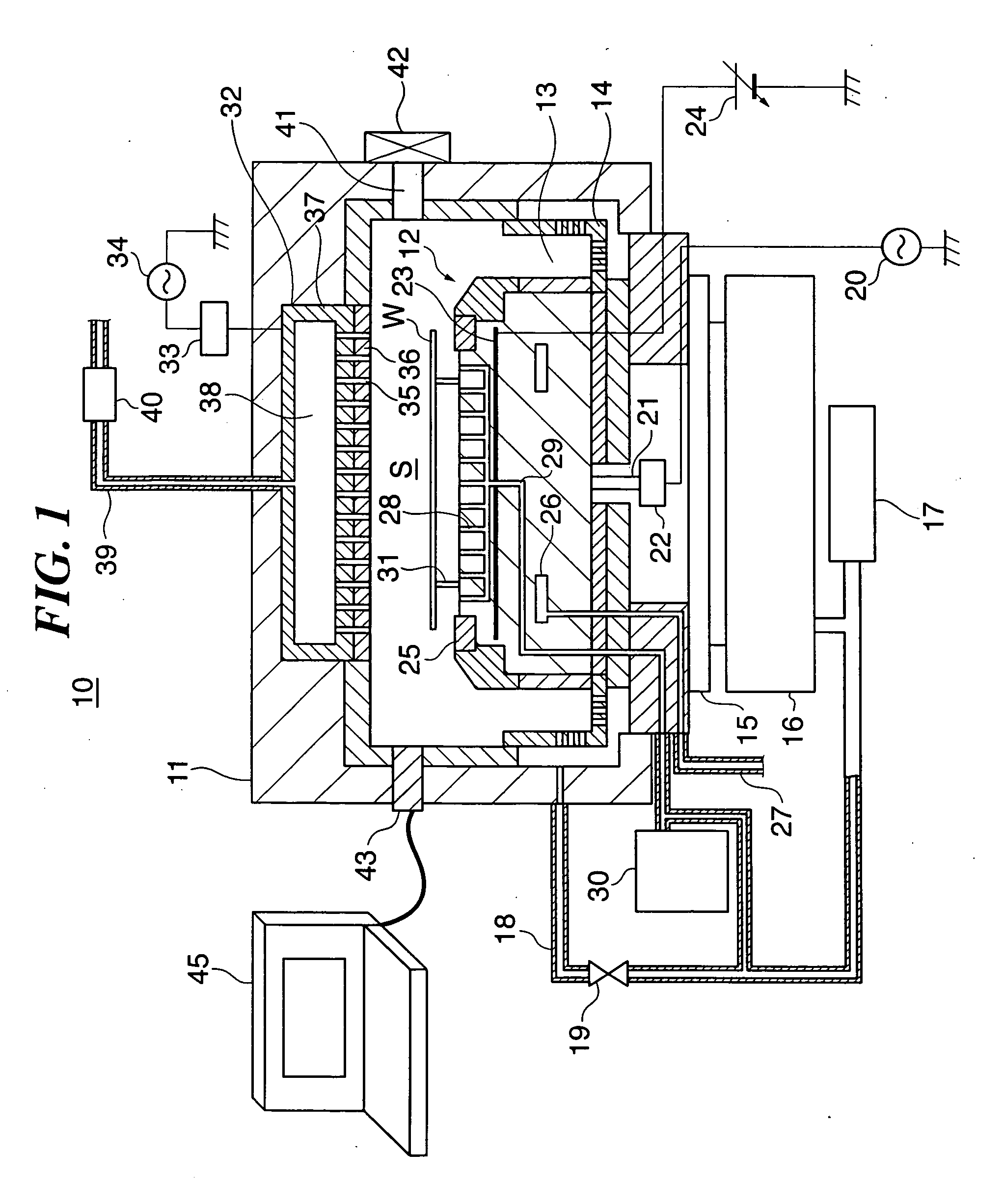

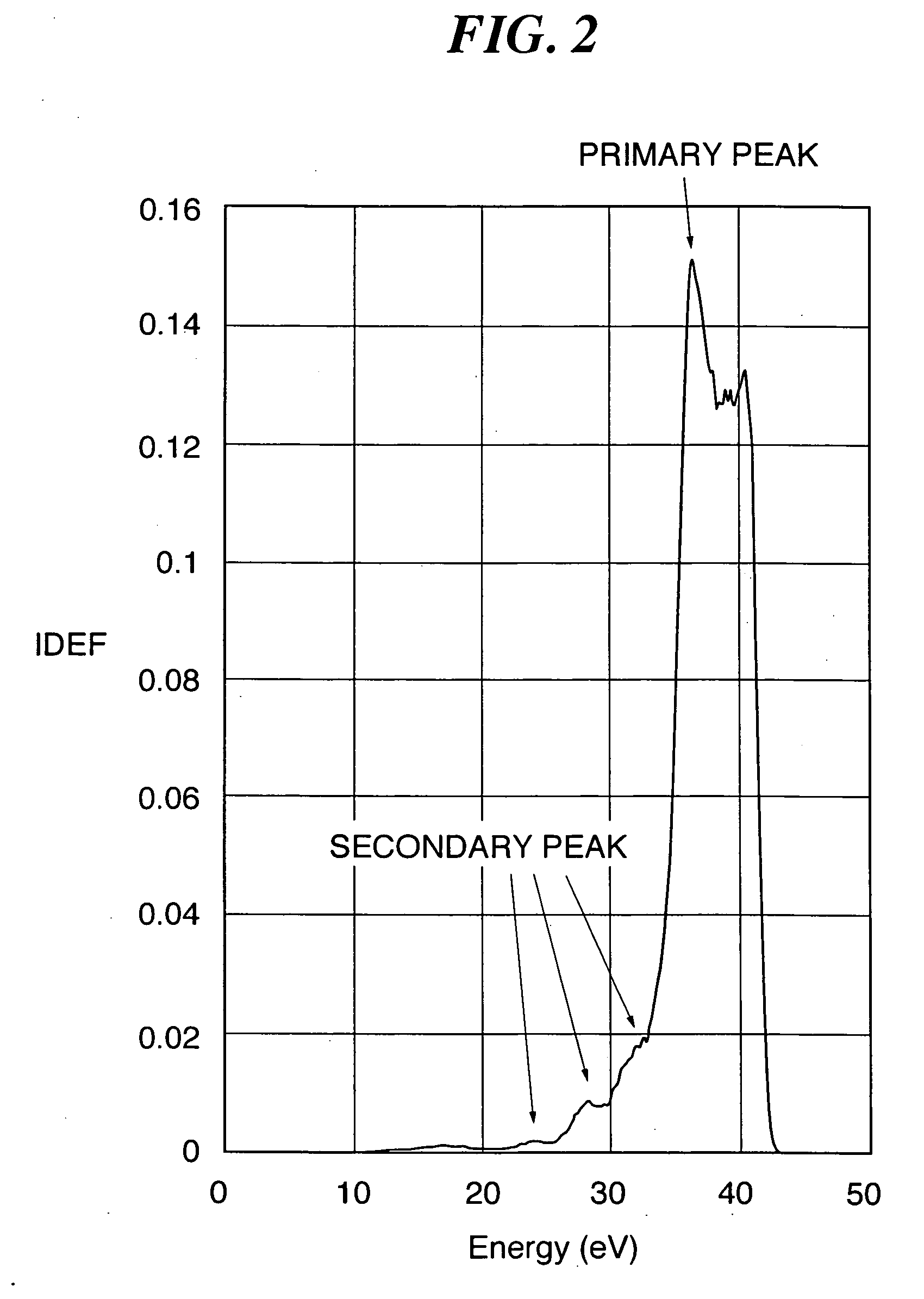

Electron temperature measurement method, electron temperature measurement program for implementing the method, and storage medium storing the electron temperature measurement program

InactiveUS20060214593A1Accurate measurementQuick measurementLiquid surface applicatorsElectric discharge tubesElectron temperatureReactive-ion etching

An electron temperature measurement method that enables an electron temperature as a plasma parameter to be measured precisely. A plasma is produced in a chamber 11 such that a wafer W is subjected to reactive ion etching therein. An ion energy distribution in the chamber 11 is measured. An ion energy distribution in the chamber 11 is simulated based on a set electron temperature. The measured ion energy distribution and the simulated ion energy distribution are compared. The electron temperature of the plasma is estimated based on results of the comparison mentioned above.

Owner:TOKYO ELECTRON LTD

Flat-loaded probe device for high-speed flow field plasma parameter diagnosis

PendingCN107817085ASolve insulation problemsImprove fitAerodynamic testingObject structureDiagnostic information

The invention discloses a flat-loaded probe device for high-speed flow field plasma parameter diagnosis. The device comprises a flat-loaded probe. The flat-loaded probe aligns the surface of the probeelectrode with the surface of an insulating sleeve. The structure well solves the problems that in a high-speed flow field plasma, a traditional electrostatic probe is easily damaged in the flow field due to the exposed electrode, and the traditional electrostatic probe protrudes from the surface of a flying object and affects flight safety. In the high-speed flow field plasma environment, the flat-loaded probe can replace the electrostatic probe to better diagnose the parameter information of the plasma. According to the invention, the structure that the surface of the electrode is flush with the surface of the flying object is adopted; and the problem that the exposed electrode of a traditional Langmuir probe is easily insulated and damaged is successfully solved.

Owner:UNIV OF SCI & TECH OF CHINA

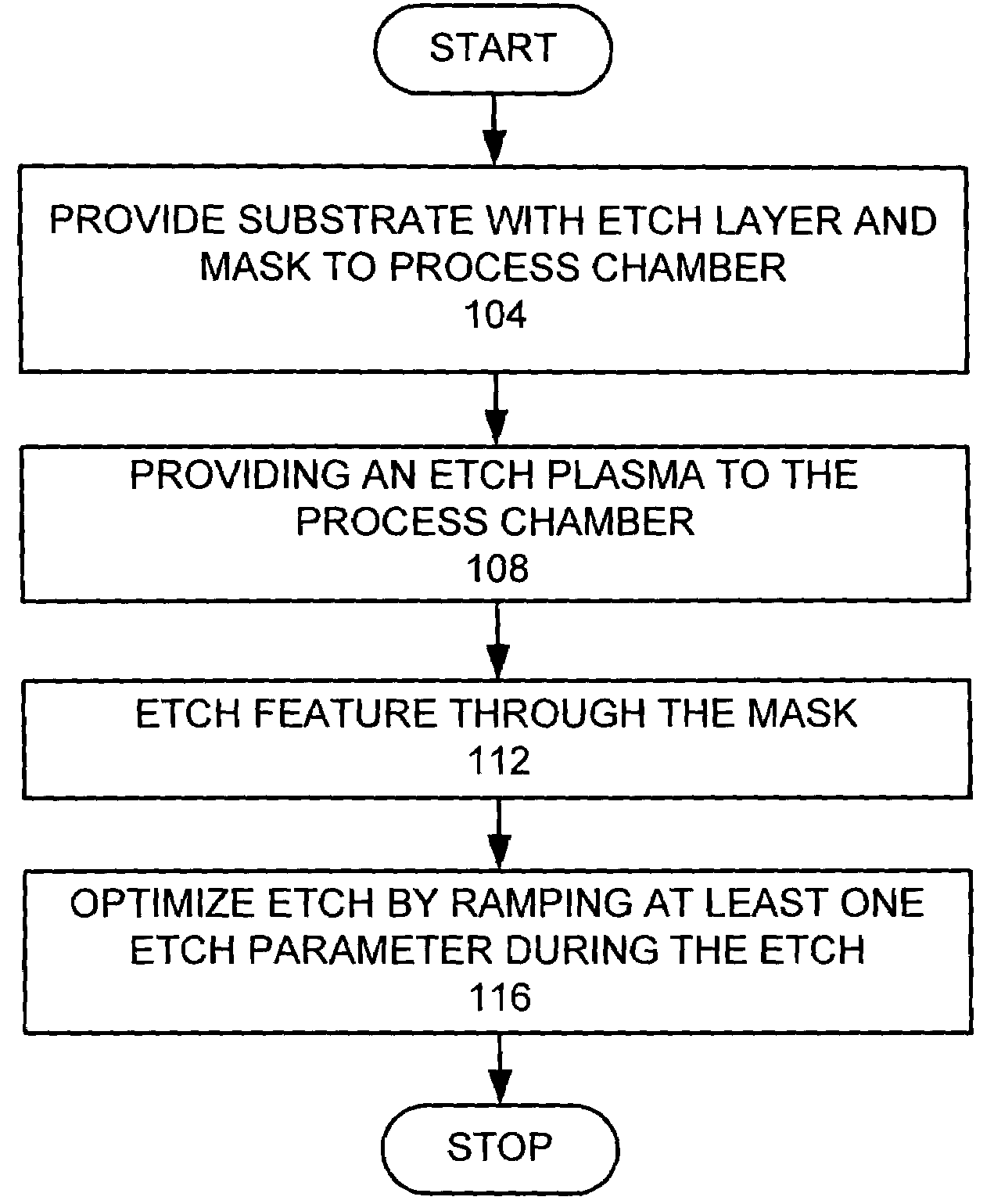

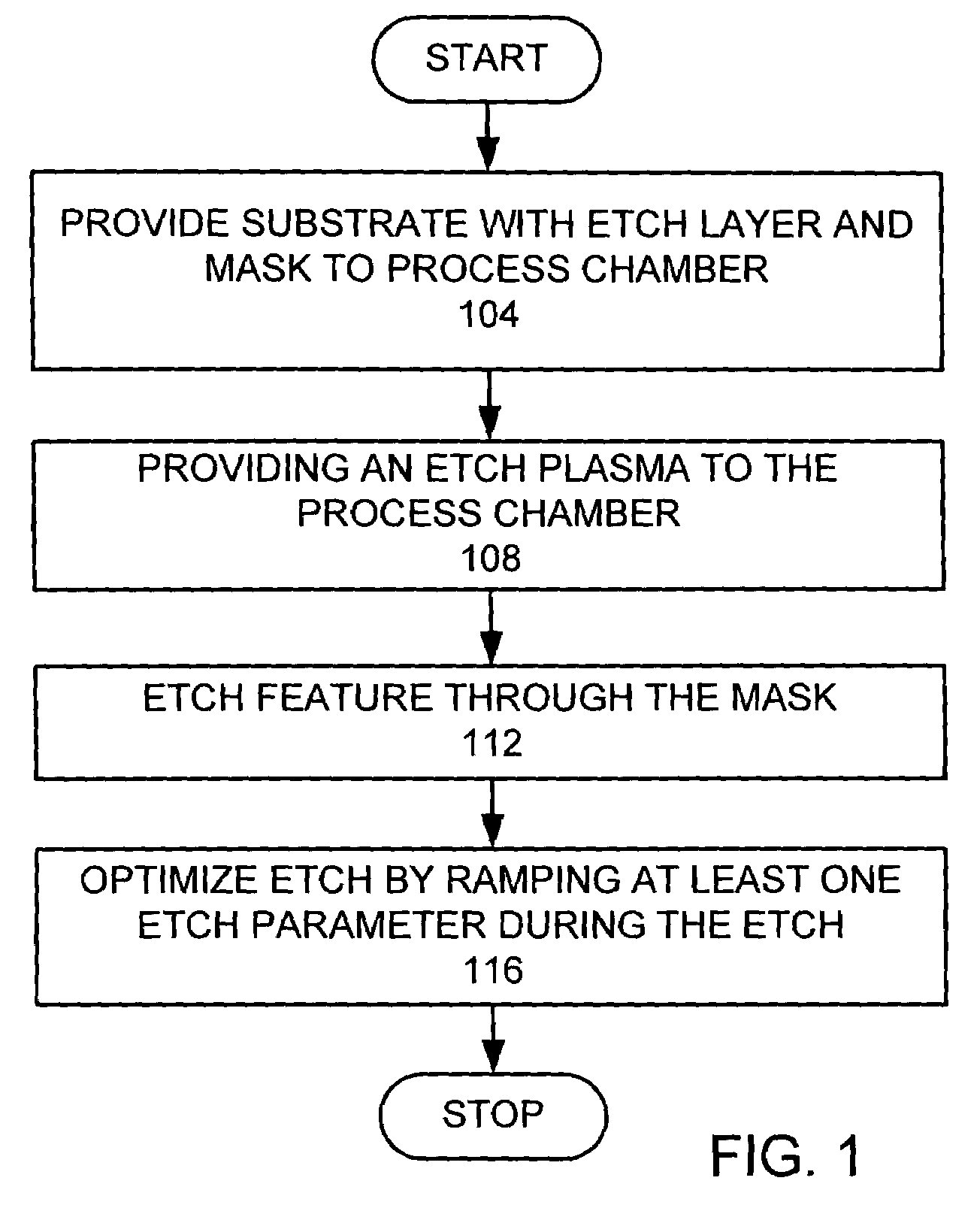

Etch with ramping

InactiveUS7135410B2Electric discharge tubesSemiconductor/solid-state device manufacturingEtchingPhysics

Owner:LAM RES CORP

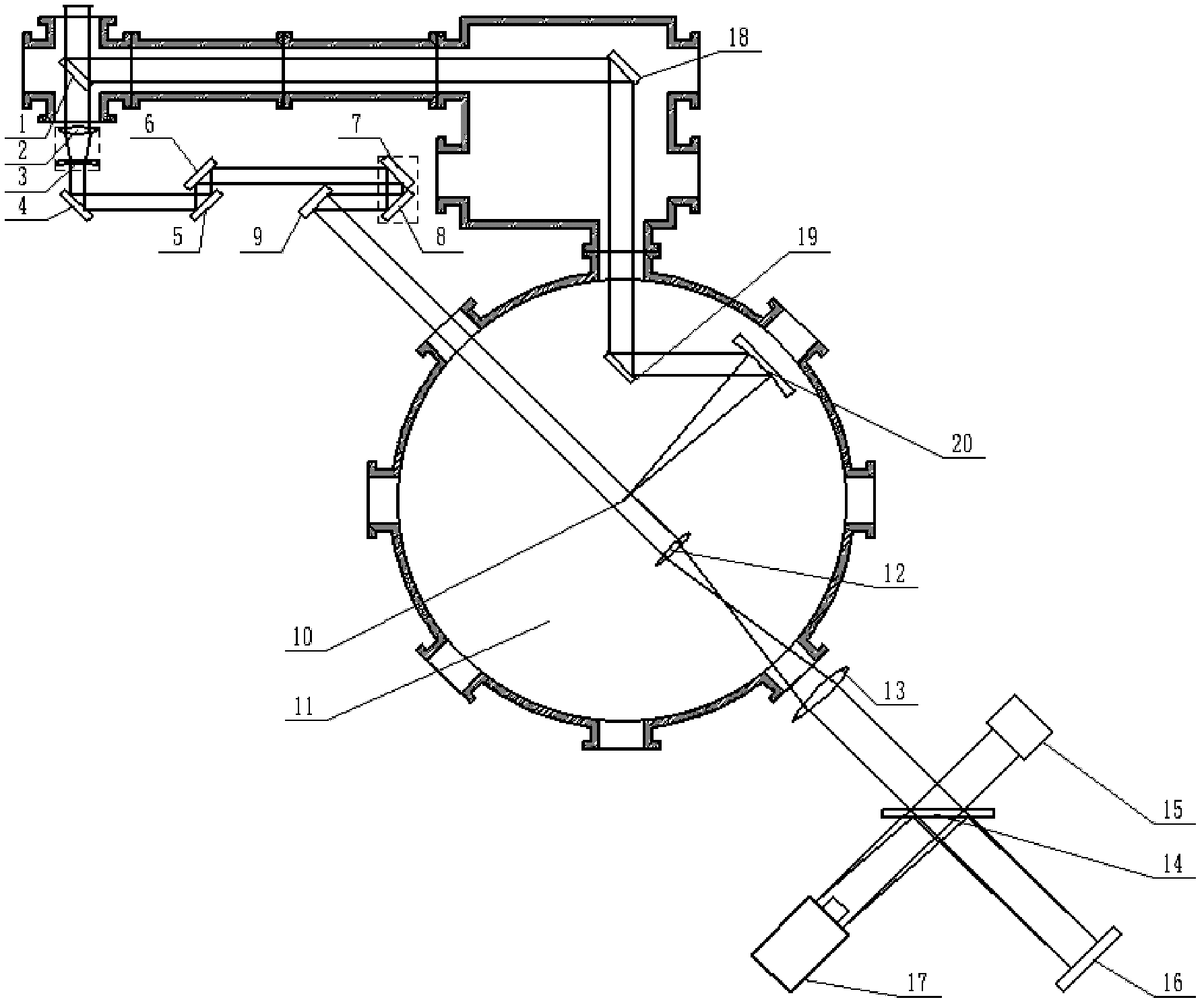

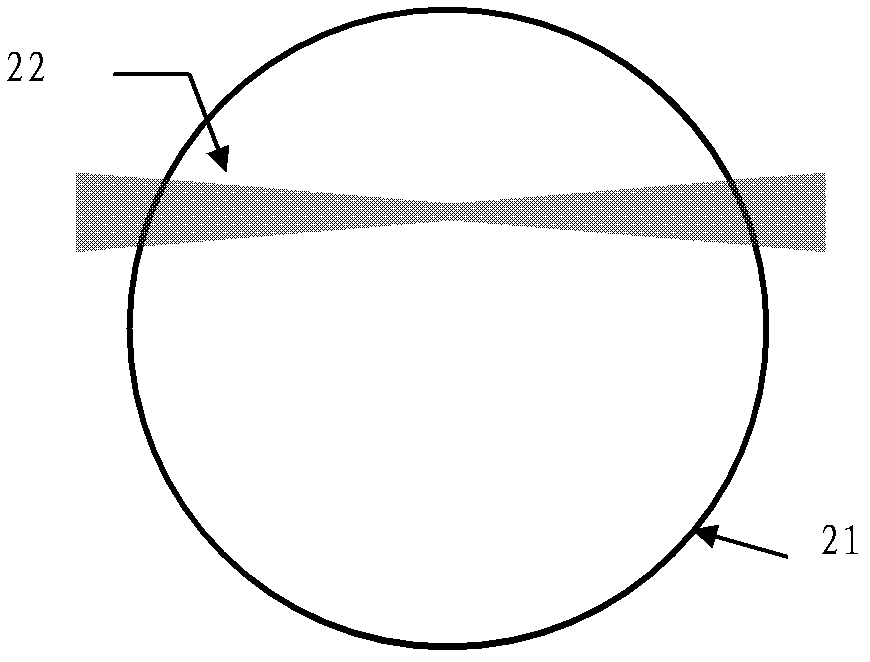

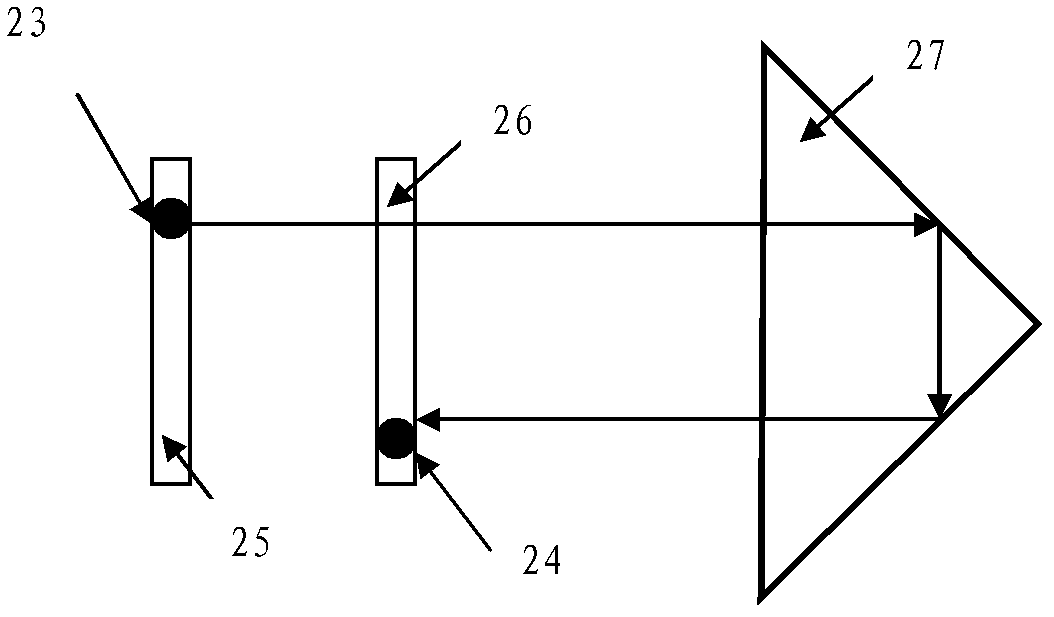

Single-beam femtosecond probe for diagnosing laser plasma parameters

ActiveCN102661908ADifficulty adjustingEasy to operateSpecific gravity measurementLight beamLaser interference

A single-beam femtosecond probe for diagnosing laser plasma parameters through interaction of ultra-short and ultra-strong laser and clusters is composed of a probe light forming, beam-shrinking and delay adjusting portion and a probe light beam-expanding and coherent measurement portion along a light path, wherein the two portions take a target spot located in a vacuum target room and above the focal point of an off-axis cast objective as the center. The single-beam femtosecond probe comprises a laser beam splitter, a laser beam-shrinking system, an optical delay system, a laser beam-expanding system and a laser interference measurement system. The single-beam femtosecond probe has the advantages of simplicity, convenience, easiness in operation, accuracy in delay, high sensitivity, low cost and the like.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

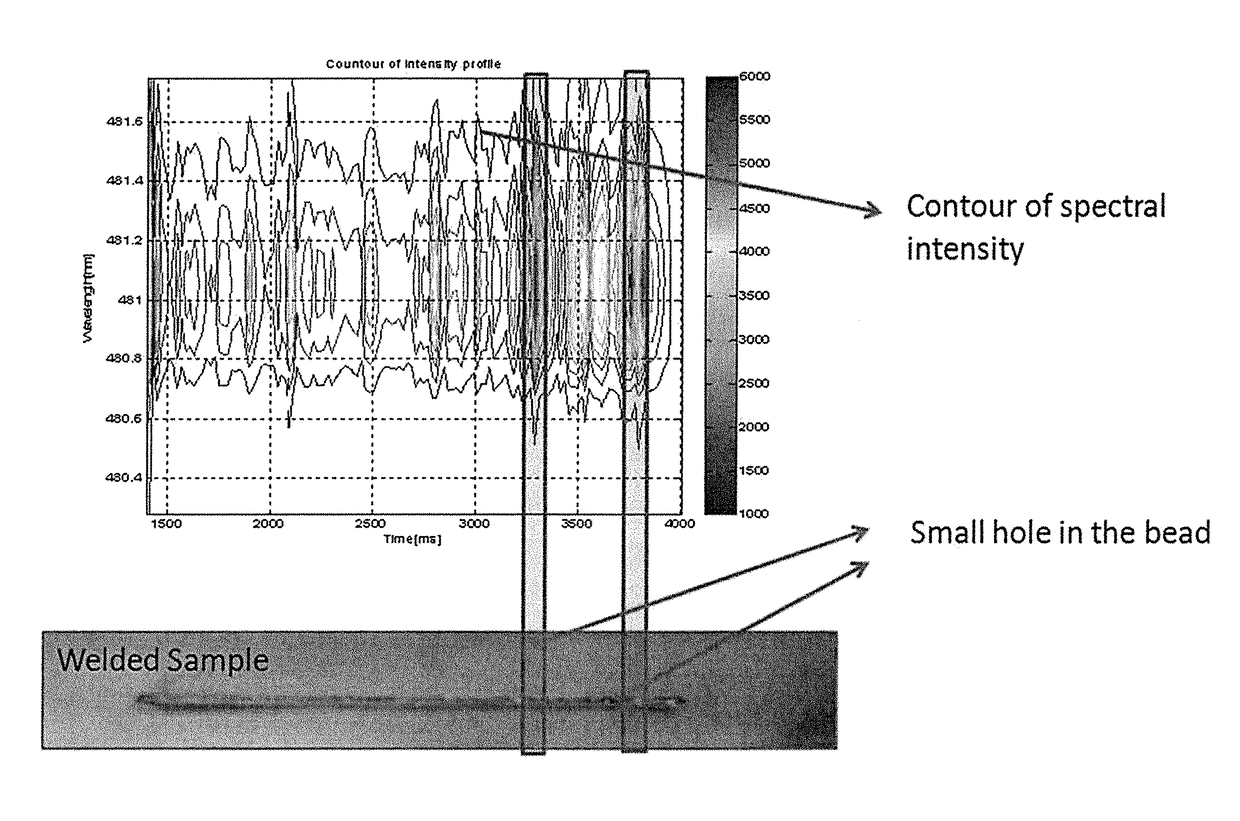

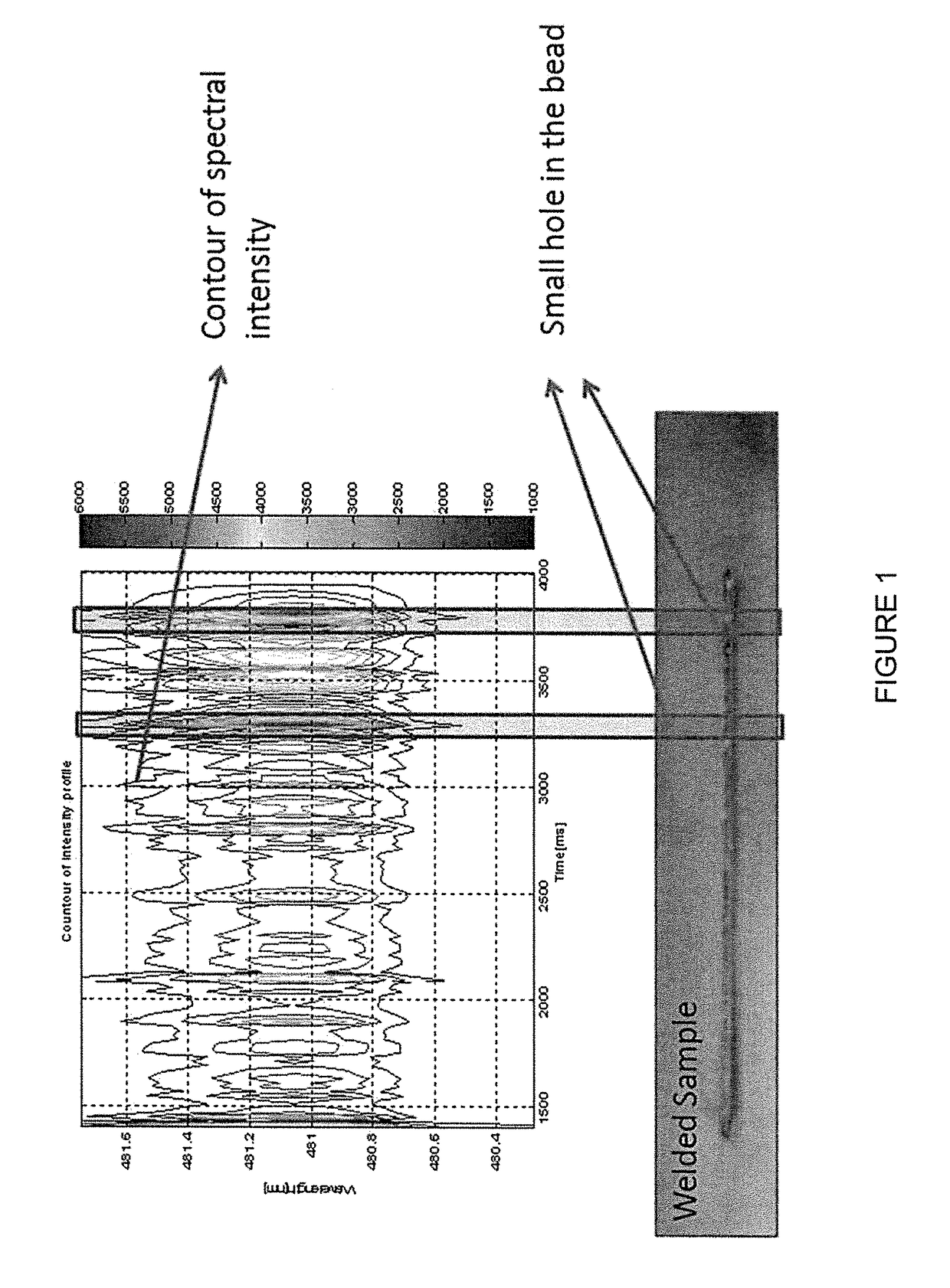

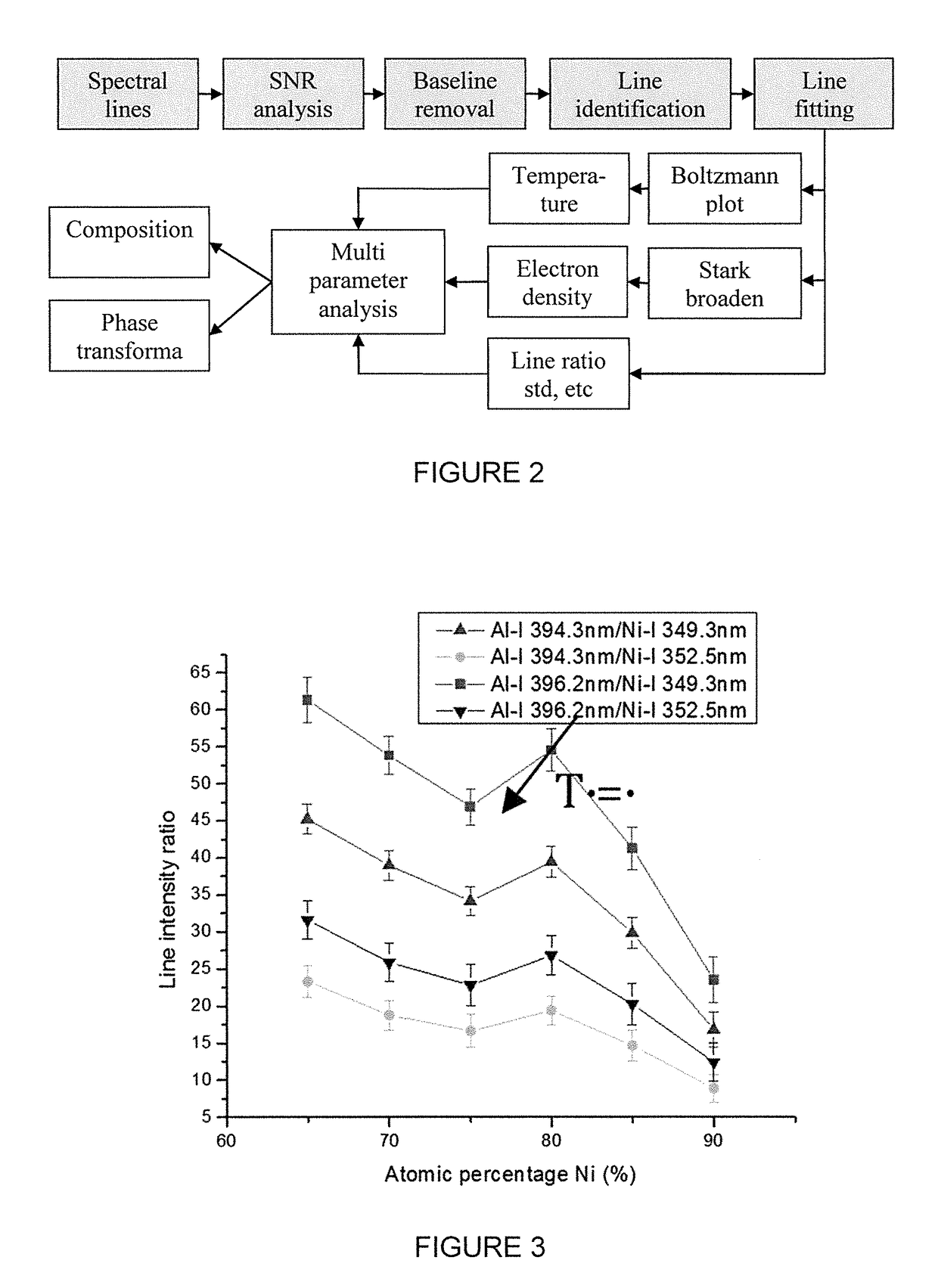

Smart additive manufacturing system (SAMS)

ActiveUS9981341B2Additive manufacturing apparatusWelding/soldering/cutting articlesOptical emission spectrometryEngineering

An additive manufacturing process is monitored, in situ, using optical emission spectroscopy to analyze the composition, phase transformation or manufacturing defects. The system or method may include an analysis of contours of the plasma line intensity, or pre-processing of the plasma spectral line including signal-to-noise ratio analysis, baseline removal, line identification, line de-convolution and fitting. Improvements may additionally involve consideration of plasma parameters such as plasma spectral line intensity, line ratio, plasma temperature and electron density using high-resolution optical emission spectroscopy in both visible and ultraviolet regions. Parameters of the plasma may be determined using an intensity ratio of the ions or atoms emission lines, a FWHM of the line profile for electron density estimation, or a Boltzmann plot for plasma temperature estimation. One or more techniques may be used to monitor when there is a lack of deposition.

Owner:MAZUMDER JYOTI +1

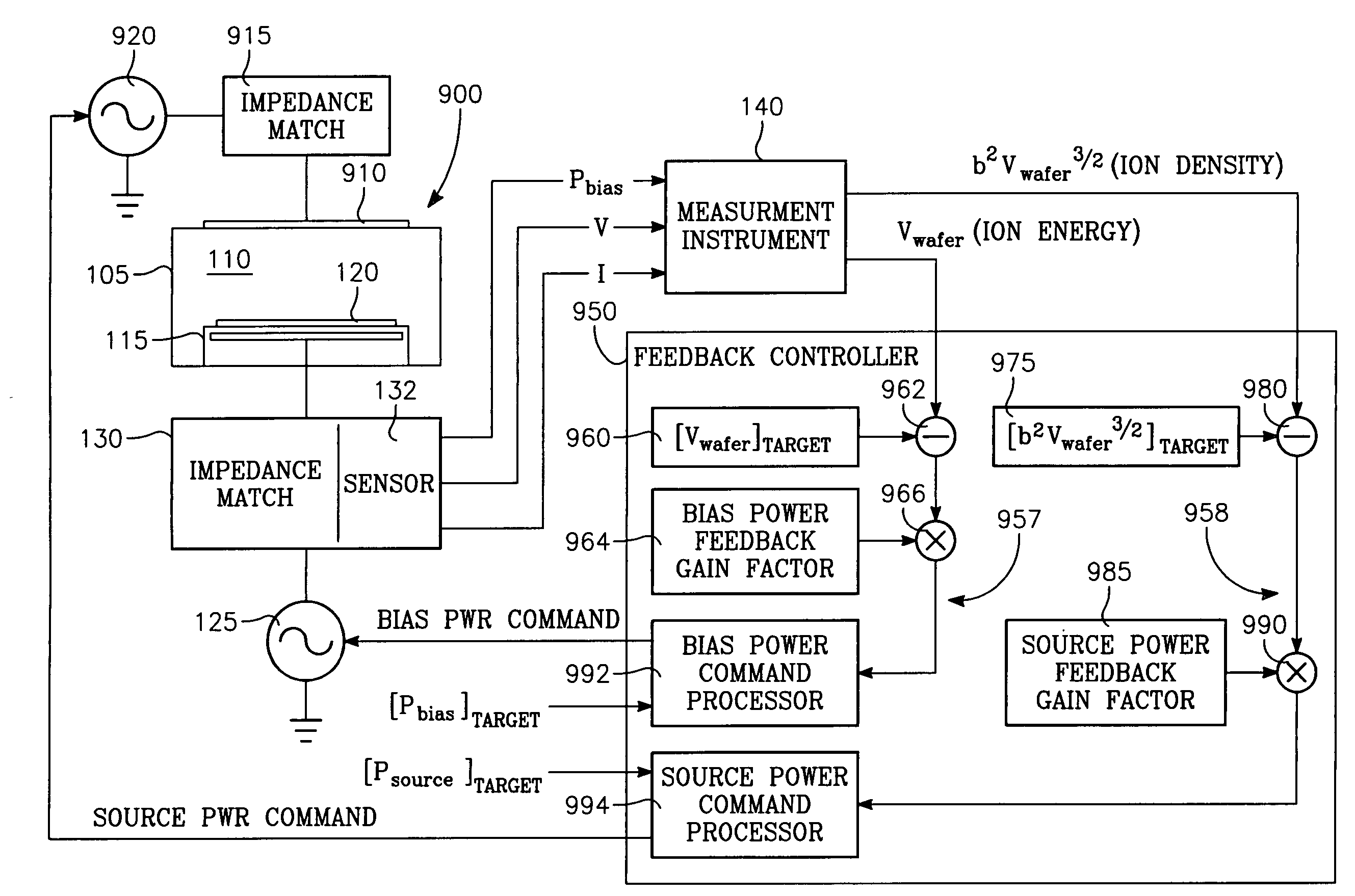

Method of operating a plasma reactor chamber with respect to two plasma parameters selected from a group comprising ion density, wafer voltage, etch rate and wafer current, by controlling chamber parameters of source power and bias power

InactiveUS20060283835A1Electric discharge tubesVacuum gauge using ionisation effectsElectric forceElectricity

A workpiece is processed in a plasma reactor chamber in accordance with desired values of two plasma parameters selected from a group comprising ion density, wafer voltage, etch rate and wafer current, by controlling chamber parameters of source power and bias power. First, the chamber is characterized by performing the following steps: (a) for each one of the chamber parameters, ramping the level of the one chamber parameter while sampling RF electrical parameters at an RF bias power input to the wafer support pedestal and computing from each sample of the RF electrical parameters the values of the plasma parameters, and storing the values with the corresponding levels of the one chamber parameter as corresponding chamber parameter data; (b) for each one of the chamber parameters, deducing, from the corresponding chamber parameter data, a single variable function for each of the plasma parameters having the one chamber parameter as an independent variable; (c) constructing combinations of the functions and from the combinations, constructing surfaces defining concurrent values of the chamber parameters, each respective surface corresponding to a respective constant value of one of the plasma parameters, and storing the surfaces.

Owner:APPLIED MATERIALS INC

Method of controlling chamber parameters of a plasma reactor in accordance with desired values of plural plasma parameters, by translating desired values for the plural plasma parameters to control values for each of the chamber parameters

InactiveUS20060278610A1Electric discharge tubesVacuum gauge using ionisation effectsElectric forceParameter control

Plural chamber parameters of a plasma reactor are controlled in accordance with desired values of plural plasma parameters, by concurrently translating desired values for the plural plasma parameters to control values for each of plural chamber parameters, and then setting each of the chamber parameters to corresponding ones of the control values. The translating consists of the following steps: (a) for each one of the chamber parameters, ramping the level of the one chamber parameter while sampling RF electrical parameters at an RF bias power input to the wafer support pedestal and computing from each sample of the RF electrical parameters the values of plural plasma parameters, and storing the values with the corresponding levels of the one chamber parameter as corresponding chamber parameter data; (b) for each one of the chamber parameters, deducing, from the corresponding chamber parameter data, a single variable function for each of the plural plasma parameters having the one chamber parameter as an independent variable; (c) from combinations of the functions, constructing surfaces defining simultaneous values of all of the chamber parameters, each respective surface corresponding to a respective constant value of one of the plural plasma parameters, and storing the surfaces.

Owner:APPLIED MATERIALS INC

Plasma processing equipment and method

ActiveCN102024658AOvercome groundingOvercome levitationElectric discharge tubesPulse voltageAlternating current

The invention provides plasma processing equipment, which comprises a process chamber, an upper electrode, a lower electrode and a grid mesh, wherein the upper electrode and the lower electrode are arranged in the process chamber; the grid mesh is arranged between the upper electrode and the lower electrode and connected with a pulse voltage or an alternating current voltage; and the parameter of the pulse voltage or the alternating current voltage can be adjusted so as to change a plasma parameter. The invention also provides a plasma processing method. In the plasma processing equipment and the plasma processing method, the plasma parameter can be adjusted effectively, the adjustment range of the plasma parameter is enlarged and particle pollution is reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

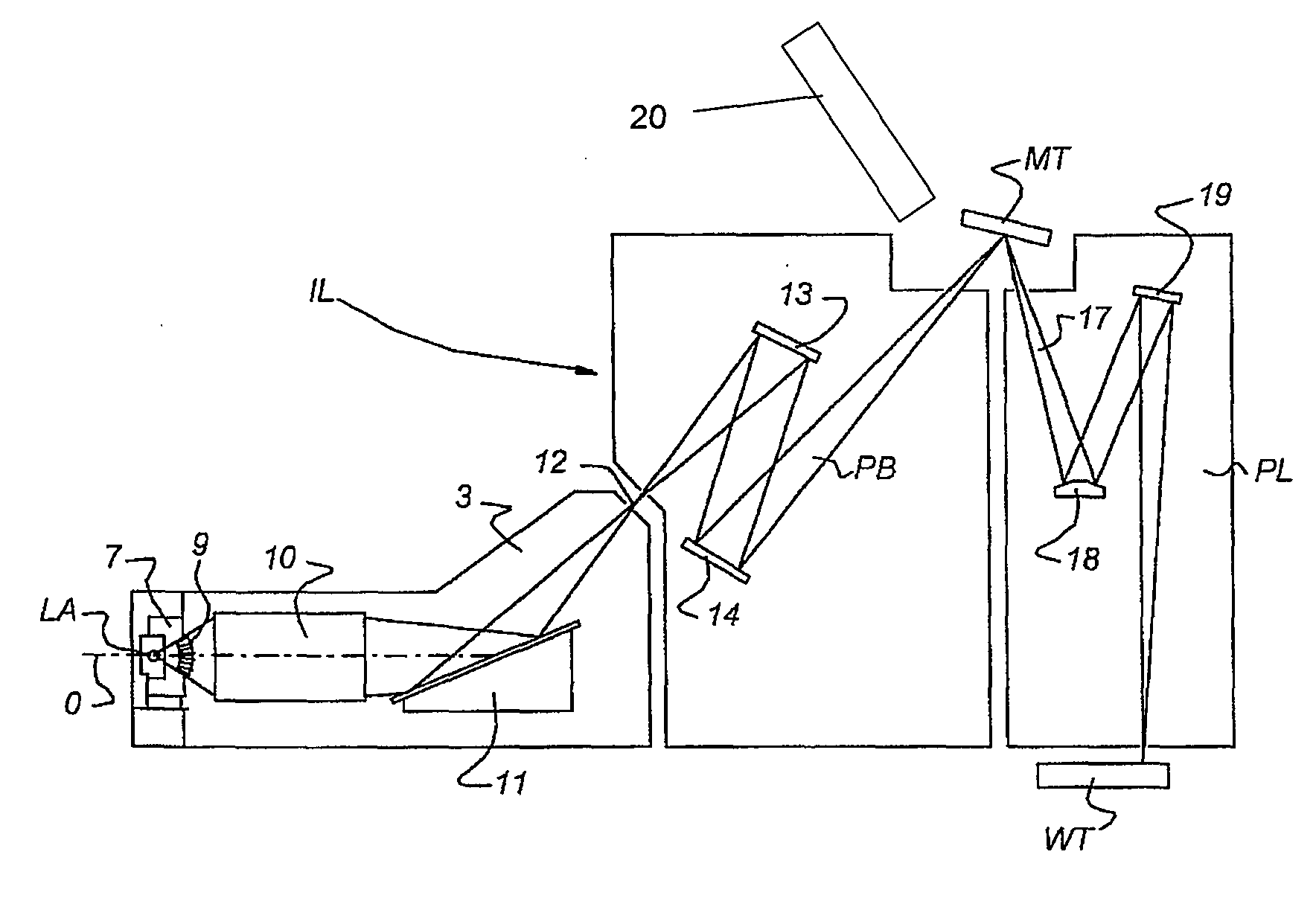

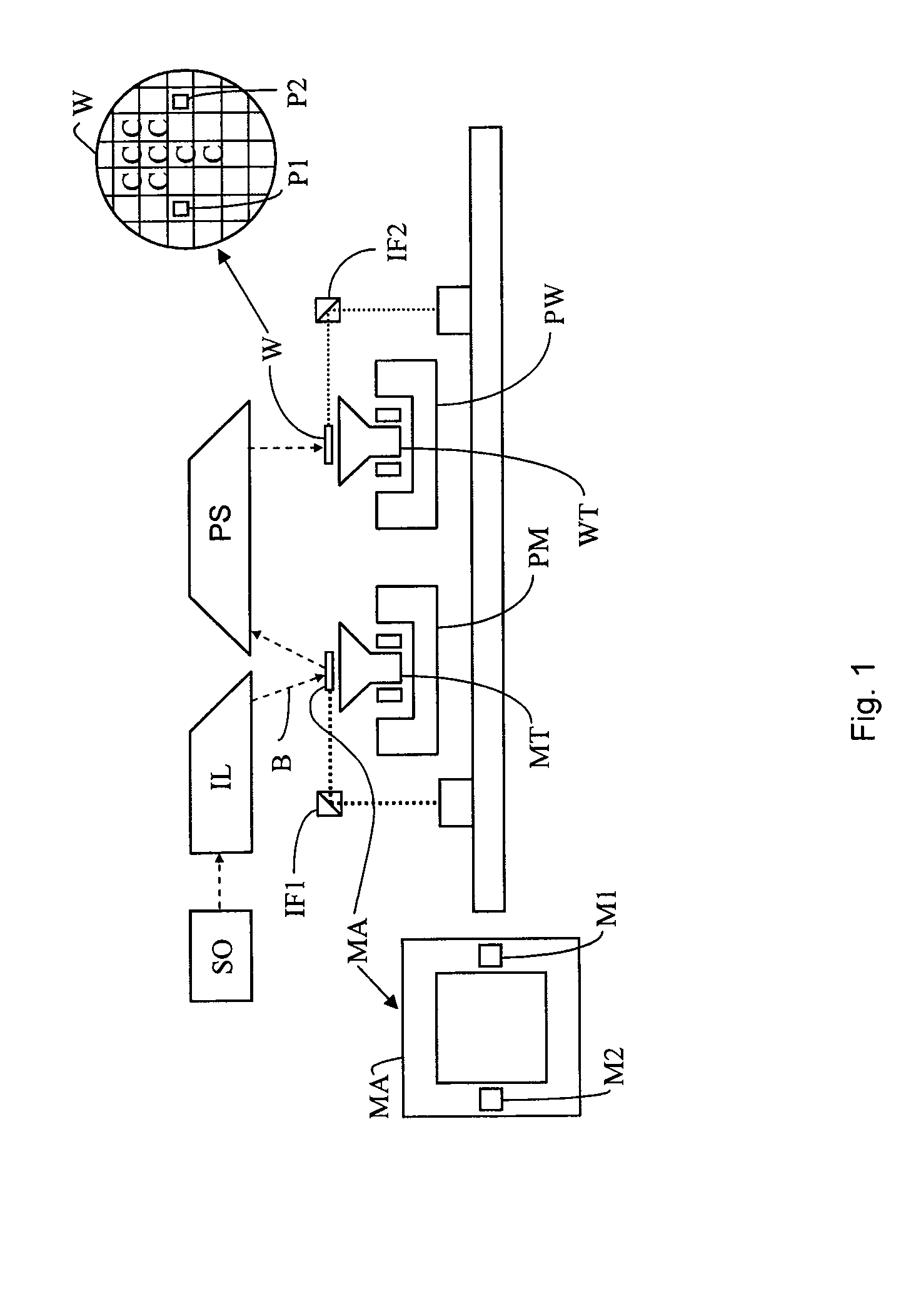

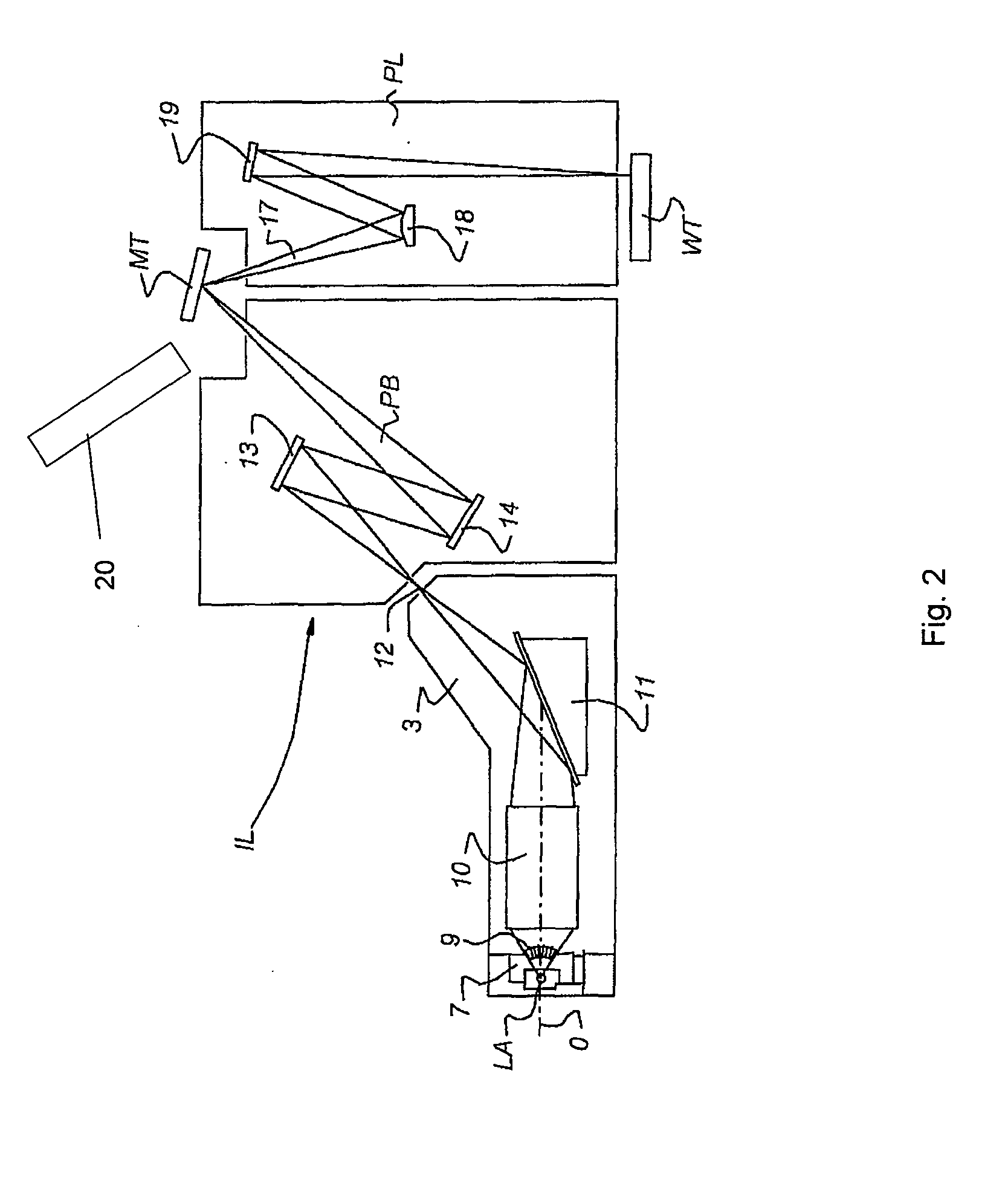

System for Contactless Cleaning, Lithographic Apparatus and Device Manufacturing Method

InactiveUS20100151394A1Increase generationExpand the populationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusElectricityEngineering

Embodiments of the invention relate to a system for contactless cleaning of an object surface, a lithographic apparatus including the system, and a method of manufacturing a device. The system may include a He plasma source contained in a chamber and a control unit constructed to modify plasma parameters in use, such as the electron energy distribution of the plasma for causing an increase in formation of He metastables without modifying operational parameters of the plasma source. The control unit may include an electrical biasing unit constructed to apply a positive bias voltage to the object, for attracting free electrons from the plasma. The system may include a supplementary gas source, which may be either pre-mixed with He or be supplied from a further gas source. The supplementary gas may be selected based on a pre-knowledge on a type of particles to be expected on the surface of the object.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com