Atomic layer deposition device

A technology of atomic layer deposition and electrode, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of low plasma density, deposition rate, deposition film quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

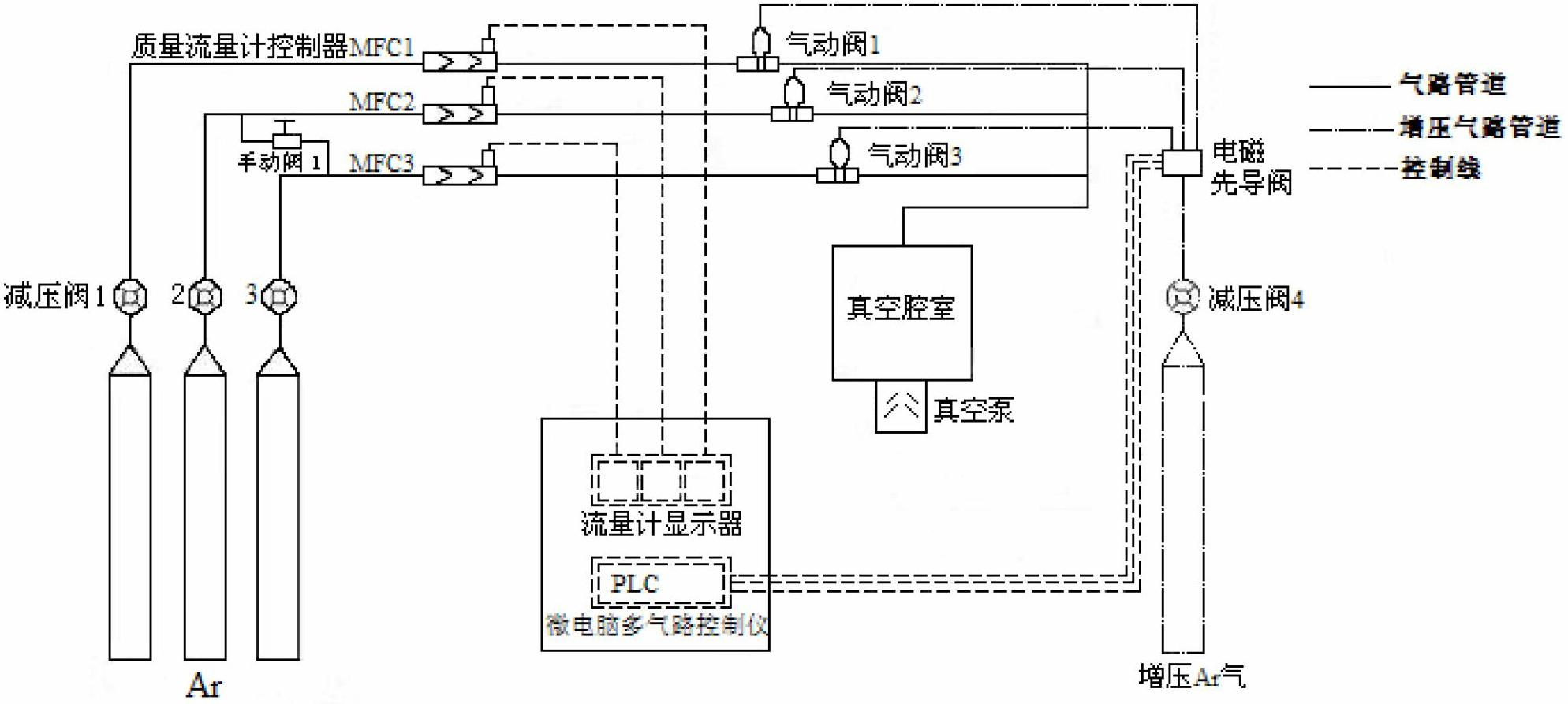

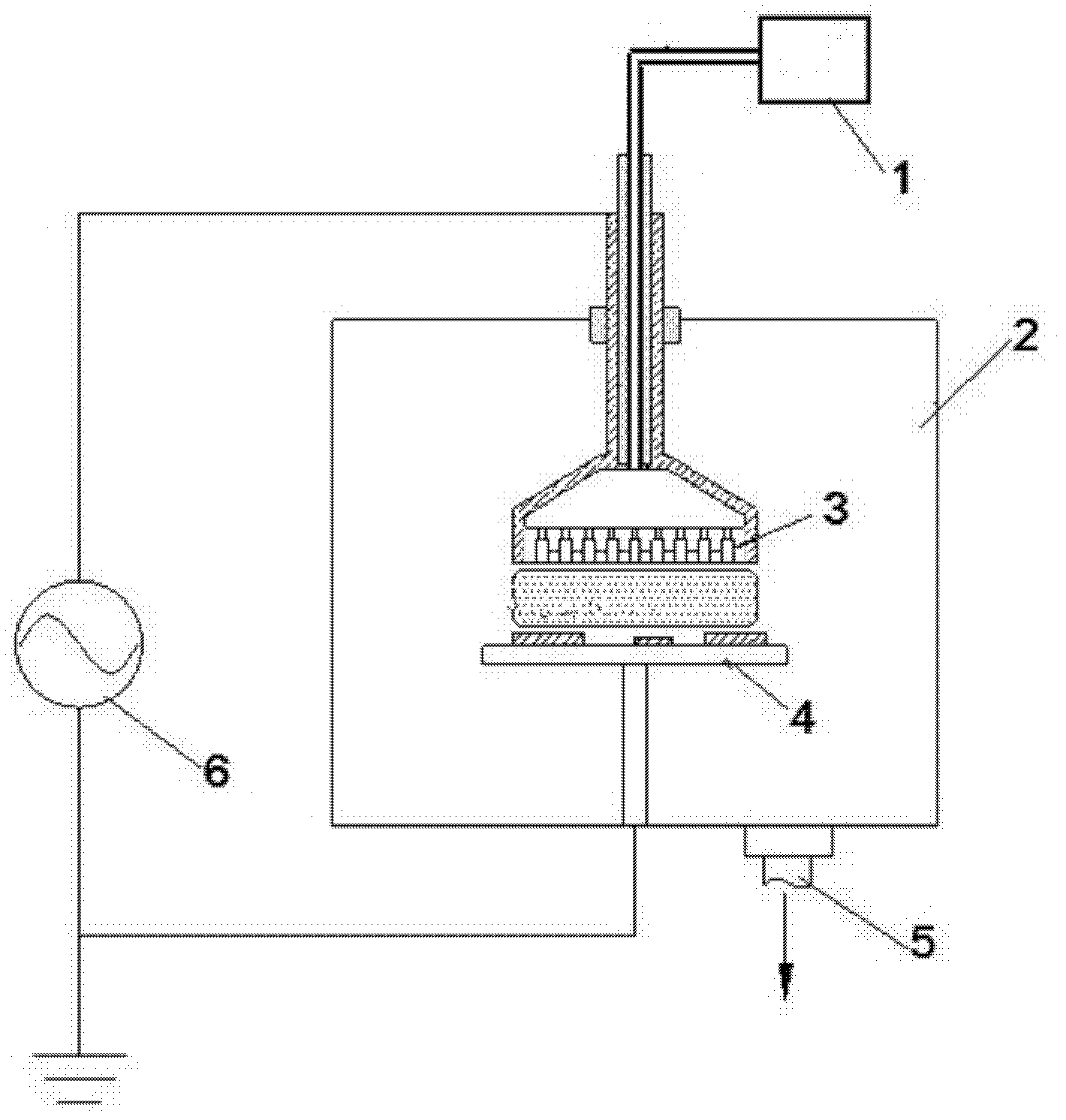

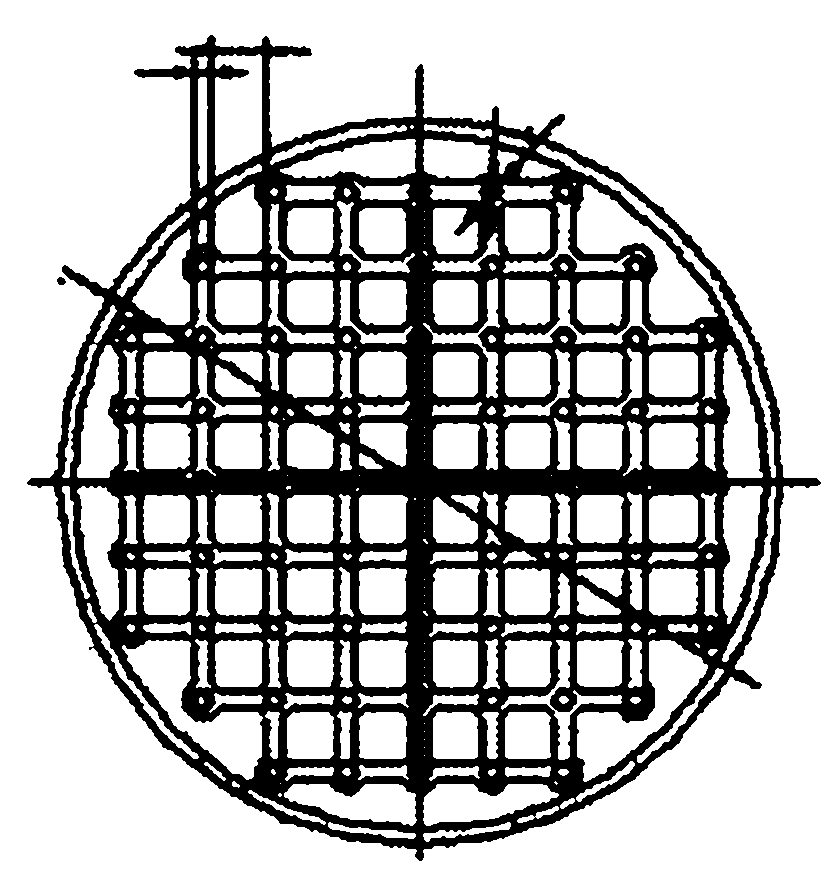

[0027] The invention provides an atomic layer deposition device with an arrayed hollow cathode structure. The set of devices includes a gas distribution system 1, a vacuum chamber 2, an array type hollow electrode 3, a flat plate electrode 4, a vacuum system 5, and a power supply system 6, etc. Utilizing the hollow cathode discharge effect of the arrayed hollow electrodes 3, the ionization efficiency of the gas can be greatly improved, the pressure and plasma density of the discharge gas can be increased, and the activation efficiency of the reaction monomer in the atomic layer deposition process can be improved, and the ionization efficiency in the space can be increased. The concentration of active groups can greatly increase the deposition rate of the film and reduce the deposition temperature. The measurement results show that this array type hollow discharge can increase the plasma density to 10 11 ~10 13 / cm 3 , reduce the plasma energy below 1eV, increase the deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com