Ion exchange technology in preparing glucose

An ion exchange and glucose technology, applied in the direction of glucose production, sugar production, sugar production, etc., can solve the problems of increasing the cost of resin replacement, resin crushing damage, and affecting production efficiency, so as to save resin consumption and regenerate Cost saving, effect of reducing impact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

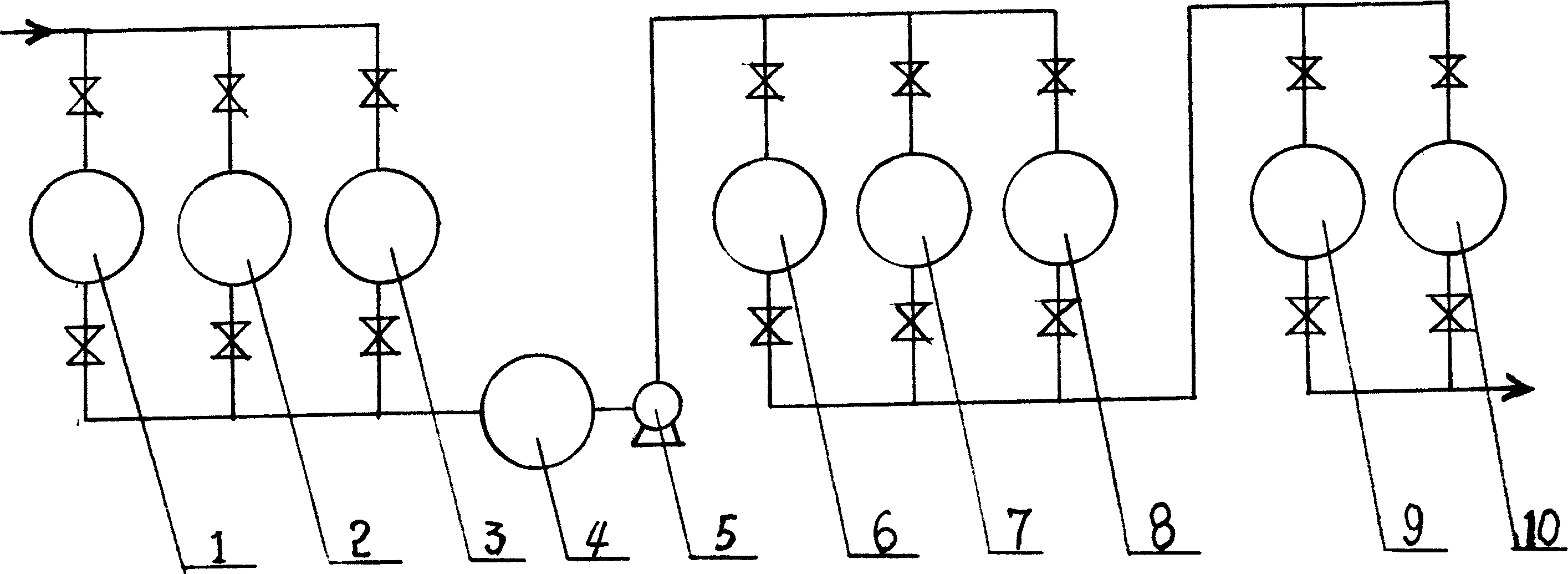

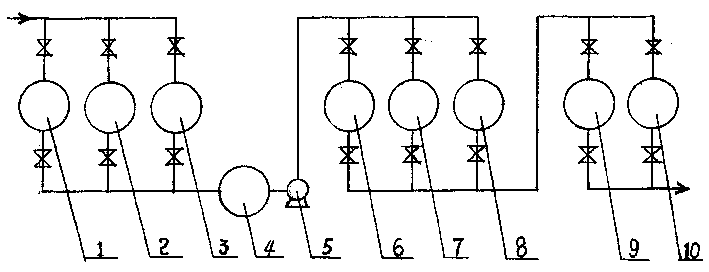

[0012] The sugar liquid after filtration and decolorization in the previous process is transported to the ion exchange process flow designed by the present invention, and successively passes through the parallel cation columns (1), (2), (3)—transfer buffer tank (4) And infusion pump (5)——pass through the parallel anion column (6), (7), (8) and then flow through the regulating column (cation column) (9), (10), and deliver to the next step of concentration and crystallization process.

[0013] Its main process operation control parameters are as follows:

[0014] The concentration of the sugar solution entering the separation process is 35-45%

[0015] Feed temperature is 40-50°C

[0016] The control parameter index of the outlet sugar liquid is PH3.5-4.5

[0017] Conductivity<50us / cm

[0018] Light transmittance > 90%

[0019] The regeneration method of the resin column in this process is similar to that of the prior art. When the index conductivity of the sugar solution at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com