A treatment process for decolorized resin regeneration waste liquid

A technology for regenerating waste liquid and processing technology, which is applied in the chemical field, can solve problems such as poor results, and achieve the effects of reducing environmental protection burden, simple production process, and simple control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

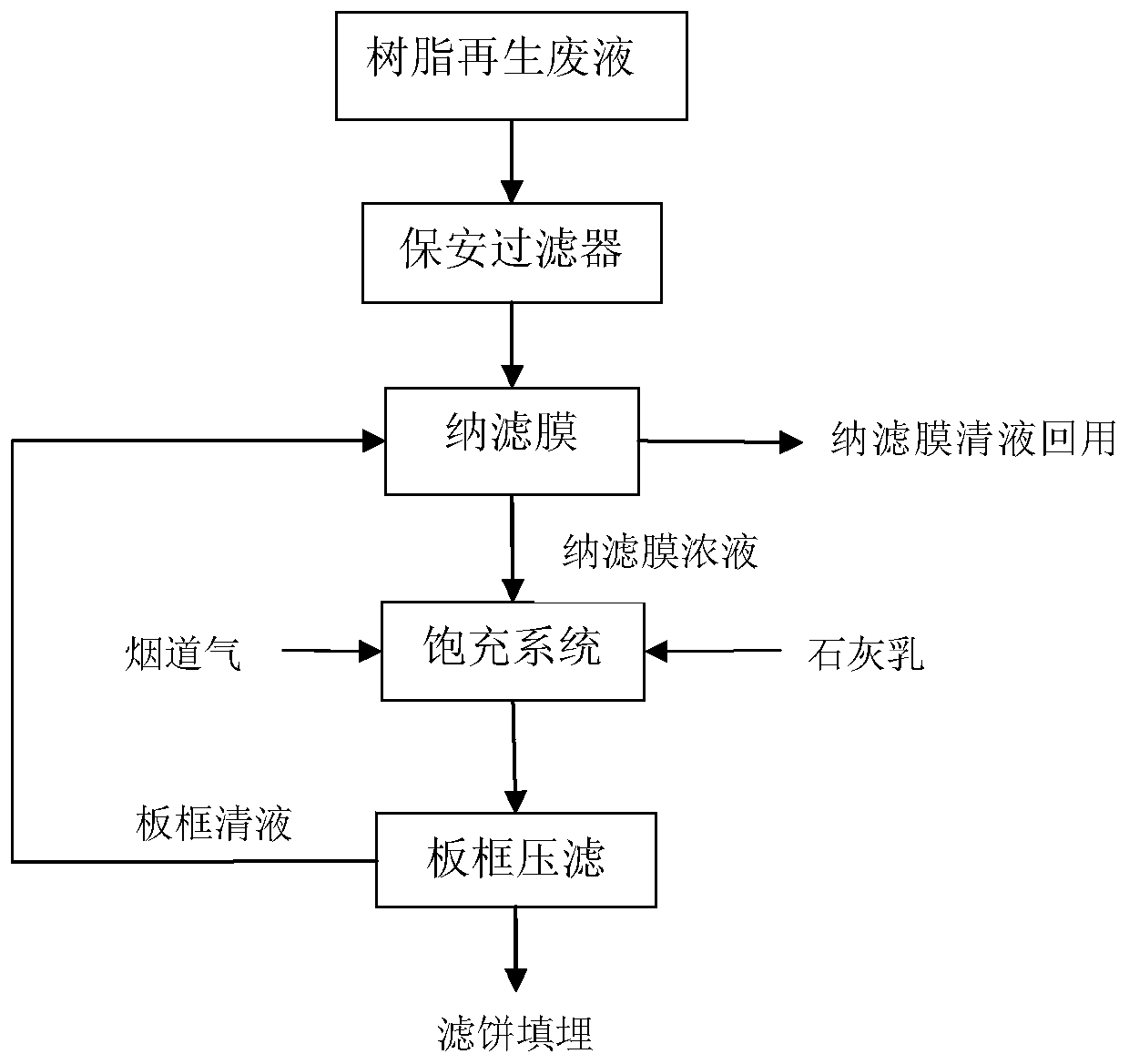

[0045] Such as figure 1 Shown, the treatment process of a kind of decolorization resin regeneration waste liquid of the present invention comprises the following steps:

[0046] (1) pre-filtering the resin regeneration liquid waste liquid through a security filter, and then decolorizing the security filter filtrate through a nanofiltration membrane to obtain a nanofiltration membrane clear liquid to be used for resin regeneration;

[0047] (2) Add milk of lime to the nanofiltration membrane concentrate, and then feed it with flue gas or carbon dioxide gas;

[0048] (3) Filtrate the fully charged nanofiltration membrane dope through the plate frame, then decolorize the obtained plate frame clear liquid through nanofiltration membrane filtration, the decolorization liquid is also used for resin regeneration, and the dope is also returned to step (2) process.

[0049] In step (1), the security filter is a bag filter with a filtration accuracy of 1um and a filtration pressure of...

Embodiment 2

[0055] Such as figure 1 Shown, the treatment process of a kind of decolorization resin regeneration waste liquid of the present invention comprises the following steps:

[0056] (1) pre-filtering the resin regeneration liquid waste liquid through a security filter, and then decolorizing the security filter filtrate through a nanofiltration membrane to obtain a nanofiltration membrane clear liquid to be used for resin regeneration;

[0057] (2) Add milk of lime to the nanofiltration membrane concentrate, and then feed it with flue gas or carbon dioxide gas;

[0058] (3) Filtrate the fully charged nanofiltration membrane dope through the plate frame, then decolorize the obtained plate frame clear liquid through nanofiltration membrane filtration, the decolorization liquid is also used for resin regeneration, and the dope is also returned to step (2) process.

[0059] In step (1), the security filter is a bag filter with a filtration precision of 10um and a filtration pressure ...

Embodiment 3

[0065] Such as figure 1 Shown, the treatment process of a kind of decolorization resin regeneration waste liquid of the present invention comprises the following steps:

[0066] (1) pre-filtering the resin regeneration liquid waste liquid through a security filter, and then decolorizing the security filter filtrate through a nanofiltration membrane to obtain a nanofiltration membrane clear liquid to be used for resin regeneration;

[0067] (2) Add milk of lime to the nanofiltration membrane concentrate, and then feed it with flue gas or carbon dioxide gas;

[0068] (3) Filtrate the fully charged nanofiltration membrane dope through the plate frame, then decolorize the obtained plate frame clear liquid through nanofiltration membrane filtration, the decolorization liquid is also used for resin regeneration, and the dope is also returned to step (2) process.

[0069] In step (1), the security filter is a bag filter with a filtration accuracy of 5um and a filtration pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com