Patents

Literature

39results about How to "Low regeneration cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for Regeneration of a Layer Transferred Wafer and Regenerated Layer Transferred Wafer

ActiveUS20070148914A1Reduce processing timeLow regeneration costSemiconductor/solid-state device manufacturingLapping machinesThin layerEngineering

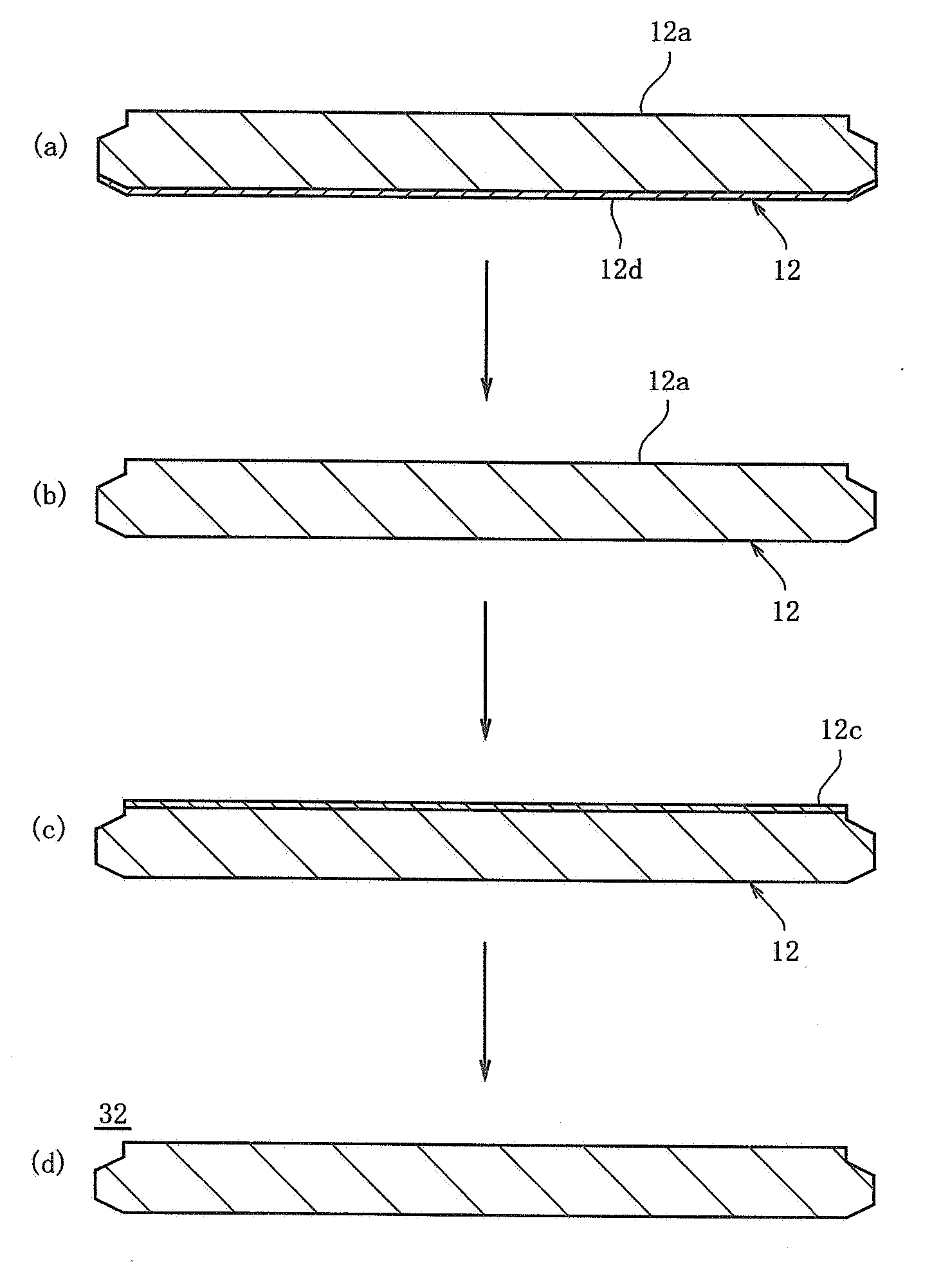

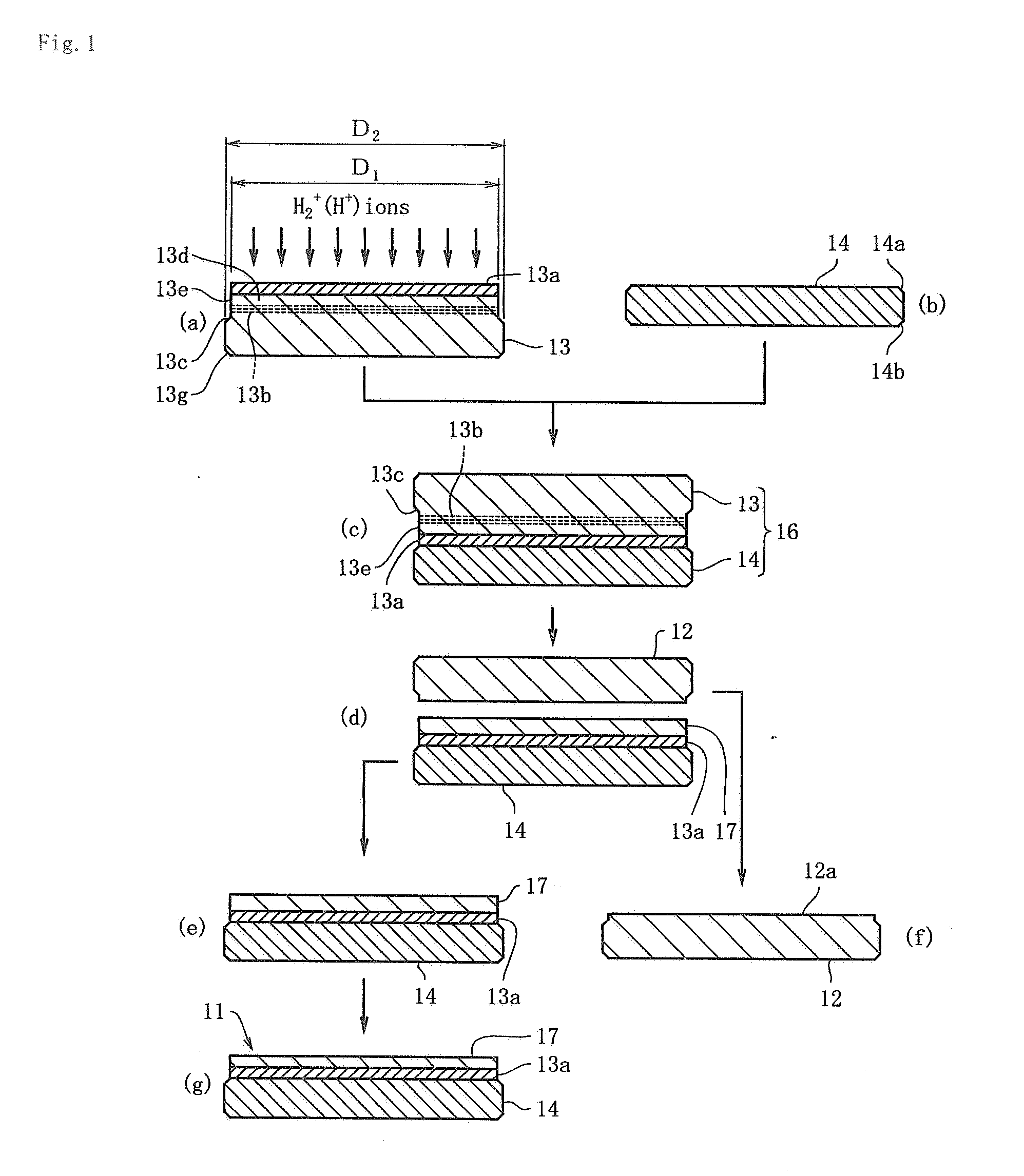

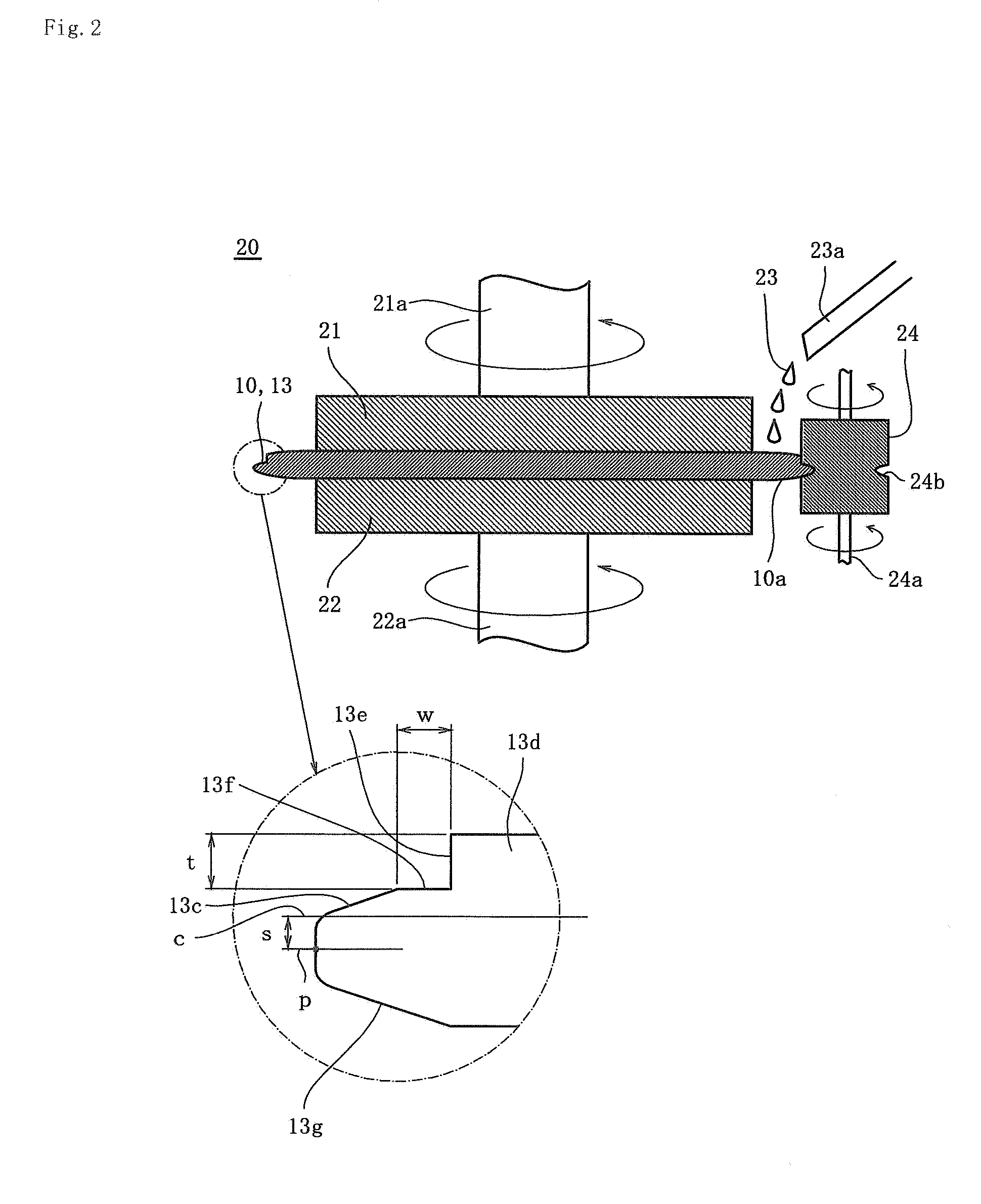

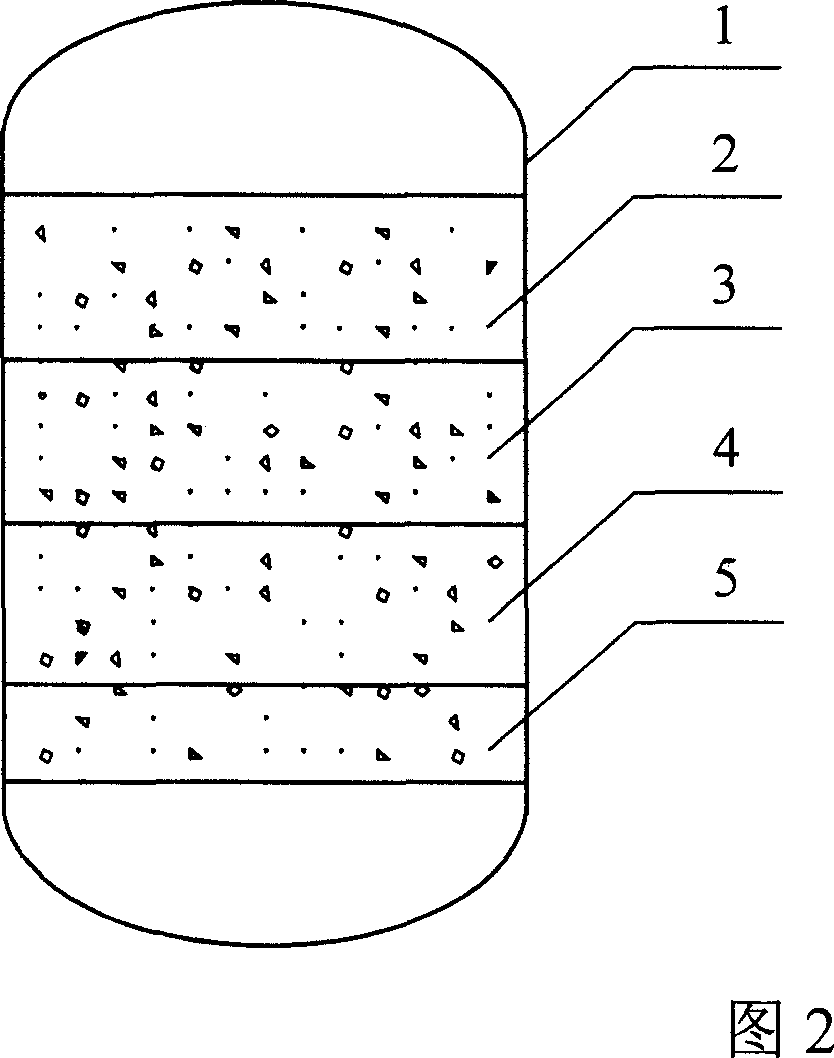

A processing time required for regeneration of a layer transferred wafer is reduced and the regeneration cost is lowered, while a removal amount at the regeneration is decreased the number of regeneration times is increased. A main surface of a semiconductor wafer (13) has a main flat portion (13d) and a chamfered portion (13c) formed in the periphery of the main flat portion (13d), an ion implanted area (13b) is formed by implanting ions only into the main flat portion (13d), a laminated body (16) is formed by laminating the main flat portion (13d) on a main surface of a support wafer (14), and moreover, the semiconductor wafer (13) is separated from a thin layer (17) in the ion implanted area (13b) by heat treatment at a predetermined temperature so as to obtain a thick layer transferred wafer (12), which is to be regenerated. The main flat portion (13d) of the semiconductor wafer (13) is formed to have a ring-shape step (13e) protruding from the chamfered portion (13c), and the semiconductor wafer (13) is separated from the thin layer (17) on the whole surface of the ion implanted area (13b) so that no step is generated in the periphery thereby to obtain the layer transferred wafer (12).

Owner:SUMCO CORP

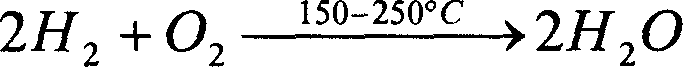

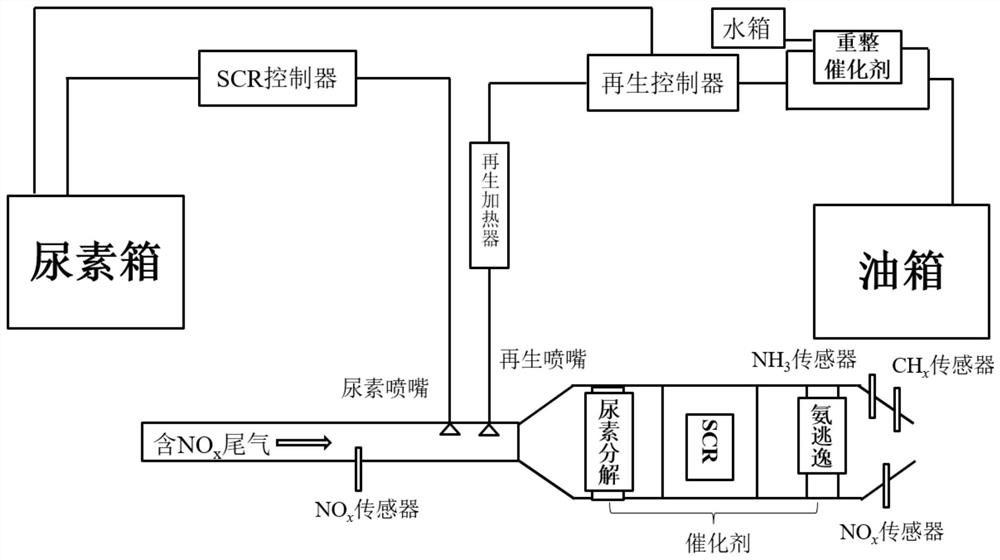

In-situ regeneration method of ammonium sulfate poisoning denitration catalyst

InactiveCN105688936AEasy to operateShort regeneration timeHeterogenous catalyst chemical elementsDispersed particle separationNitrogen oxidesFlue gas

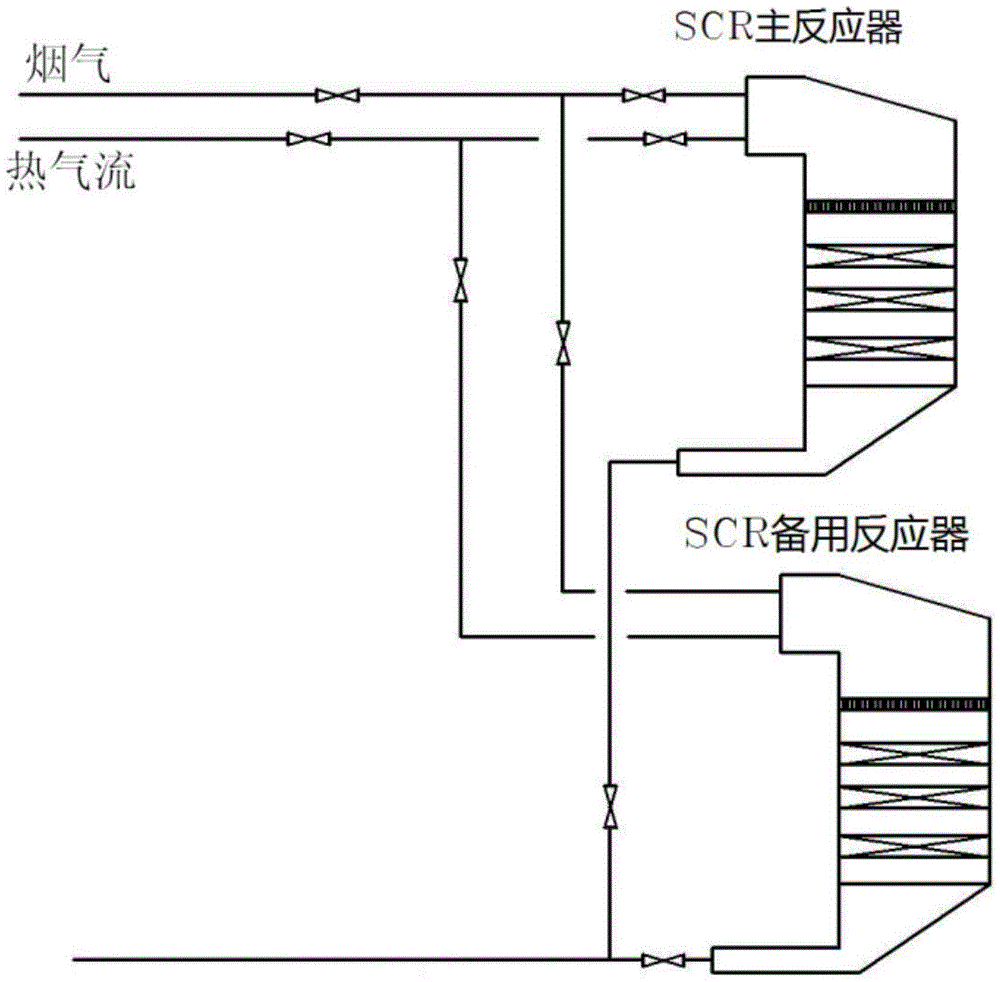

The invention relates to an in-situ regeneration method of an ammonium sulfate poisoning denitration catalyst and belongs to the technical field of an industrial denitration catalyst. The in-situ regeneration method comprises the following steps: (1) when the concentration of nitrogen oxide in outlet flue gas of an SCR (Semiconductor Control Rectifier) main reactor is close to an emission limit value, switching the flue gas to an SCR reserved reactor; (2) introducing hot gas flow into the SCR main reactor and decomposing an ammonium sulfate layer deposited on the surface of the catalyst under the action of the hot gas flow; continuously introducing the hot gas flow for 1 hour to 8 hours to finish regeneration of the denitration catalyst; (3) switching the flue gas back to the SCR main reactor and continually carrying out a denitration reaction. Under the action of the hot gas flow, ammonium sulfate is decomposed into ammonia gas, sulfur trioxide and water steam and is removed along the flowing of the hot gas flow, so that the denitration performance of the catalyst can be recovered. The in-situ regeneration method of the ammonium sulfate poisoning denitration catalyst has the advantages of simplicity in operation, short regeneration time, low regeneration cost, safety and environmental friendliness, high denitration efficiency of the regenerated catalyst, and no changes of the strength and pore structure of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

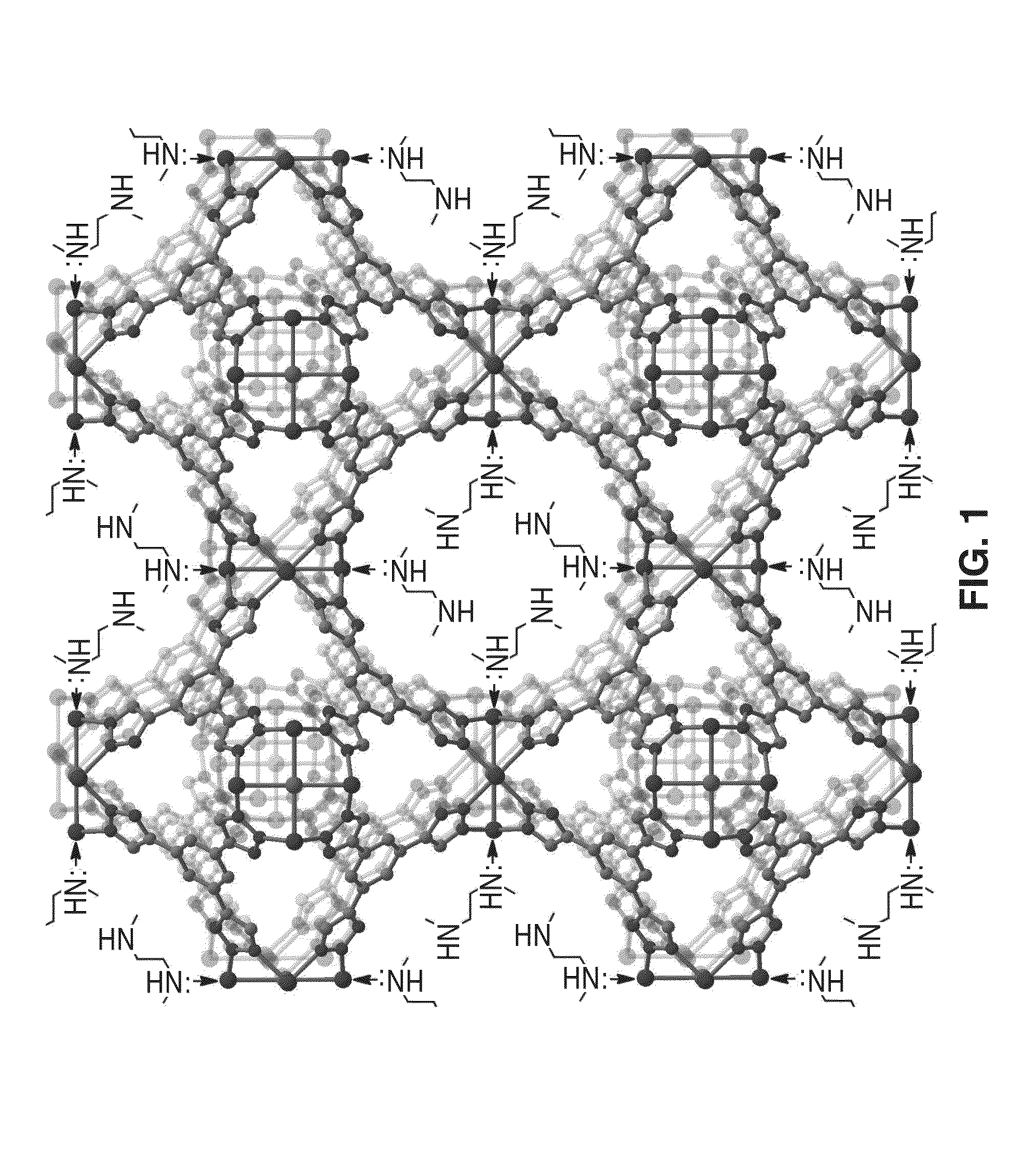

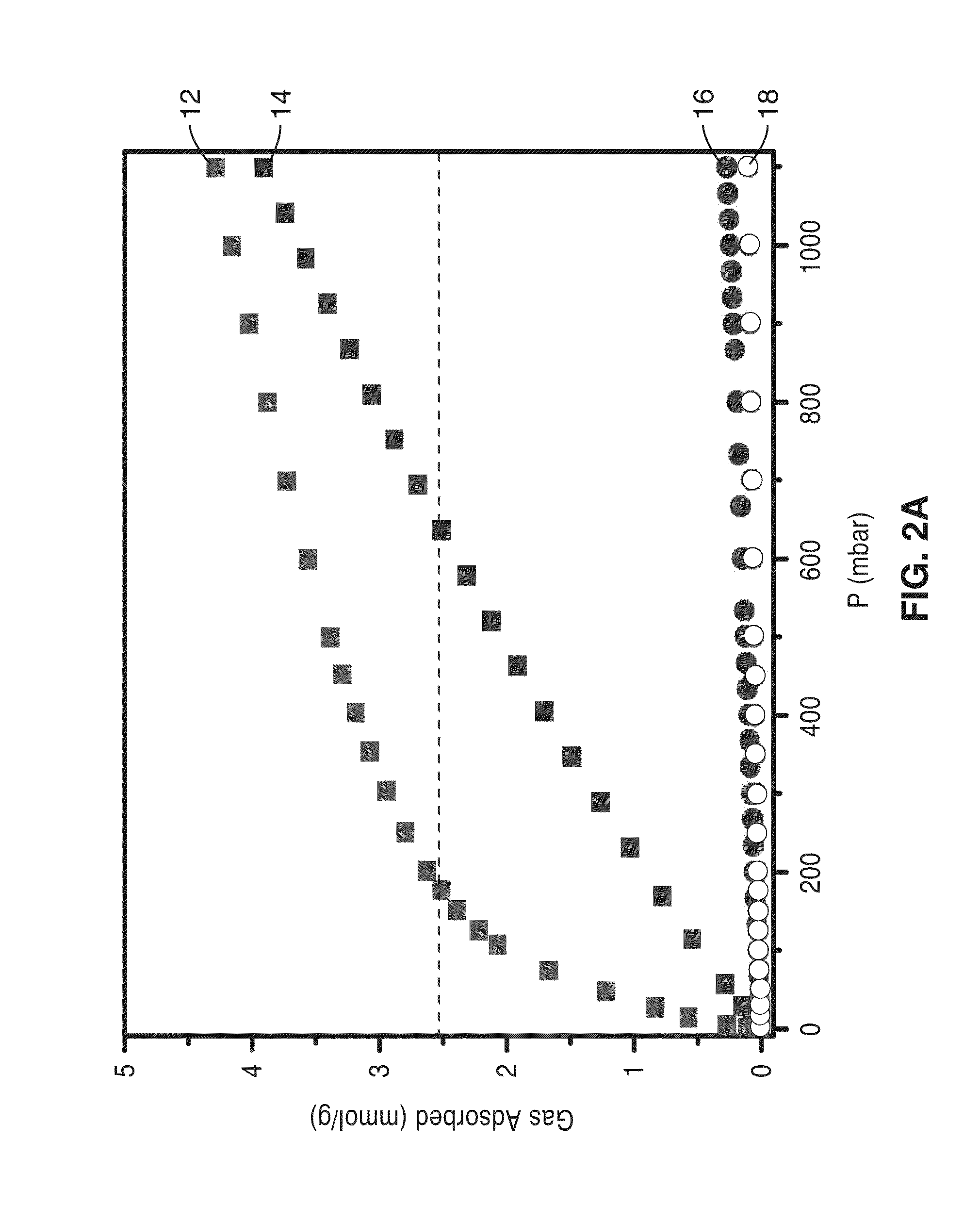

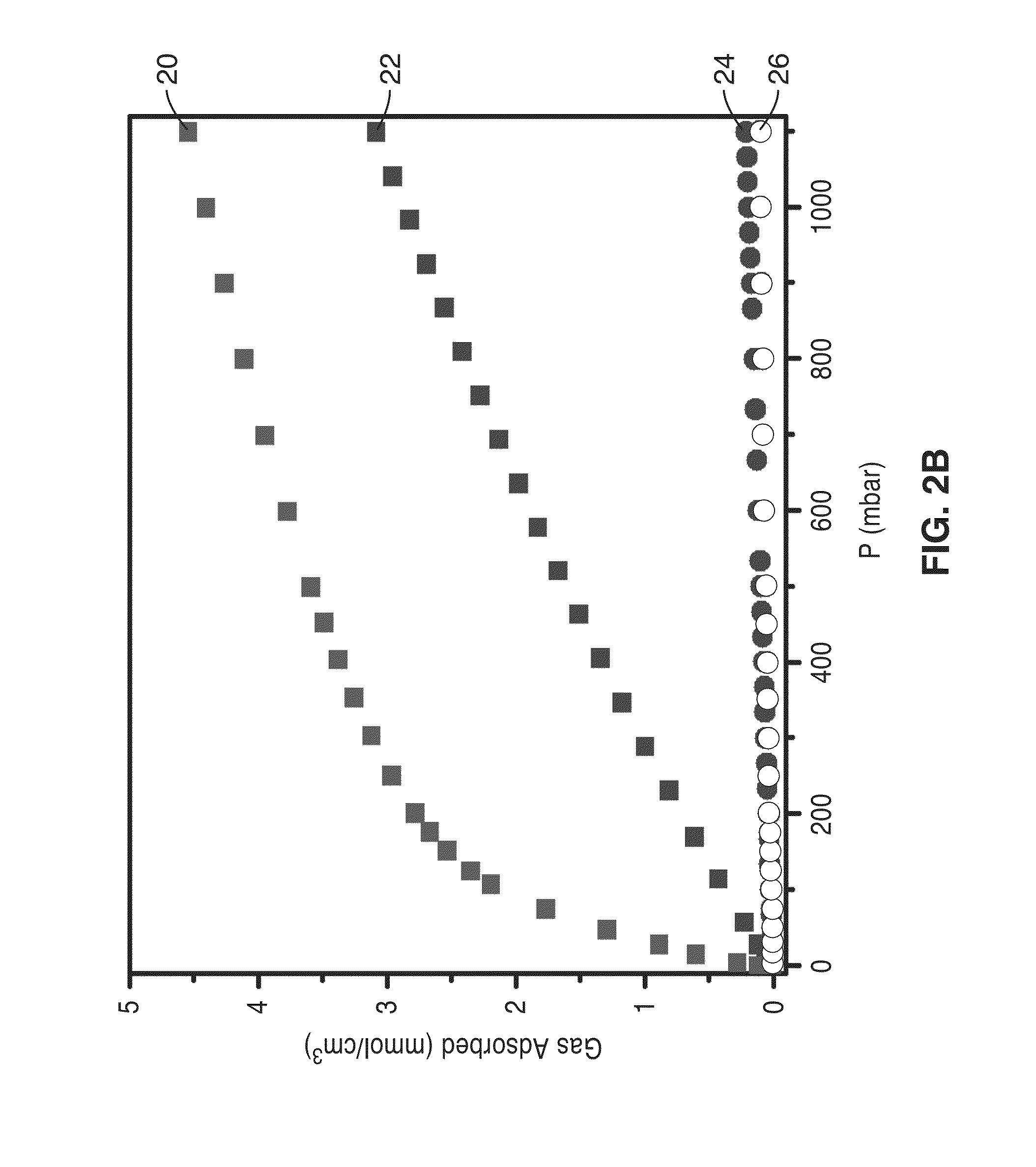

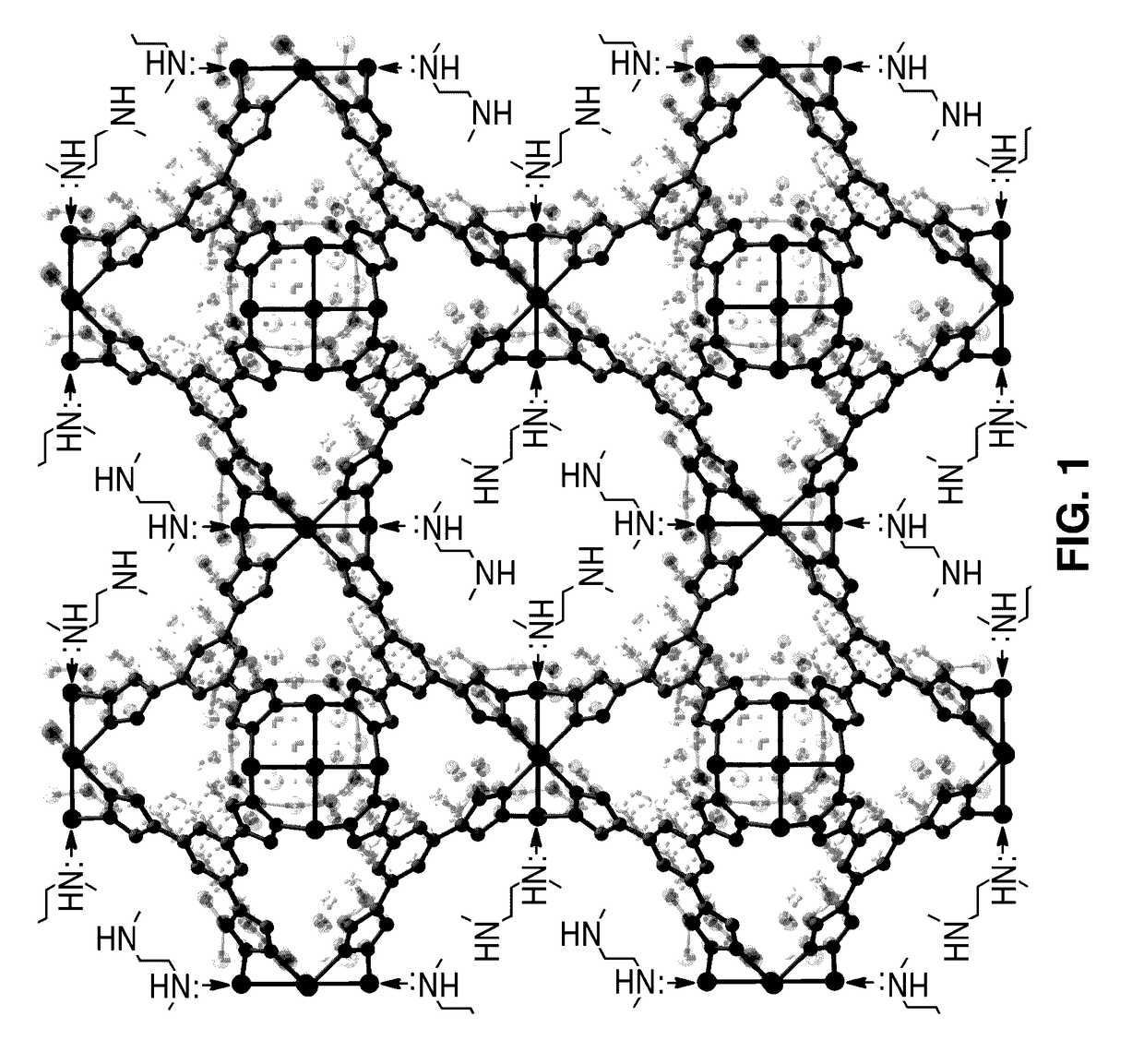

Alkylamine functionalized metal-organic frameworks for composite gas separations

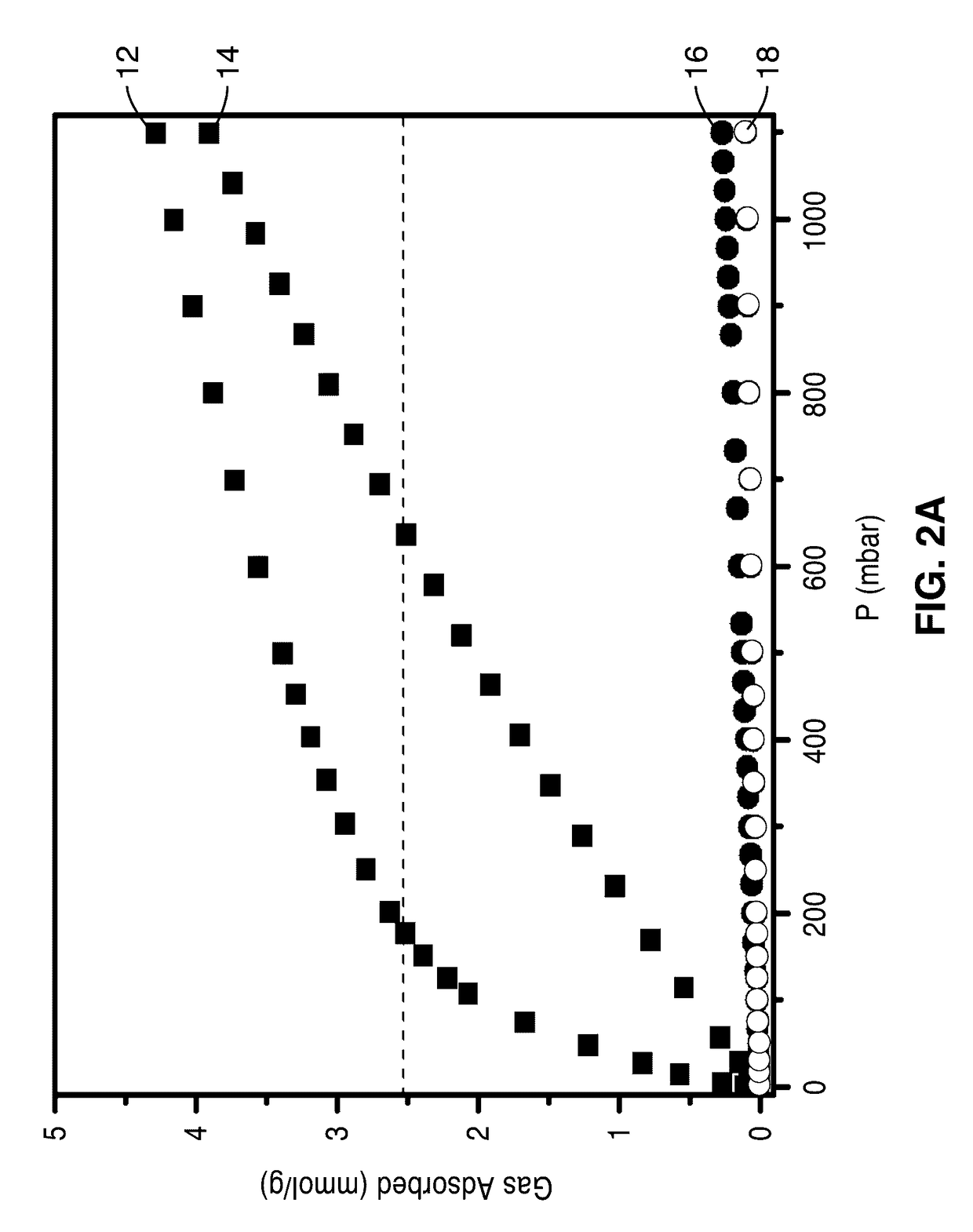

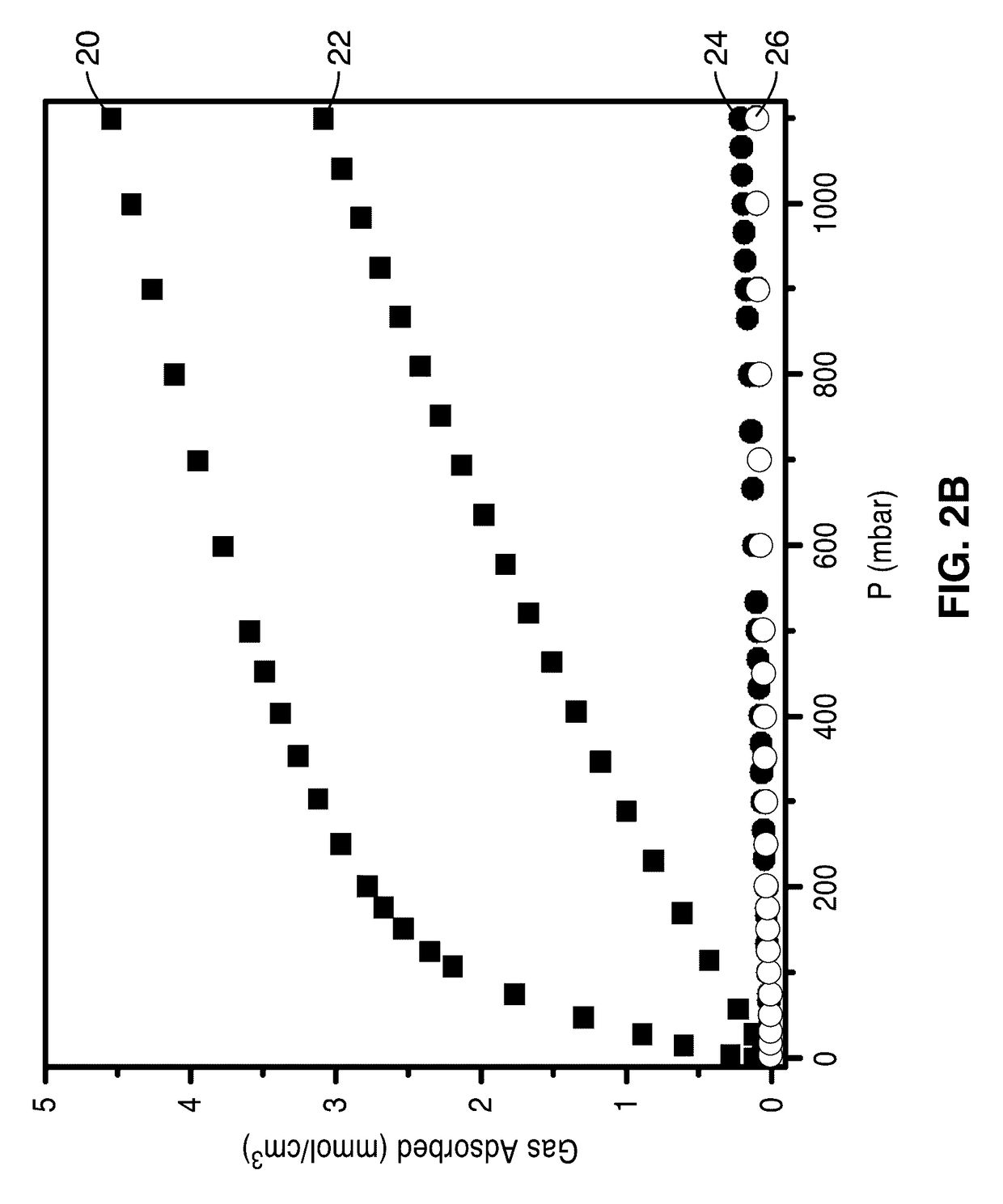

InactiveUS20140294709A1Low pressureReduce the temperatureGas treatmentCarbon compoundsSorbentMetal-organic framework

Functionalized metal-organic framework adsorbents with ligands containing basic nitrogen groups such as alkylamines and alkyldiamines appended to the metal centers and method of isolating carbon dioxide from a stream of combined gases and carbon dioxide partial pressures below approximately 1 and 1000 mbar. The adsorption material has an isosteric heat of carbon dioxide adsorption of greater than −60 kJ / mol at zero coverage using a dual-site Langmuir model.

Owner:RGT UNIV OF CALIFORNIA

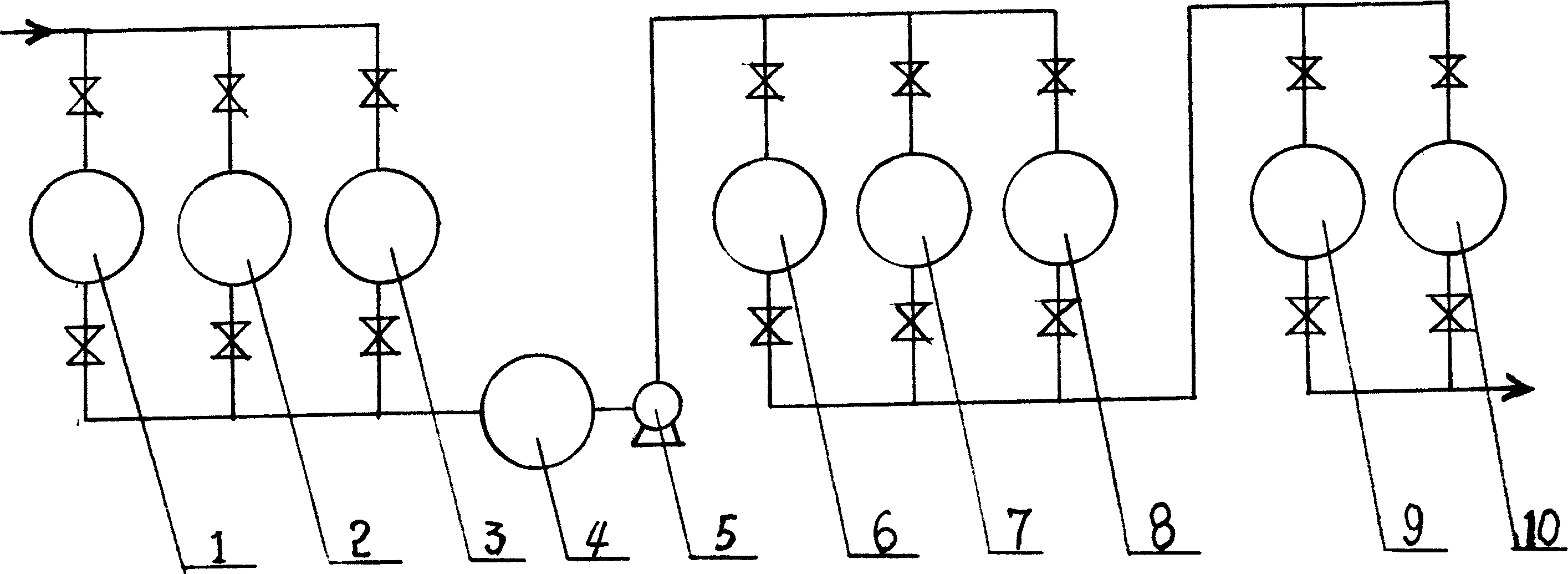

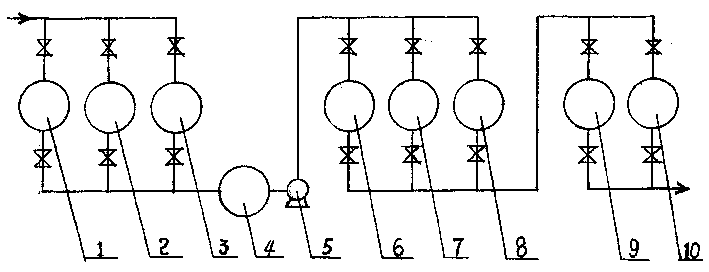

Ion exchange technology in preparing glucose

InactiveCN1390845ALow regeneration costExtended recovery periodMonosaccharidesGlucose productionIon exchangeIon

An ion exchange process for preparing glycose features that multiple cationic resin columns are parallelly connected into a group, multiple anionic resin columns are parallelly connected into a group, and both groups are connected via buffer tank and pump. Its advantages are regeneration of any resin column without stopping production, low cost for regeneration and saving resin by 30%.

Owner:XIWANG GROUP

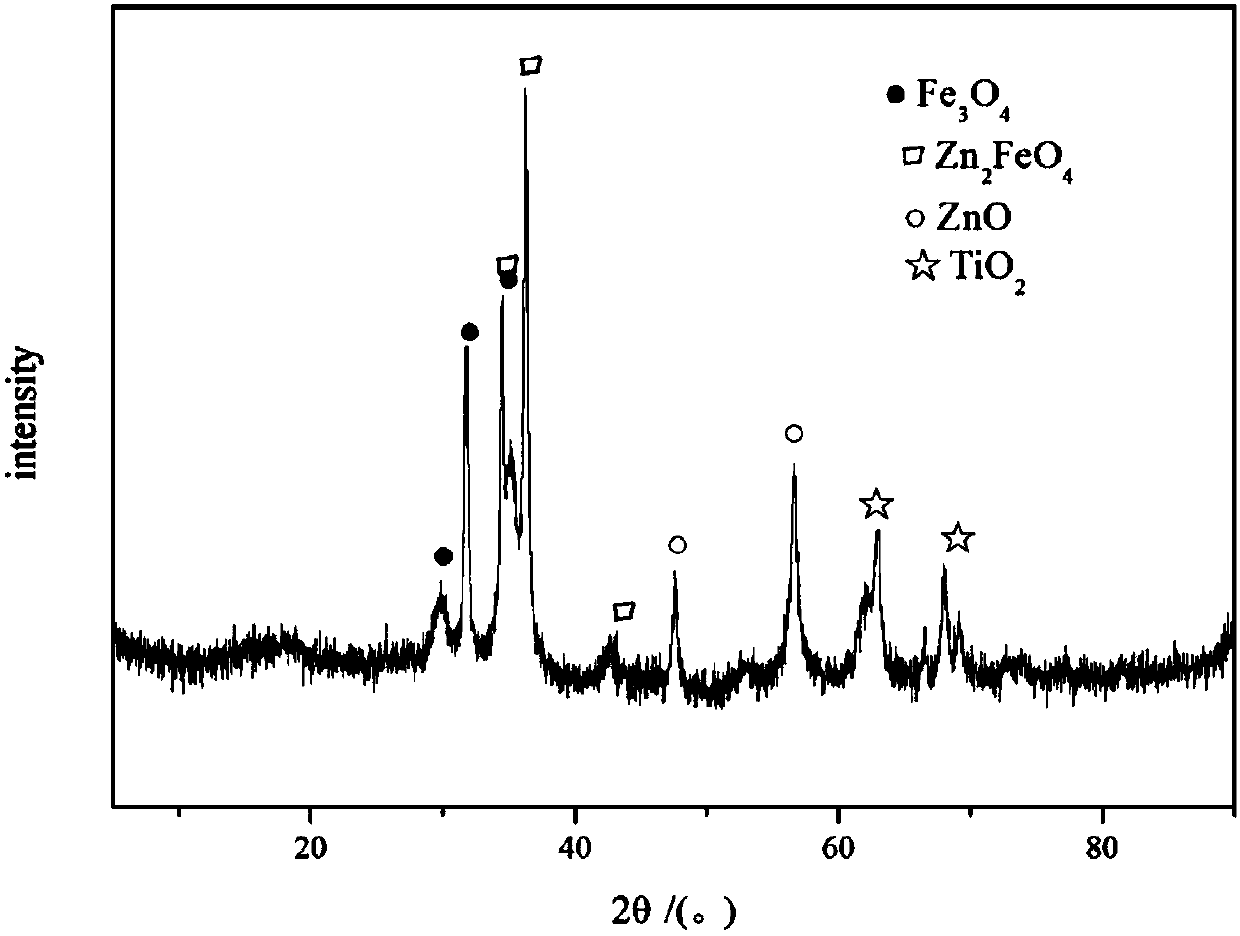

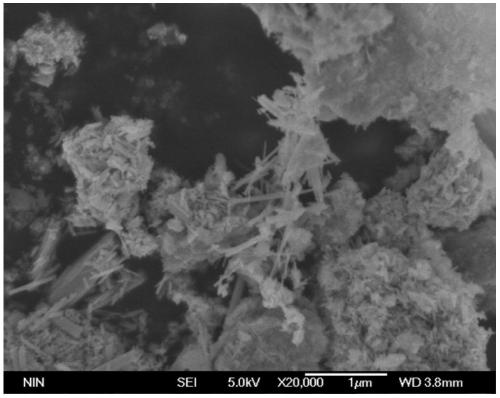

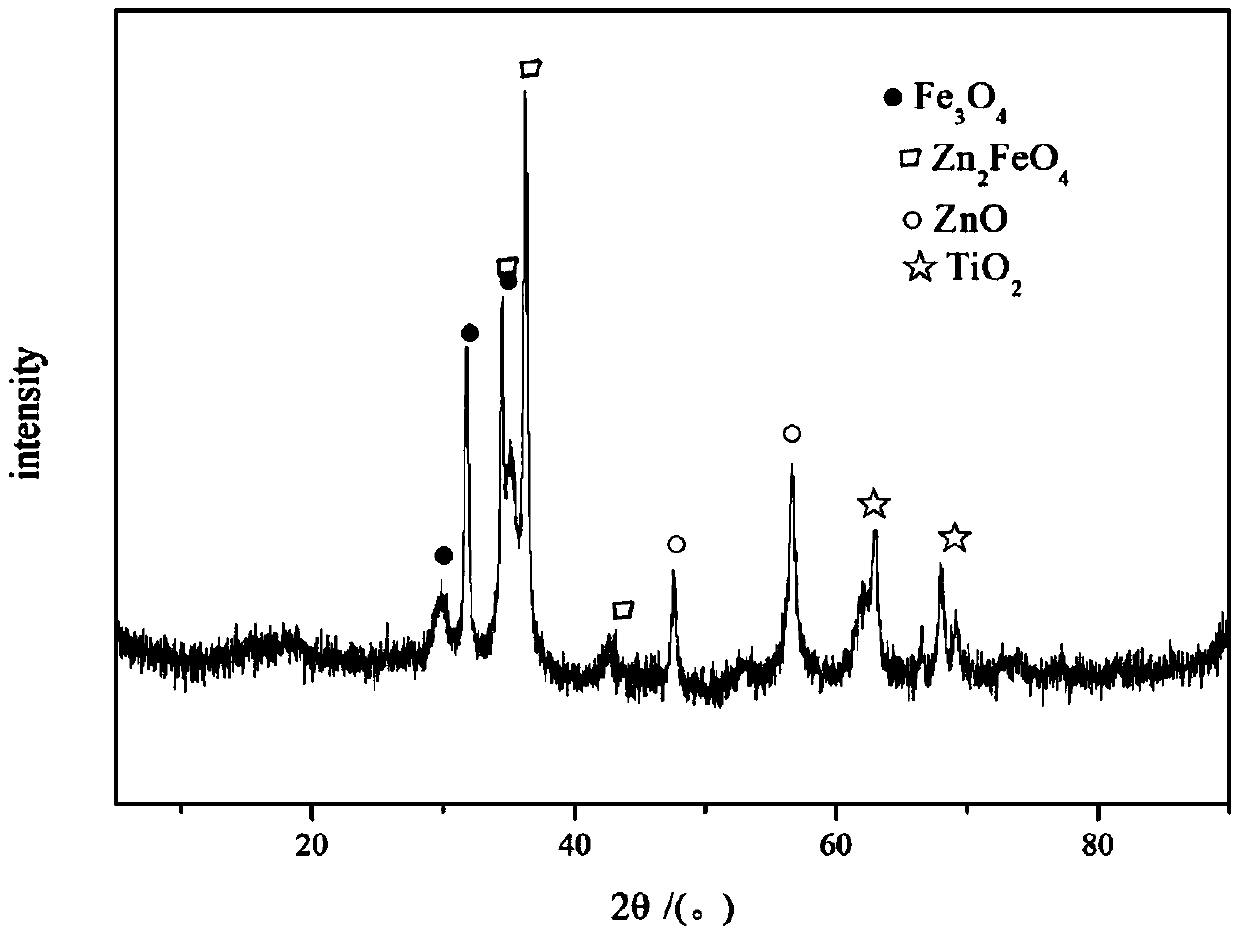

Preparation and application of nitrate treatment agent

ActiveCN107694541AAvoid secondary pollutionSimple processWater/sewage treatment by irradiationOther chemical processesNitrateHydrotalcite

The invention discloses preparation and application of a nitrate treatment agent. The preparation method includes: taking cotton as the template, using coprecipitation process to synthesize biomorphiczinc titanium iron ternary hydrotalcite, and conducting roasting in a muffle furnace so as to obtain the nitrate treatment agent. The invention also provides application of the nitrate treatment agent prepared by the method in treatment of nitrate wastewater. The nitrate treatment agent prepared by the method has good adsorption effect on nitrate and is easy to separate, and has simple and feasible regeneration method, thus having broad application prospects in the field of nitrate wastewater treatment.

Owner:XIAN UNIV OF SCI & TECH

Method of eleminating miniature amount of impurities in epsilon-caprolactam water solution

InactiveCN1453271AReduce conductivityReduced extinction valueLactams separation/purificationDialysis membranesIon exchange

The present invention features that electric dialysis membrane is used to eliminate the inorganic impurities and miniature amount of organic impurities in water solution of epsilon-caprolactam, that is, water solution of epsilon-caprolactam of 5-90 wt% concentration is made to pass through electric dialysis membrane at 0-150 deg.c. The said method is used to replace ion exchange process for refining caprolactam and can reduce greatly the conductivity and extinction value of water solution of epsilon-caprolactam and eliminate ammonium radical, acid radical and other ions and miniature amount of organic impurities in water solution of epsilon-caprolactam. s

Owner:CHINA PETROLEUM & CHEM CORP

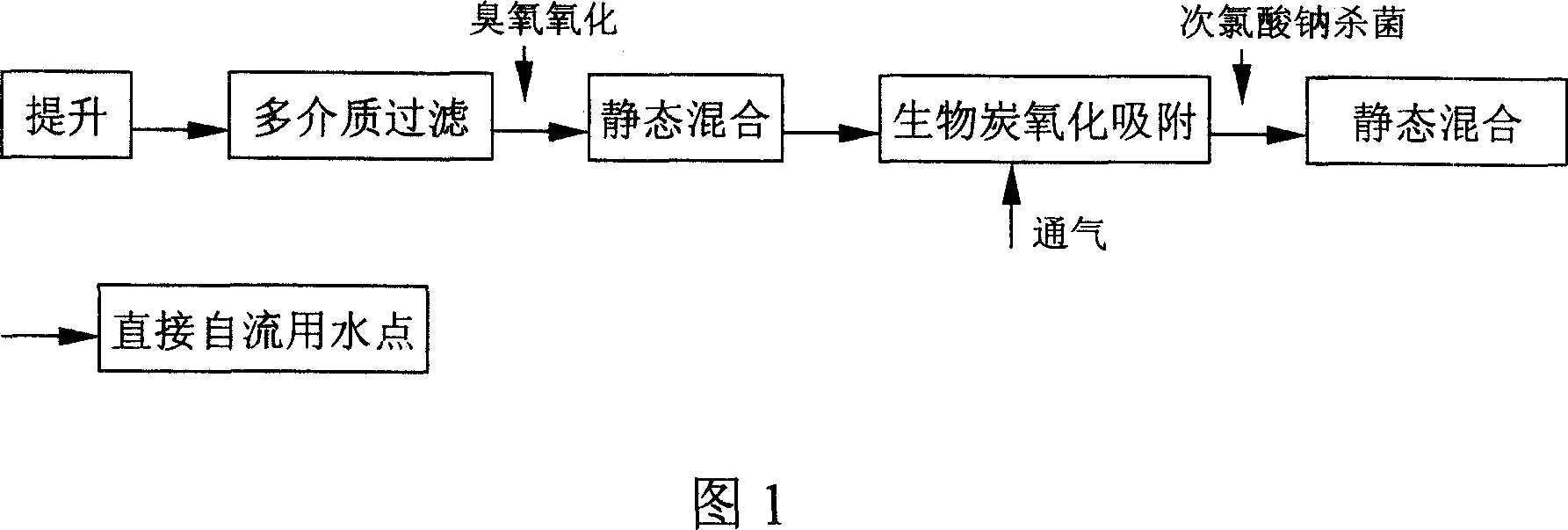

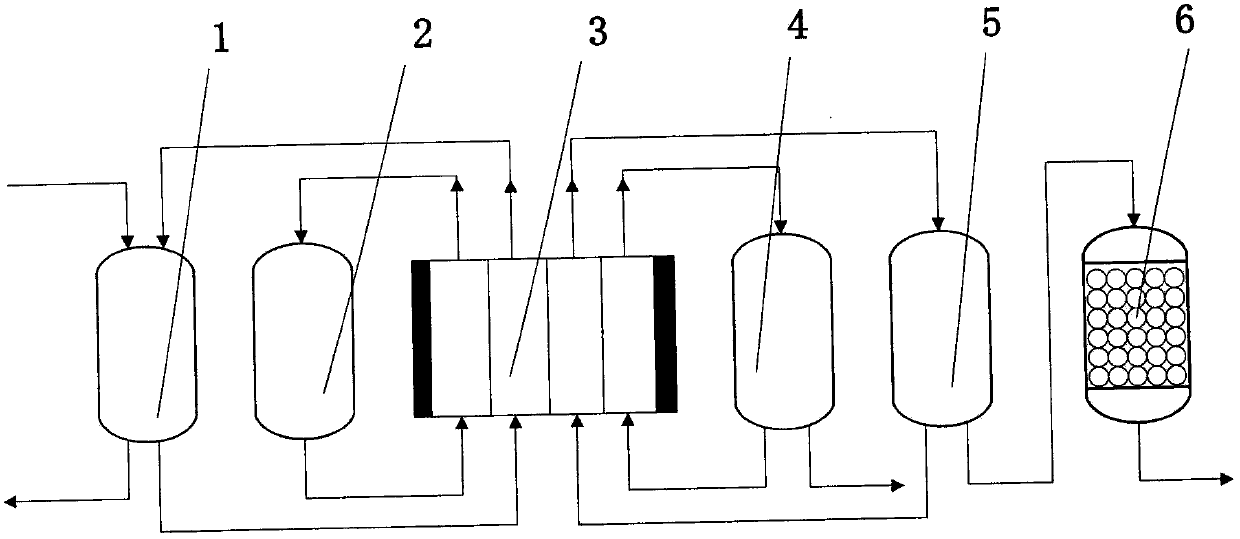

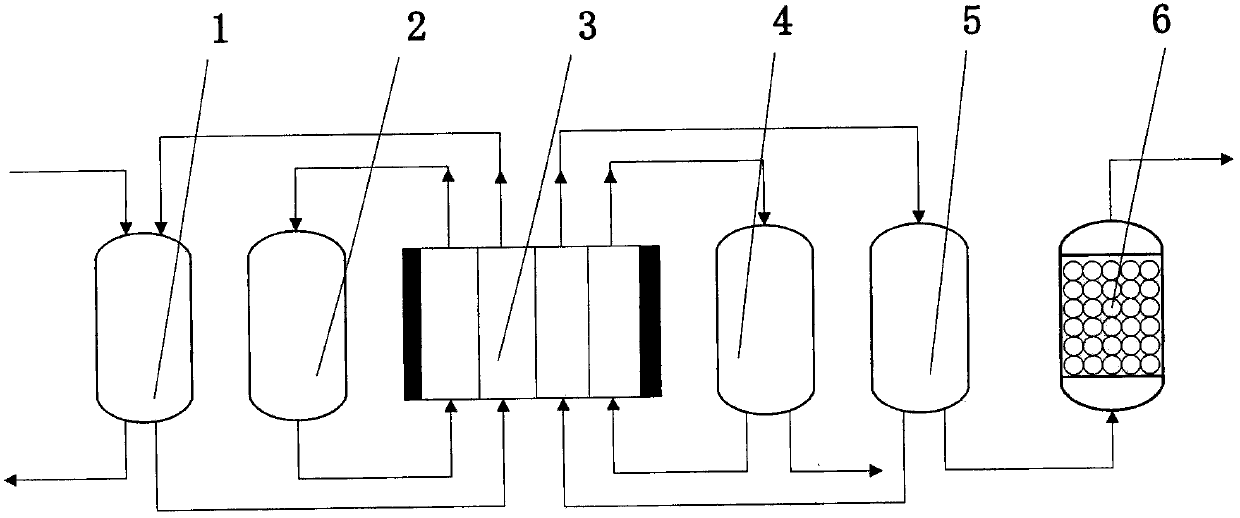

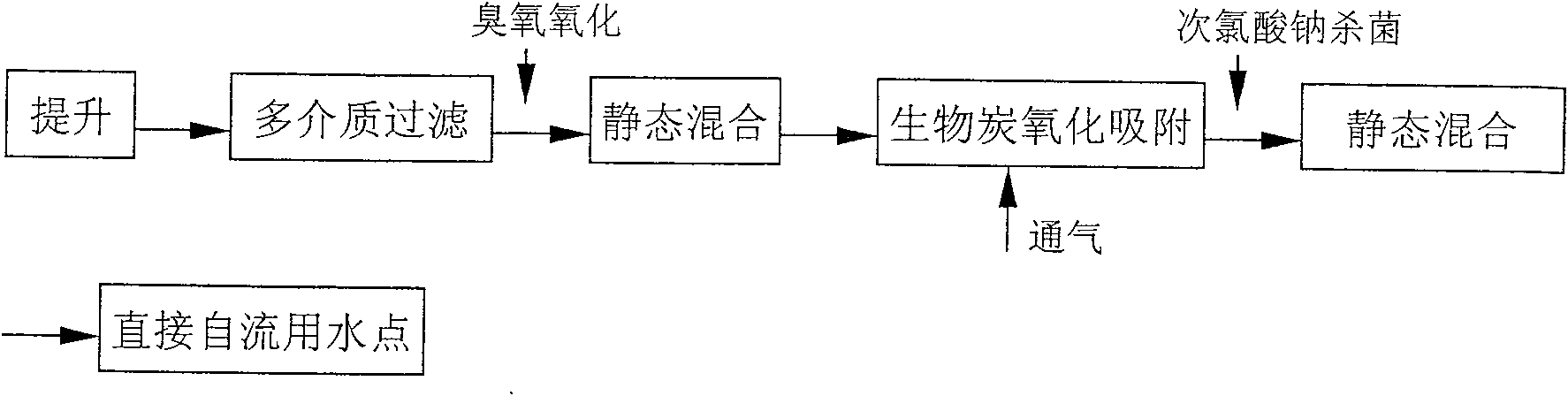

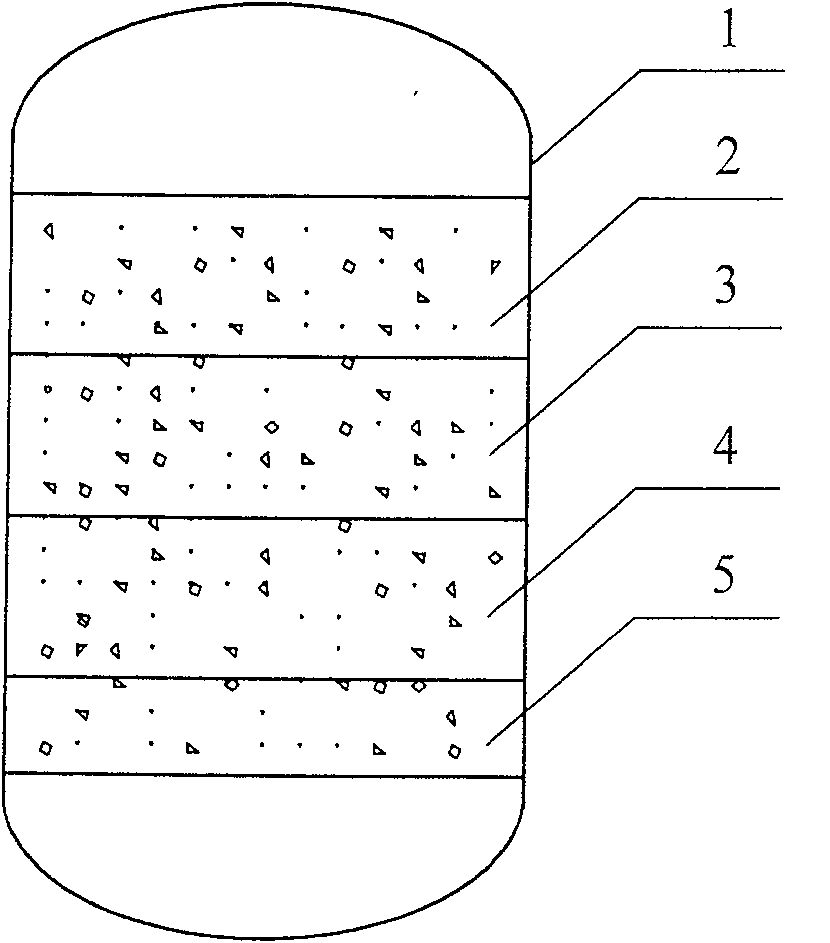

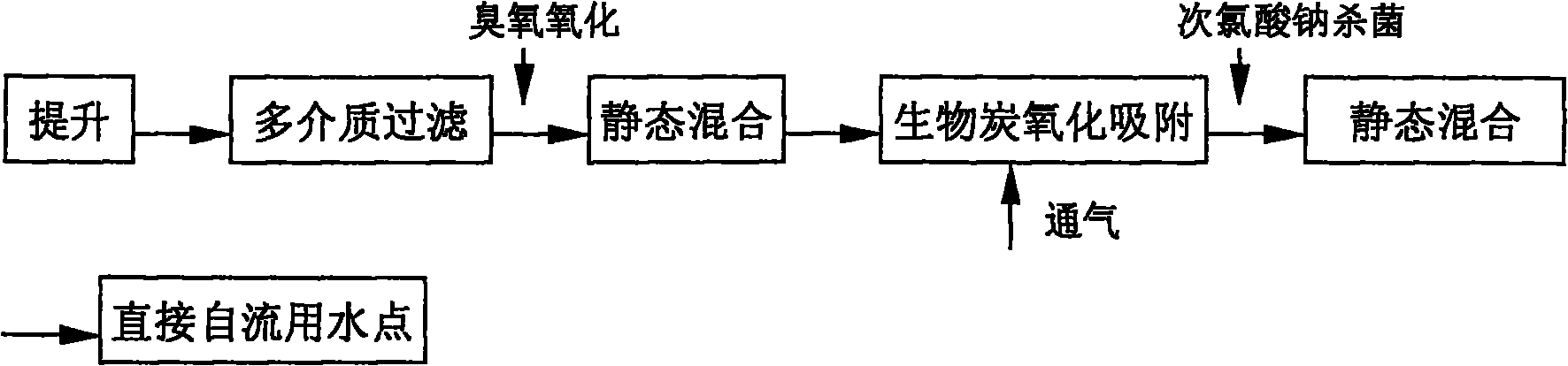

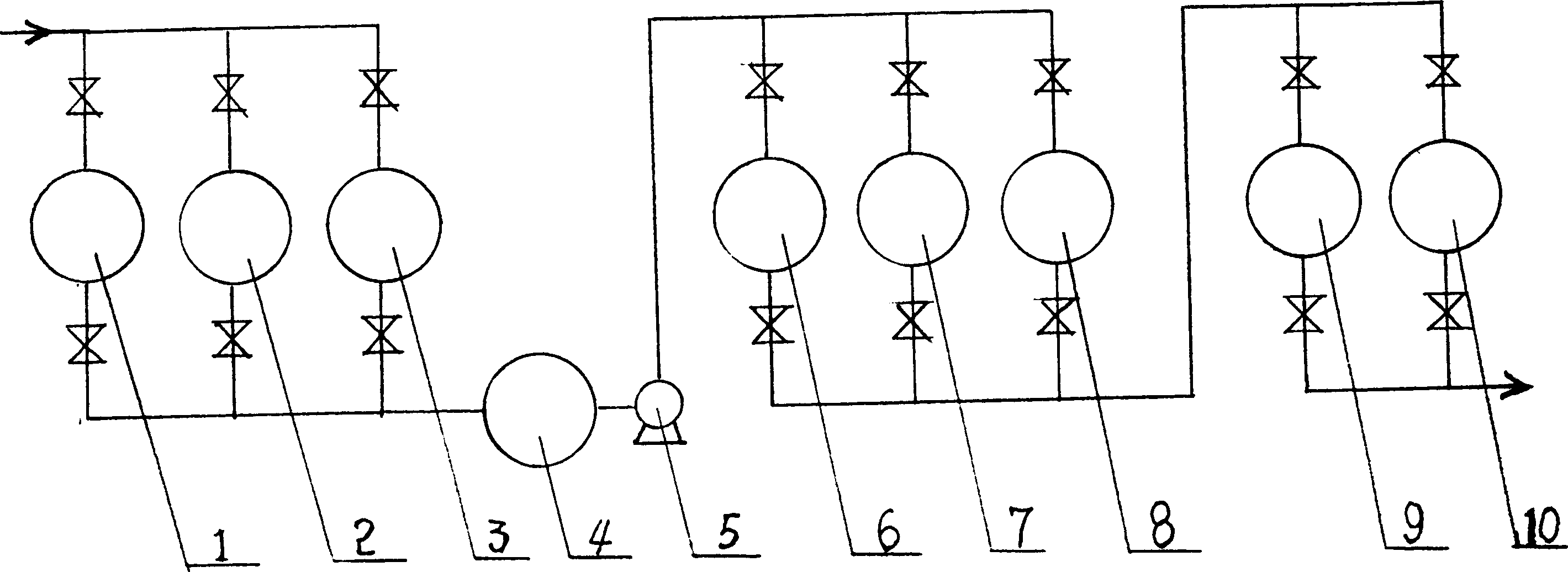

Petrochemical effluent treating and reusing process

ActiveCN1931750ASimple processSmall footprintTreatment using aerobic processesMultistage water/sewage treatmentSmall footprintPetrochemical

The present invention is improved petrochemical effluent treating and reusing process, and features that the petrochemical effluent after conventional treatment is further treated in a pressure filter with anthracite filter material, quartz sand filter material and magnetite filter material successively loaded in the water flow direction in layers; oxidized with ozone in the amount of 6-12 mg each gram of CODcr; and treated in aerobic biofilter with loaded active carbon. The treated petrochemical effluent can reach the standard of reused water, and the present invention has the advantages of simple technological process, less needed apparatus, small covered area, low cost, no secondary pollution, etc.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

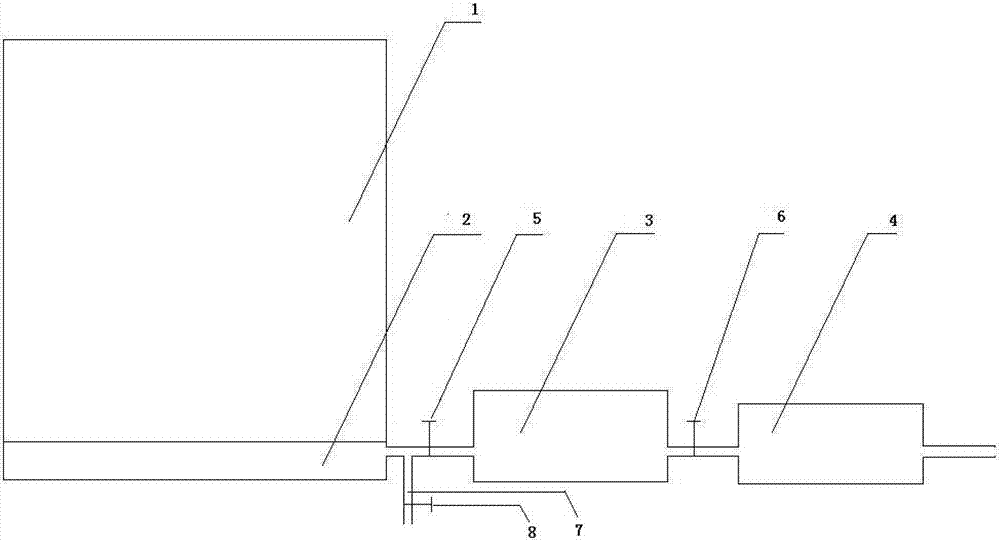

Perfusion type electronickelling and silicon carbide device for air cylinder

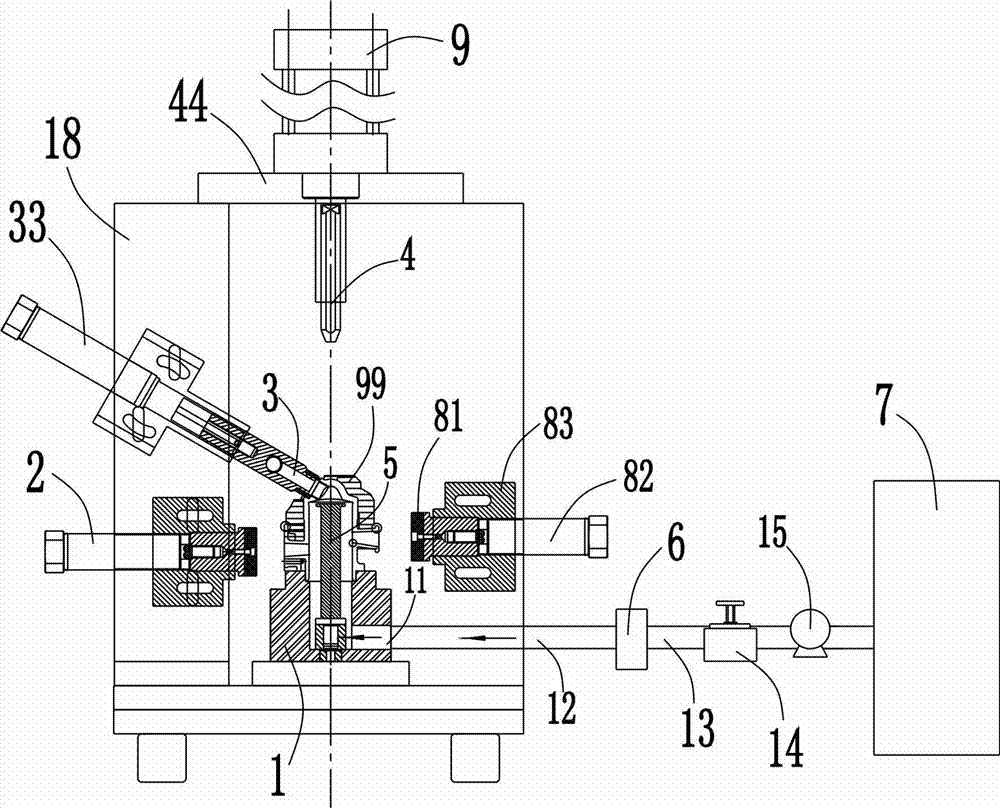

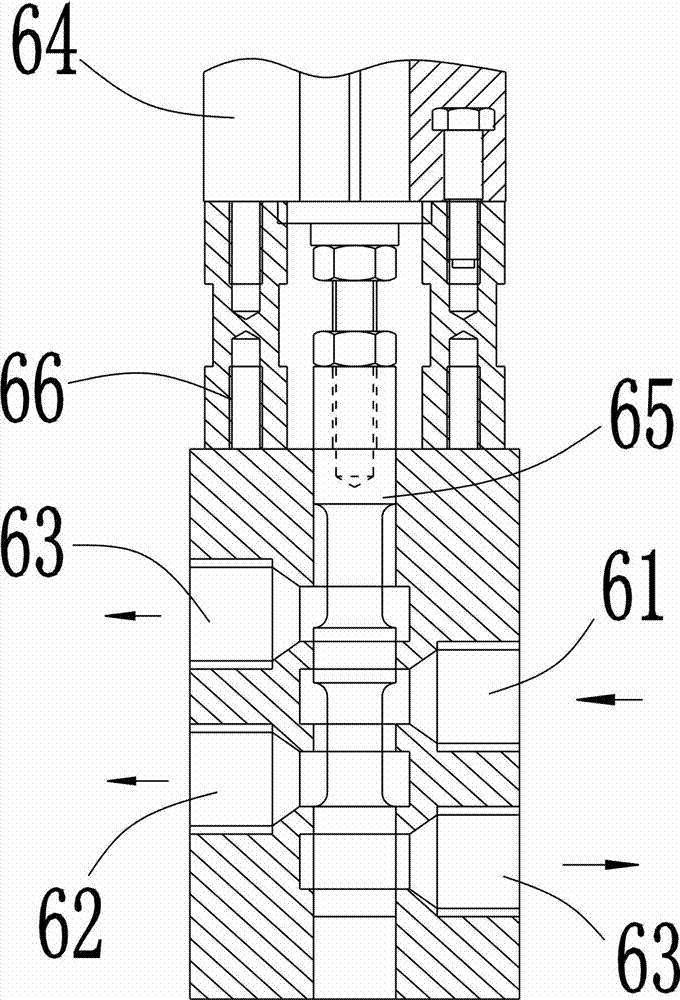

The invention discloses a perfusion type electronickelling and silicon carbide device for an air cylinder. The perfusion type electronickelling and silicon carbide device for the air cylinder comprises an electroplating base, an electroplating solution groove, a cathode conducting rod and an anode conducting rod. The air cylinder to be electroplated is placed inversely on the electroplating base which is internally provided with a groove. One end of the anode conducting rod is arranged in the groove, while the other end of the anode conducting rod extends into a chamber of the air cylinder to be electroplated. The cathode conducting rod is arranged above the electroplating base and can move up and down. The electroplating base is provided with a liquid inlet which is communicated with the electroplating solution groove through a flow divider. The flow divider comprises an electroplating solution inlet, an electroplating solution outlet and at least a return opening. The electroplating solution outlet is communicated with a liquid outlet. The electroplating solution inlet and the return opening are communicated with the electroplating solution groove. The perfusion type electronickelling and silicon carbide device for the air cylinder further comprises a drive device which drives the electroplating solution to flow upward along the inner wall of the air cylinder and flow from the top of the air cylinder back to the electroplating solution groove. According to the device, the electroplating solution is less polluted, the life cycle of the electroplating solution is long, the electroplating solutions in grooves are not needed to be prepared, and the regenerating time and cost of the electroplating solution are reduced.

Owner:ZHENGJIANG FENGLONG ELECTRIC CO LTD

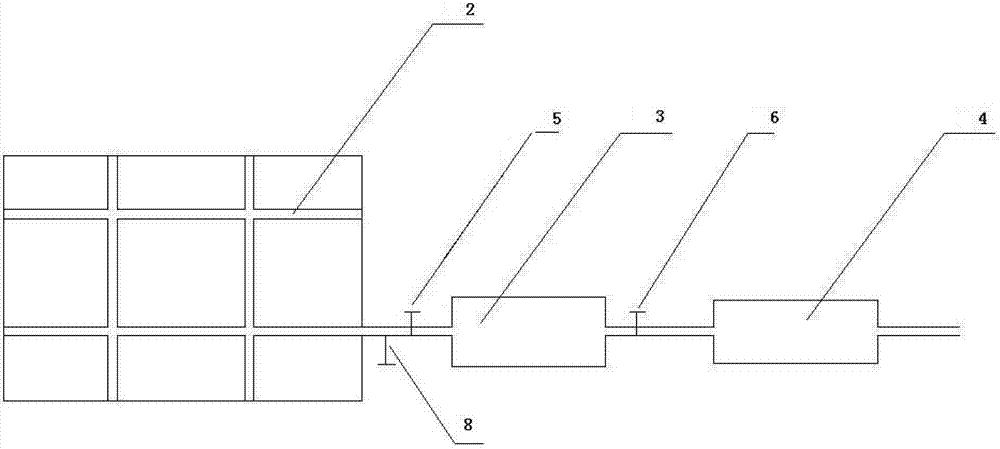

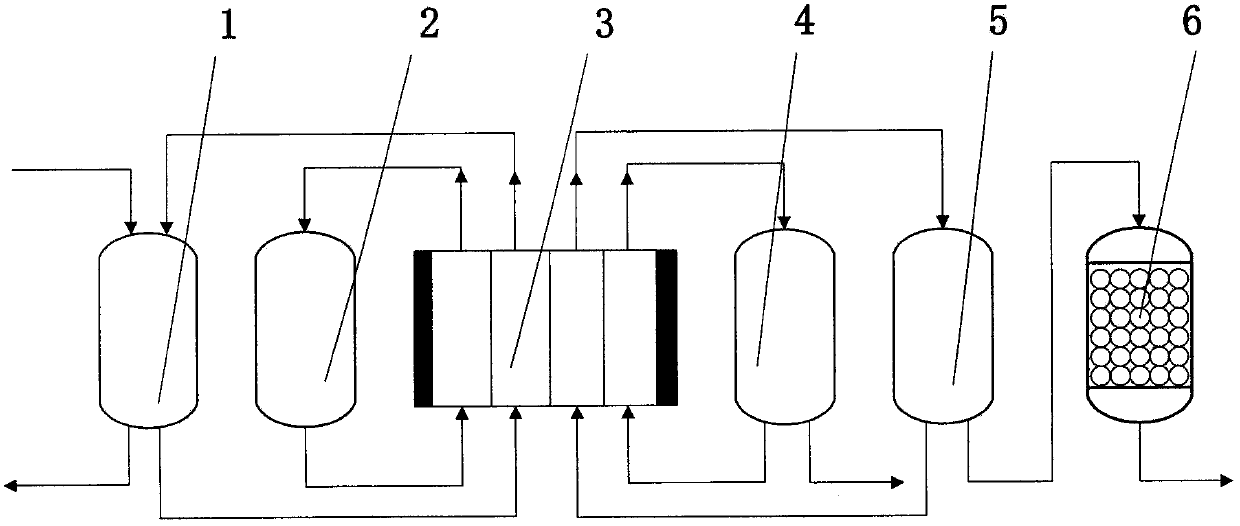

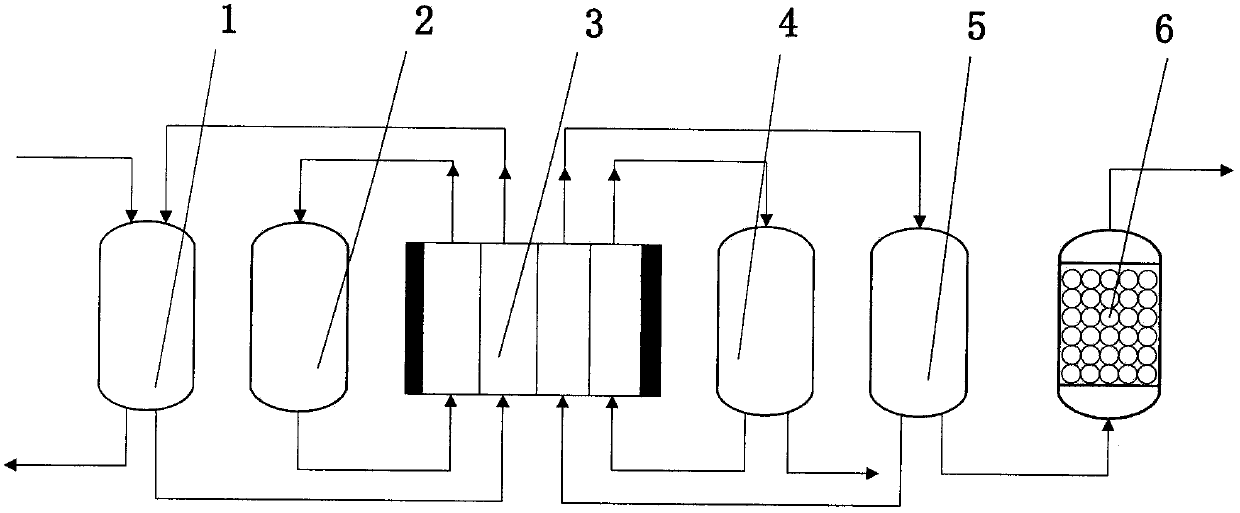

Device for regenerating spherical hydroxyapatite for defluorination

ActiveCN102728333AGood regeneration performanceAchieve regenerationOther chemical processesWater contaminantsApatiteProcess engineering

The invention provides a device for regenerating spherical hydroxyapatite for defluorination. The device comprises a defluorination reactor (1), a steam supply device (2), a steam generation device (3) and a water softener (4), wherein the steam supply device (2) is arranged at the bottom of the defluorination reactor (1); and the steam supply device (2), the steam generation device (3) and the water softener (4) are connected sequentially. According to the device for regenerating spherical hydroxyapatite for the defluorination, spherical hydroxyapatite is regenerated in a mode that steam is used for heating; the device has the characteristics of rapidness and high efficiency; and furthermore, the regeneration effect is improved greatly.

Owner:HOHAI UNIV

Composite regenerant for resin

InactiveCN1390646AReduce regenerant consumptionLow regeneration costIon-exchanger regenerationWater/sewage treatment by ion-exchangeEnvironmental chemistryAmmonium chloride mixture

A composite regenerant of resin used in treating water contains sodium sulfate (3.5-6 wt portions), sodium chloride (3-6), ammonium chloride (0-0.9), complexing agent (0-0.08) and surfactant (0-0.08). Its advantages are less consumption (decreased by 10%), high regeneration effect and the quantity of soft water to be treated, low Cl content in discharged water, and proper basicity of water in boiler.

Owner:代世杰

Macro-porous adsorption resin regeneration method

InactiveCN102949984AReduce recycling costsLow regeneration costCombustible gas purificationFilter regenerationSaline waterAlcohol

The invention discloses a macro-porous adsorption resin regeneration method. The method is characterized in that the method comprises the following steps: 1, cleaning a resin bed after the return of hydrogen peroxide, pressing the resin bed with nitrogen to complete remove desalinized water in the resin bed, and displacing residual water in the resin bed with an alcohol compound; 2, immersing the resin bed in the alcohol compound; 3, displacing out the alcohol compound containing water and organic impurities in the resin bed with the alcohol compound; 4, immersing the resin bed with the alcohol compound; 5, respectively repeating step 3 and step 4 two-three times; 6, carrying out circulation cleaning of the resin bed with the alcohol compound; and 7, removing the alcohol compound in the resin bed, and obtaining the resin bed for later use after the cleaning of the resin bed is qualified. The macro-porous adsorption resin regeneration method which adopts the alcohol compound as a regeneration agent effectively reduces the hydrogen peroxide resin regeneration cost, has the advantages of simple technology, simple operation, good regeneration effect, low regeneration cost and high safety, and enables above 90% of the adsorptive performance of the resin to be recovered through the regeneration.

Owner:CHINA PETROLEUM & CHEM CORP

Alkylamine functionalized metal-organic frameworks for composite gas separations

ActiveUS20170151549A1Reduce capacityLower average energyGas treatmentOther chemical processesSorbentMetal-organic framework

Functionalized metal-organic framework adsorbents with ligands containing basic nitrogen groups such as alkylamines and alkyldiamines appended to the metal centers and method of isolating carbon dioxide from a stream of combined gases and carbon dioxide partial pressures below approximately 1 and 1000 mbar. The adsorption material has an isosteric heat of carbon dioxide adsorption of greater than −60 kJ / mol at zero coverage using a dual-site Langmuir model.

Owner:RGT UNIV OF CALIFORNIA

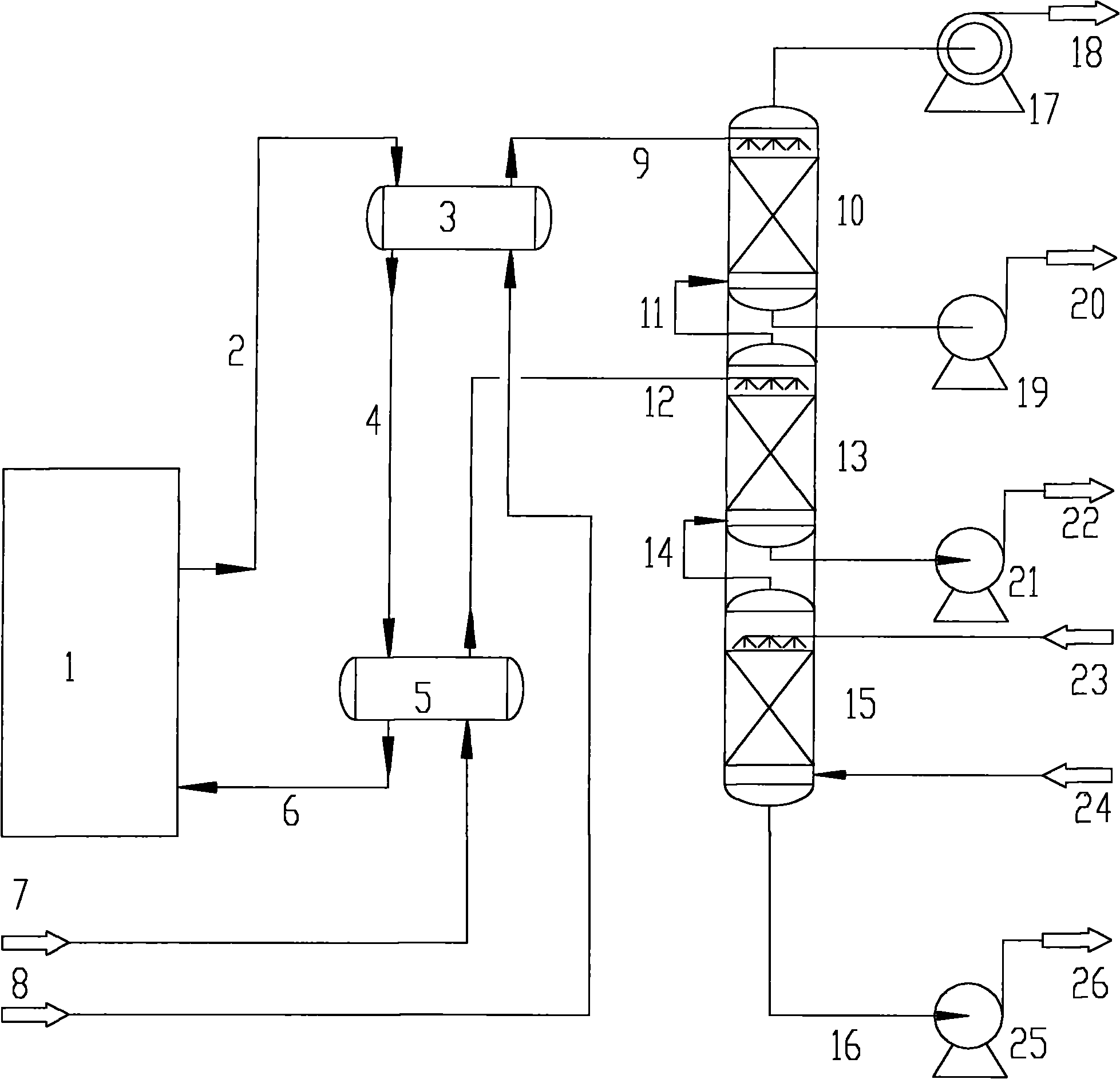

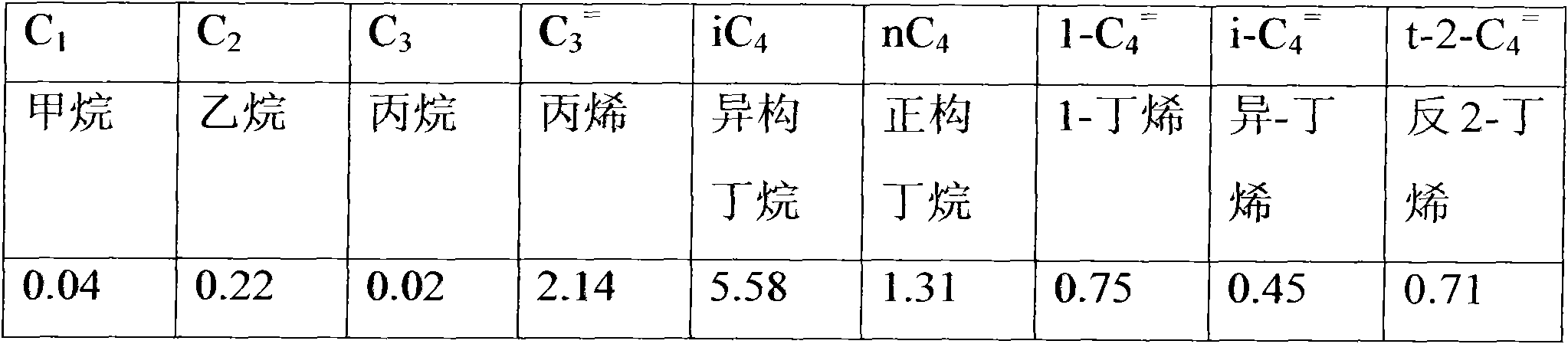

Segmental oil gas absorption recovering method

ActiveCN102463023AGuaranteed emission standardsPromote regenerationDispersed particle separationRecovery methodRoom temperature

The invention discloses a segmental oil gas absorption recovering method, which comprises the following steps of: absorbing oil gas at normal temperature with a method for recovering oil gas through at least two sections; and absorbing at a low temperature, wherein a medium-temperature absorption section of which the absorption temperature is between normal-temperature absorption and low-temperature absorption is selectively formed between a normal-temperature absorption section and a low-temperature absorption section; and a low-temperature absorption temperature is 3-8 DEG C. Due to the adoption of the method disclosed by the invention, oil gas recovery rate is very high and is about 99 percent, tail gas can be discharged within controlling indexes of a national standard, and remarkable environmental benefit and economic benefit can be achieved; and a recovery method for segmentally and gradually absorbing is designed according to respective absorption characteristic of a normal-temperature absorption method and a low-temperature absorption method, so that energy consumption is lowered, and energy is saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for regenerating urea dehydrogenation noble metal catalyst

ActiveCN1709576AReduce energy consumptionEasy to operateCatalyst regeneration/reactivationChemical recyclingDehydrogenationHigh heat

This is the room temperature regeneration method of the catalyst for noble metal dehydrogenization by carbamide. Adopt 3 - 15wt% complex compound watery solution containing ammonium ion or ammonia, at 5 - 80 Deg. C, soak out the poison produced on the surface of deactivated heavy metal catalyst in carbamide dehydrogenization. The volume proportion of soaking solid and liquid is 1 : 2.5 - 5, soaking time is 4 - 8 hours, after get out the catalyst, wash over three times with distilled water or deionized water, then lay at 110 - 120 Deg. C to dry, so it can achieve the purpose of renewing activeness and reuse. Compared with the present high temperature hydrogen deoxidizing regeneration technology, the invention has following advantages: needn't hydrogen source; needn't operate at 500 - 600 Deg. C high temperature, and can be operated at room temperature of 5 - 80 Deg. C; can very remarkably save energy waste, needn't regeneration system and electric heating device; its operation is simple, has no security hidden trouble, and can save regeneration time; the regeneration expense can be saved by 90%; after regenerated, the quality of catalyst can be ensured.

Owner:HAISO TECH

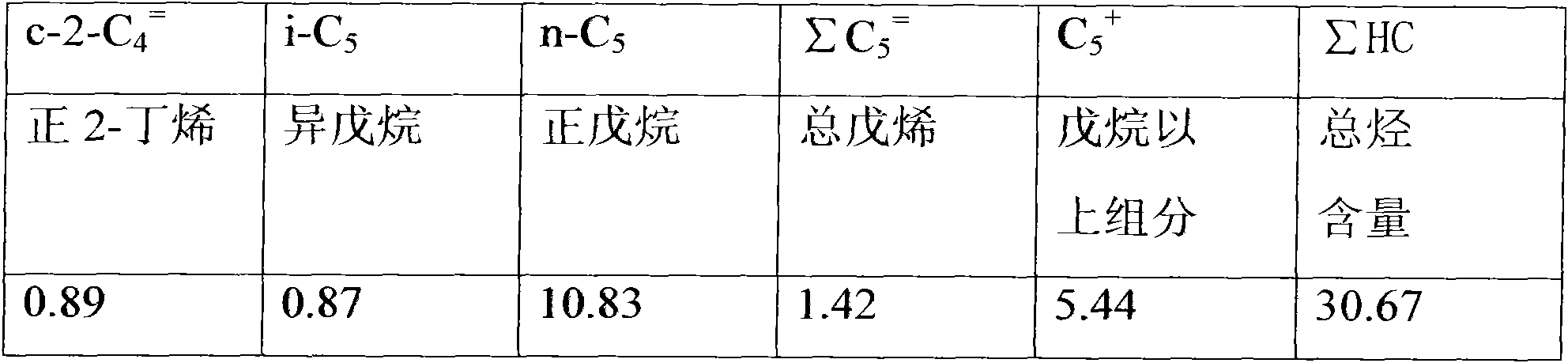

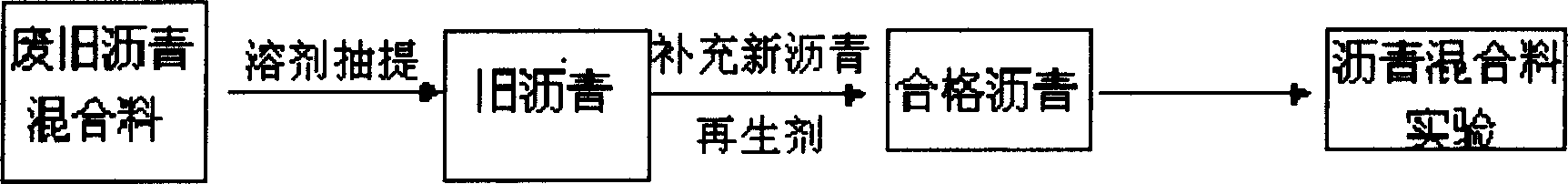

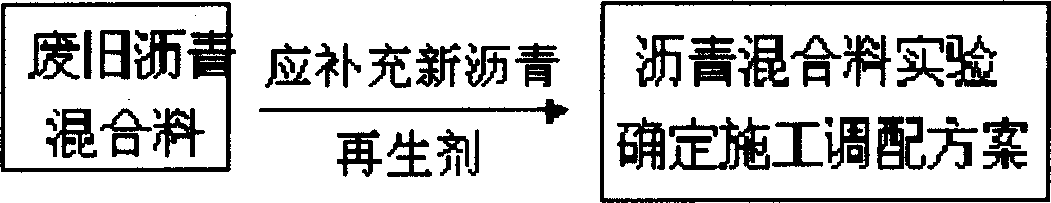

Composite-complexation type regenerator for worn-out mixture of asphaltum and preparation method

InactiveCN1696203AReduce manufacturing costReduce dosageWorking-up pitch/asphalt/bitumenBuilding insulationsFuraldehydeColloid

A compounding-complexing regenerating agent for the mixture of used and waste asphalt is prepared from the rejected materials of oil refinery, which are rich in aromatic component and colloid and include the oil extracted from furaldehyde, asphalt extracted from propane, the oil slurry thrown out during catalytic cracking, nitrogen dregs generated by denitriding furaldehyde and the third or the fourth side-cut fractional oil of cycloalkyl crude oil, through respectively dewatering and extracting, and selective mixing.

Owner:辽宁省交通科学研究院有限责任公司 +1

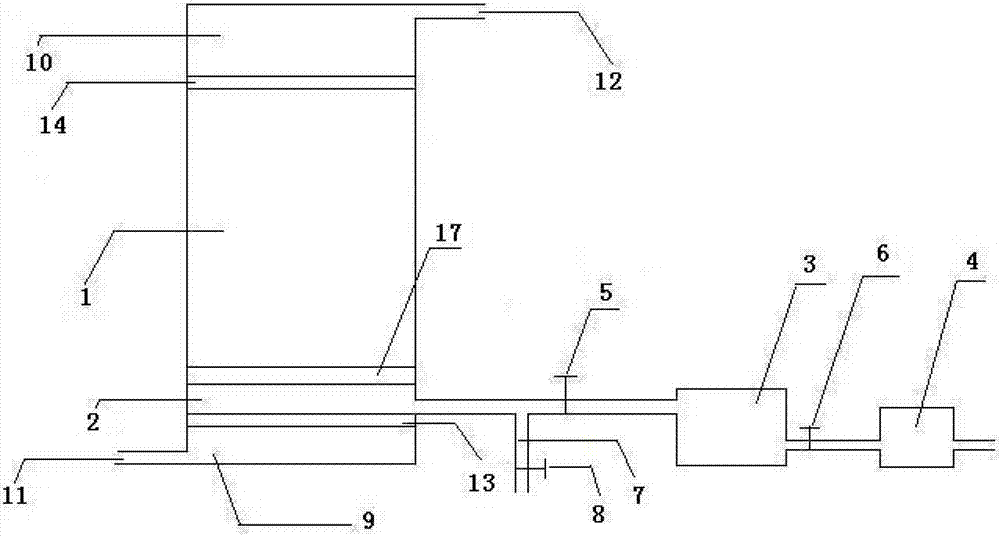

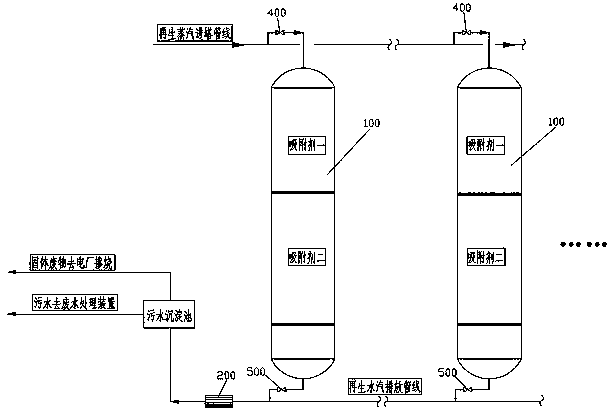

On-line regeneration system and method of flue gas denitration catalyst

ActiveCN103127963BEliminate damageReduce consumptionDispersed particle separationCatalyst regeneration/reactivationFlue gasProcess engineering

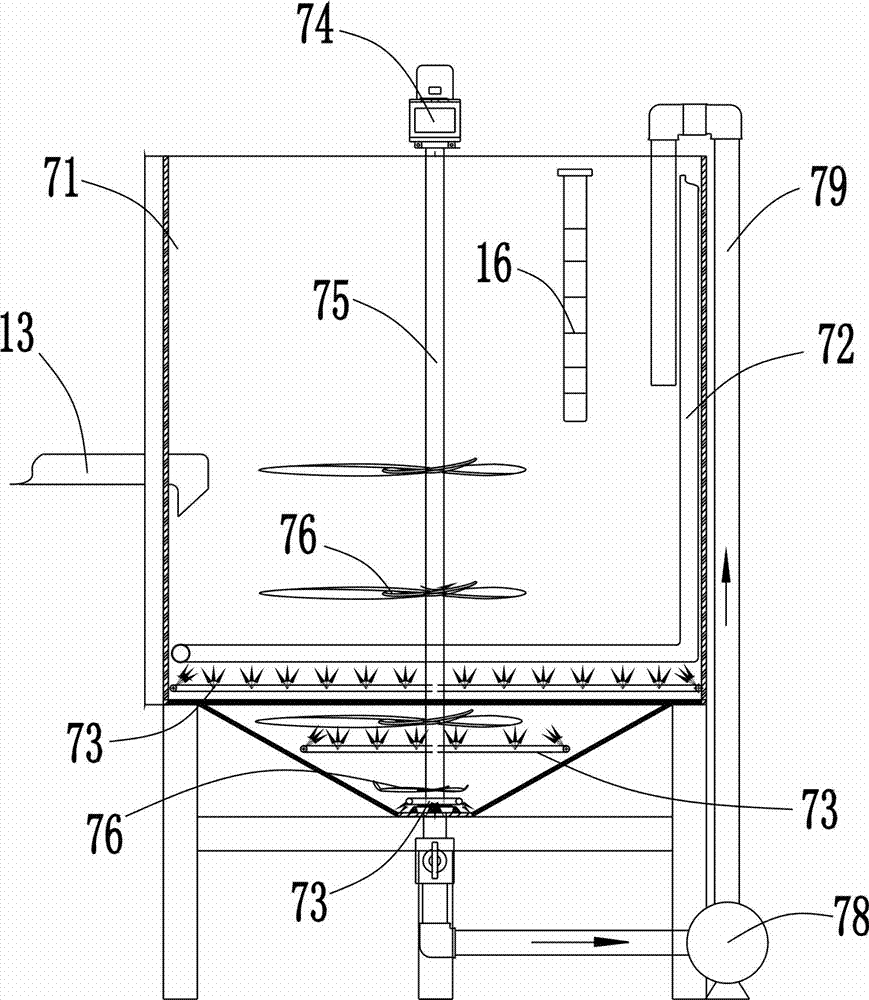

The invention provides an on-line regeneration system and a method of a flue gas denitration catalyst. The system comprises a gas duct external system, a gas duct internal system and a connection pipeline. The gas duct external system comprises a regeneration medium storage or generation component, a regeneration medium heating component and a generation medium conveying component. The gas duct internal system comprises a regeneration medium distribution component which is arranged in a gas duct and capable of moving to positions above any catalyst modules in the gas duct. A regeneration medium is conveyed into the regeneration medium distribution component in the gas duct to carry out catalyst regeneration steps including soot blowing, cleaning, drying and activation on the catalyst modules in the gas duct through regulation and starting and closing of the regeneration medium storage or generation component, the regeneration medium heating component and the generation medium conveying component in the gas duct external system, and the catalyst modules do not need to be moved out of the gas duct for regeneration. The on-line regeneration system and the method of the flue gas denitration catalyst avoid damage to the catalyst modules in the process of moving, simplify operation steps, reduce energy consumption, save cost and improve work efficiency.

Owner:北京宝莱尔科技有限公司

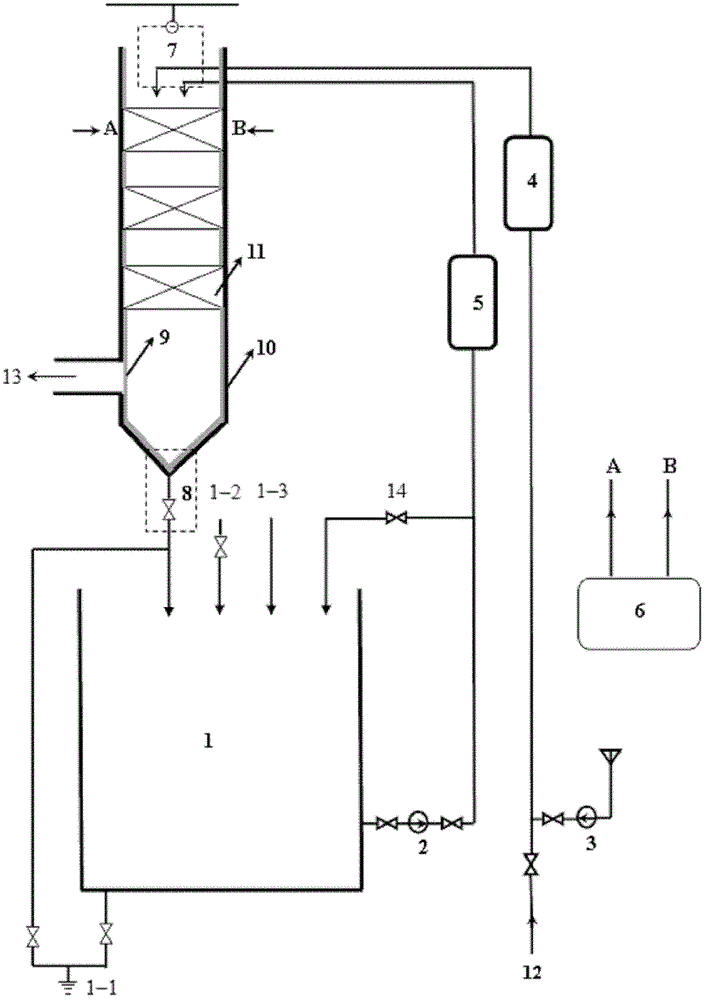

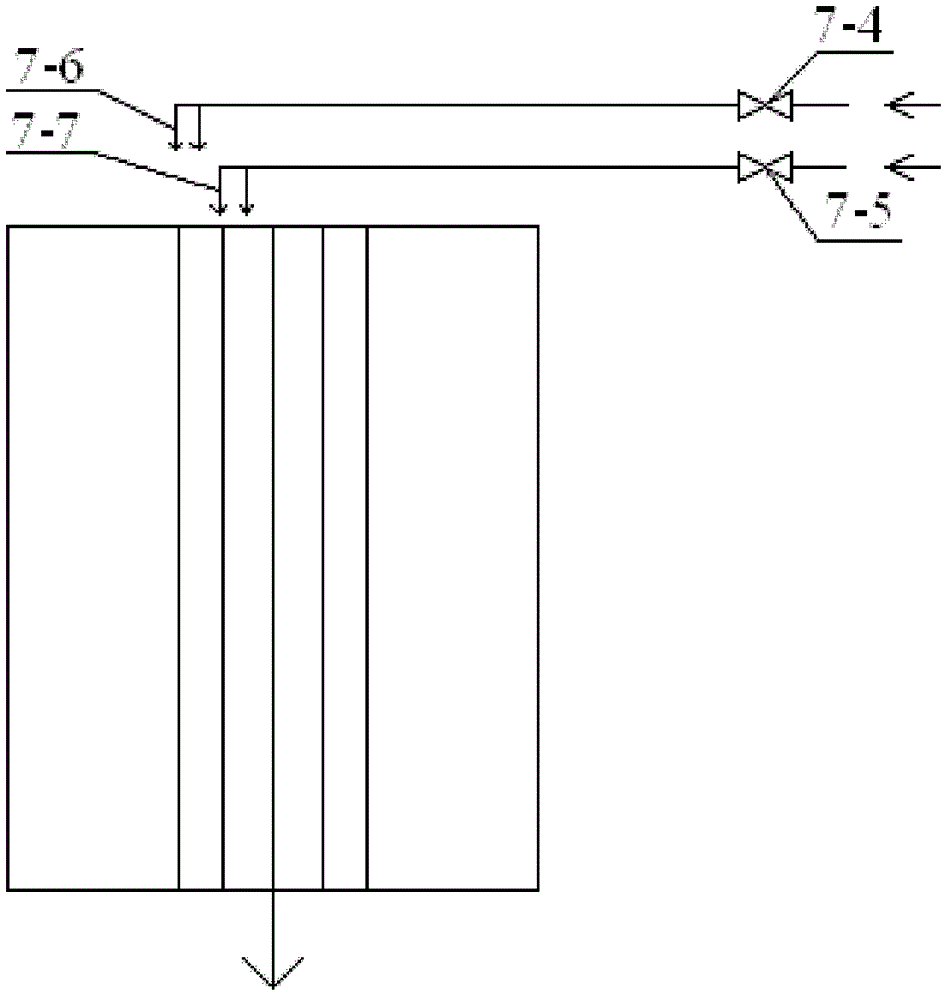

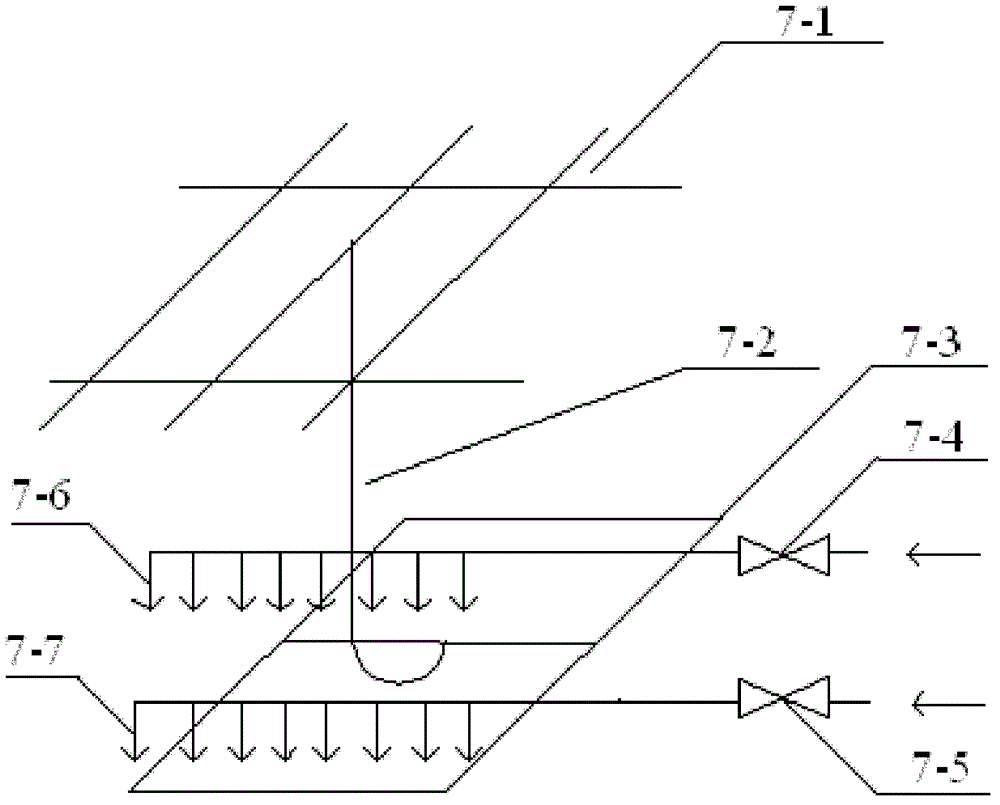

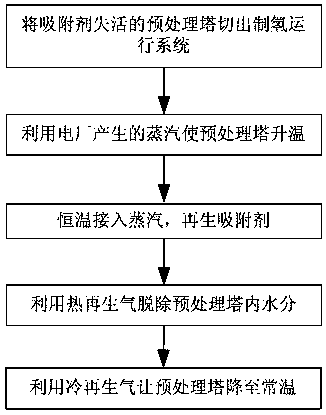

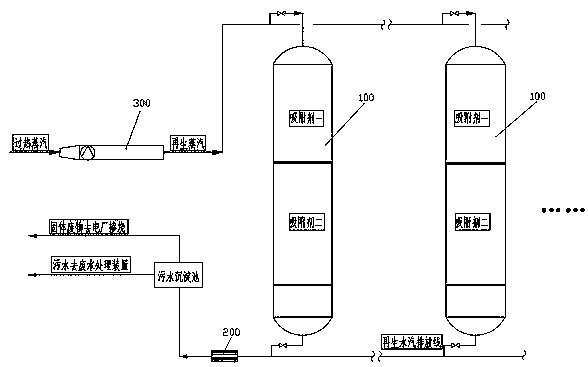

Regeneration technology of hydrogen-generation adsorbent

InactiveCN109928363ALow regeneration costHydrogen separationOther chemical processesCombustionHydrogen

The invention provides a regeneration technology of a hydrogen-generation adsorbent. A hydrogen-generation operation system is removed from a pretreater with an inactive adsorbent, and other pretreaters of the operation system operate normally; superheated steam generated by a power plant are treated to be regenerative steam, then the regenerative steam is uninterruptedly fed into the pretreaterfrom the top of the pretreater, the regenerative steam regenerates the adsorbent in the pretreater and then is discharged from the bottom of the pretreater, and after the adsorbent is regenerated to be qualified, feeding of the regenerative steam is stopped; hot regenerative gas and cold regenerative gas generated by the operation system are introduced from the top of the pretreater, the hot regenerative gas passes through the interior of the pretreater to remove moisture of the adsorbent, and an adsorption tower with the moisture being removed is cooled to the operation temperature of the adsorption tower by the cold regenerative gas; and the adsorption ability of the pretreater is restored, and the pretreater enters a stand-by pretreater or is merged into the operation system. Accordingto the regeneration technology, the adsorbent in the pretreater is regenerated through the high-temperature steam of the power plant, regenerative desorbed gas generated by the operation system coolsthe pretreater and then is fed to a boiler of the power plant to be subjected to blending combustion, the regeneration cost is saved, and waste heat of the power plant and the waste regenerative desorbed gas are utilized in a mode of turning waste into wealth.

Owner:SHAANXI DONGXINYUAN CHEM CO LTD

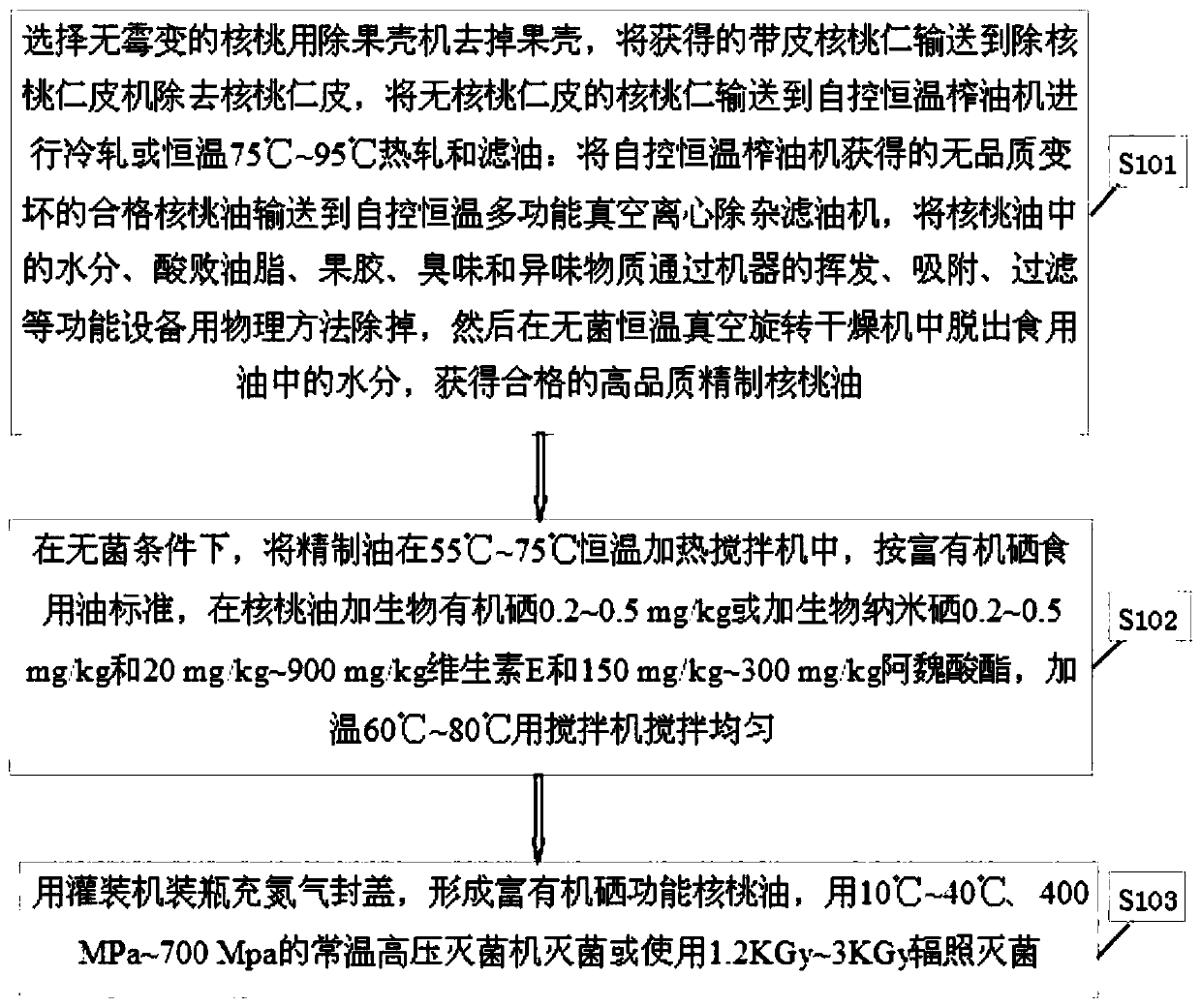

Production method of functional walnut oil rich in biological organic selenium

PendingCN111411015ANo lossRegenerative cleaning is convenient and quickFatty-oils/fats refiningFood preservationBiotechnologyWalnut Nut

The invention belongs to the technical field of fat or grease oil refining, and discloses a production method of functional walnut oil rich in biological organic selenium. The production method comprises the following steps: selecting mildew-free walnuts, removing shells of the walnuts by using a shell removing machine, conveying obtained walnut kernels with shells to a walnut kernel skin removingmachine to remove walnut kernel skins, and producing qualified high-quality refined walnut oil by using high-tech physical walnut oil squeezing equipment and high-tech physical refined oil refining equipment; under a sterile condition, adding biological organic selenium or biological nano-selenium into the refined oil in a 55-75 DEG C constant-temperature heating stirrer, and uniformly stirring;and bottling by using a filling machine, filling nitrogen and sealing to form the functional walnut oil rich in biological organic selenium. The qualified high-quality refined walnut oil is obtained,the taste and quality of the walnut oil are remarkably improved, and the impurity content of the walnut oil is greatly reduced; meanwhile, biological organic selenium or biological nano-selenium is added to form a new organic-selenium-rich functional walnut oil commodity which has market requirements and is beneficial to human health, and the quality and additional value of the walnut oil are improved.

Owner:HUBEI HUALONG XIKE BIOLOGICAL TECH CO LTD

A kind of ion exchange resin regeneration method

ActiveCN105080624BIncrease profitImprove recovery performanceIon exchange beds cleaning/rinsingIon-exchange resinChemistry

The invention provides an ion exchange resin regeneration method. The ion exchange resin regeneration method is characterized by comprising the following steps: (1) carrying out backwashing, namely introducing dilute regenerating liquid from the bottom of an ion exchange resin column, carrying out backwashing on the inside ion exchange resin, soaking for 25-35min, then converting the dilute regenerating liquid into concentrated regenerating liquid in a column body, and discharging the obtained concentrated regenerating liquid to a concentrated liquid collecting groove through compressed air, wherein the liquid inlet flow rate of the dilute regenerating liquid is 2-4BV / h, and the using amount of the dilute regenerating liquid is one-time bed body; (2) washing, namely, introducing 10% dilute sulphuric acid from the top of the ion exchange resin column, converting the dilute sulphuric acid into dilute regenerating liquid in the column body, discharging the dilute regenerating liquid to a dilute liquid collecting groove, and emptying residual liquid to complete the regeneration of the ion exchange resin, wherein the flow rate of the inlet liquid is 1-2BV / h and the using amount of 10% dilute sulphuric acid is one-time bed body. According to the regeneration method, the regenerating liquid is divided into the concentrated liquid and the dilute liquid, so that the using amount of the regenerating liquid can be effectively saved, and the regenerating cost can be effectively lowered.

Owner:中新联科环境科技(安徽)有限公司

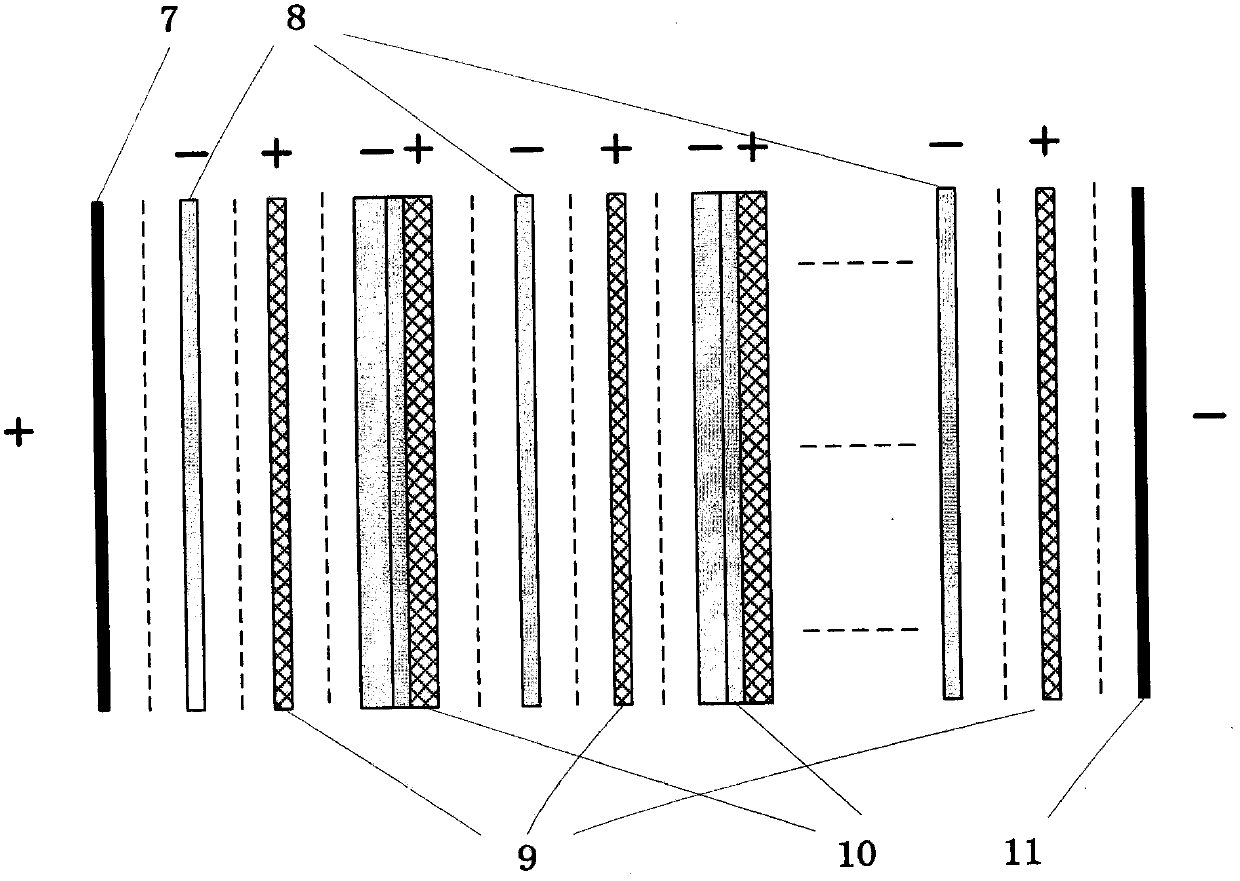

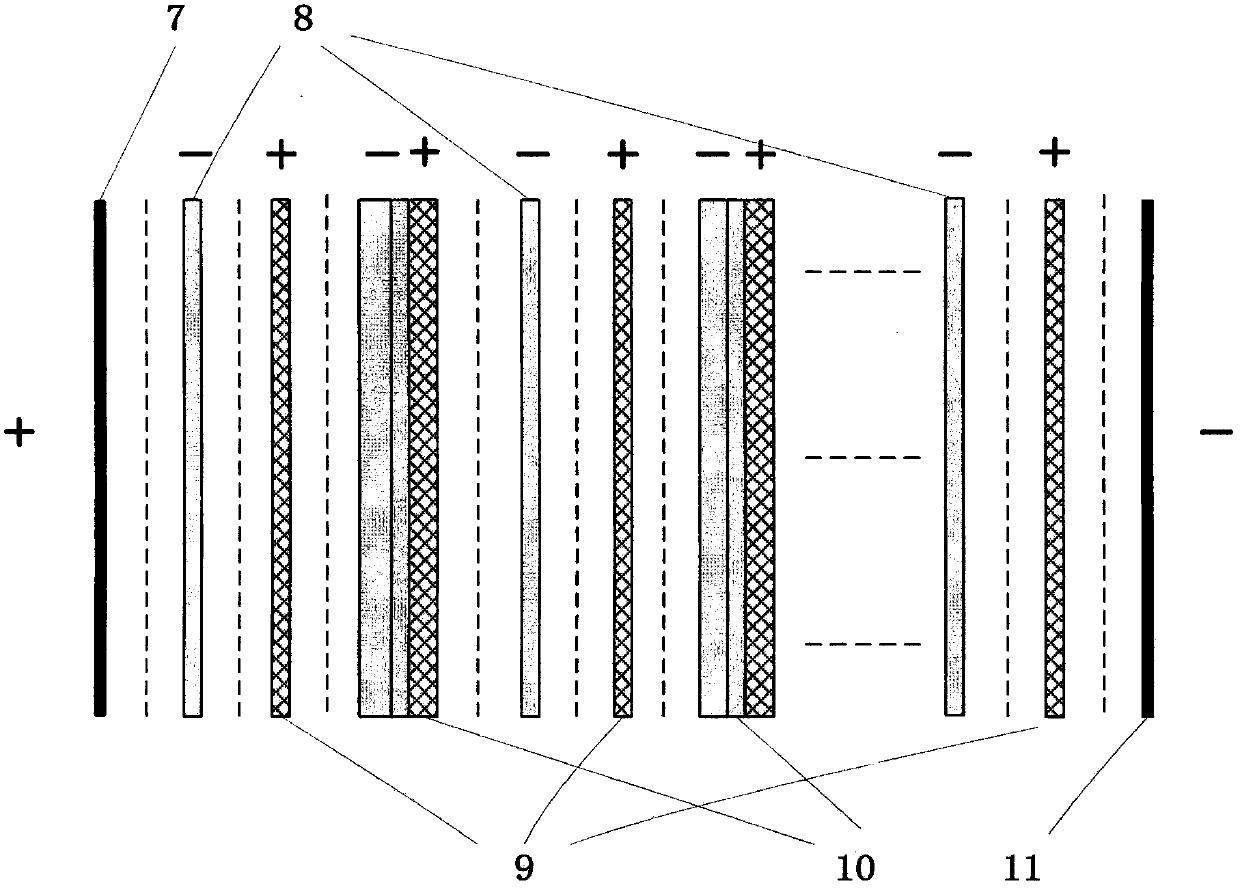

Apparatus for electrically regenerating OH type anion bed failure anion exchange resin through bipolar membrane method

InactiveCN109908978ANo need for storageImprove working conditionsElectric regenerationMembrane methodSalt water

The invention relates to an apparatus for electrically regenerating an OH type anion bed failure anion exchange resin through a bipolar membrane method. The apparatus comprises three parts of a bipolar membrane electrodialyzer, a liquid storage tank and an ion exchange tank, wherein the bipolar membrane electrodialyzer is plate-and-frame type, and comprises multiple sets of membrane pairs, each set of the membrane pair comprises a cation membrane, an anion membrane and a bipolar membrane, separation plates are arranged between each membrane, both ends are electrode plates and end plates, fixing is performed by a plurality of bolts, clamping is performed to form an integration, the liquid storage tank comprises a dilute salt water tank, a polar water tank, a dilute acid tank and a dilute alkali regenerating liquid tank, and the ion exchange tank is an OH type anion bed ion exchange tank. According to the present invention, the traditional process for regenerating the OH type anion bed by purchasing the alkali liquid is replaced with the process for preparing the alkali liquid through water dissociation by the bipolar membrane electrodialyzer under the action of the direct current electric field, such that the regeneration level of the OH type anion bed anion resin is improved, the storage and transportation link of the regenerated alkali liquid is eliminated, the regeneration operation of the anion resin is convenient, the safety level is improved, and the environment is friendly.

Owner:SUZHOU HUAQING WATER TREATMENT TECH

In-situ regeneration system and method of Cu-based molecular sieve denitrification catalyst for diesel vehicle exhaust gas purification

ActiveCN108295891BEasy to operateLow regeneration temperatureMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

An in-situ regeneration system and method for a Cu-based molecular sieve denitrification catalyst for diesel vehicle exhaust purification, when the SCR purifier outlet NO x When the concentration is close to the emission limit, start in-situ regeneration; in addition to normal spraying of urea, an additional reducing gas at a certain temperature is introduced into the SCR purifier to remove the sulfur species deposited on the surface and inside of the catalyst pores, and realize the in-situ catalyst Regeneration, continue to pass the reducing gas for 0.5-1.5h, that is, complete the regeneration of the SCR catalyst; the process of the present invention utilizes the reducing atmosphere to reduce (NH 4 ) 2 SO 4 and CuSO 4 The decomposition temperature is high, and the sulfur species deposited on the catalyst can be removed in situ to quickly realize the in situ regeneration of the catalyst and ensure the normal driving of the vehicle during the regeneration process.

Owner:SHAOXING UNIVERSITY

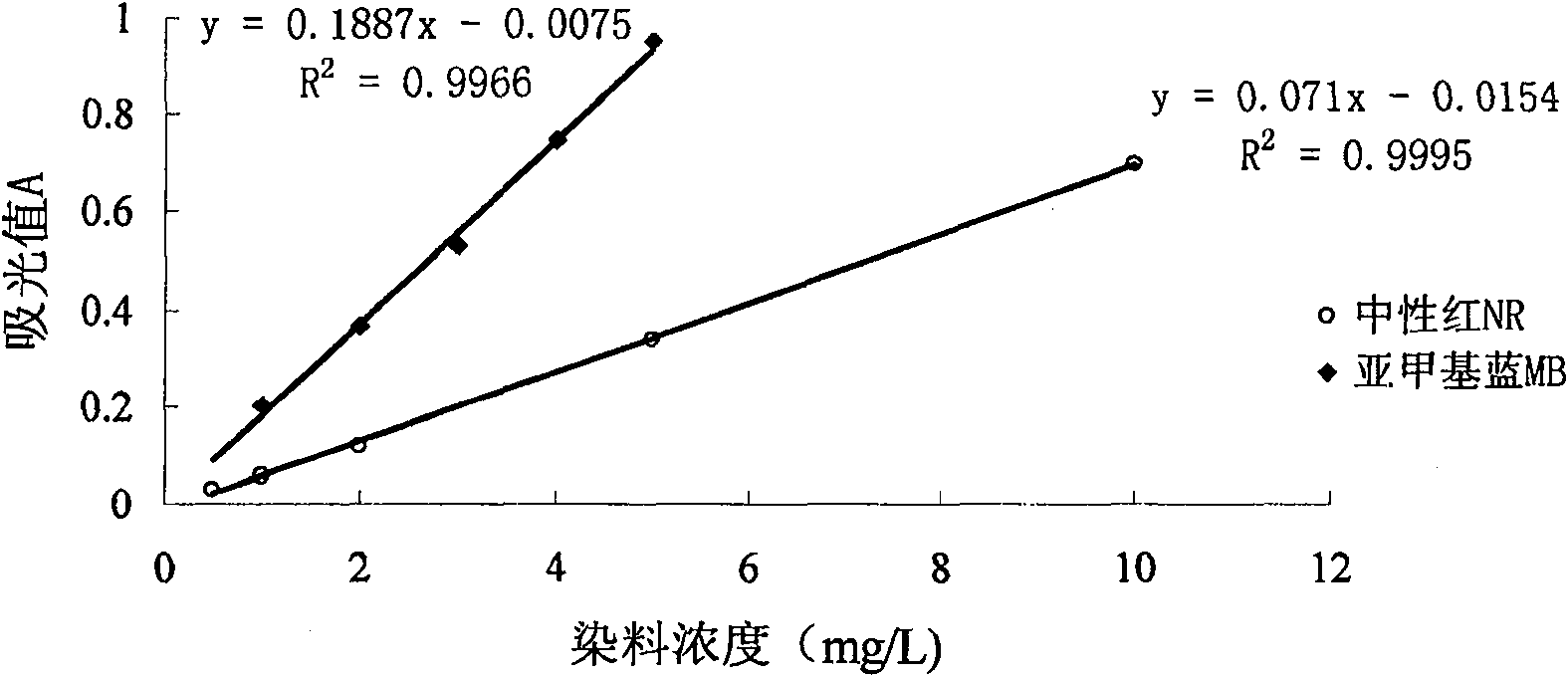

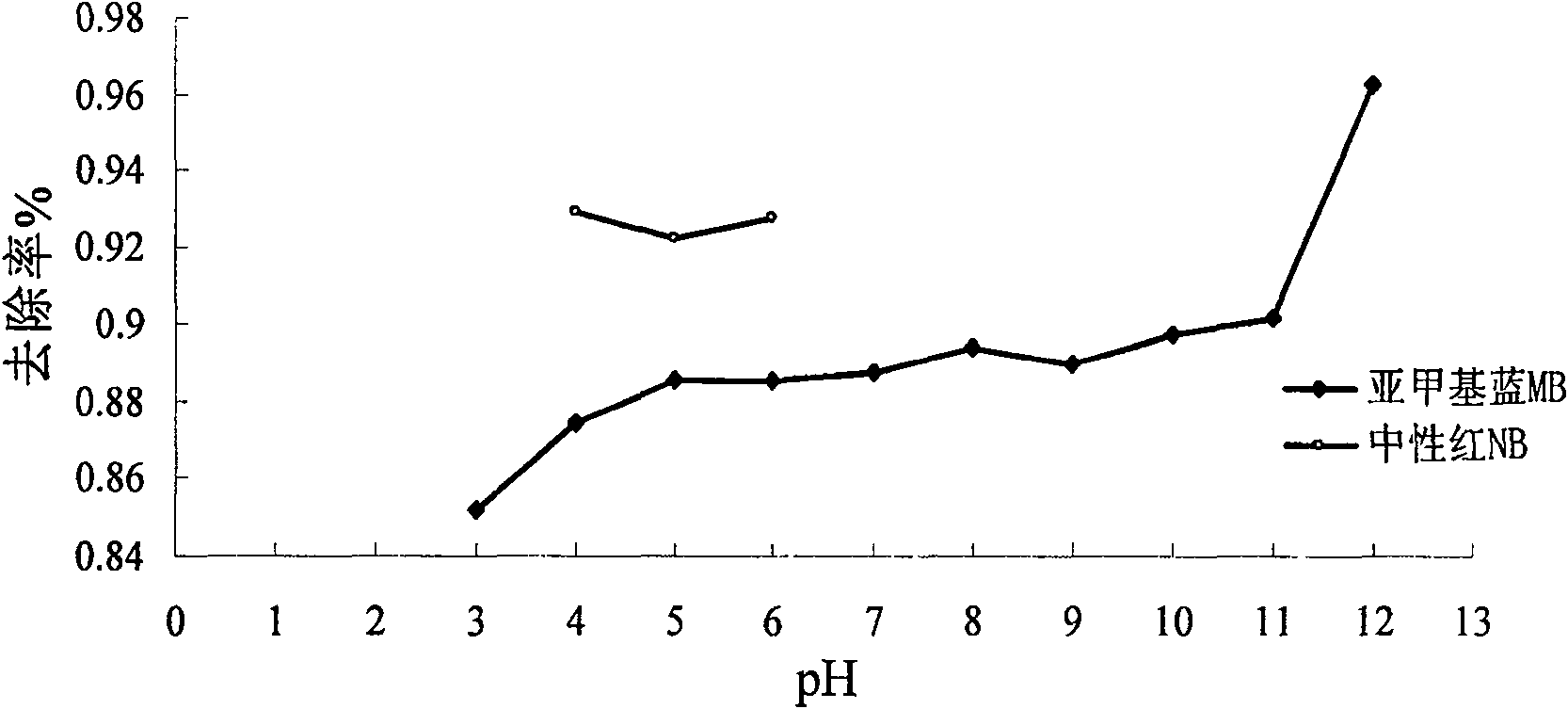

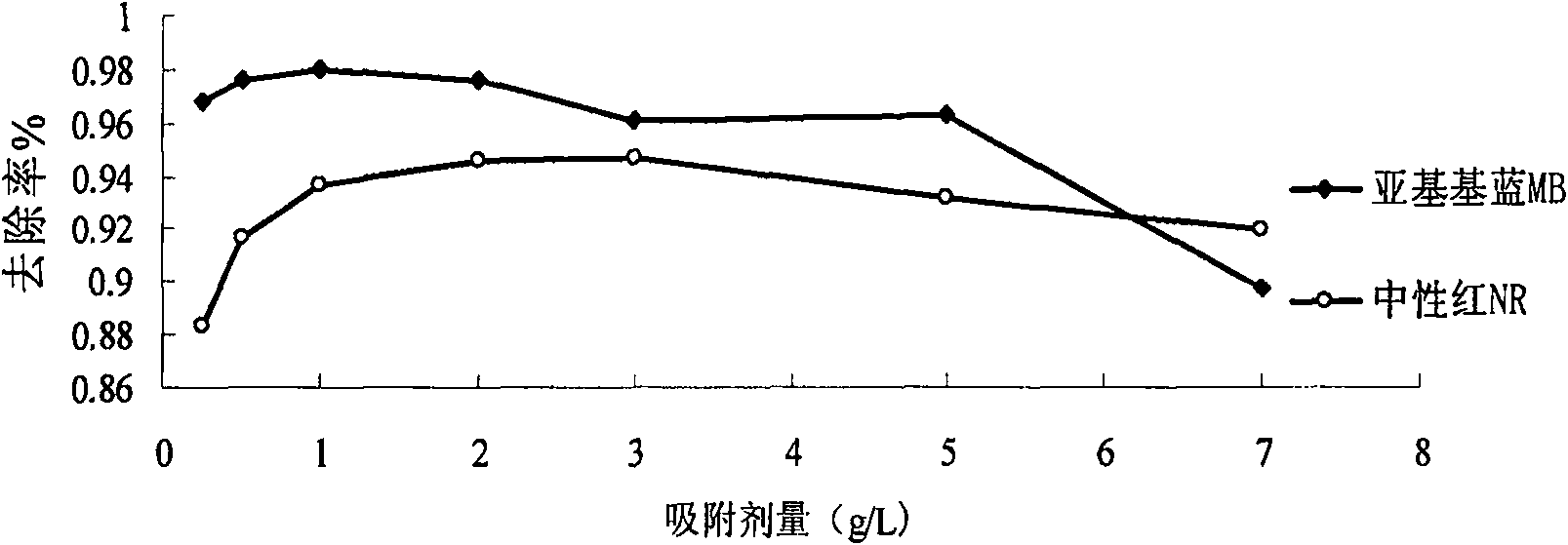

Natural plant material of processing cationic dye in industrial wastewater and method thereof

InactiveCN101224411BEasy to operateLow regeneration costOther chemical processesWater/sewage treatment by sorptionActivated carbonIndustrial effluent

The invention pertains to the technical field of industrial effluents treatment, which more particularly relates to the adoption of a natural plant material, grapefruit shell, which is widely available but not utilized at present. After the grapefruit shell is ground, the optimality condition for treating effluents is obtained through test according to the characteristics of the cations in the grapefruit shell and industrial effluents to achieve the effect of better removing the cationic dyes in the effluents. The preferred process method is that: Under the condition of room temperature and stirring, the pH of the effluents is adjusted to 3 to 12 by acid or alkali, and 0.25 to 7 g of grapefruit shell particles with the particle size of 40 to 140mm is added to each liter of water, then theeffluents are stirred at least for 15 minutes. The grapefruit shell particles are separated and the purpose of removing the cationic dyes in the effluents is achieved. Under the best treatment condition, the removing rate can reach above 95%. Compared with the activated carbon which is widely used at present, the invention has obvious cost advantages in the treatment of dyeing effluents. Comparedwith the existing adsorbent made from natural plant materials, the removal efficiency is much better.

Owner:NANJING UNIV

Petrochemical effluent treating and reusing process

ActiveCN1931750BSimple processSmall footprintTreatment using aerobic processesMultistage water/sewage treatmentSmall footprintPetrochemical

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

A process for removing alkaline impurities in caprolactam refining process

ActiveCN107235901BAlkalinity qualified rate increasedReduce alkalinityLactams separation/purificationDistillationIon exchange

The invention discloses a process for removing alkaline impurities in the caprolactam refining process. The caprolactam refining process includes the processes of extraction, ion exchange, hydrogenation, evaporation and distillation. Passing oxygen-containing gas and / or adding acidic potassium permanganate solution, heating for oxidation treatment; or passing high-temperature oxygen-containing gas and / or adding high-temperature acidic potassium permanganate solution in caprolactam solution for oxidation treatment; A process for effectively reducing basic impurities in caprolactam products while other indicators are not affected, the process is simple in operation, low in cost, and meets the requirements of industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ion exchange technology in preparation of glucose

InactiveCN1162439CReduce dosageGuaranteed continuous operationMonosaccharidesGlucose productionBuffer tankIon exchange

An ion exchange process for preparing glycose features that multiple cationic resin columns are parallelly connected into a group, multiple anionic resin columns are parallelly connected into a group, and both groups are connected via buffer tank and pump. Its advantages are regeneration of any resin column without stopping production, low cost for regeneration and saving resin by 30%.

Owner:XIWANG GROUP

Regenerating agent for sodium or ammonium ionic resin

InactiveCN1113697CIncrease throughputExtended regeneration cycleCation exchanger materialsIon-exchanger regenerationSoft waterWater quality

A regenerating agent of sodium and ammonium ion resin is prepared from sodium chloride (4-6 wt.portions), sodium sulfate (1-3), ammonium chloride (1-4), complexing agent (0-0.2) and surfactant (0-0.2) and can be used for water processing to obtain soft water. Its advantages include less consumption of edible salt saved by 5-10%, low cost reduced by 10%, high quality of soft water, long service life of resin and low chlorine content in discharged water (reduced by 25%).

Owner:WUTONG SALT PRODUCING LESHAN CITY

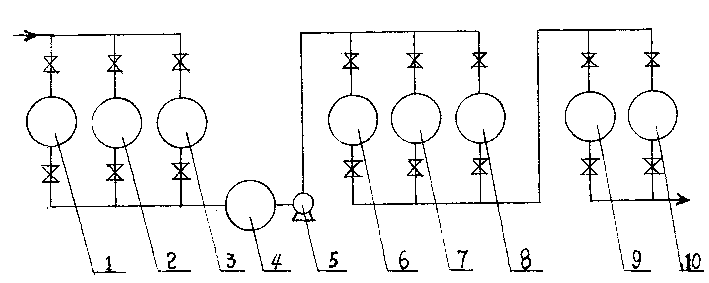

A treatment process for decolorized resin regeneration waste liquid

ActiveCN108503084BPigment removalHigh decolorization rateMultistage water/sewage treatmentLiquid wasteFiltration membrane

The invention discloses a treatment technology of decolorized resin regenerated waste liquid. The treatment technology comprises the following steps: after filtering the decolorized resin regeneratedwaste liquid through a filter, filtering through a nano-filtration membrane; recycling permeated liquid; adding lime milk into obtain intercepted liquid; introducing flue gas and fully filling; aftercarrying out plate and frame filtering on a fully-filled mixing system, recycling permeated liquid and repeating the operation on intercepted liquid. Compared with the prior art, pigments in resin regenerated waste liquid can be effectively removed; the recycling rate of resin regenerated liquid is high and the production cost is low; the treatment technology is simple to operate and has the advantages of high efficiency, energy saving and emission reduction.

Owner:凌国庆

Method of eliminating miniature amount of impurities in epsilon-caprolactam water solution

InactiveCN1247545CLow regeneration costNo corrosionLactams separation/purificationDialysis membranesIon exchange

The present invention features that electric dialysis membrane is used to eliminate the inorganic impurities and miniature amount of organic impurities in water solution of epsilon-caprolactam, that is, water solution of epsilon-caprolactam of 5-90 wt% concentration is made to pass through electric dialysis membrane at 0-150 deg.c. The said method is used to replace ion exchange process for refining caprolactam and can reduce greatly the conductivity and extinction value of water solution of epsilon-caprolactam and eliminate ammonium radical, acid radical and other ions and miniature amount of organic impurities in water solution of epsilon-caprolactam. s

Owner:CHINA PETROLEUM & CHEM CORP

Preparation and application of a kind of nitrate treatment agent

ActiveCN107694541BImprove thermal stabilityGood acid and alkali resistanceWater/sewage treatment by irradiationOther chemical processesNitrateHydrotalcite

The invention discloses the preparation and application of a nitrate treatment agent. In the invention, cotton is used as a template, and zinc-titanium-iron ternary hydrotalcites with biological forms are synthesized by co-precipitation method, and then roasted in a muffle furnace to obtain nitrate treatment agent. The present invention also provides the application of the nitrate treatment agent prepared by the above method in the treatment of nitrate wastewater. The nitrate treatment agent prepared by the method has good adsorption effect on nitrate, is convenient for separation, and has a simple and easy regeneration method, and has broad application prospects in the field of nitrate wastewater treatment.

Owner:XIAN UNIV OF SCI & TECH

Method for electrically regenerating OH type anion bed failure anion exchange resin through bipolar membrane method

InactiveCN109908979ANo need for storageImprove working conditionsElectric regenerationIon exchange beds cleaning/rinsingMembrane methodSalt water

The invention relates to a method for electrically regenerating an OH type anion bed failure anion exchange resin through a bipolar membrane method, wherein the method comprises: dilute salt water preparing, dilute alkali regeneration liquid preparing, back flushing, regeneration and washing, and the mass percentage concentration of the dilute alkali regeneration liquid used in the regeneration ofthe OH type anion bed failure anion exchange resin is less than or equal to 8%. According to the present invention, the new process for preparing the alkali liquid for the OH type anion bed failure anion exchange resin regenerating from the salt water by the bipolar membrane electrodialyzer according to the water dissociation effect under the action of the direct current electric field is provided, and can replace the traditional process for chemically regenerating the OH type anion bed failure anion exchange resin by purchasing the alkali liquid, such that the regeneration level of the OH type anion bed anion resin is improved, the storage and transportation link of the regenerated alkali liquid is eliminated, the regeneration operation of the OH type anion bed failure anion exchange resin is convenient, the safety level is improved, and the environment is friendly.

Owner:SUZHOU HUAQING WATER TREATMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com