Composite-complexation type regenerator for worn-out mixture of asphaltum and preparation method

A waste asphalt and regeneration agent technology, applied in the field of resource-environmental chemistry, can solve problems such as waste of resources, environmental pollution, and land occupation, and achieve the effects of reducing project costs, saving land resources, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

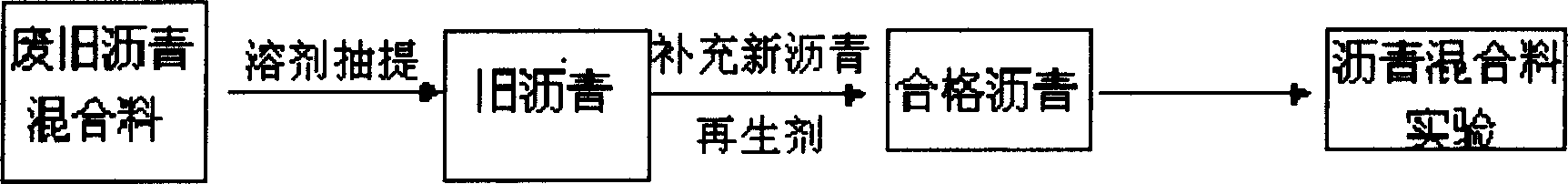

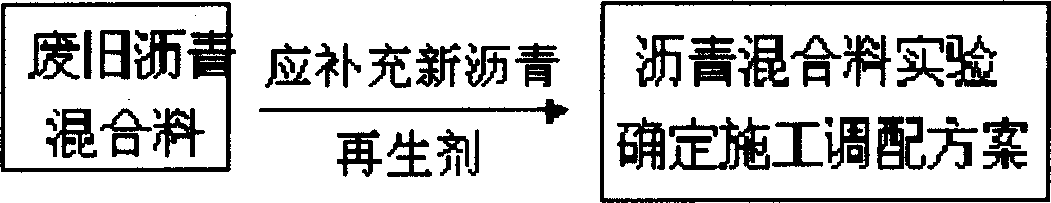

Method used

Image

Examples

Embodiment 1

[0041] A regenerant is prepared from monomer regenerant components (weight ratio) (a): (b) = 50:50 ratio to restore the physical and chemical properties of "Shenda" waste recycled asphalt, and the amount of A regenerant is 8.3% (accounting for recycling old asphalt), the results are shown in Table 2. It is known from Table 2 that the physical and chemical indicators of "Shenda" waste asphalt fully meet the requirements of the GB50092-96 standard.

Embodiment 2

[0043] B regenerant is prepared from monomer regenerant components (weight ratio) (a): (b): (c) = 34:45:21 ratio, used to restore the physical and chemical properties of "Shenda" waste recycled asphalt, B regenerated The amount of additive added is 8.3% (accounting for recovered old asphalt), and the results are shown in Table 2. It is known from Table 2 that the physical and chemical indicators of "Shenda" waste asphalt fully meet the requirements of the GB50092-96 standard.

[0044]

Embodiment 3

[0046] The C regenerant is prepared from monomer regenerant components (weight ratio) (a): (b): (c): (e) = 30: 26: 23: 21 ratio, which is used to restore "Shenda" waste recycling Asphalt physical and chemical properties, the addition of C regenerant is 8.3% (accounting for recovered old asphalt), the results are shown in Table 2. It is known from Table 2 that the physical and chemical indicators of "Shenda" waste asphalt fully meet the requirements of the GB50092-96 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com