On-line regeneration system and method of flue gas denitration catalyst

A denitrification catalyst and regeneration system technology, applied in the field of online regeneration system of flue gas denitrification catalyst, can solve the problems of high consumption of regeneration medicine, high resistance of flue gas, high regeneration cost, etc., achieve low consumption of regeneration medium, improve work efficiency, and regenerate The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

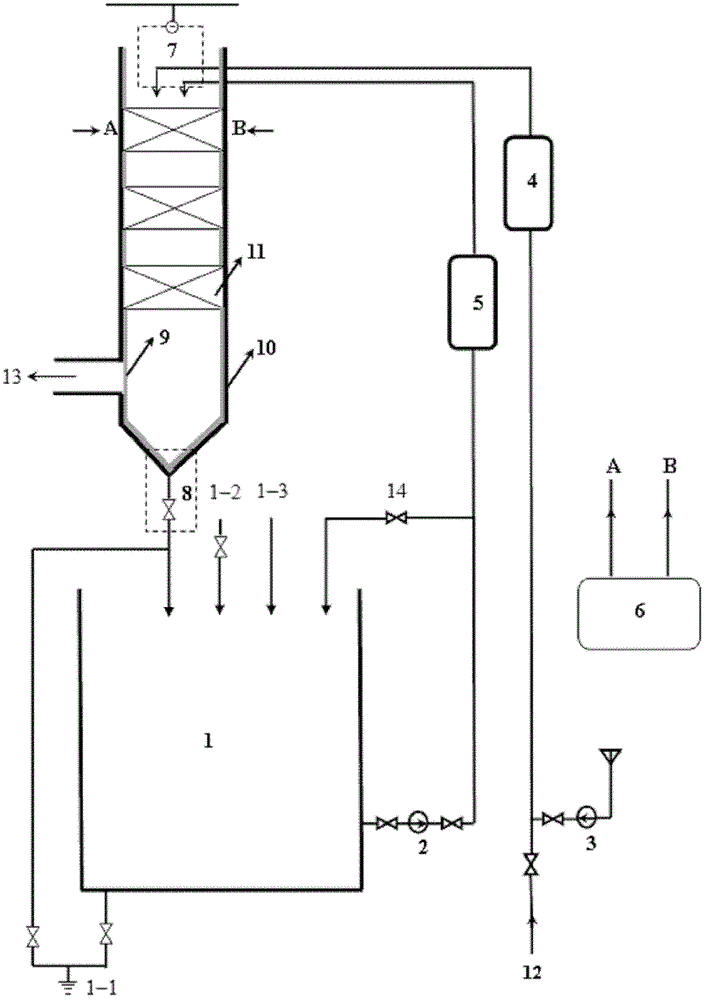

[0044] Such as figure 1 As shown, an on-line regeneration system for flue gas denitrification catalysts includes an external flue system, an internal flue system and connecting pipes; the external flue system and the internal flue system are connected through connecting pipes.

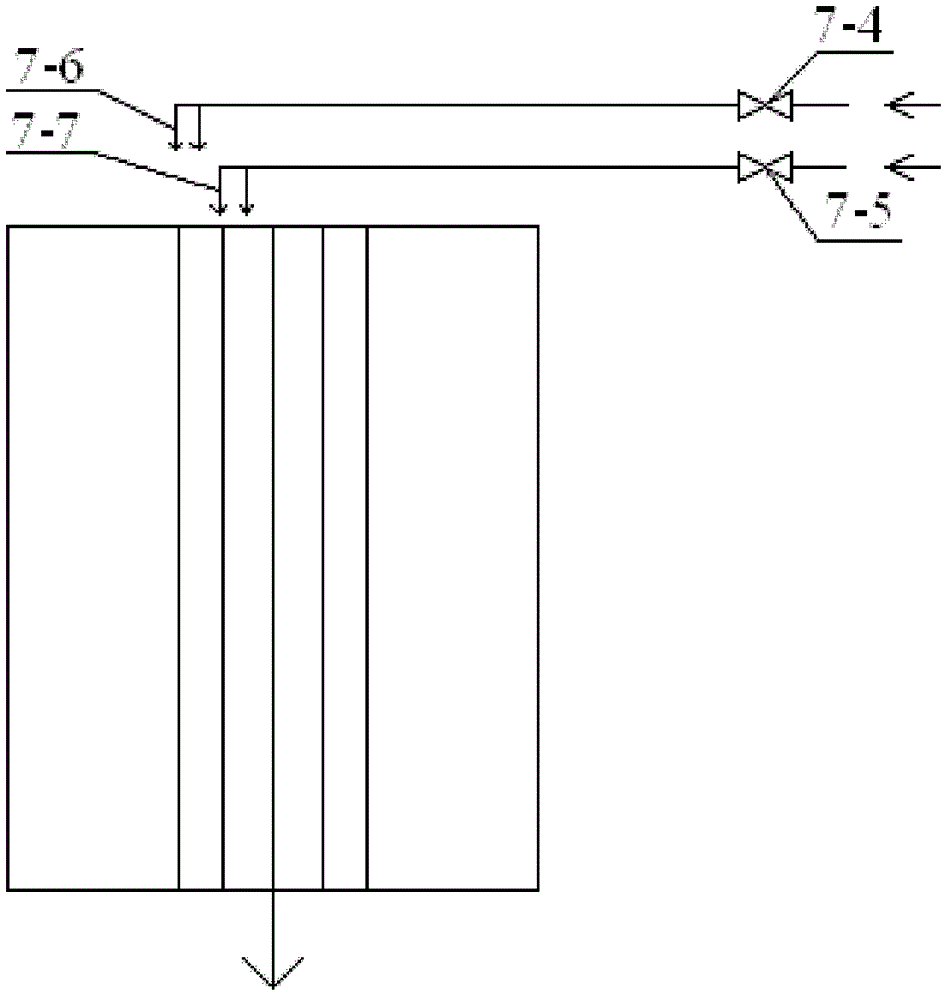

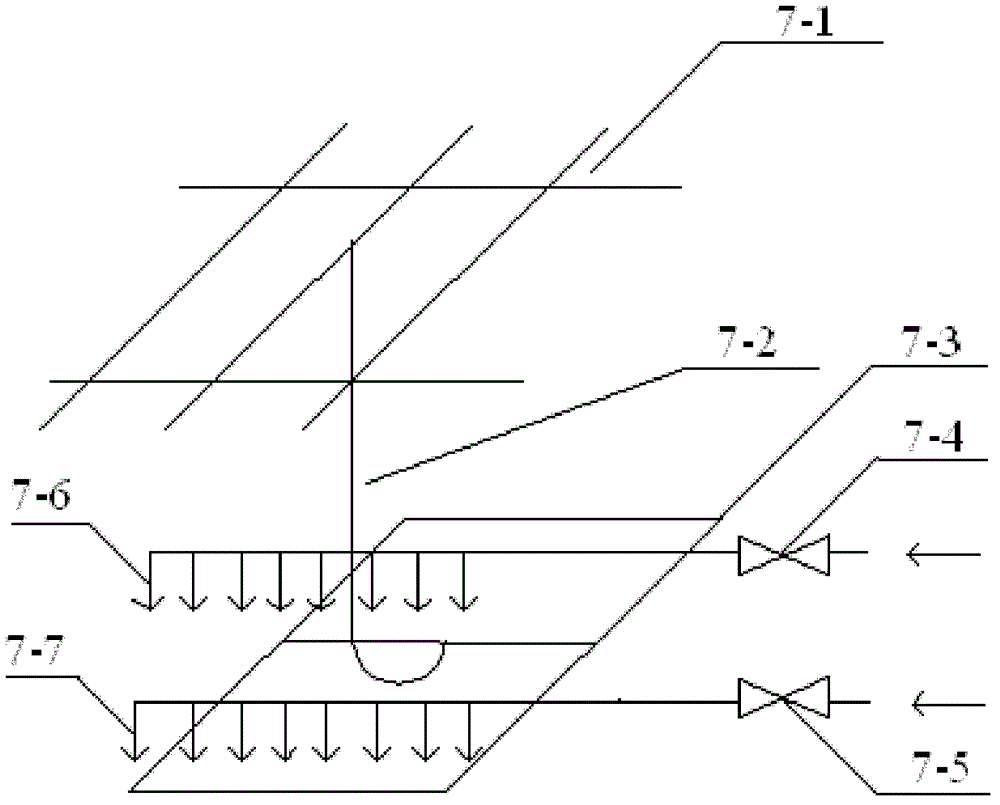

[0045] The system in the flue includes a distributor 7, a collector 8, and a protective film 9.

[0046] The collector 8 is installed at the bottom of the flue 10, establishes a liquid flow path with the distributor 7, and returns the liquid medium to the liquid storage tank 1 through the pipe.

[0047] When the flue gas denitration catalyst is regenerated online, the protective film 9 is fixed on the steel plate on the inner wall of the flue 10 by magnets to prevent the regeneration medium from corroding the inner wall of the flue and from polluting the regeneration medium by flue impurities. effect. Protective film 9 is plastic cloth.

[0048] The system outside the flue includes a liquid storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com