Production method of functional walnut oil rich in biological organic selenium

A production method and technology of walnut oil, applied in the directions of fat oil/fat production, fat production, food science, etc., can solve the problems of not removing Aspergillus flavus, destroying the health properties of linoleic acid and linolenic acid, and not combining selenium, etc. The effect of retaining active ingredients, convenient and quick regeneration and cleaning, and complete separation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

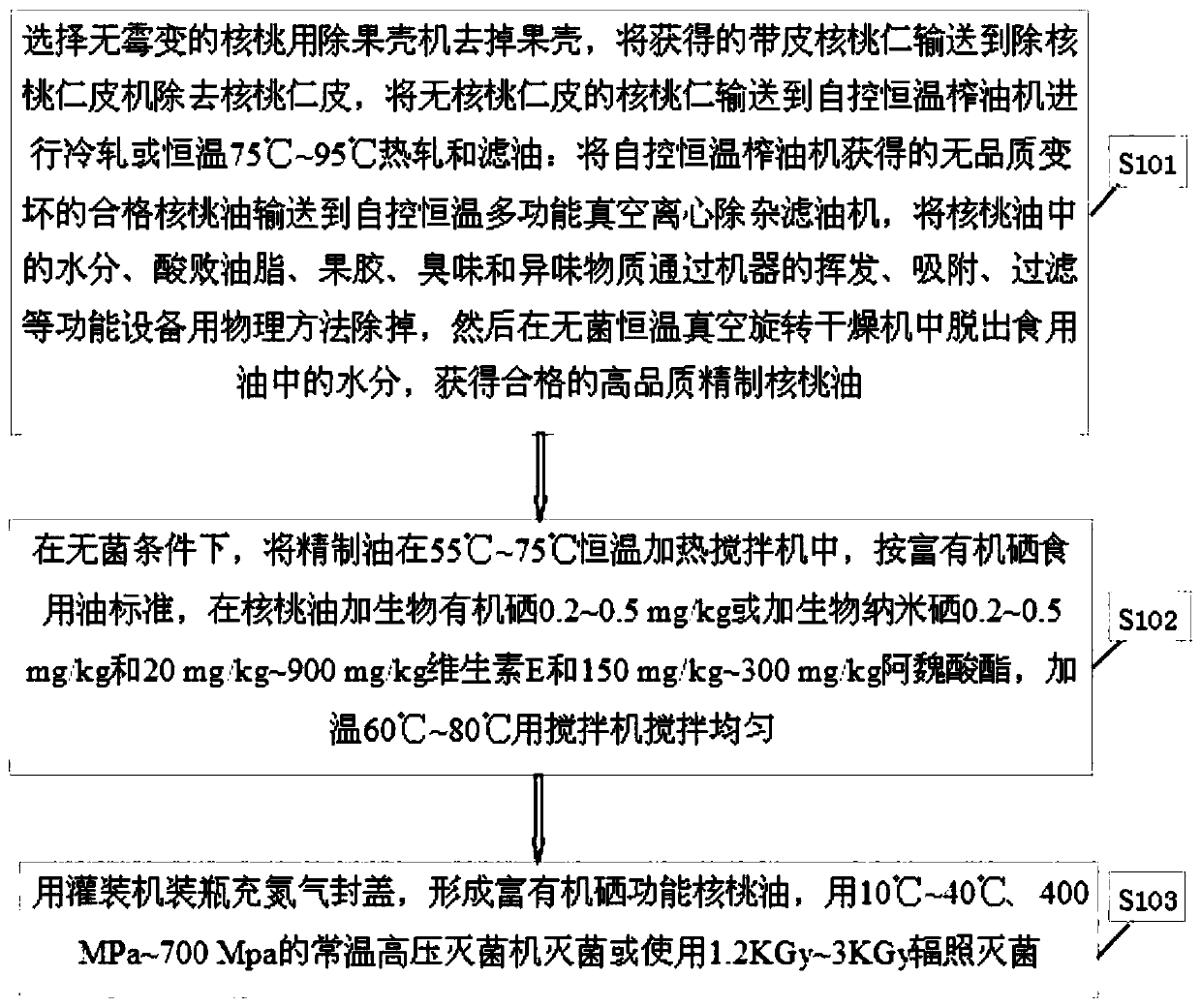

[0054] The bio-organic selenium-rich functional walnut oil production method provided by the embodiments of the present invention comprises the following steps:

[0055] (1) Select walnuts with no moldy kernels containing 0.6 mg / kg of bio-organic selenium and remove the shells with a sheller.

[0056] (2) The obtained walnut kernels with skin are transported to the walnut kernel peeling machine to remove the walnut kernels.

[0057] (3) Transport walnut kernels without walnut kernel skin to a self-controlled constant temperature oil press for hot rolling and oil filtration at a constant temperature of 75°C.

[0058] (4) Transport the qualified walnut oil obtained from the self-controlled constant temperature oil press without deterioration of quality to the self-controlled constant temperature 55°C multifunctional vacuum centrifugal impurity removal oil filter, and remove the moisture, rancid oil, pectin, and odor from the walnut oil. and odor substances are removed by physic...

Embodiment 2

[0062] The bio-organic selenium-rich functional walnut oil production method provided by the embodiments of the present invention comprises the following steps:

[0063] (1) Select walnuts without mildew and use a sheller to remove the shells.

[0064] (2) The obtained walnut kernels with skins are transported to the walnut kernel peeling machine to remove the walnut kernel peels.

[0065] (3) Transport walnut kernels without walnut kernel skin to a self-controlled constant temperature oil press for hot rolling and oil filtering at a constant temperature of 85°C.

[0066] (4) Transport the qualified walnut oil obtained from the self-controlled constant temperature oil press without deterioration of quality to the self-controlled constant temperature 65°C multifunctional vacuum centrifugal impurity removal oil filter to remove moisture, rancid oil, pectin, and odor from the walnut oil. The odor and odor substances are removed by physical methods through the volatilization, ads...

Embodiment 3

[0070] The bio-organic selenium-rich functional walnut oil production method provided by the embodiments of the present invention comprises the following steps:

[0071] (1) Select walnuts without mildew and use a sheller to remove the shells.

[0072] (2) The obtained walnut kernels with skins are transported to the walnut kernel peeling machine to remove the walnut kernel peels.

[0073] (3) Transport walnut kernels without walnut kernel skin to a self-controlled constant temperature oil press for hot rolling and oil filtering at a constant temperature of 95°C.

[0074] (4) Transport the qualified walnut oil without quality deterioration obtained by the self-controlled constant temperature oil press to the self-controlled constant temperature 75°C multifunctional vacuum centrifugal impurity removal oil filter to remove moisture, rancid oil, pectin, and odor from the walnut oil. The odor and odor substances are removed by physical methods through the volatilization, adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com