In-situ regeneration system and method of Cu-based molecular sieve denitrification catalyst for diesel vehicle exhaust gas purification

A denitration catalyst and in-situ regeneration technology, which is applied in the direction of molecular sieve catalyst, catalyst regeneration/reactivation, physical/chemical process catalyst, etc., can solve the problems that are not suitable for off-line cleaning regeneration, inconvenient disassembly, difficult regeneration, etc., and achieve regeneration cost Low, short regeneration time, low-cost regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Fresh Cu / SAPO-34 catalyst was heated at a temperature of 300 °C, the ratio of ammonia to nitrogen was 1:1, NO x The concentration is 500ppm, SO 2 The concentration is 100ppm, the space velocity is 80,000h -1 The denitrification efficiency of the catalyst dropped from 98% to 50% after running for 36 hours under the exhaust gas condition.

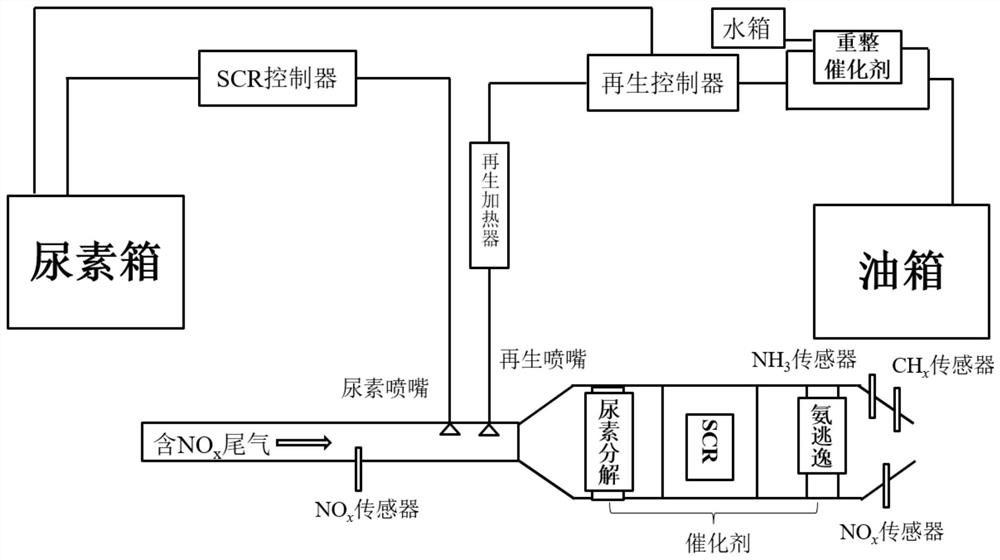

[0036] The regenerative device process flow of the present invention is as followsfigure 1 As shown, the hot ammonia gas is fed through the external nozzle in front of the catalyst, the concentration is 3000ppm, the temperature is 450°C, and the hot ammonia gas is fed for 1 hour.

[0037] The denitrification efficiency of the Cu / SAPO-34 catalyst recovered to 96.5% after the feed was stopped, and no ammonia slip was detected during the regeneration process.

Embodiment 2

[0039] The fresh Cu / SSZ-13 catalyst was heated at a temperature of 350 °C, with an ammonia-to-nitrogen ratio of 1:1, NO x The concentration is 500ppm, SO 2 The concentration is 150ppm, the space velocity is 100,000h -1 The denitrification efficiency of the catalyst dropped from 99% to 41% after running for 48 hours under the exhaust gas condition.

[0040] The regenerative device process flow of the present invention is as follows figure 1 As shown, hot diesel steam is fed through the external injection nozzle in front of the catalyst, the concentration is 5000ppm, the temperature is 550°C, and the hot diesel steam is fed for 1 hour.

[0041] The denitrification efficiency of the Cu / SSZ-13 catalyst recovered to 92.4% after the feed was stopped, and no diesel vapor escape was detected during the regeneration process.

Embodiment 3

[0043] The fresh Cu / ZSM-5 catalyst was heated at a temperature of 250°C, with an ammonia-to-nitrogen ratio of 1:1, NO x The concentration is 500ppm, SO 2 The concentration is 100ppm, the space velocity is 60,000h -1 The denitrification efficiency of the catalyst dropped from 95% to 32% after running for 72 hours under the exhaust gas condition.

[0044] The regenerative device process flow of the present invention is as follows figure 1 As shown, hot diesel reformed gas is introduced from the external injection nozzle in front of the catalyst, the concentration is 4000ppm, the temperature is 500°C, and the hot diesel reformed gas is introduced for 1.5 hours.

[0045] The denitrification efficiency of the Cu / ZSM-5 catalyst recovered to 91.9% after the feed was stopped, and no diesel vapor escape was detected during the regeneration process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com