Preparation and application of nitrate treatment agent

A nitrate, treatment agent technology, applied in special treatment targets, water/sewage treatment, special compound water treatment, etc., can solve the problems of secondary pollution, slow reaction, no selectivity, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

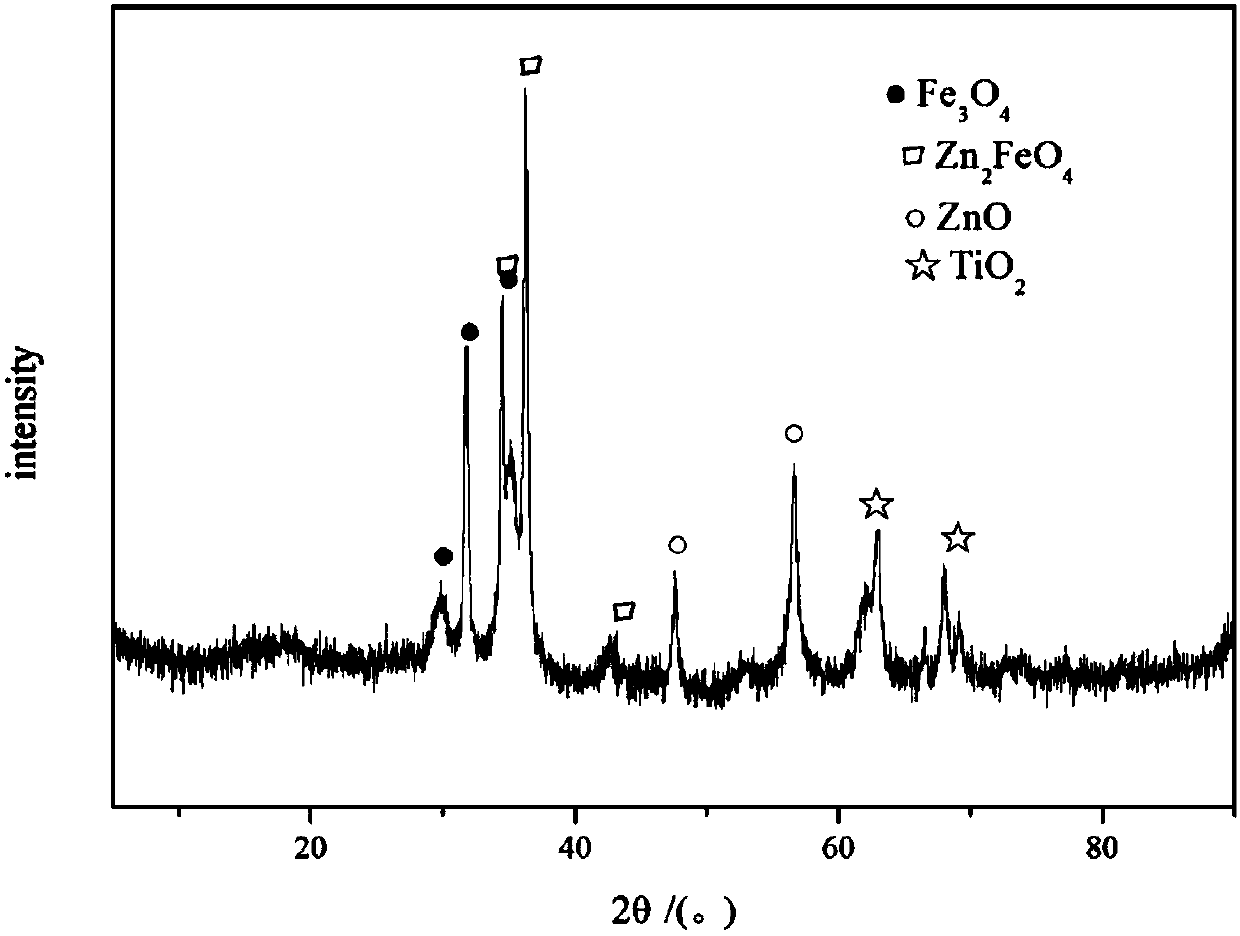

[0026] Embodiment 1 A kind of preparation method of nitrate treatment agent, specifically comprises the following steps:

[0027] (1) The cotton was washed three times with distilled water and absolute ethanol, and dried at 60°C for later use.

[0028] (2) Weigh 5.94g Zn(NO 3 ) 2 ·6H 2 O, 3mL Ti(SO 4 ) 2 , 4.04g Fe(NO 3 ) 3 9H 2 O in a beaker, add 100ml of distilled water to prepare mixed salt solution A.

[0029] (3) Weigh 12.00g NaOH and 2.67g NaOH 2 CO 3 In a beaker, add 150ml of distilled water to prepare coprecipitant solution B.

[0030] (4) 3g of treated cotton is put into a beaker, and 250ml of distilled water is added at the same time, then the mixed salt solution A and coprecipitant solution B are added dropwise therein simultaneously, and the rate of addition is controlled to be 1 drop per second, while the magnetic force is violently stirred, After the dropwise addition, continue to stir for 30 minutes, sonicate for 10 minutes, and adjust the pH to 9.5-1...

Embodiment 2

[0035] Embodiment 2 A kind of preparation method of nitrate treatment agent, specifically comprises the following steps:

[0036] (1) The cotton was washed three times with distilled water and absolute ethanol, and dried at 60°C for later use.

[0037] (2) Weigh 11.88g Zn(NO 3 ) 2 ·6H 2 O, 6mL Ti(SO 4 ) 2 , 8.08g Fe(NO 3 ) 3 9H 2 O in a beaker, add 200ml of distilled water to prepare a mixed salt solution.

[0038] (3) Weigh 24.00gNaOH and 5.34gNa 2 CO 3 In a beaker, add 300ml of distilled water to prepare coprecipitant.

[0039] (4) Put 4g of treated cotton into a beaker, add 500ml of distilled water at the same time, then drop the mixed salt solution and coprecipitant into it at the same time, control the dropping rate to 1 drop per second, and stir vigorously with magnetic force at the same time. Afterwards, continue to stir for 30 minutes, sonicate for 10 minutes, and adjust the pH to 9.5-10.5.

[0040] (5) Place the obtained suspension in a blast oven at 65°C an...

Embodiment 3

[0042] Embodiment 3 Application of a nitrate treatment agent in water

[0043] Add 0.1g of nitrate treatment agent to a 250mL Erlenmeyer flask, then add 150mL of waste water containing 221mg / L nitrate, shake in a constant temperature water bath at 25°C for 3h. After magnetic separation, the nitrate content in the supernatant was measured, and the calculated nitrate adsorption capacity was 300.06 mg / g, and the nitrate removal rate was 90.34%.

[0044] Add 10mL of distilled water to the nitrate treatment agent obtained after magnetic separation, put it into a photocatalytic reactor, turn on the ultraviolet lamp, react for 0.5h, magnetically separate it, and put it into an oven for drying. Then add 150mL of wastewater containing 221mg / L nitrate, shake in a constant temperature water bath at 25°C for 3h. After magnetic separation, the nitrate content in the supernatant was measured, and the calculated nitrate adsorption capacity was 288.88 mg / g, and the nitrate removal rate was 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com