Patents

Literature

30results about How to "Extend regeneration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for establishing hematopoietic stem cells bank by extracting hematopoietic cells from placenta tissues

InactiveCN1407088AIncrease the number ofSave livesMammal material medical ingredientsBlood/immune system cellsHigh concentrationHematopoietic cell

A process for extracting hemopoietic stem cells from the placenta of healthy puerperant to create hemopoistic stem cell bank features that the mechanical, enzyme digestive and monoclonal antibody-magnetic bead method is used to extract blood stem cells from placenta, and concentrate and purify them. Its advantages are high activity and high concentration.

Owner:上海厚东生物科技有限公司

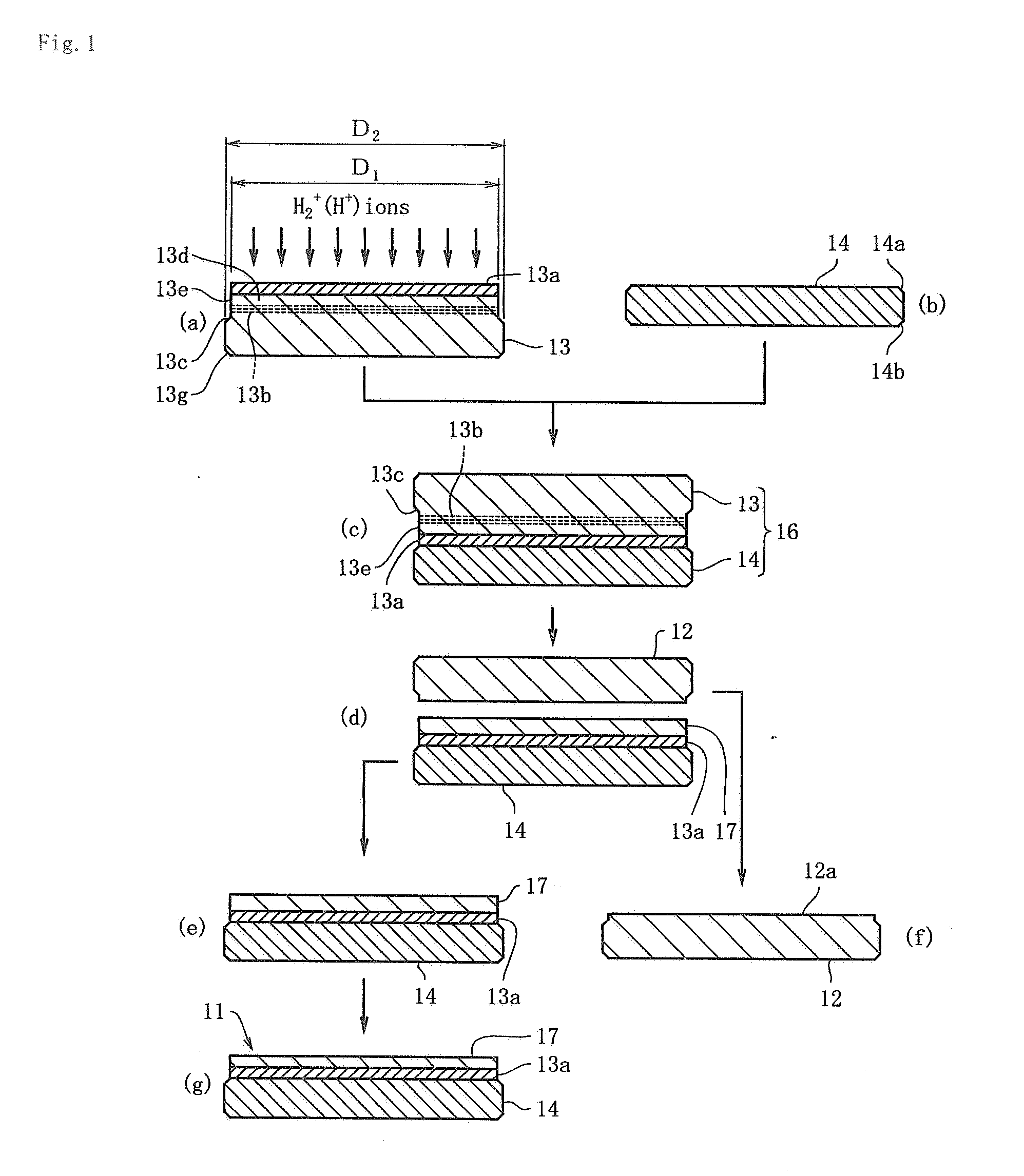

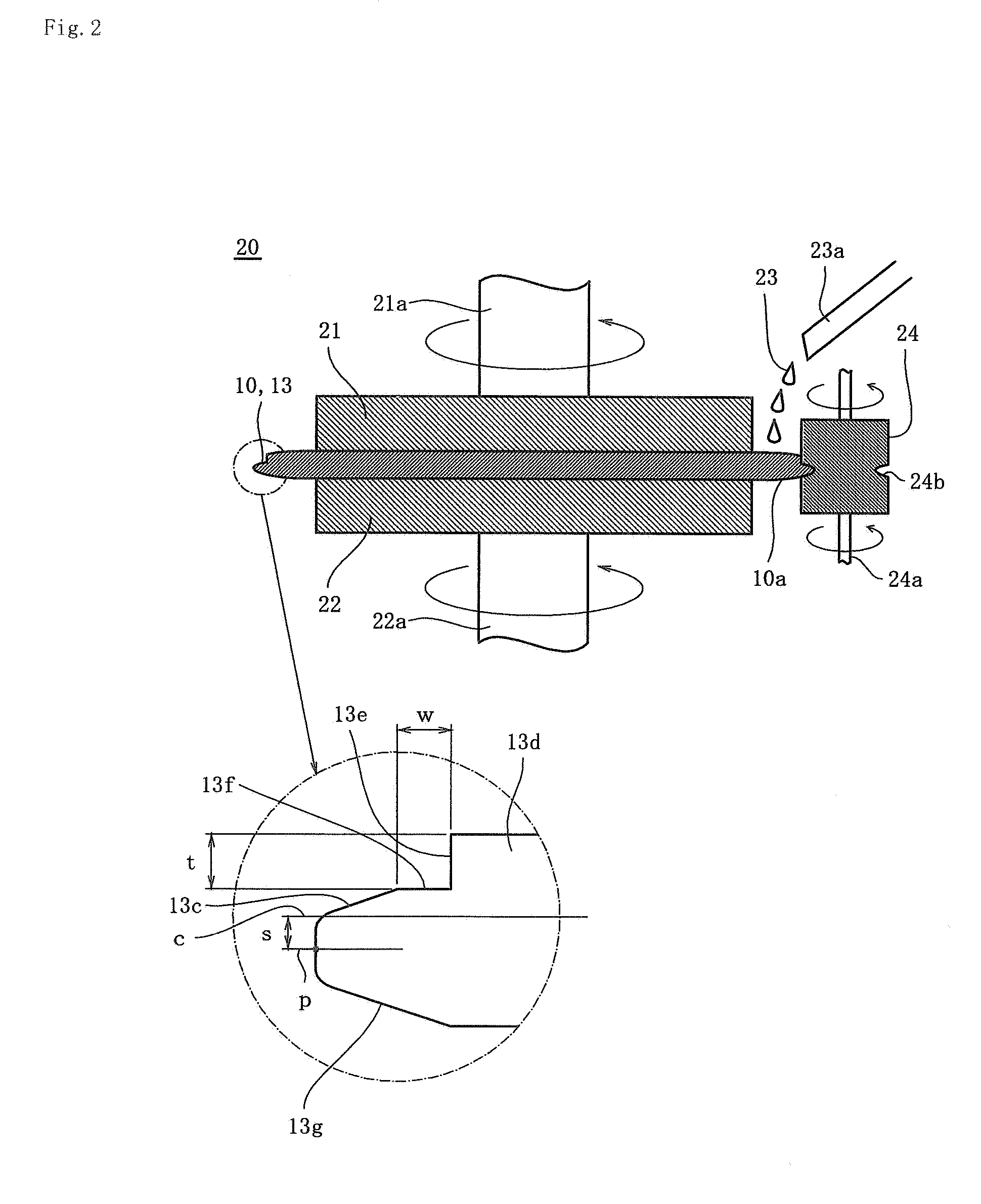

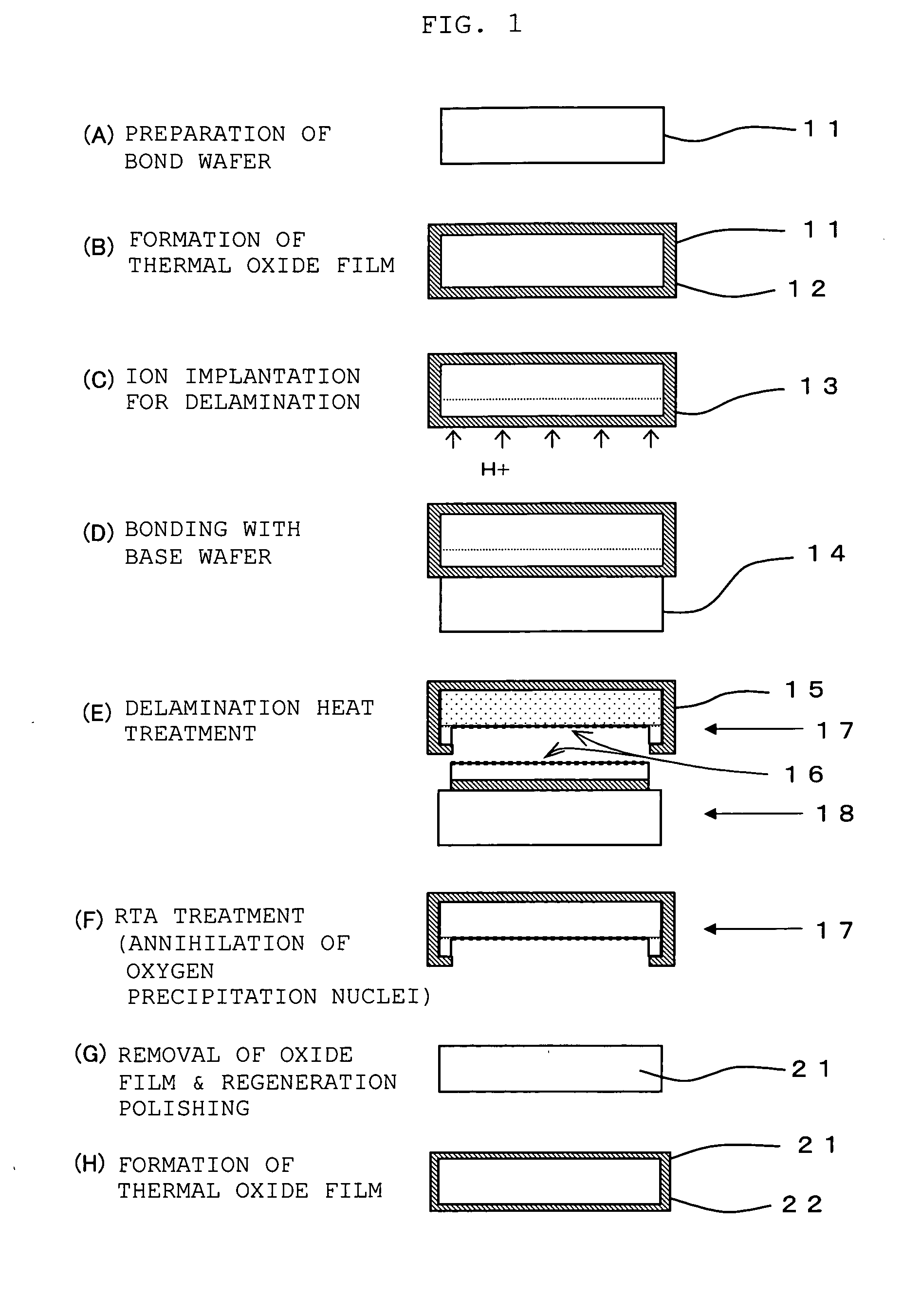

Process for Regeneration of a Layer Transferred Wafer and Regenerated Layer Transferred Wafer

ActiveUS20070148914A1Reduce processing timeLow regeneration costSemiconductor/solid-state device manufacturingLapping machinesThin layerEngineering

A processing time required for regeneration of a layer transferred wafer is reduced and the regeneration cost is lowered, while a removal amount at the regeneration is decreased the number of regeneration times is increased. A main surface of a semiconductor wafer (13) has a main flat portion (13d) and a chamfered portion (13c) formed in the periphery of the main flat portion (13d), an ion implanted area (13b) is formed by implanting ions only into the main flat portion (13d), a laminated body (16) is formed by laminating the main flat portion (13d) on a main surface of a support wafer (14), and moreover, the semiconductor wafer (13) is separated from a thin layer (17) in the ion implanted area (13b) by heat treatment at a predetermined temperature so as to obtain a thick layer transferred wafer (12), which is to be regenerated. The main flat portion (13d) of the semiconductor wafer (13) is formed to have a ring-shape step (13e) protruding from the chamfered portion (13c), and the semiconductor wafer (13) is separated from the thin layer (17) on the whole surface of the ion implanted area (13b) so that no step is generated in the periphery thereby to obtain the layer transferred wafer (12).

Owner:SUMCO CORP

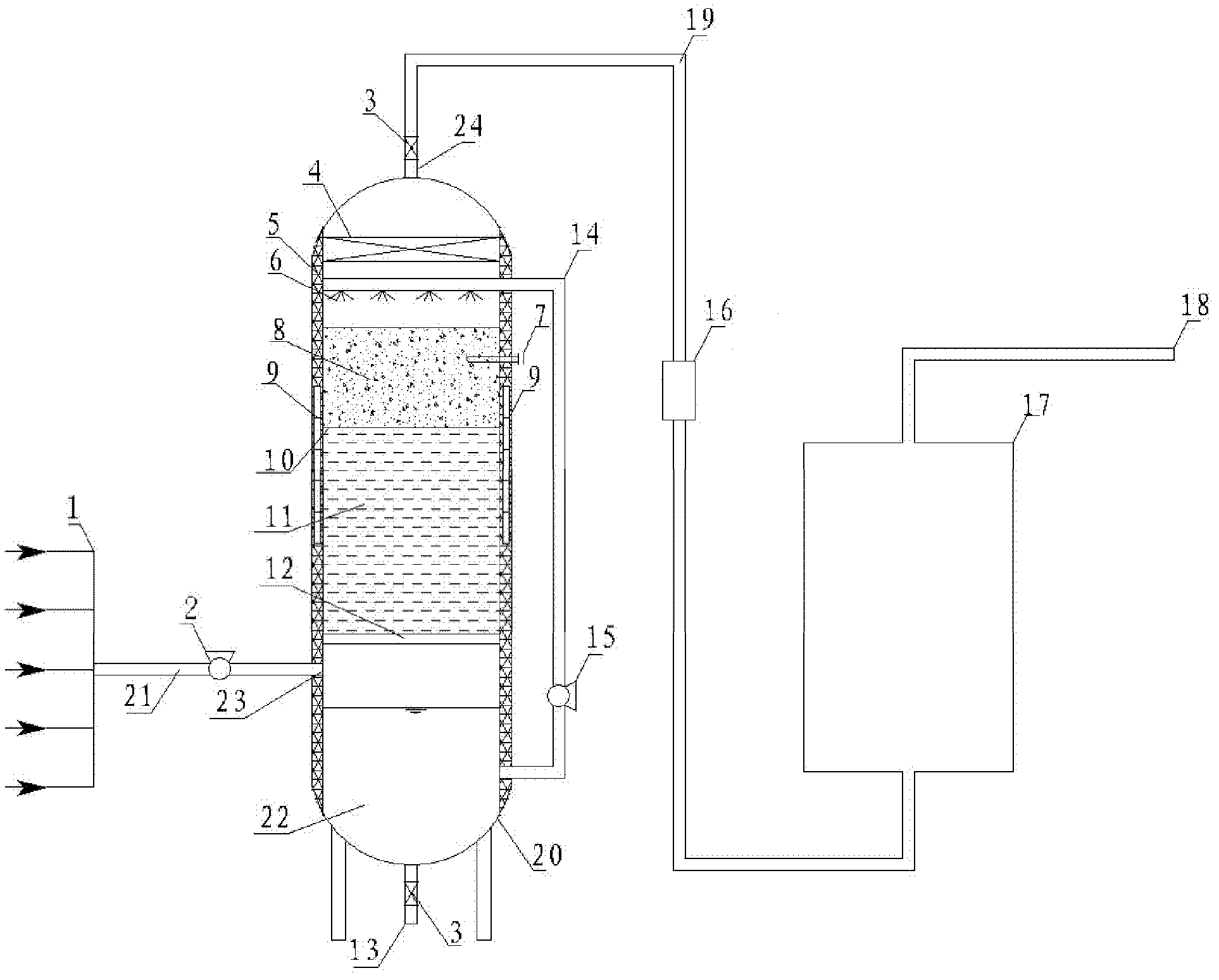

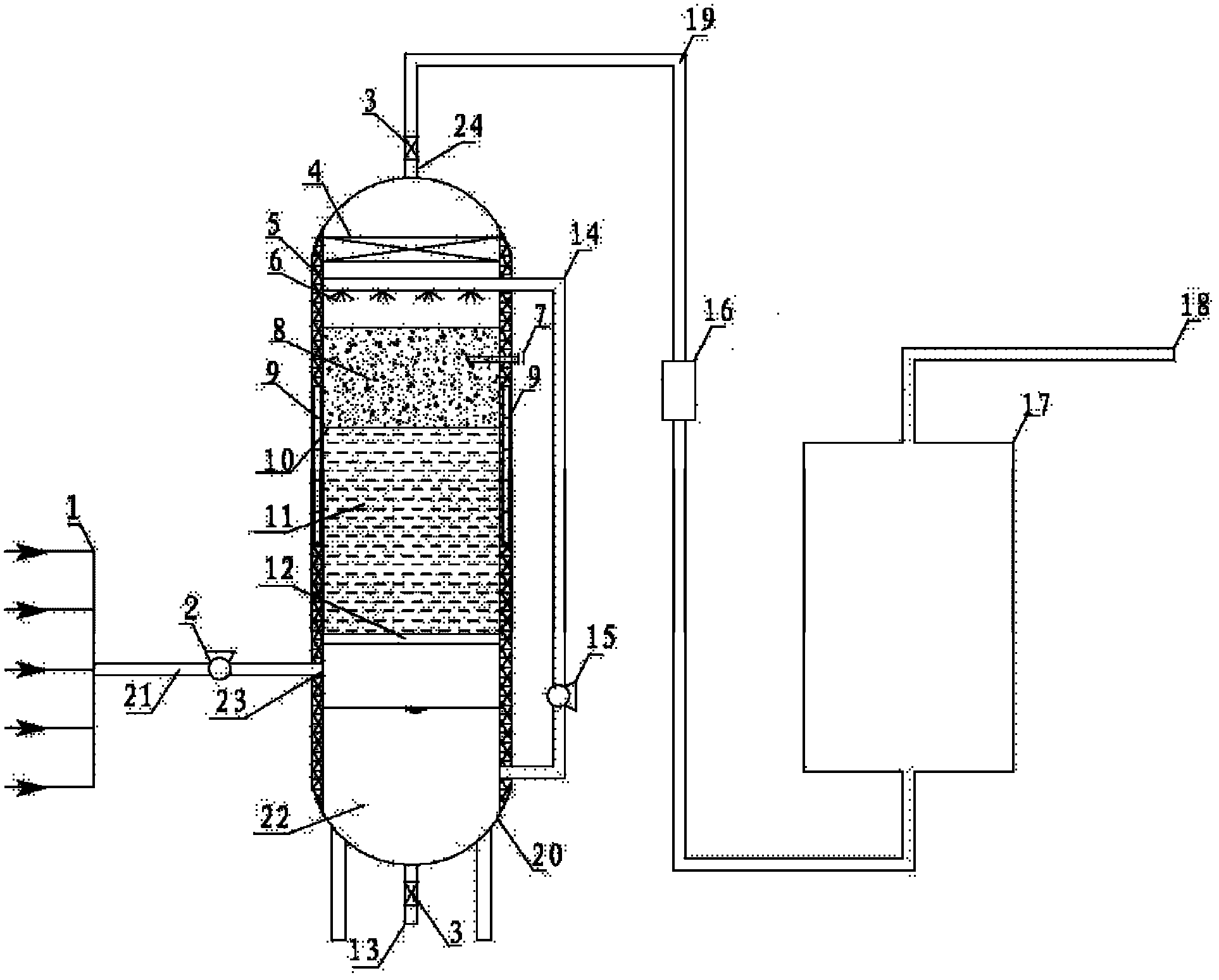

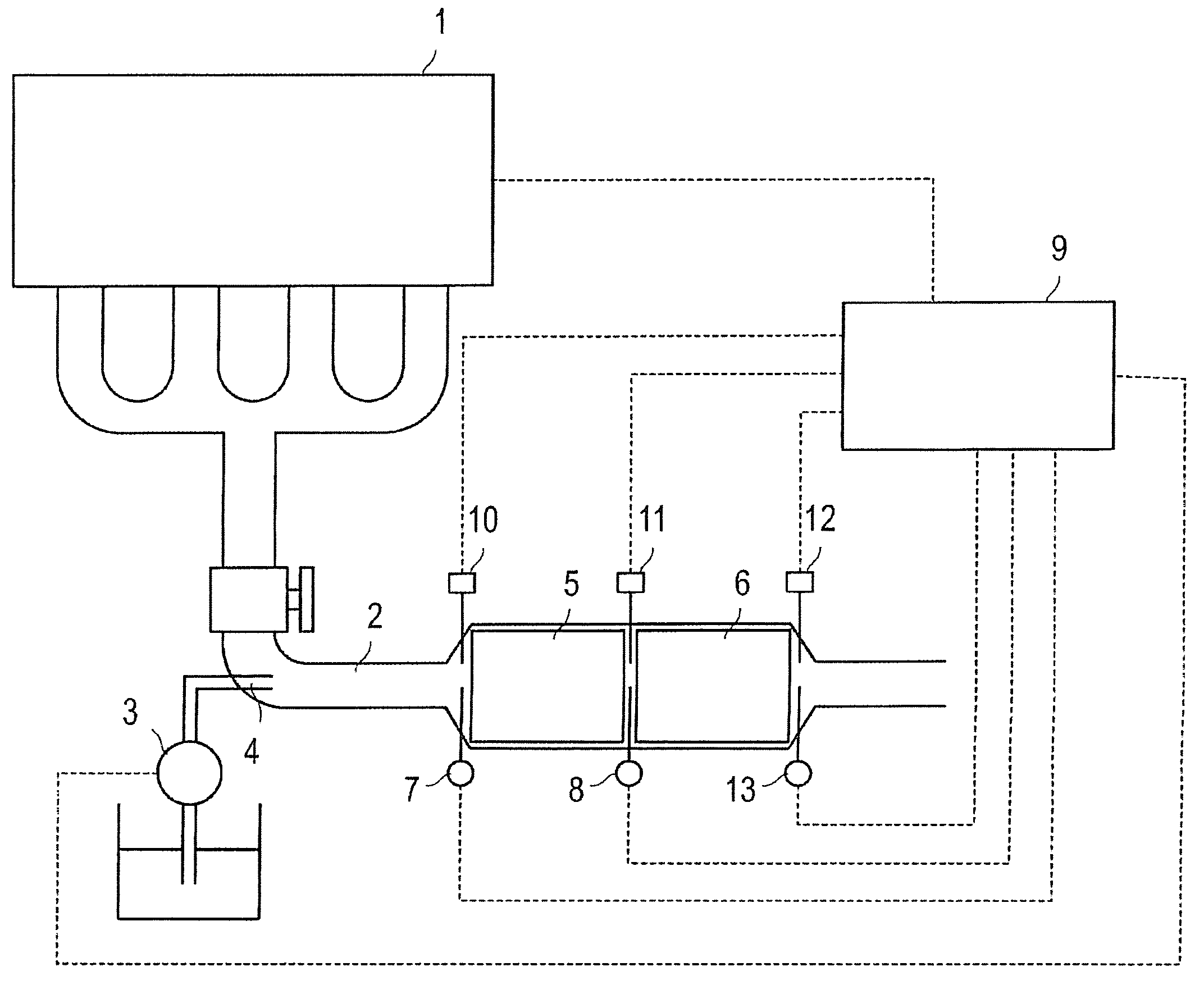

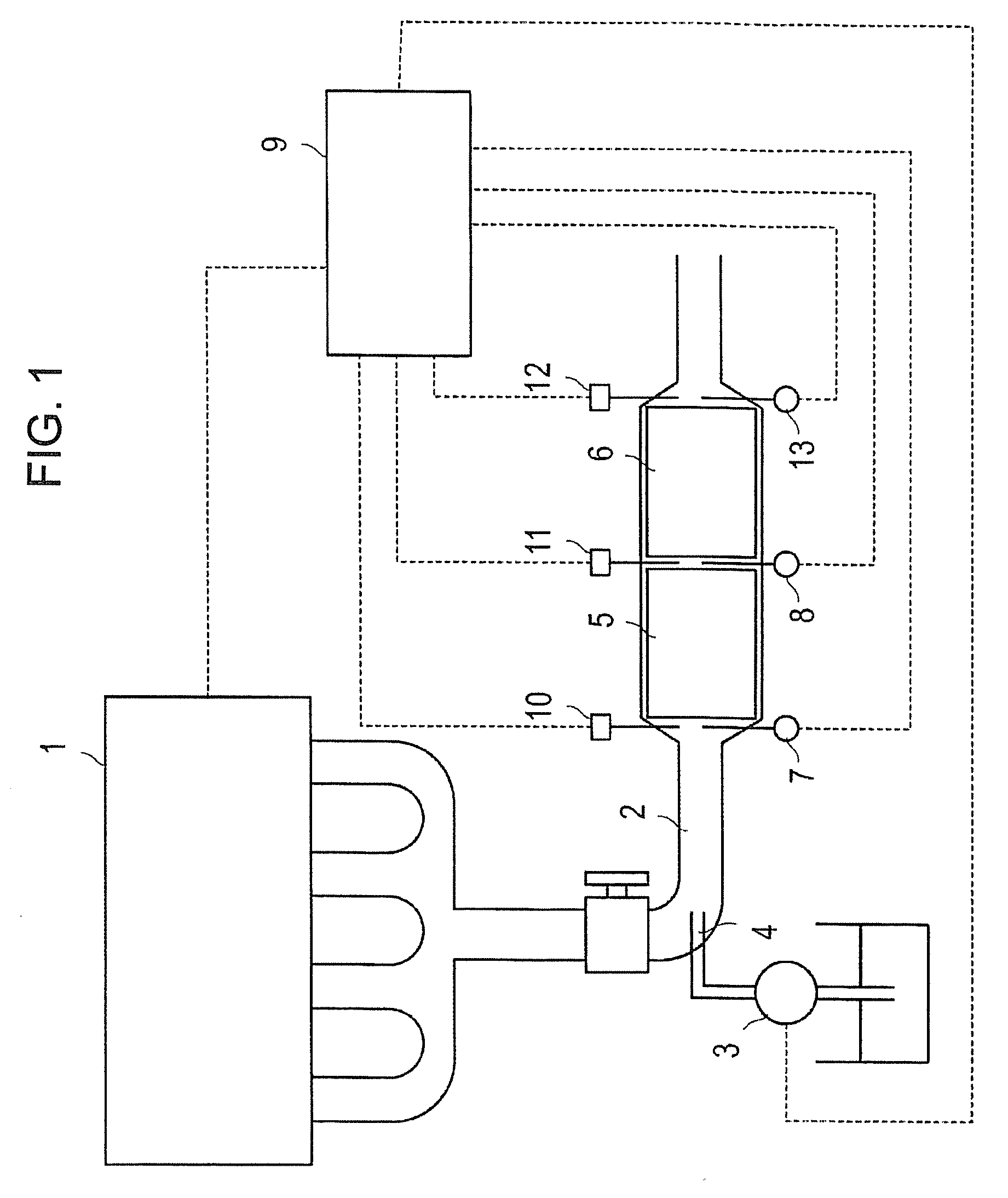

Biological treatment system of sludge odor and method for treating sludge odor by utilizing same

InactiveCN102614774AEfficient removalImprove processing efficiencyDispersed particle separationAir quality improvementActivated carbonSludge

The invention discloses a biological treatment system of sludge odor and a method for treating the sludge odor by utilizing the same, relating to the field of solid waste treatment. The biological treatment system of the sludge odor comprises an odor collector, an odor fan, an intake pipe, a biological deodorization tower, an outlet pipe, an active carbon adsorption device, a gas monitor and a discharge pipe. The method for treating the sludge odor by utilizing the biological treatment system comprises the following steps of: (1) injecting a bacterial solution enriched with thiobacillus denitrificans and nitrobacteria, acclimatizing for three weeks to finish starting; and (2) charging odor into the biological treatment system for treating through the odor fan. According to the biological treatment system of the sludge odor and the method for treating the sludge odor by utilizing the same, disclosed by the invention, main components of the sludge odor are removed by utilizing thiobacillus denitrificans and nitrobacteria, soft-hard bilayer fillers are adopted and active carbon is adopted for the following adsorption, thus the treatment effect is ensured; in addition, the biological treatment system of the sludge odor and the method for treating the sludge odor by utilizing the same, disclosed by the invention, have the advantages of low energy consumption and operation cost, and high safety and reliability, and is suitable for odor treatment of a large / middle sludge treatment project.

Owner:HARBIN INST OF TECH

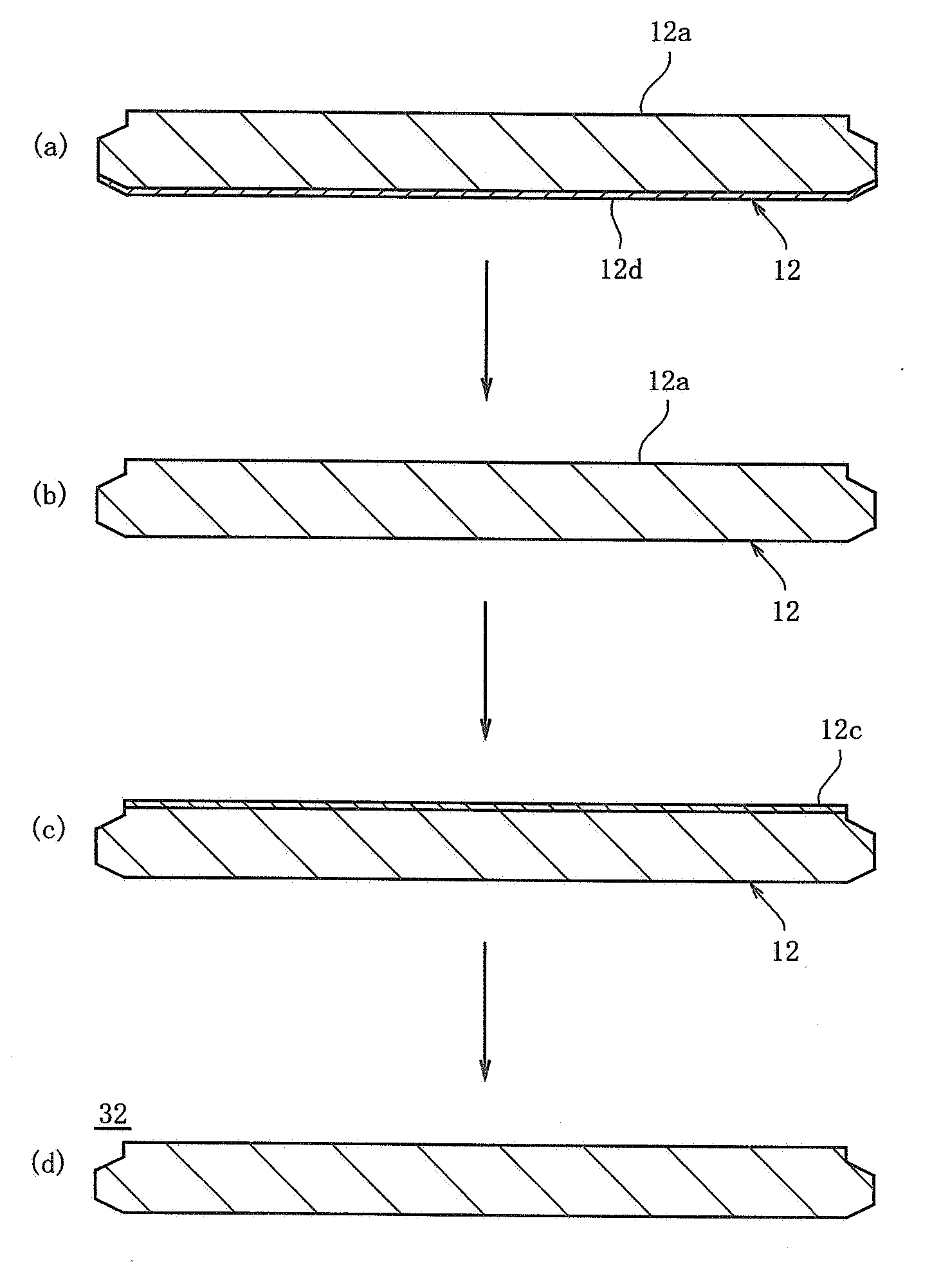

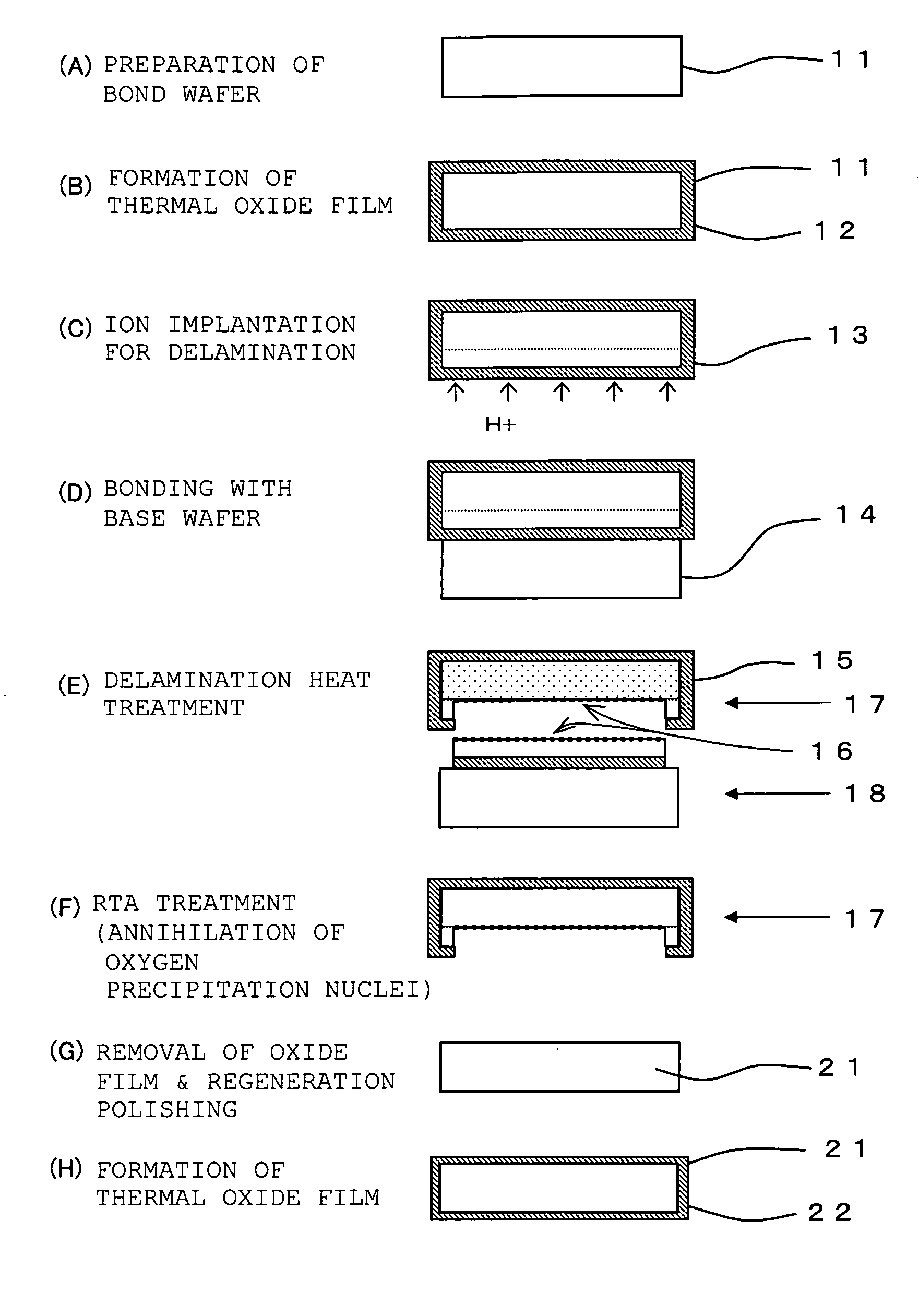

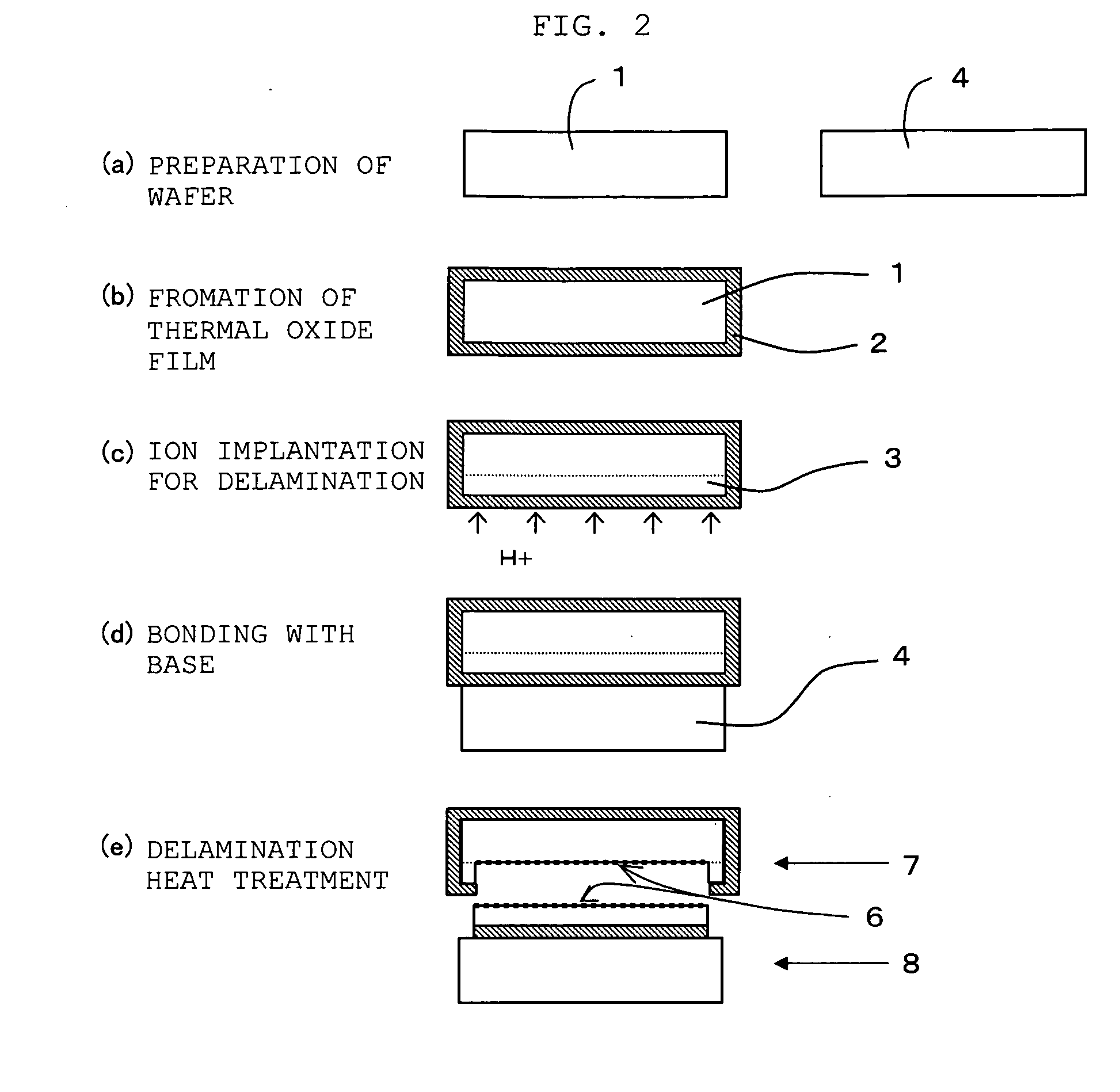

Method for reusing delaminated wafer

InactiveUS20090209085A1Required thicknessIncreased bond failureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringIon implantation

The present invention provides a method for reusing a delaminated wafer, which is a method for applying reprocessing that is at least polishing to a delaminated wafer 17 byproduced when manufacturing an SOI wafer based on an ion implantation delamination method and thereby again reusing the delaminated wafer 17 as a bond wafer 21 in an SOI wafer manufacturing process, wherein, at least, a CZ wafer 11 used as the bond wafer is a low-defect wafer whose entire surface is formed of an N region, and an RTA treatment is carried out in the reprocessing with respect to the delaminated wafer 17 at a higher temperature than a temperature in formation of a thermal oxide film 12 performed with respect to the bond wafer in the SOI wafer manufacturing process. As a result, there can be provided the method for reusing a delaminated wafer which does not induce a bonding failure or a reduction in quality of an SOI layer even if the delaminated wafer byproduced when the CZ wafer having a large diameter of 200 mm or above is used as the bond wafer to fabricate the SOI wafer based on the ion implantation delamination method is repeatedly reused as the bond wafer.

Owner:SHIN-ETSU HANDOTAI CO LTD

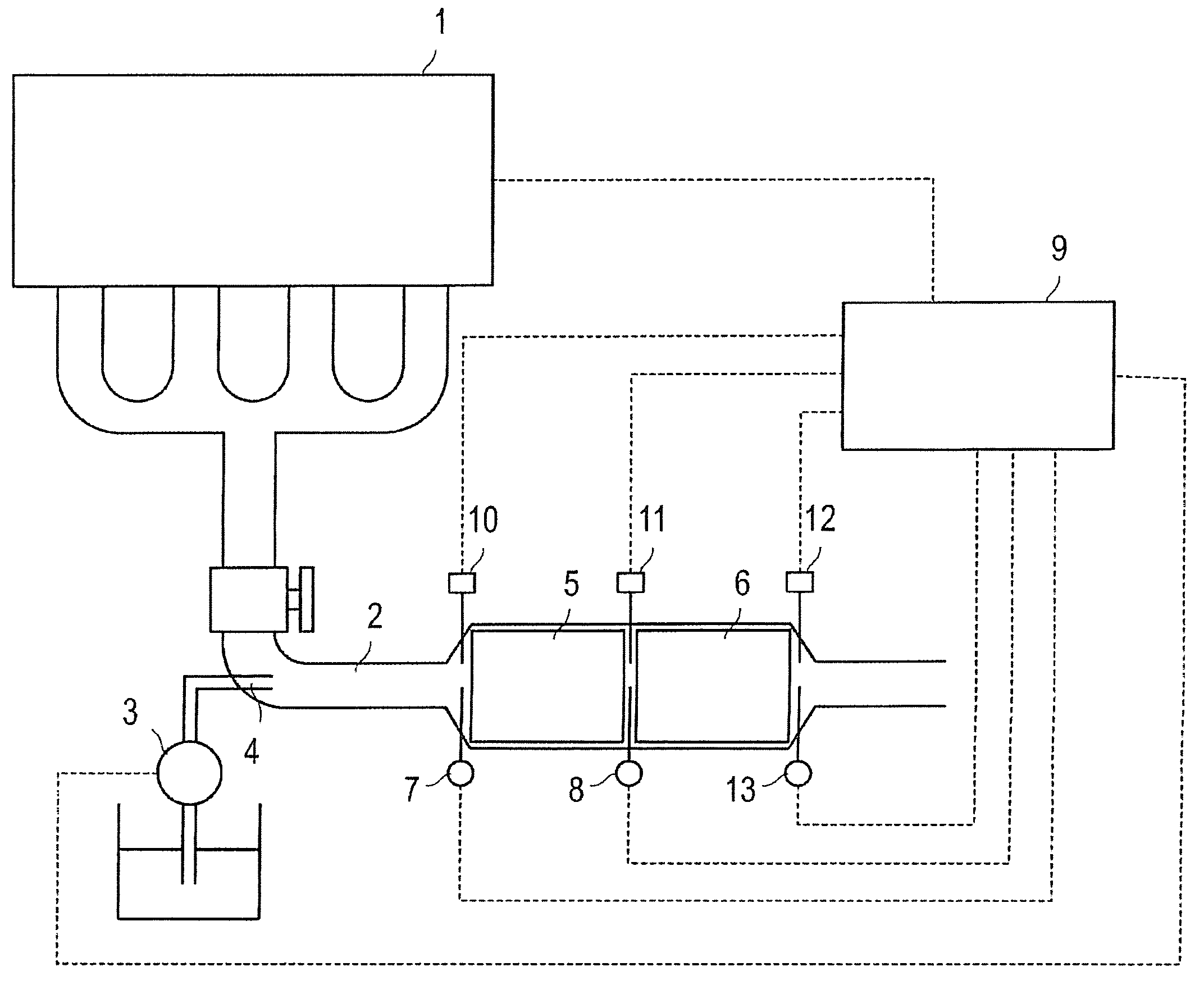

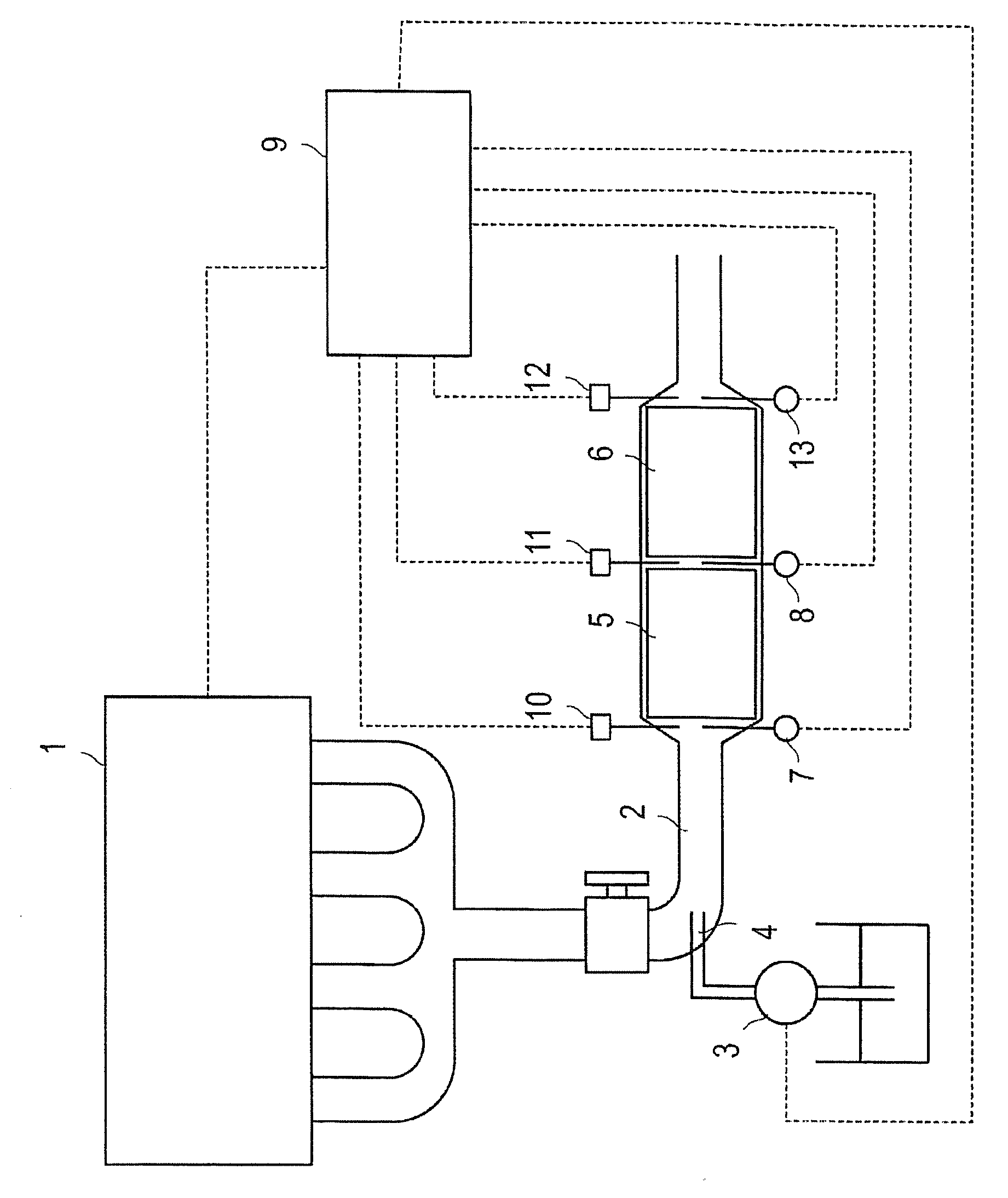

Method for purification of exhaust gas from internal combustion engine

ActiveUS20090107122A1Stable increase in exhaust gas temperatureIncrease concentrationCombination devicesInternal combustion piston enginesHigh concentrationCombustion

Temperature range enabling combustion of high concentration hydrocarbon is enlarged, or high temperature gas is rapidly supplied to a latter part catalyst. Provided is a method for purification of exhaust gas from an internal combustion engine, by using a catalyst for increasing temperature of exhaust gas from an internal combustion engine, wherein hydrocarbon from 1,000 to 40,000 ppm by volume, as converted to methane, to the exhaust gas, is introduced at the upstream side of the catalyst for increasing temperature, along flow of the exhaust gas inside a passage of exhaust gas from the internal combustion engine.

Owner:UMICORE SHOKUBAI USA +1

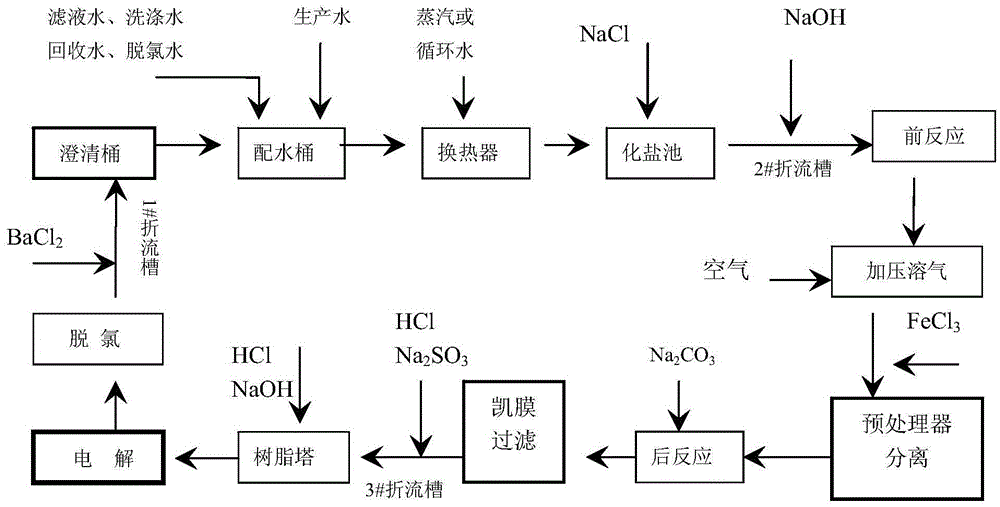

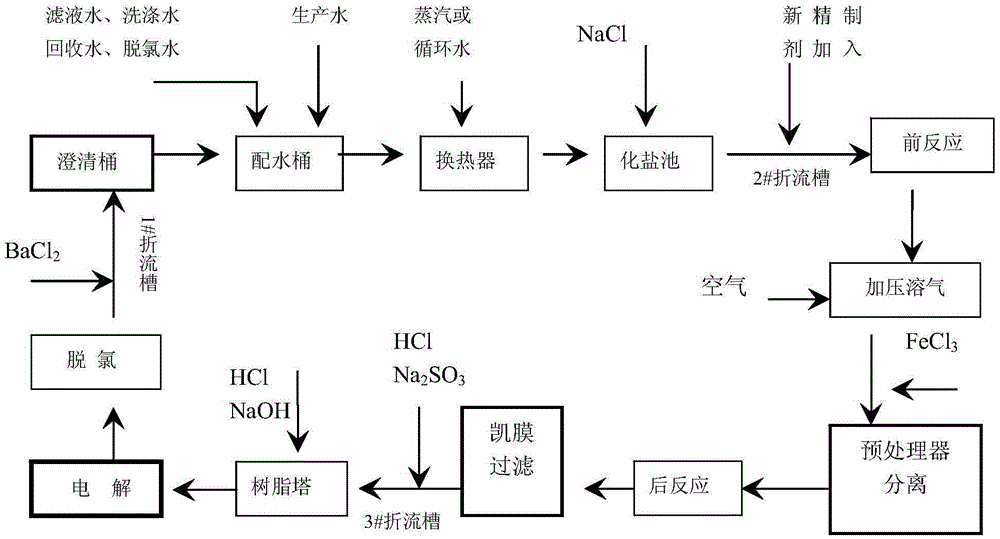

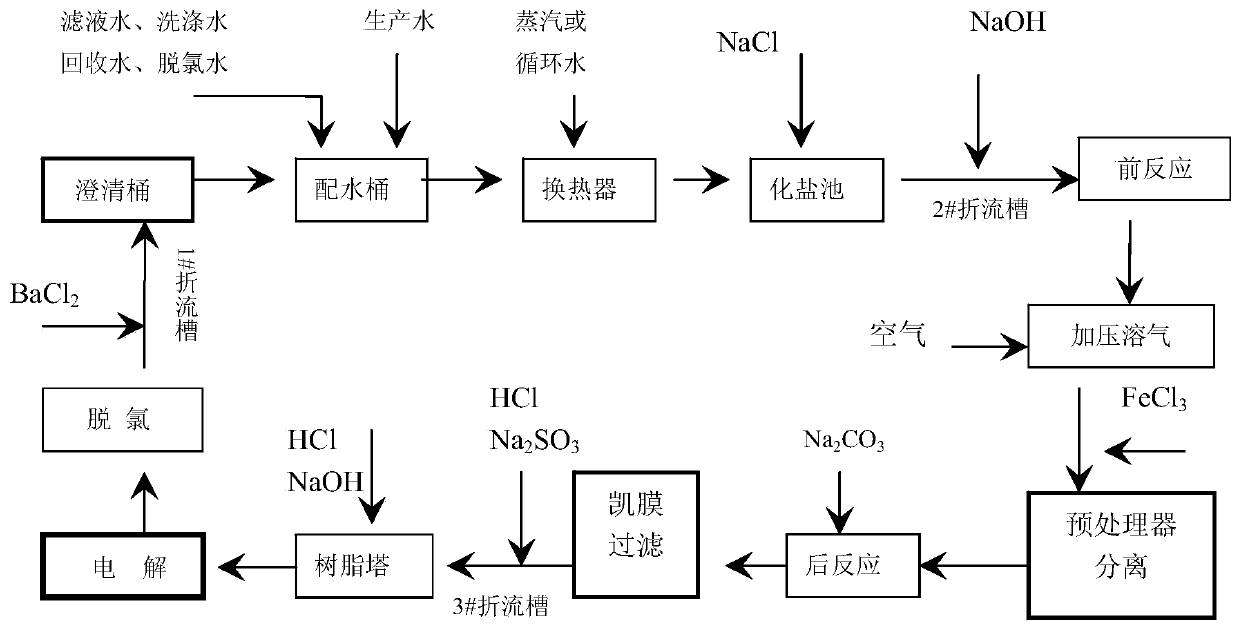

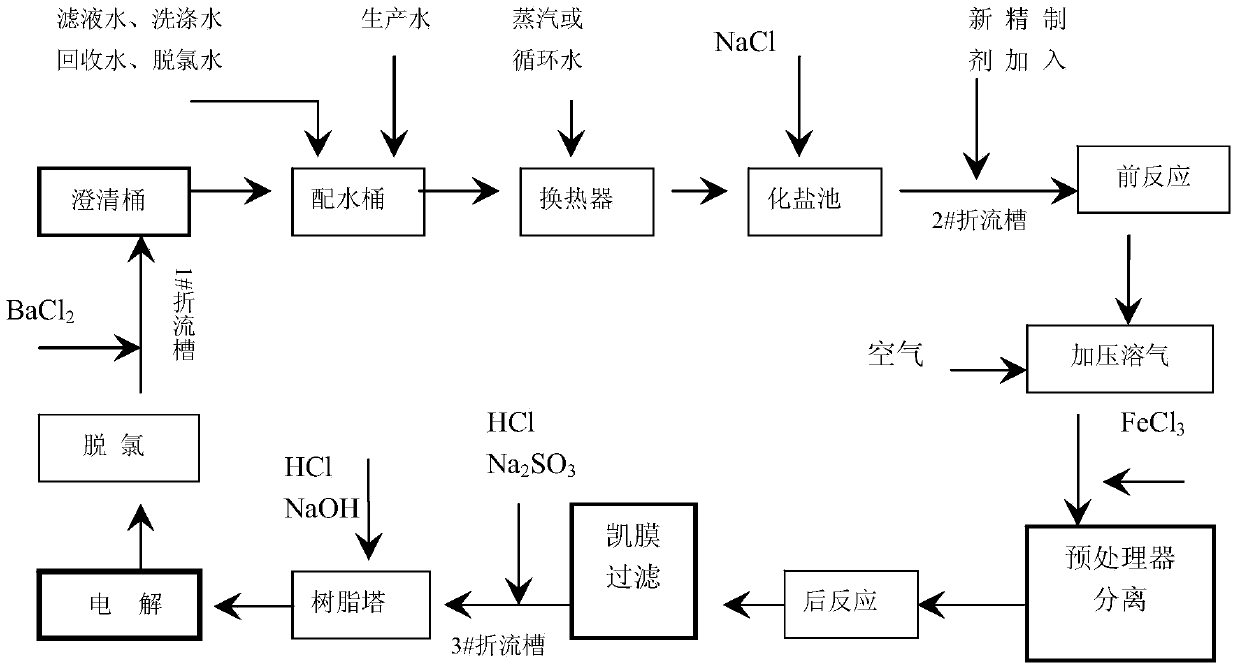

Refining agent for refining primary brine in chlorine alkali industry and application of refining agent

ActiveCN105565342AAdaptableReduce operating loadAlkali metal halide purificationChemical industryPhosphate

The invention relates to the field of the chlorine alkali chemical industry, and in particular relates to a novel refining agent for replacing an existing refining agent in a refining process of primary brine in the chlorine alkali industry. The invention aims to solve the technical problem that in the chlorine alkali chemical industry process at present, the quality of brine entering a resin tower is still not high. The technical scheme for solving the technical problem is to provide the novel refining agent used in the refining process of the brine used in the chlorine alkali industry to replace the originally used 'two-alkali' refining agent. The refining agent takes phosphate as an active ingredient. The novel refining agent is strong in adaptability, and can reduce the total amount of calcium and magnesium in the primary brine by 10 times by replacing the original refining agent, so that the operating load of the resin tower is reduced, the regeneration time of the resin tower is prolonged, then the production cost is reduced, and the refining agent has a very good application prospect.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

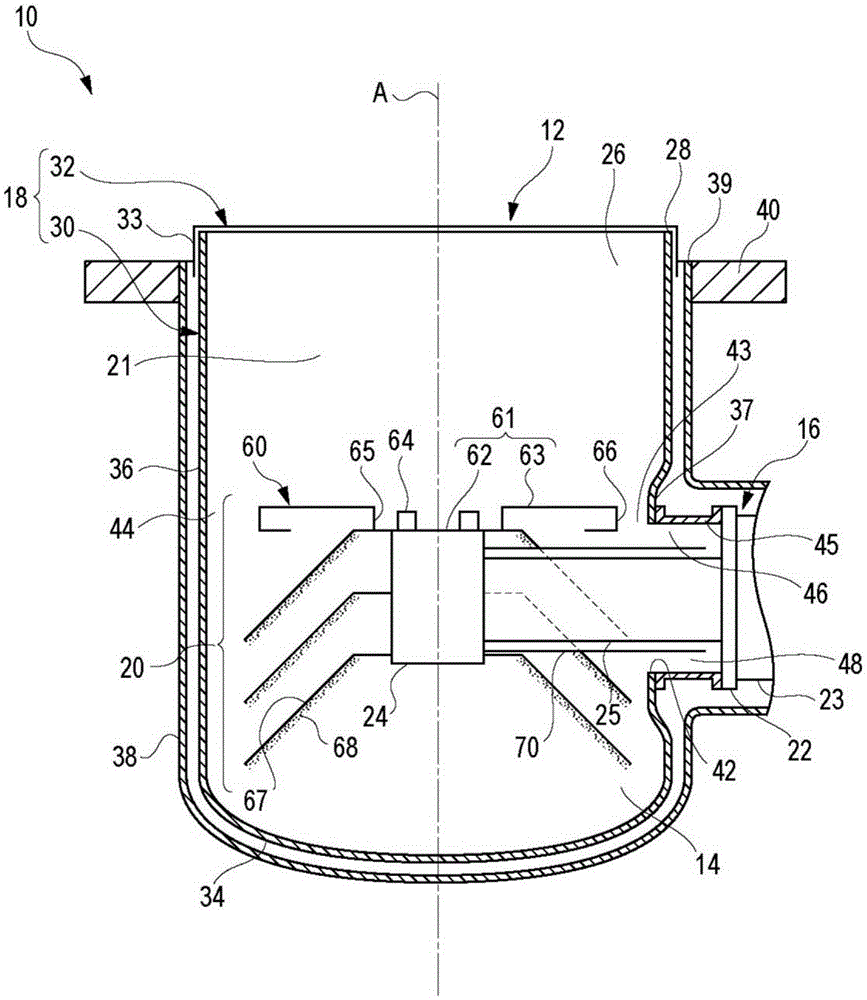

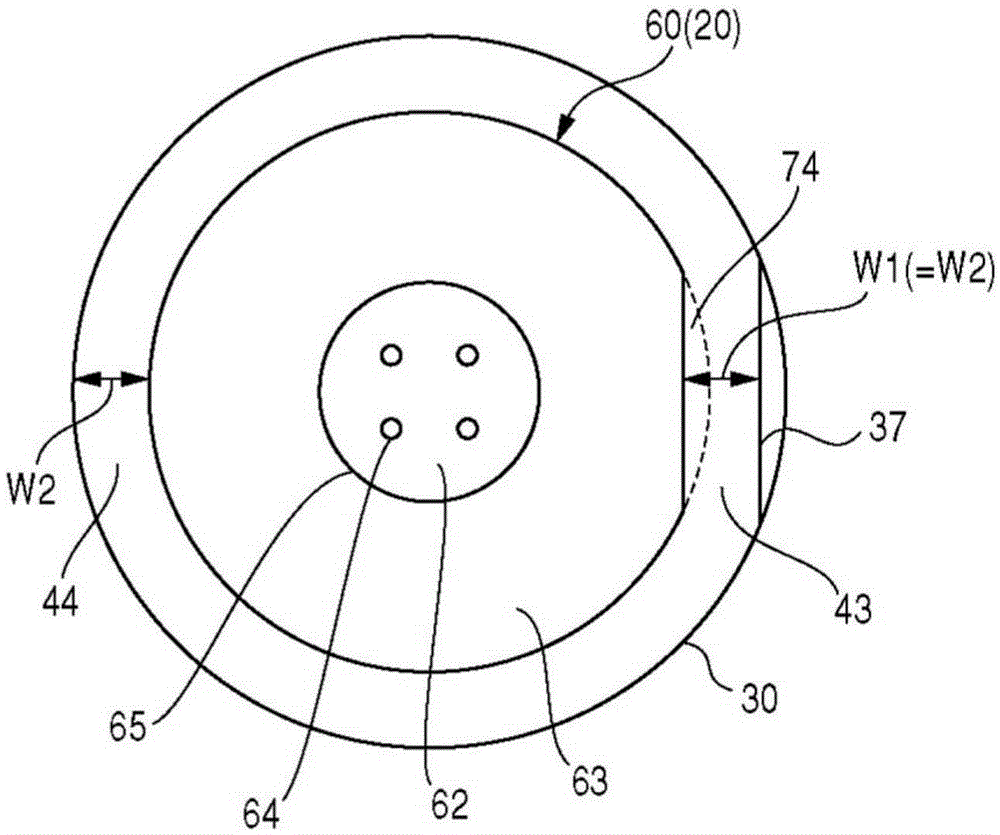

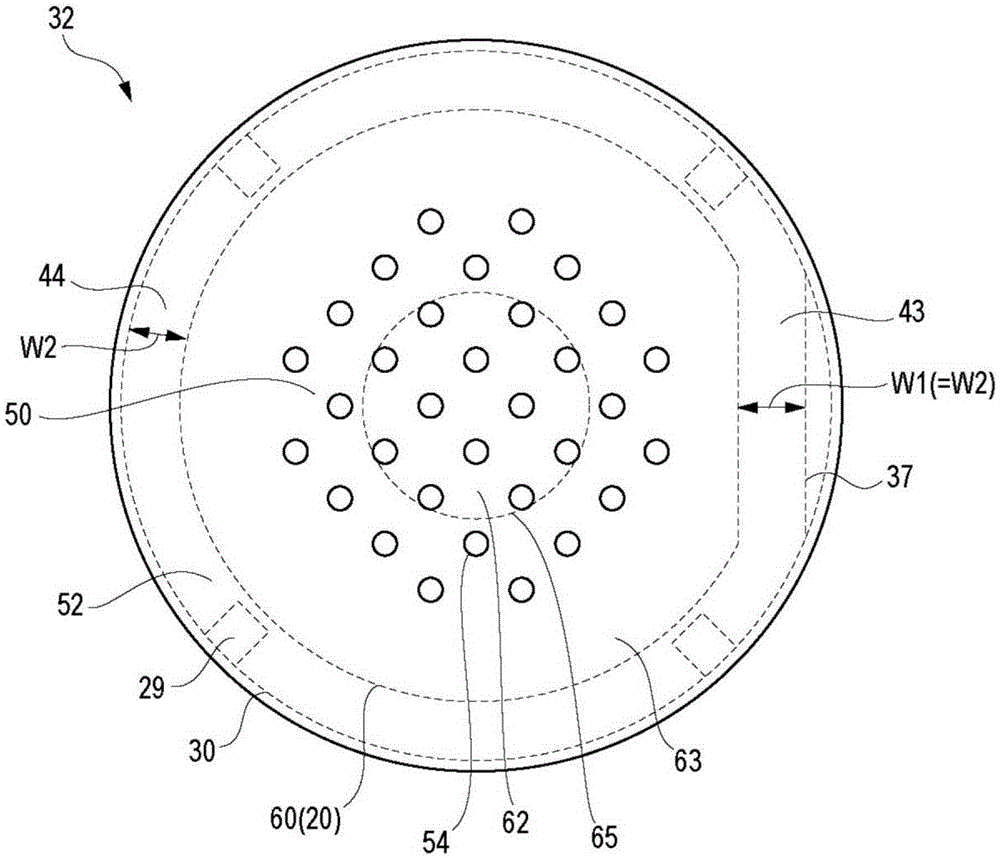

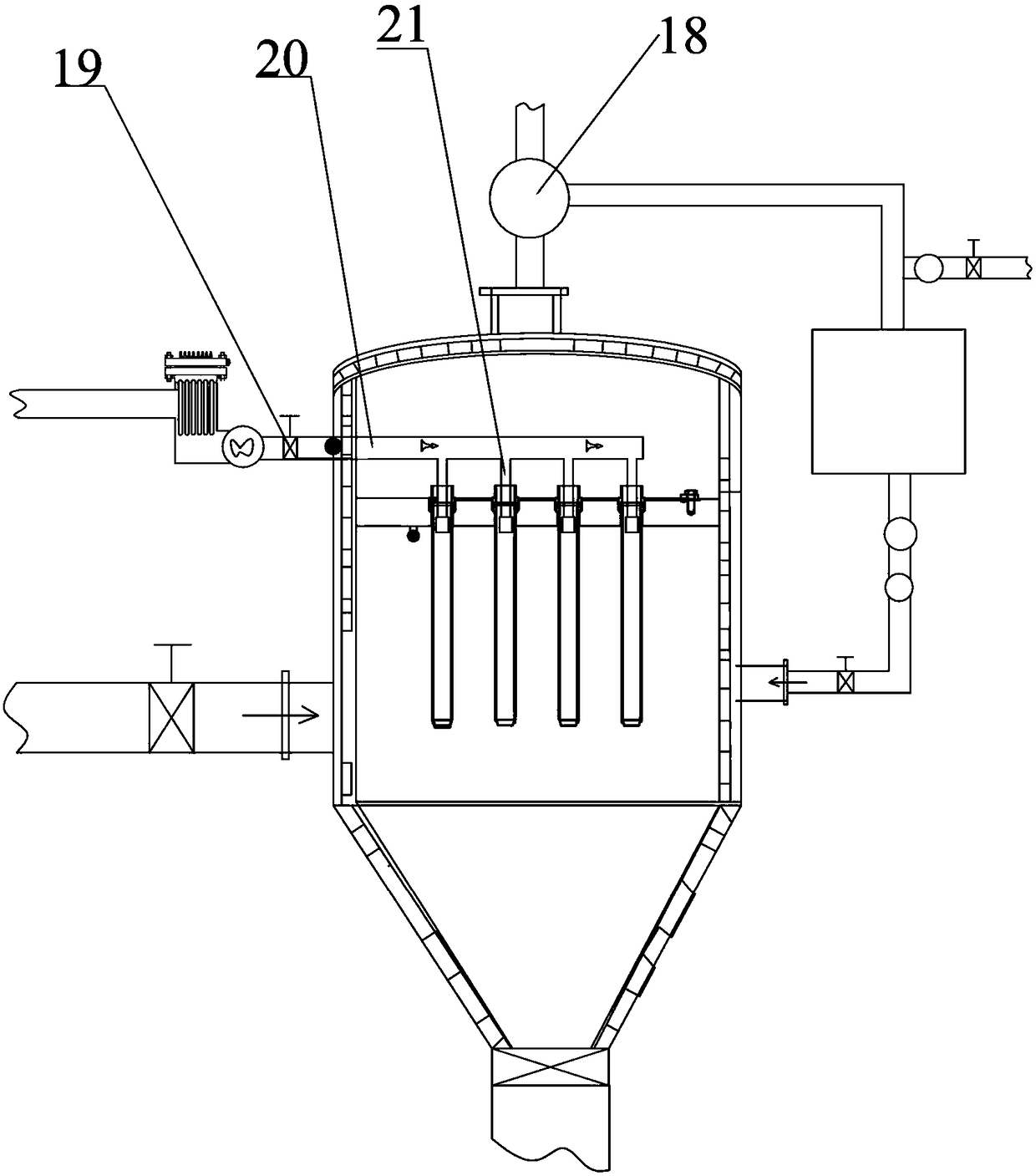

Cryopump

ActiveCN105484968AExtend regeneration timeExtend regeneration intervalPumpsPositive-displacement liquid enginesEngineeringCryopump

A cryopump includes: a cryopump vessel that defines an inlet; a refrigerator including a first stage and a second stage housed in the cryopump vessel, the second stage being cooled to a lower temperature than that of the first stage; a first cryopanel thermally connected to the first stage and surrounded by the cryopump vessel; and a second cryopanel thermally connected to the second stage and surrounded by the first cryopanel. The first cryopanel includes a plate member having an inlet aperture at the inlet. The inlet aperture is formed in the plate member such that a ratio of a conductance of the plate member with respect to an aperture conductance of the inlet is 6% or less.

Owner:SUMITOMO HEAVY IND LTD

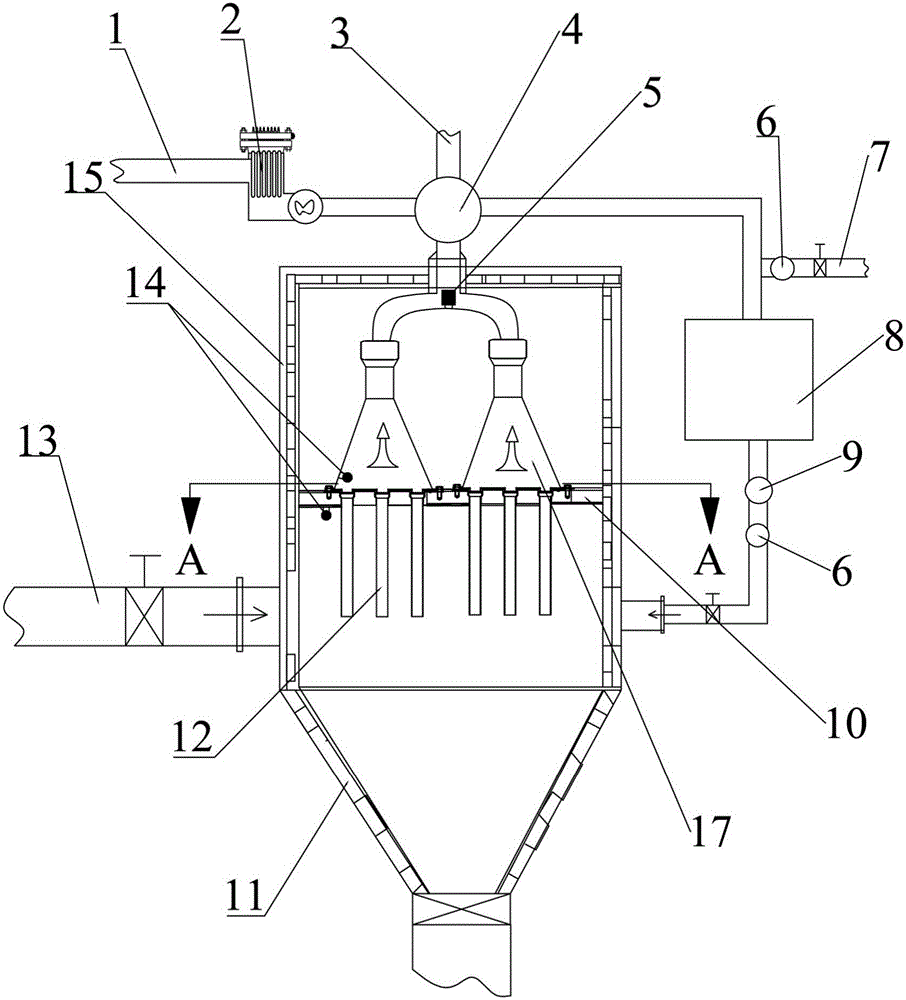

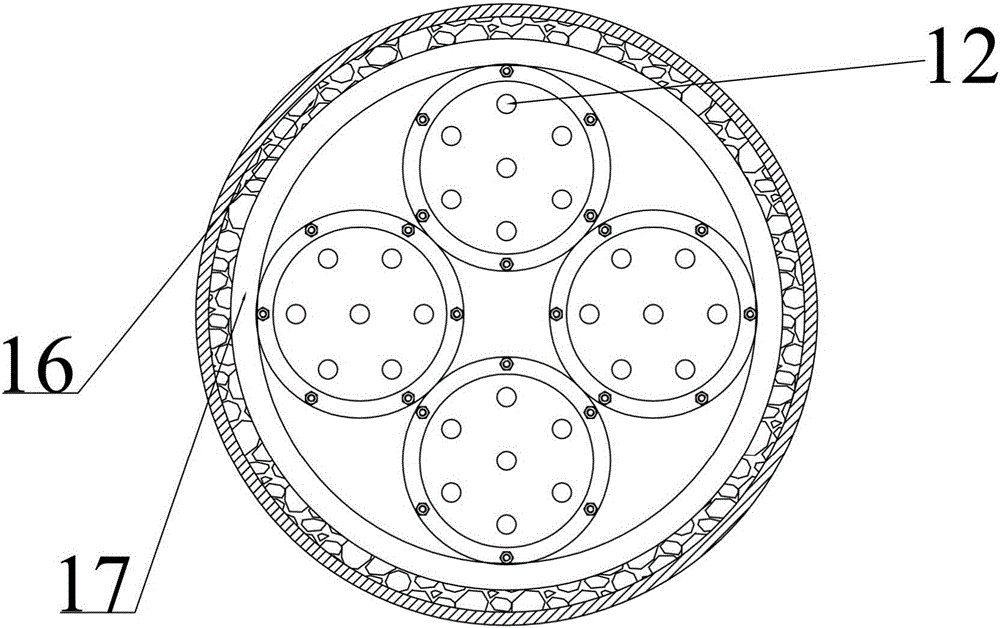

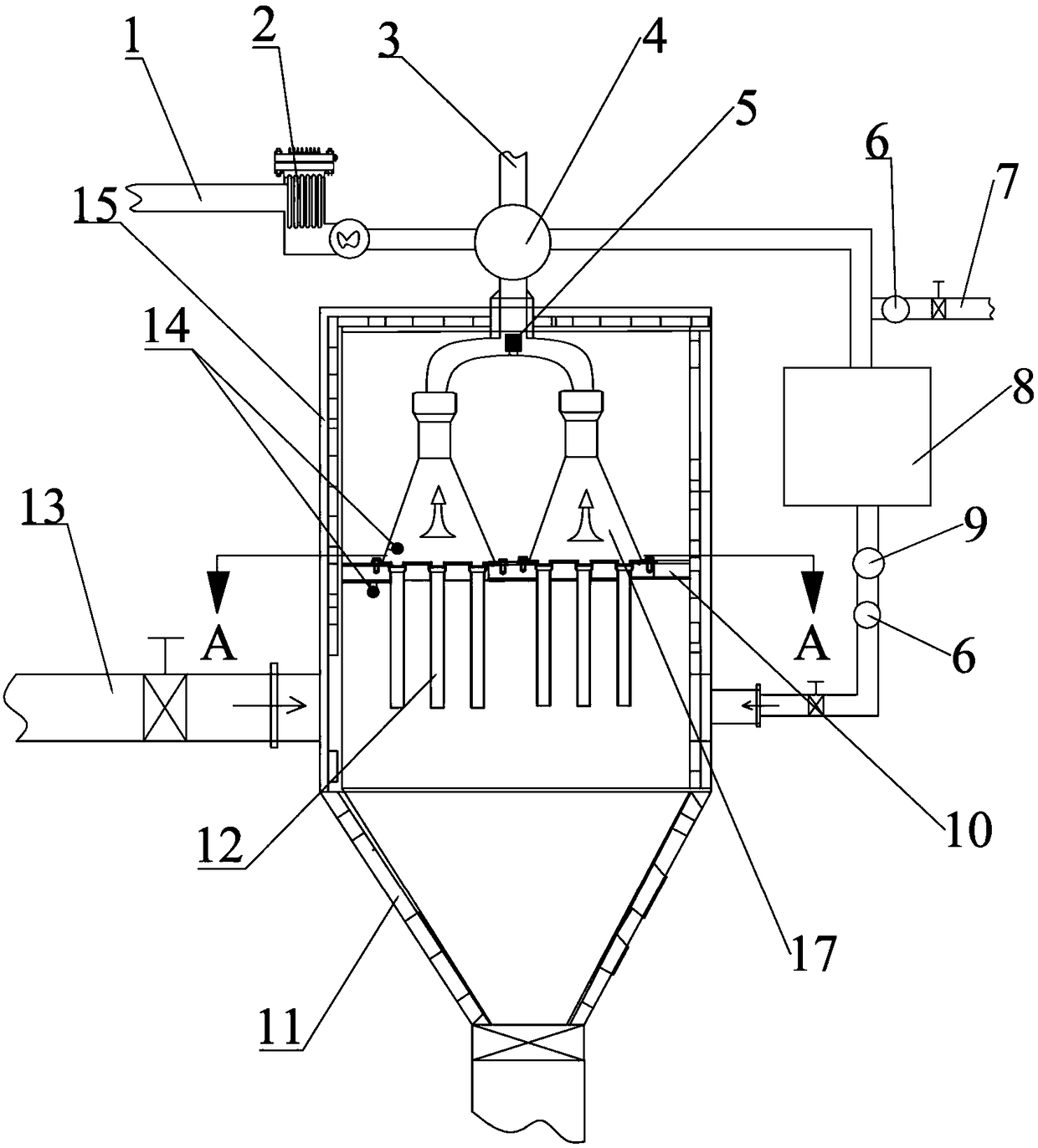

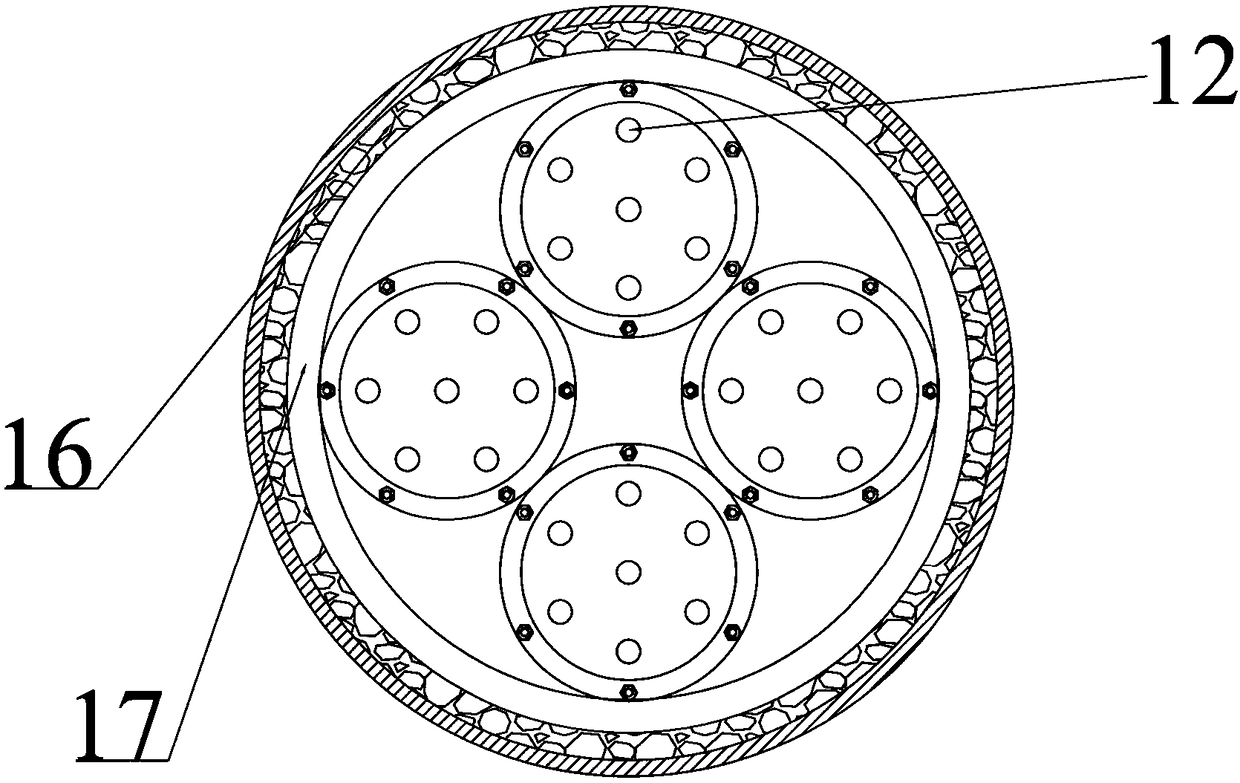

Dust removing and tar removing device and method for high-tar and high-dust high-temperature gas

ActiveCN105861077AEfficient removalExtended service lifeDispersed particle filtrationTransportation and packagingComing outCombustion

The invention relates to a dust removing and tar removing device and a dust removing and tar removing method for a high-tar and high-dust high-temperature gas. The dust removing and tar removing device for the high-tar and high-dust high-temperature gas comprises a filtering device, a casing device and a back blowing device, wherein the casing device is used for accommodating filters; the back blowing device is used for cleaning dust on the filters; the dust removing and tar removing device for the high-tar and high-dust high-temperature gas also comprises a high-temperature gas circulating device; the high-temperature gas circulating device comprises a circulated gas heating device used for heating a purified gas coming out from the filters; an inlet end of the circulated gas heating device is communicated with outlets of the filters; an outlet end of the circulated gas heating device is communicated with the casing device; the circulated gas heating device is provided with a gas supplementing device used for supplementing an oxygen-containing gas. The device provided by the invention, by combing back blowing and combustion manners, can effectively remove the pollution caused by the dust and tar on the filters, effectively prolongs and improves the service life and the filtration efficiency of the filters, decreases the regeneration time of the filters from 60h to 10h, and increases the service life of the filters by above 50%.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

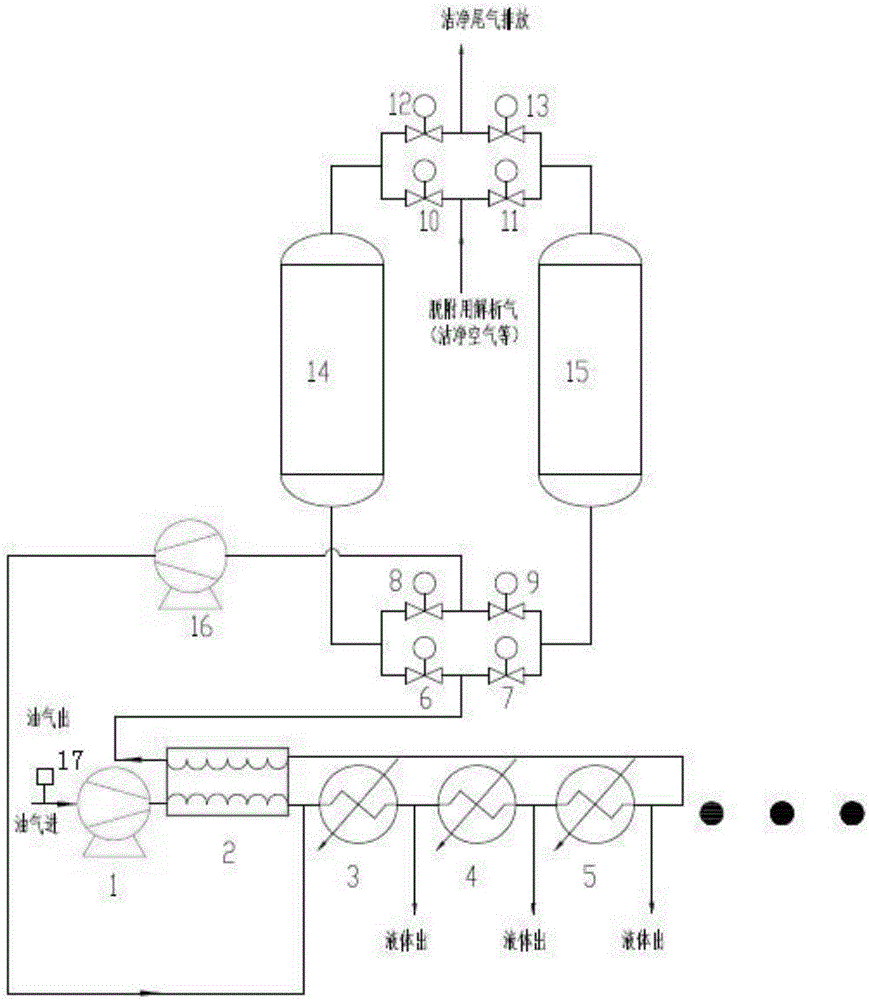

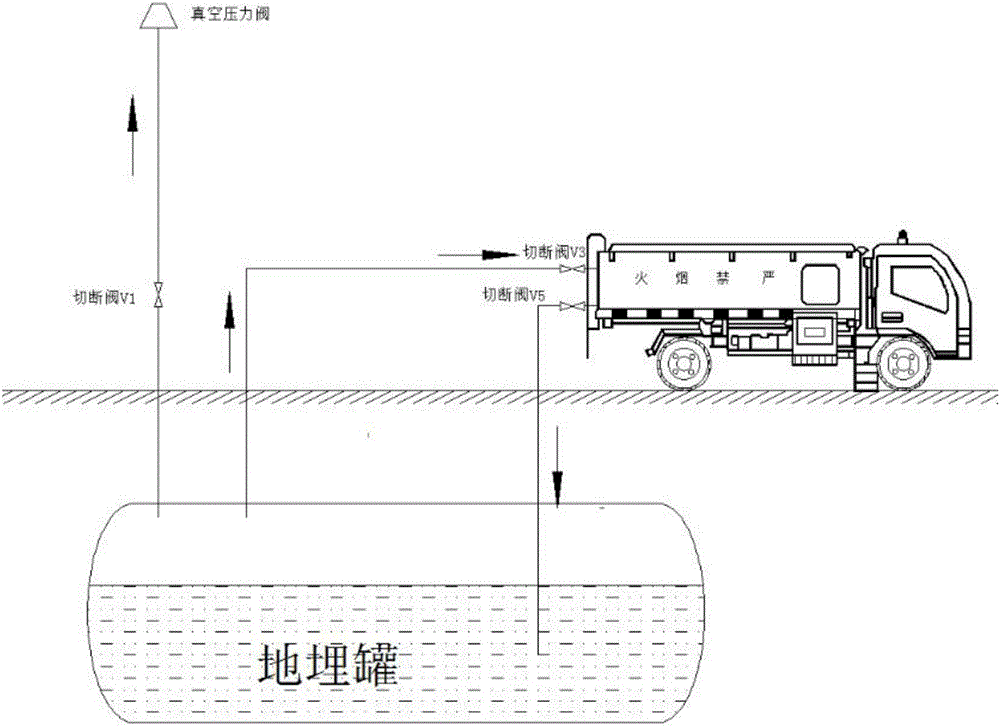

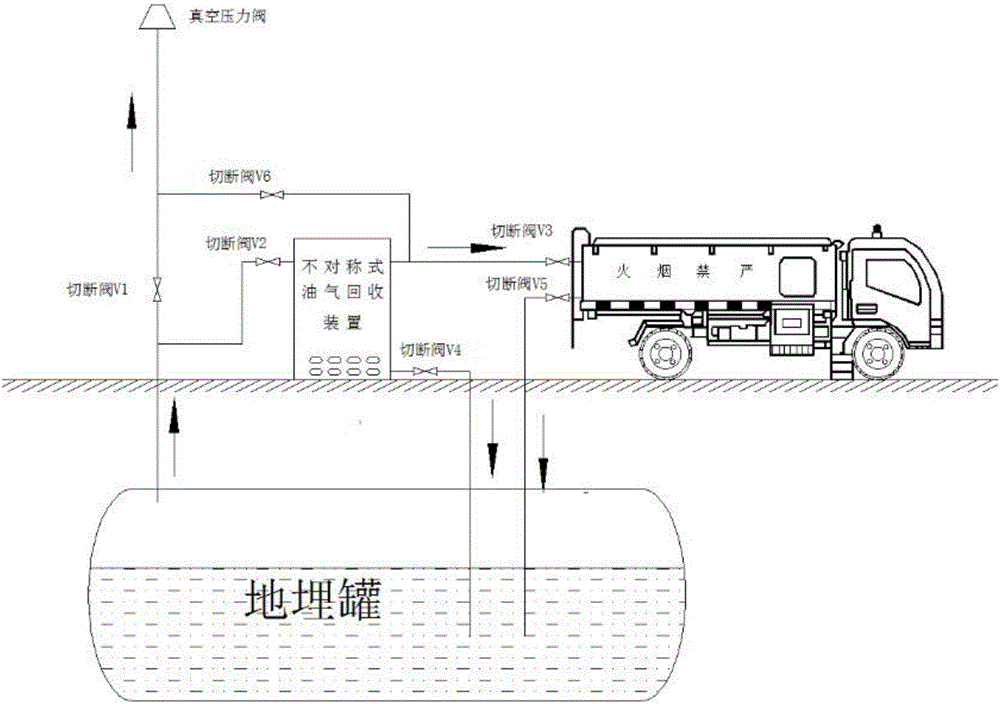

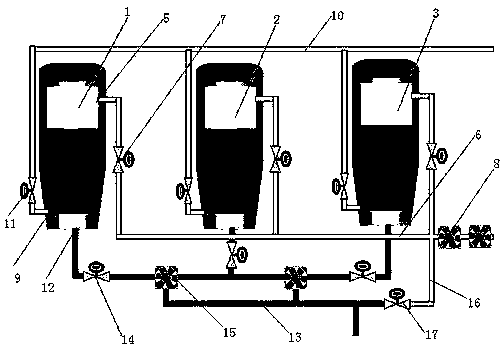

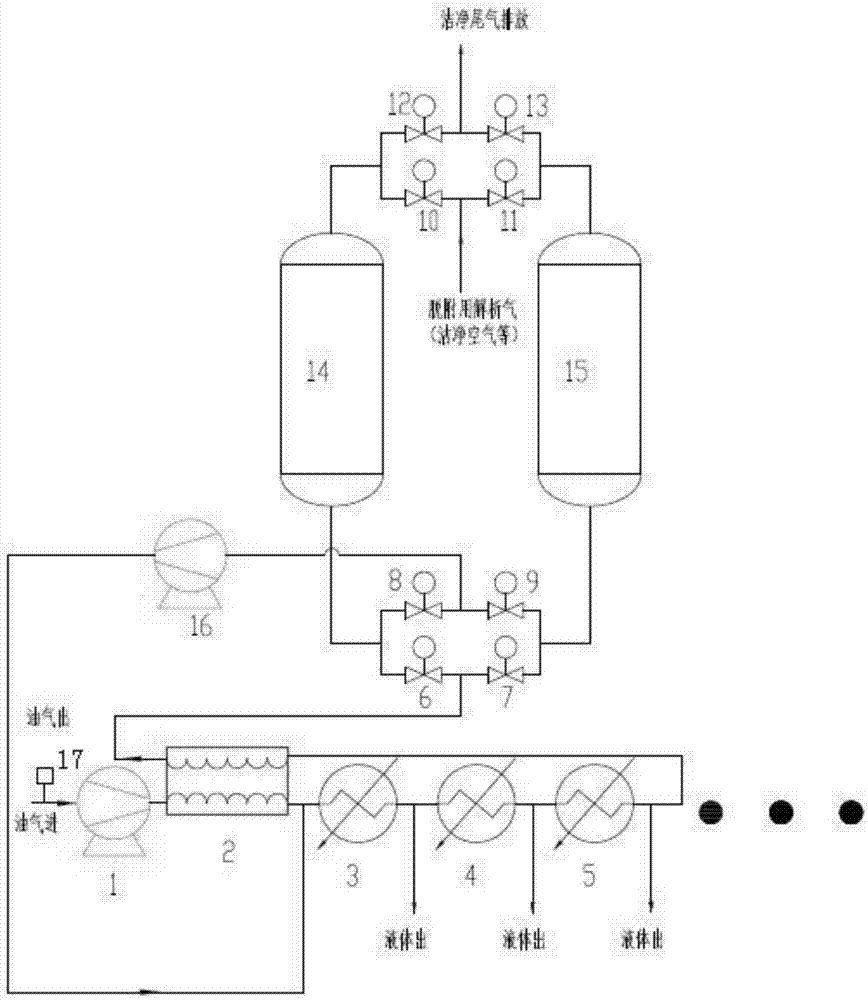

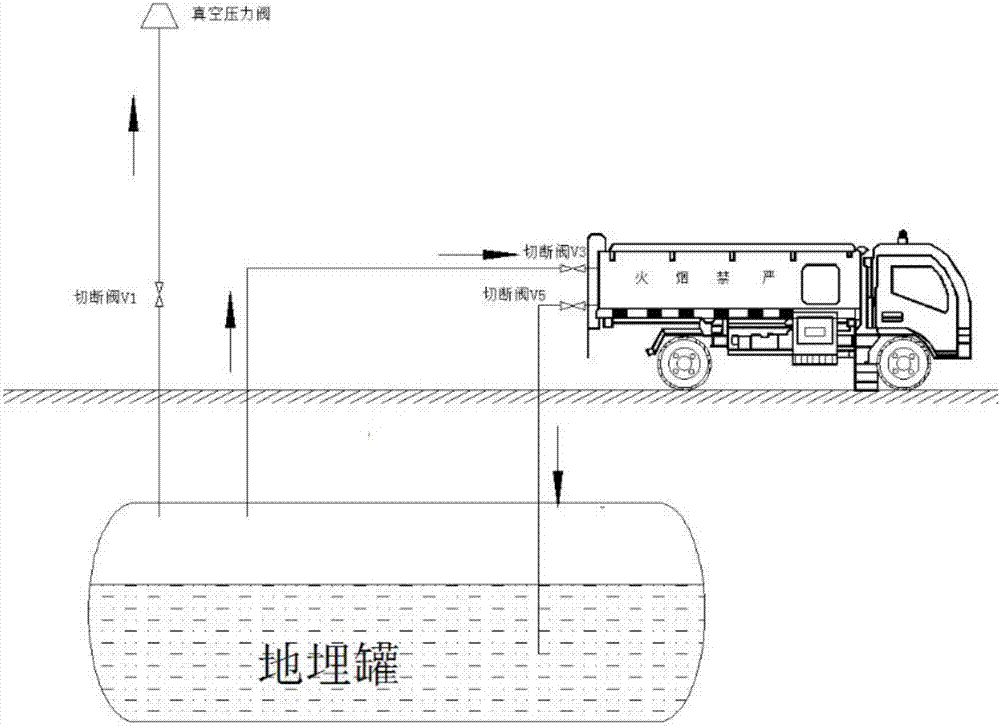

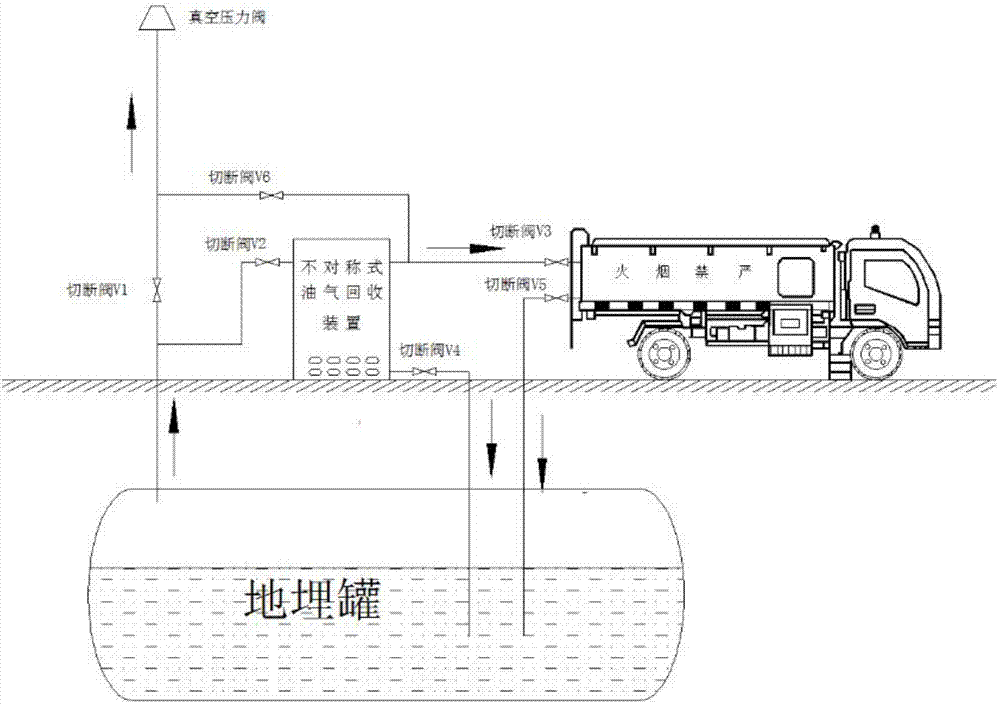

Recovery system and recovery method for oil gas absorbed and desorbed by asymmetric double pots

ActiveCN106310699AReduce the pumping volumeExtend regeneration timeGas treatmentDispersed particle separationActivated carbonRecovery method

The invention discloses a recovery system and a recovery method for an oil gas absorbed and desorbed by asymmetric double pots. The recovery system comprises a first stop valve, a first-level oil gas condenser, a second-level oil gas condenser, a second stop valve, a first-level big activated carbon canister and a third stop valve, wherein an oil gas inlet is connected with one end of the first stop valve; a positive input end of the first-level oil gas condenser is connected with the other end of the first stop valve; a positive output end of the first-level oil gas condenser is connected with an input end of the second-level oil gas condenser; an output end of the second-level oil gas condenser is connected with a negative input end of the first-level oil gas condenser; a negative output end of the first-level oil gas condenser is connected with one end of the second stop valve; the other end of the second stop valve is connected with one end of the first-level big activated carbon canister; one end of the third stop valve is connected with the other end of the first-level big activated carbon canister; the other end of the third stop valve is connected with a first oil gas outlet; the first stop valve, the first-level oil gas condenser, the second-level oil gas condenser, the first-level oil gas condenser, the second stop valve, the first-level big activated carbon canister and the third stop valve are successively connected and form an oil gas recycling subsystem.

Owner:上海聚宸新能源科技有限公司

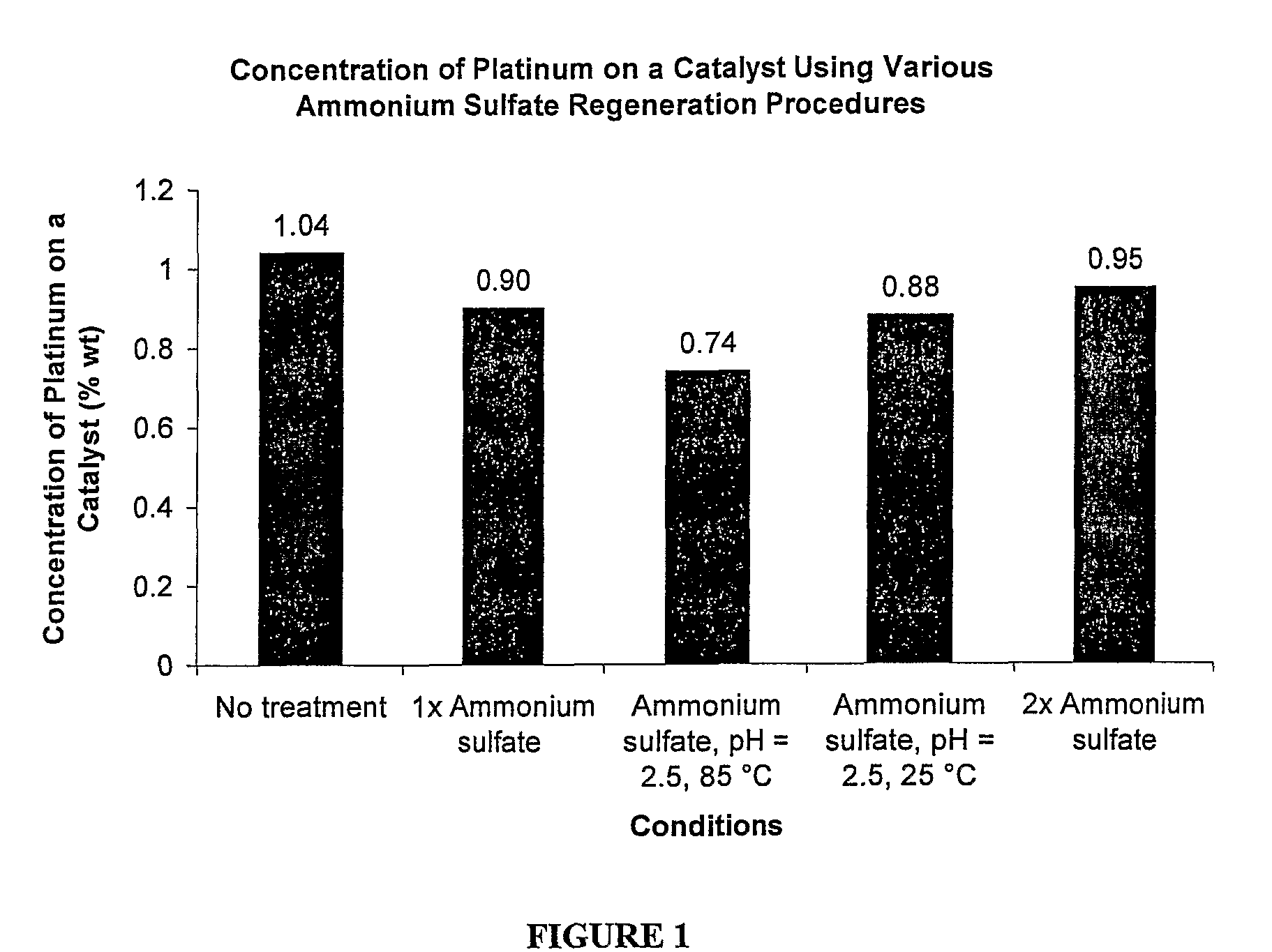

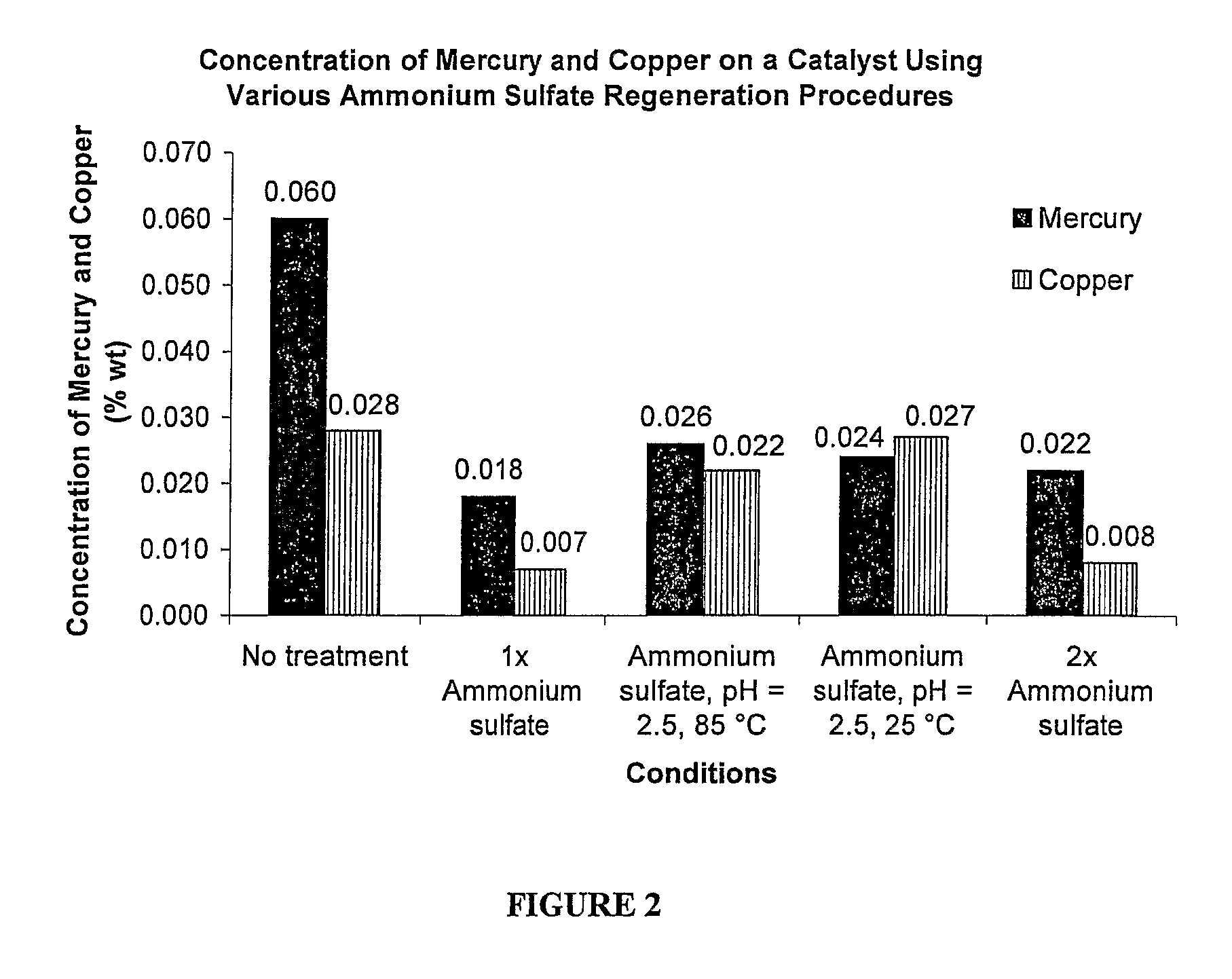

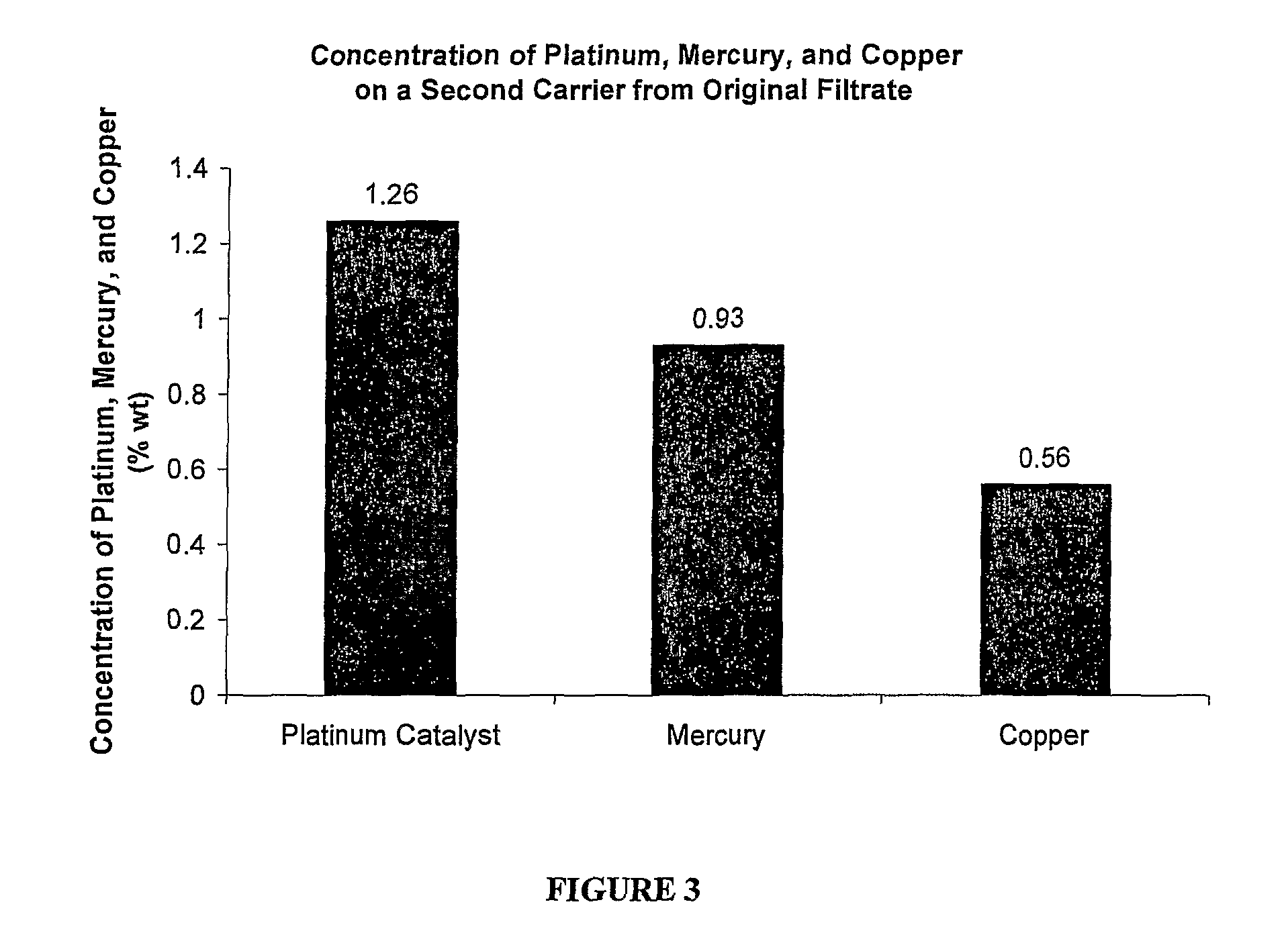

Method of regenerating a catalyst

InactiveUS7811955B2Extend regeneration timeLimit lossNitrogen compoundsOther chemical processesGraphitePt element

Owner:BASF AG

Method for purification of exhaust gas from internal combustion engine

ActiveUS8418444B2Low production costPlacement is limitedCombination devicesInternal combustion piston enginesHigh concentrationCombustion

Temperature range enabling combustion of high concentration hydrocarbon is enlarged, or high temperature gas is rapidly supplied to a latter part catalyst. Provided is a method for purification of exhaust gas from an internal combustion engine, by using a catalyst for increasing temperature of exhaust gas from an internal combustion engine, wherein hydrocarbon from 1,000 to 40,000 ppm by volume, as converted to methane, to the exhaust gas, is introduced at the upstream side of the catalyst for increasing temperature, along flow of the exhaust gas inside a passage of exhaust gas from the internal combustion engine.

Owner:UMICORE SHOKUBAI USA +1

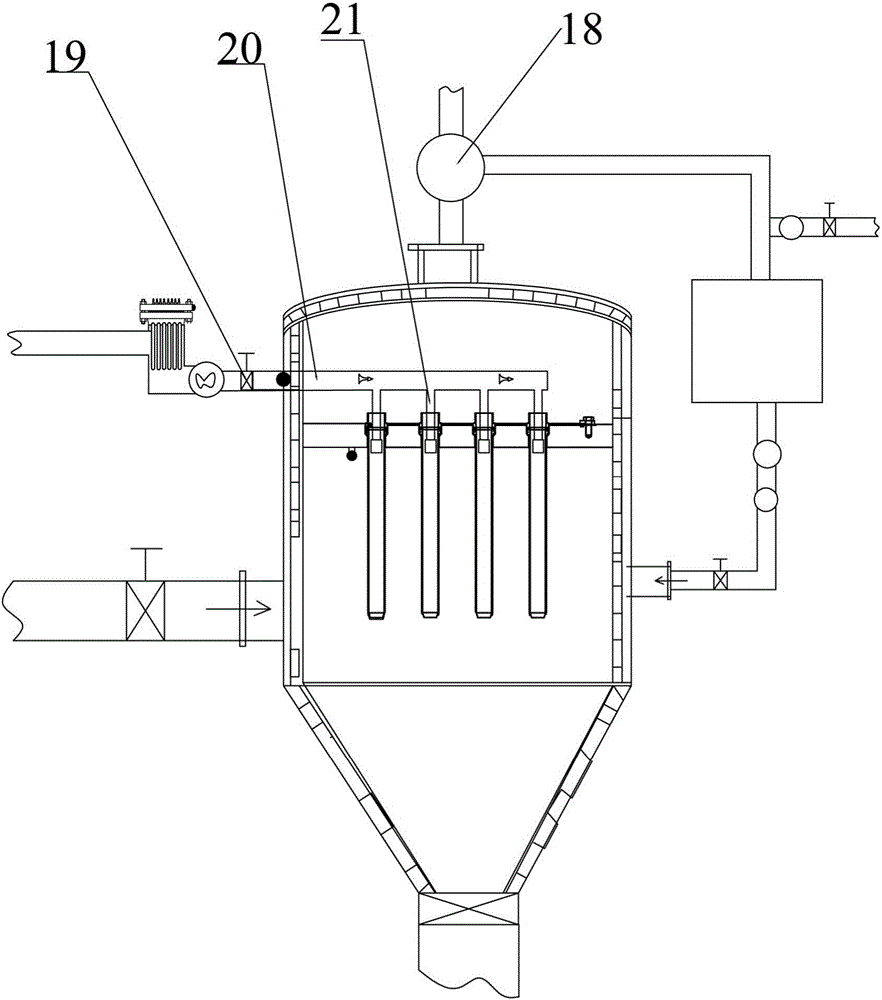

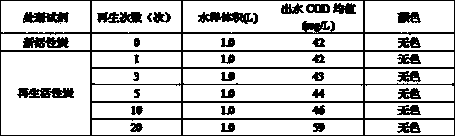

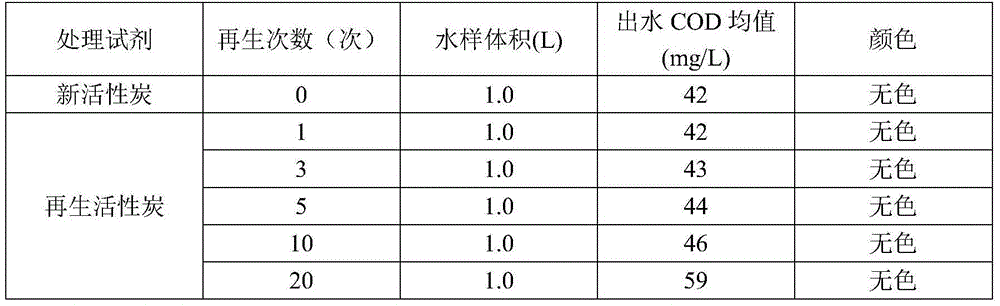

Device and method for regeneration of powdered activated carbon

ActiveCN103752296AHigh operational control requirementsHigh pollutant removal efficiency and decolorization efficiencyOther chemical processesCombustible gas purificationExhaust gasActivated carbon

The invention discloses a device and a method for regeneration of powdered activated carbon. The device comprises a furnace body, wherein a retractable furnace door is arranged on the furnace body; an internal hollow hearth is arranged inside the furnace body; insulating layers are arranged at the four walls and the periphery of the top part of the hearth; heating wires are embedded in the insulating layers. The device is characterized by also comprising an exhaust and tail gas combustion treatment system, an intake valve, a bracket structure, more than one drawer-type box body and a gas outlet valve, wherein the bracket structure is fixedly arranged inside the hearth; the drawer-type box body is detachably arranged on the bracket structure; the exhaust and tail gas combustion treatment system is fixedly arranged at the top part of the furnace body; the intake valve is fixedly arranged at the top of the furnace body; the gas outlet valve is fixedly arranged at the bottom of the furnace body. Compared with the prior art, the regeneration treatment efficiency can be greatly improved, energy consumption and time are saved, and the operation is simple and feasible.

Owner:HUBEI JUNJI WATER TREATMENT

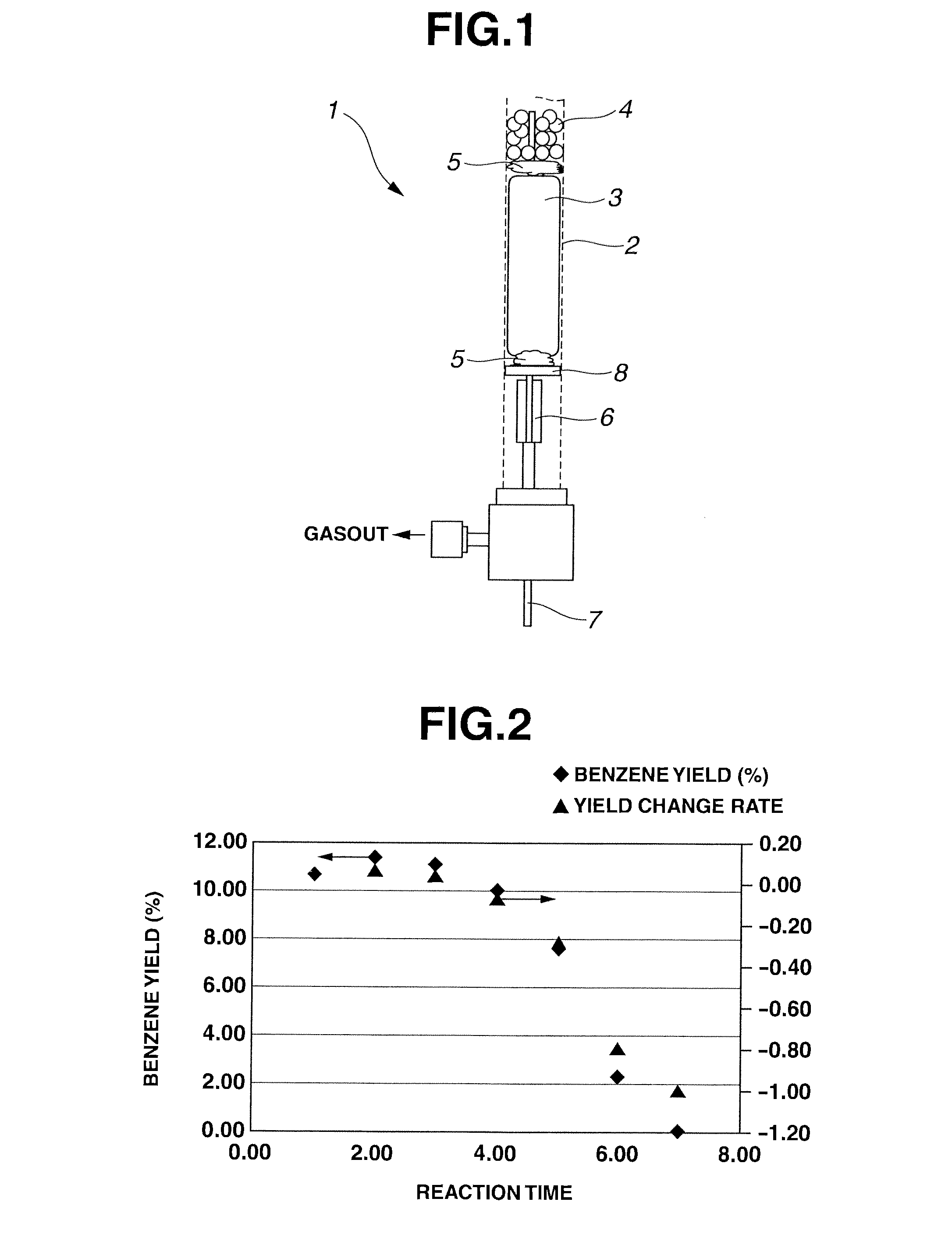

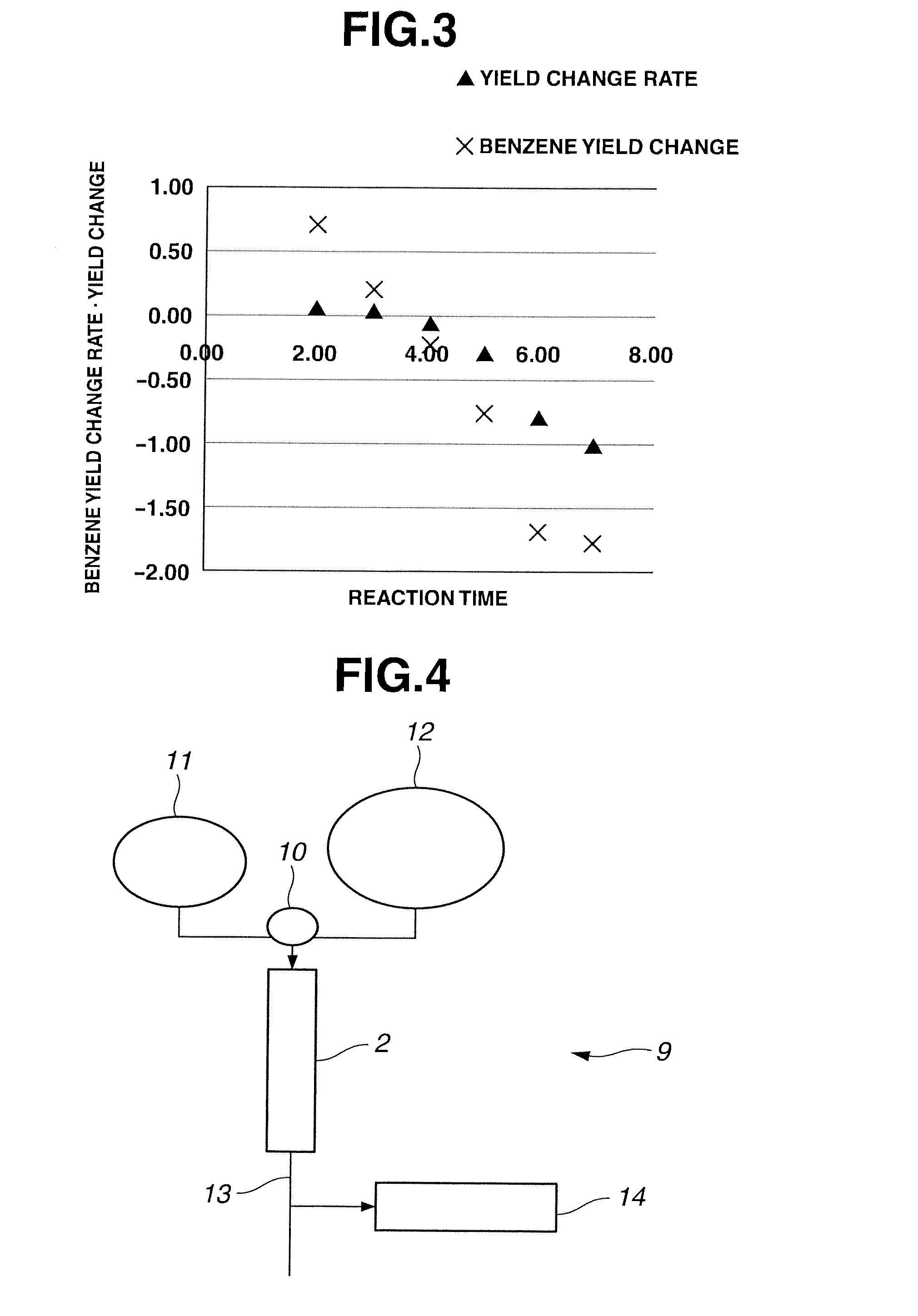

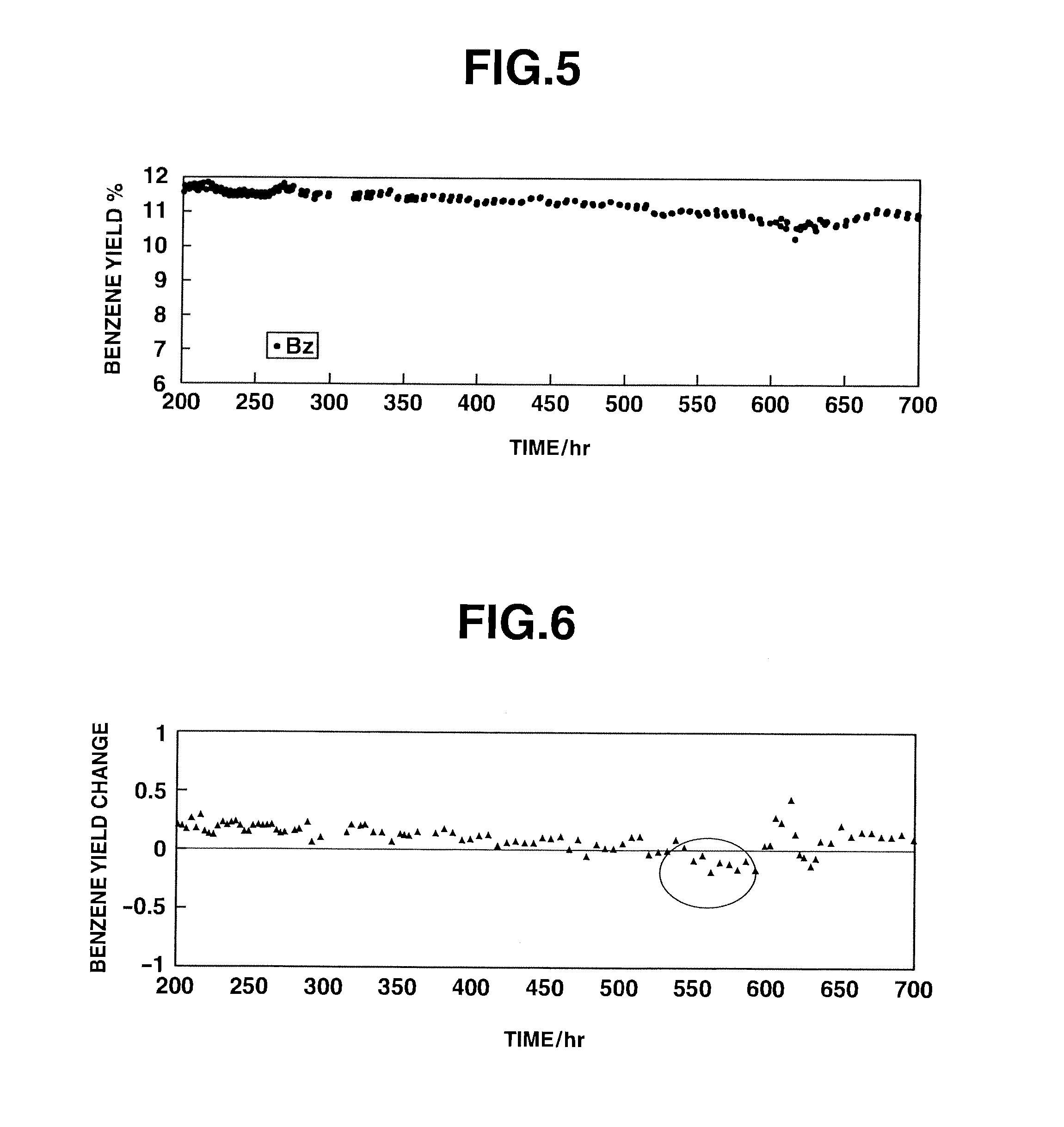

Method for producing aromatic hydrocarbon

InactiveUS20130090506A1Extend regeneration timeMolecular sieve catalystCatalystsContact reactionReaction step

When producing an aromatic hydrocarbon by a contact reaction of a lower hydrocarbon with a catalyst, the aromatic hydrocarbon is produced stably for a long time while maintaining a high aromatic hydrocarbon yield.In a process for producing an aromatic hydrocarbon by being equipped with a reaction step for obtaining the aromatic hydrocarbon by a contact reaction of a lower hydrocarbon with a catalyst and a regeneration step for regenerating the catalyst used in this reaction step, and by repeating the reaction step and the regeneration step, yield of the aromatic hydrocarbon is calculated at constant intervals of time. A yield as the standard is set up from this calculated yield. Based on the change of yield relative to this standard, the regeneration time of the regeneration step is prolonged. A threshold value is set up in the change of yield. In case that the change of yield of the aromatic hydrocarbon has been lower than the threshold value in the reaction step, the regeneration time of the regeneration step is prolonged.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

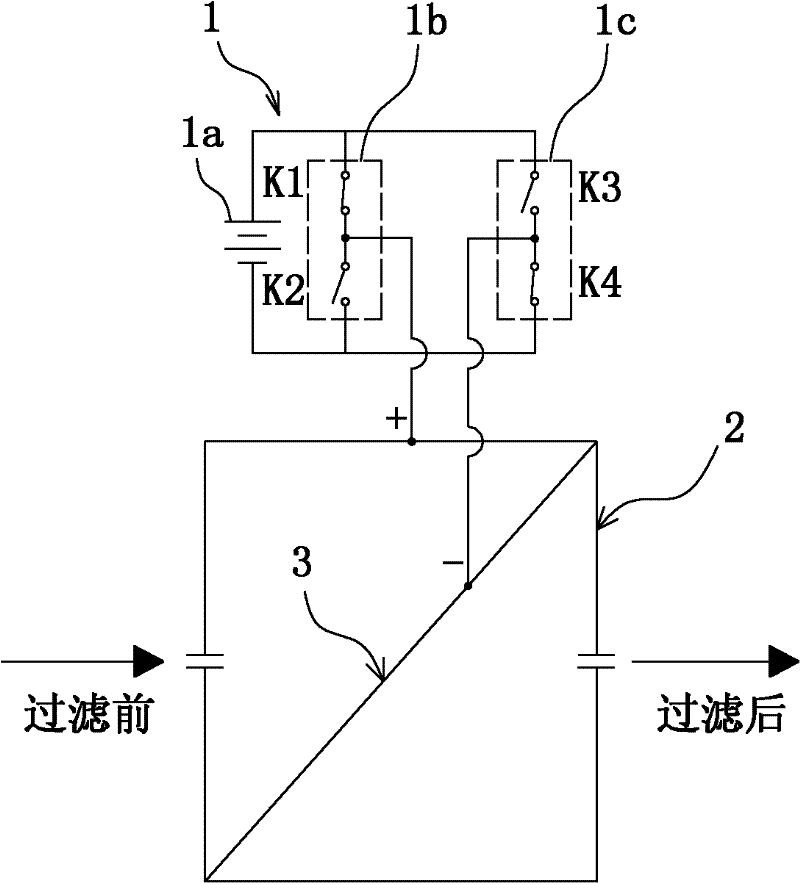

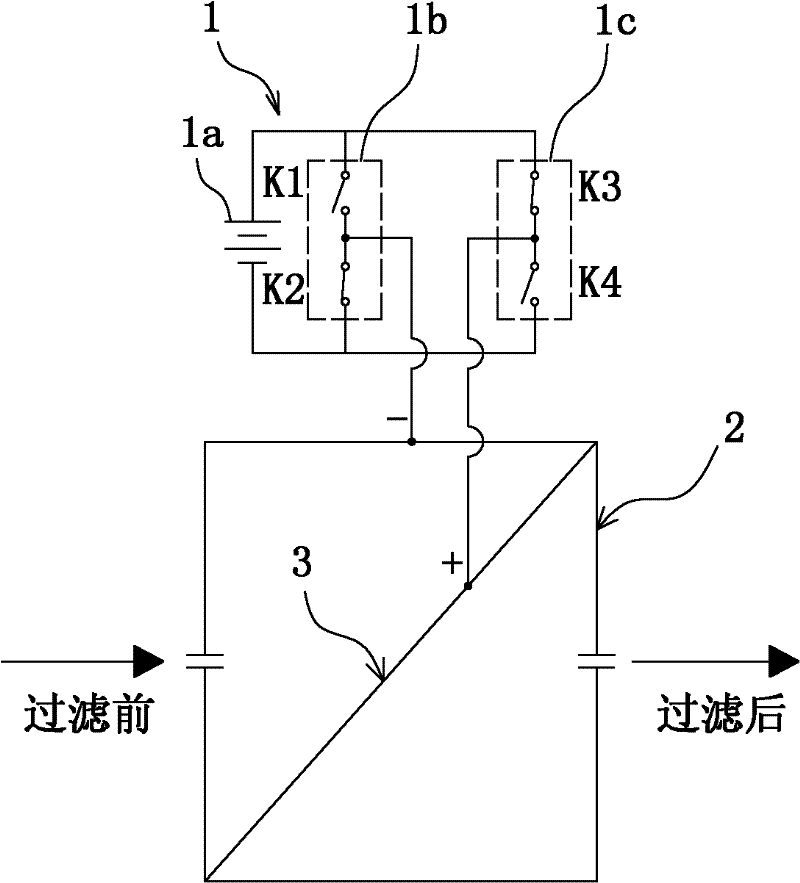

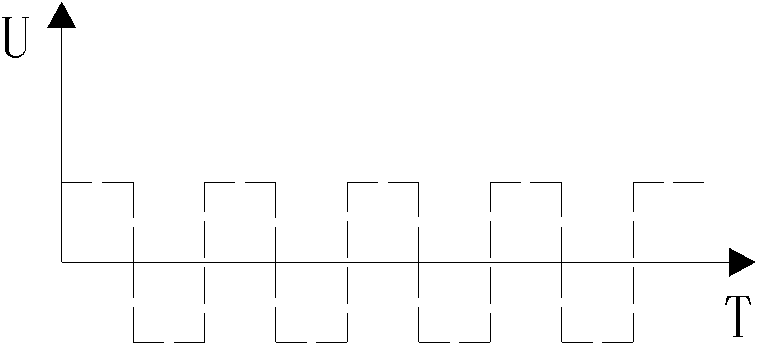

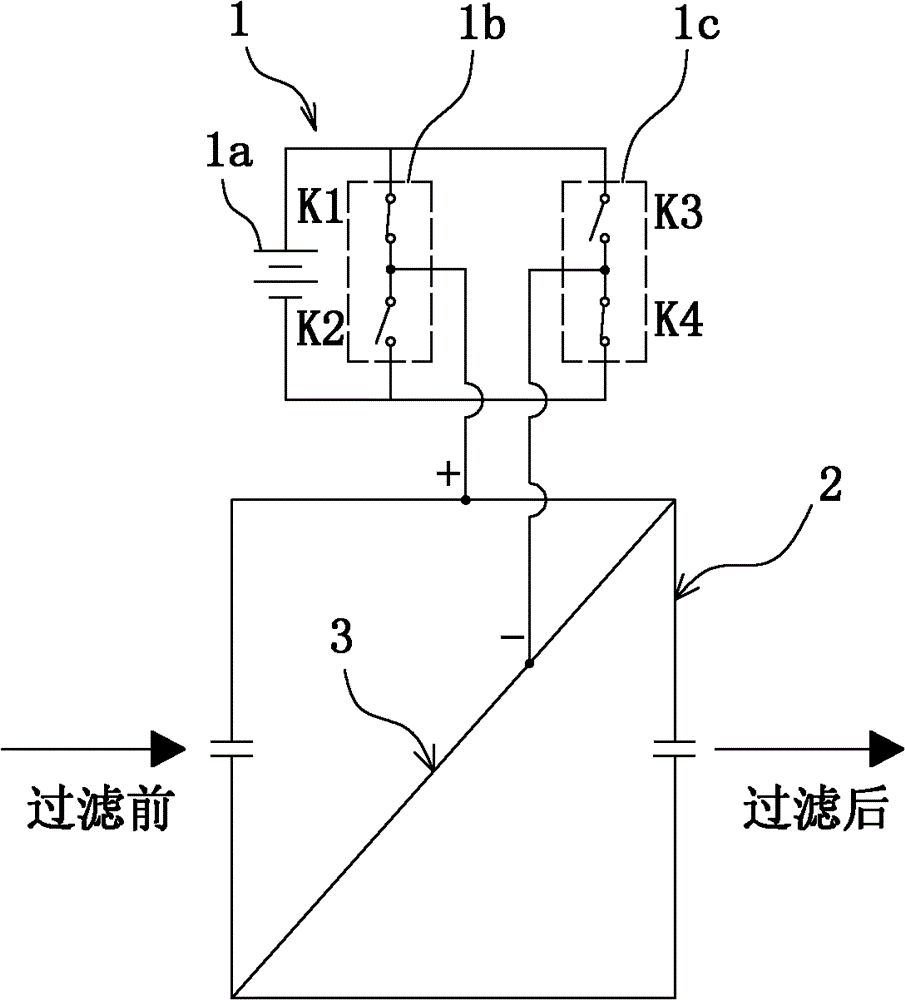

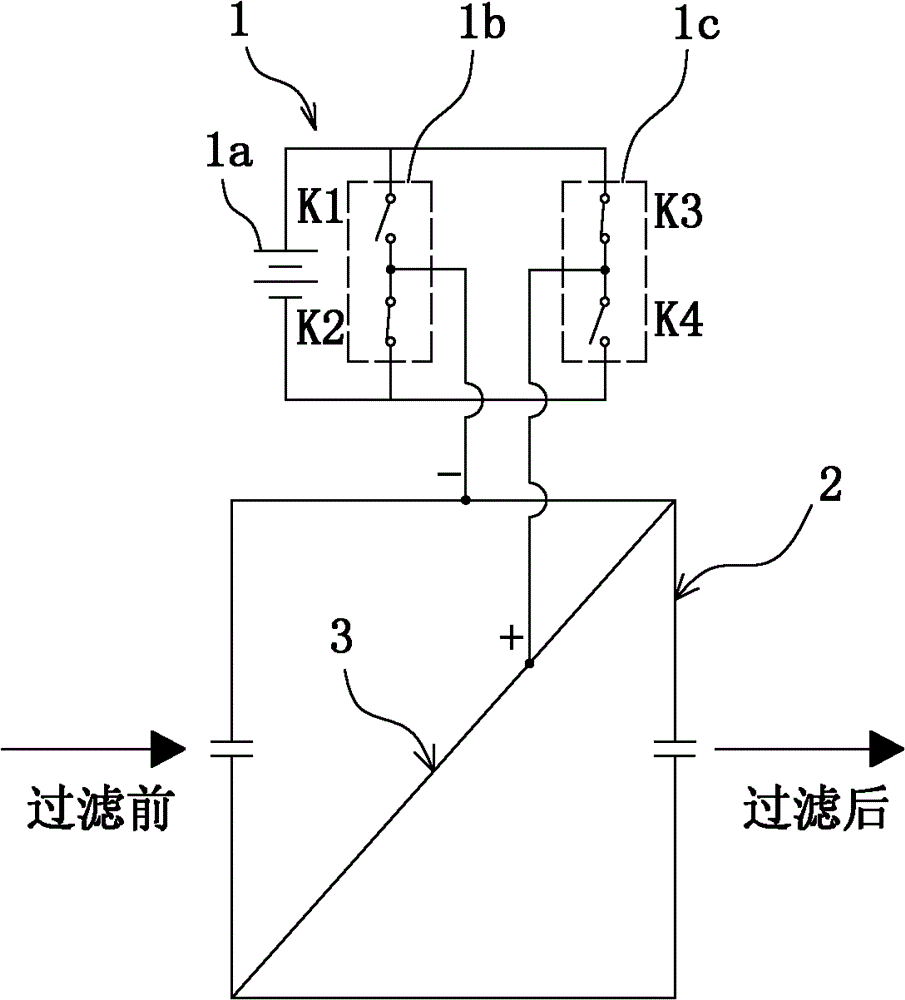

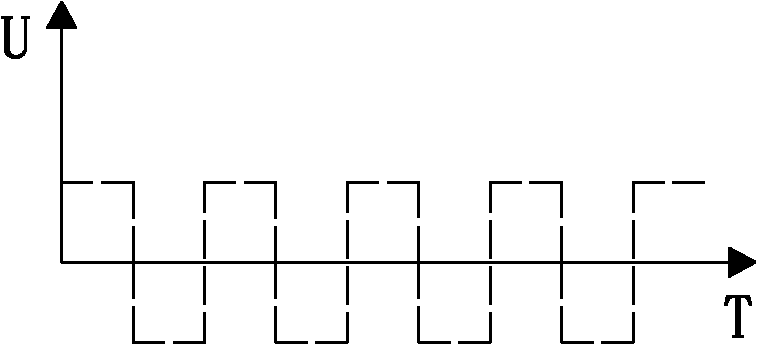

Filtering method and filtering device with alternating electric field on filter element

ActiveCN102380250AReduce the rate of formationImprove stabilitySemi-permeable membranesStationary filtering element filtersEngineeringElectric field

The invention discloses a filtering method, which not only can prevent charged particles from polluting a filter element, but also can increase filtering stability. The method includes that alternating voltage of 10HZ to 50HZ is applied between the filter element and a shell of a filtering device when substances to be filtered realize gas-solid or liquid-solid separation via the filtering device. Under the action of the alternating electric field, the charged particles in the filtering device move repeatedly, as masses of the particles are different and flowing speeds of the particles under the action of the same force are different, the particles with different masses can be separated within a certain space, so that the particles with different masses are successively distributed between the filter element and the shell, and the integral filtering stability is increased. The invention further provides a filtering device comprising a shell and a filter element which are insulated from each other, and the shell and the filter element are respectively connected with two output poles of a power polarity converting circuit with the alternating frequency of 10HZ to 50HZ.

Owner:CHENGDU INTERMENT TECH

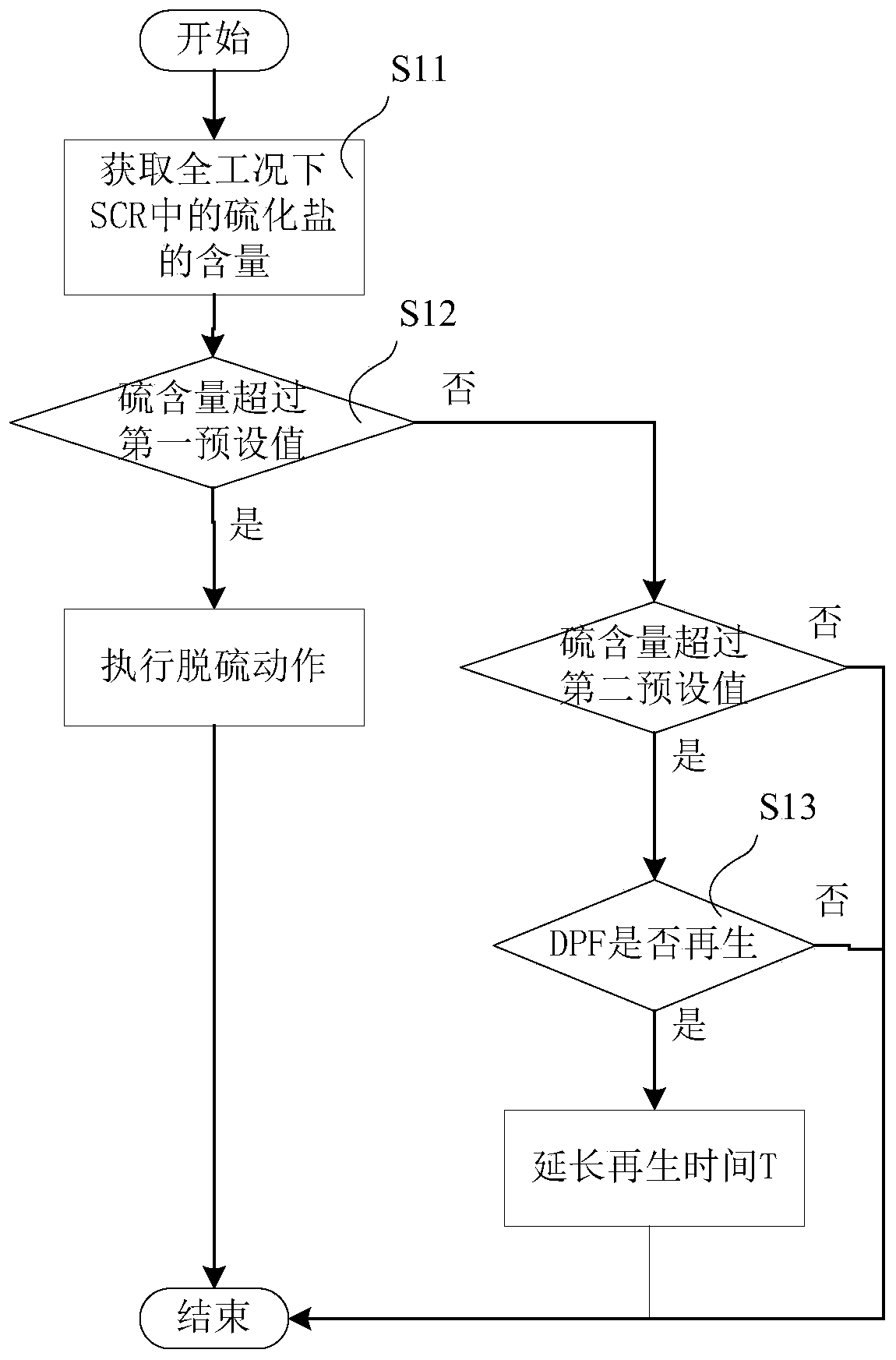

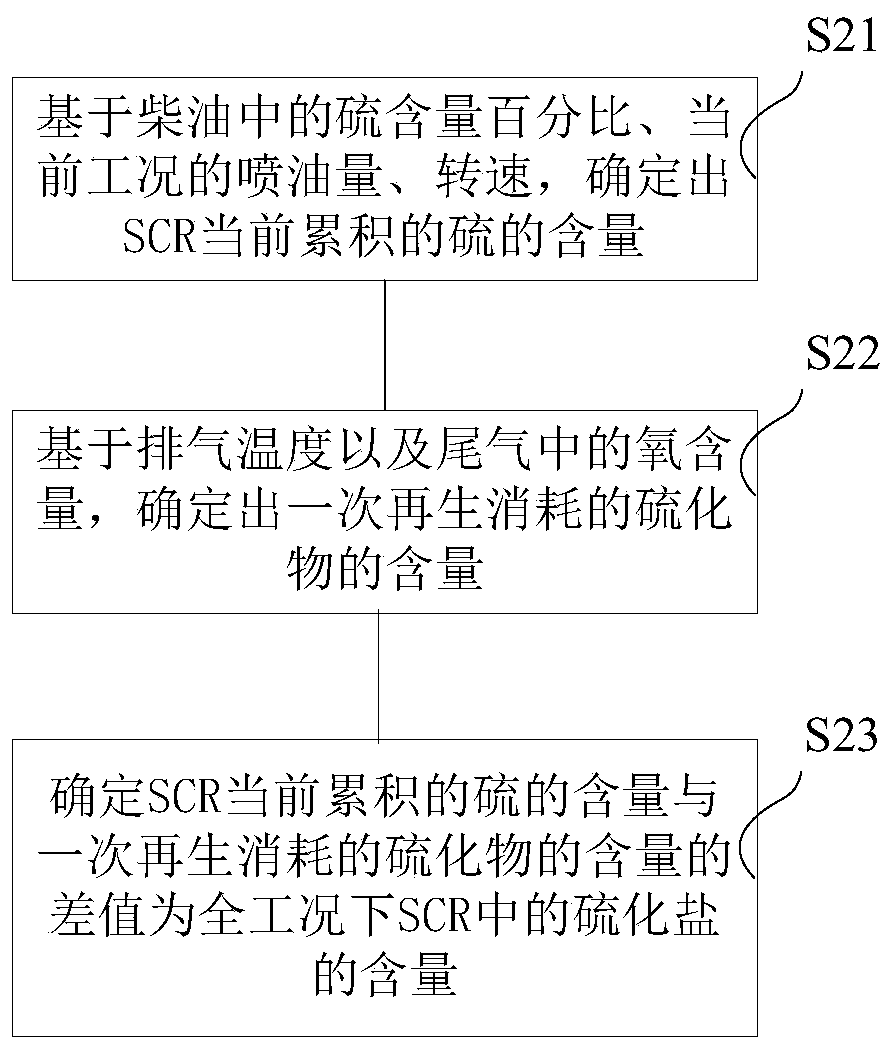

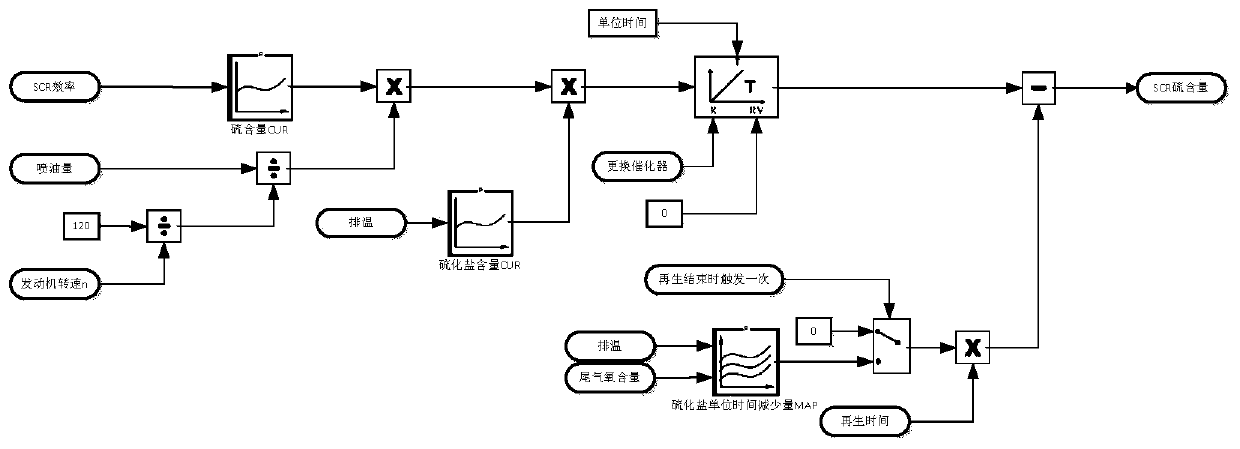

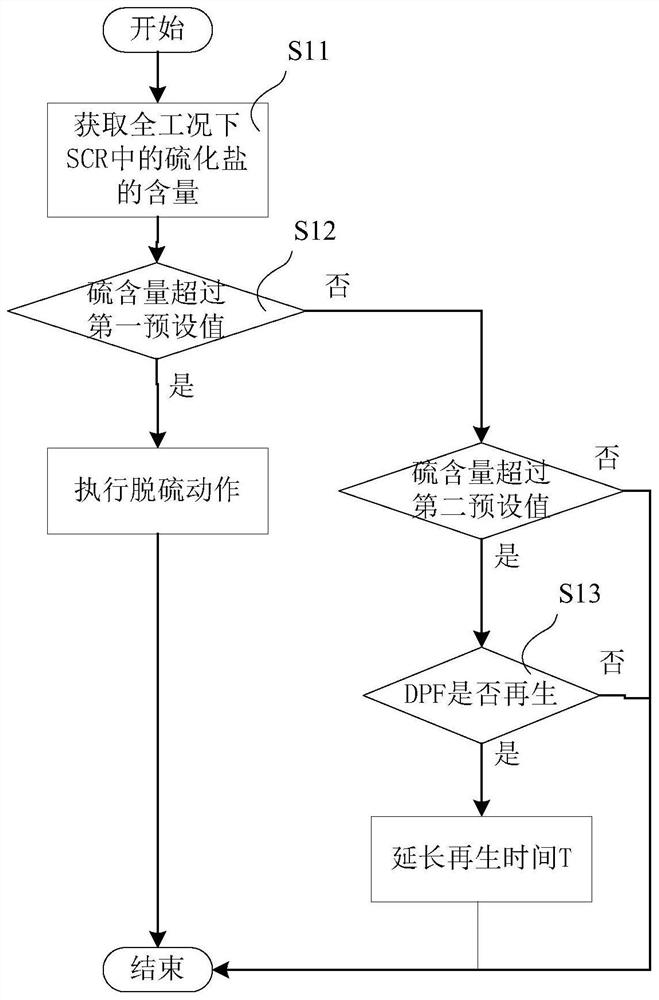

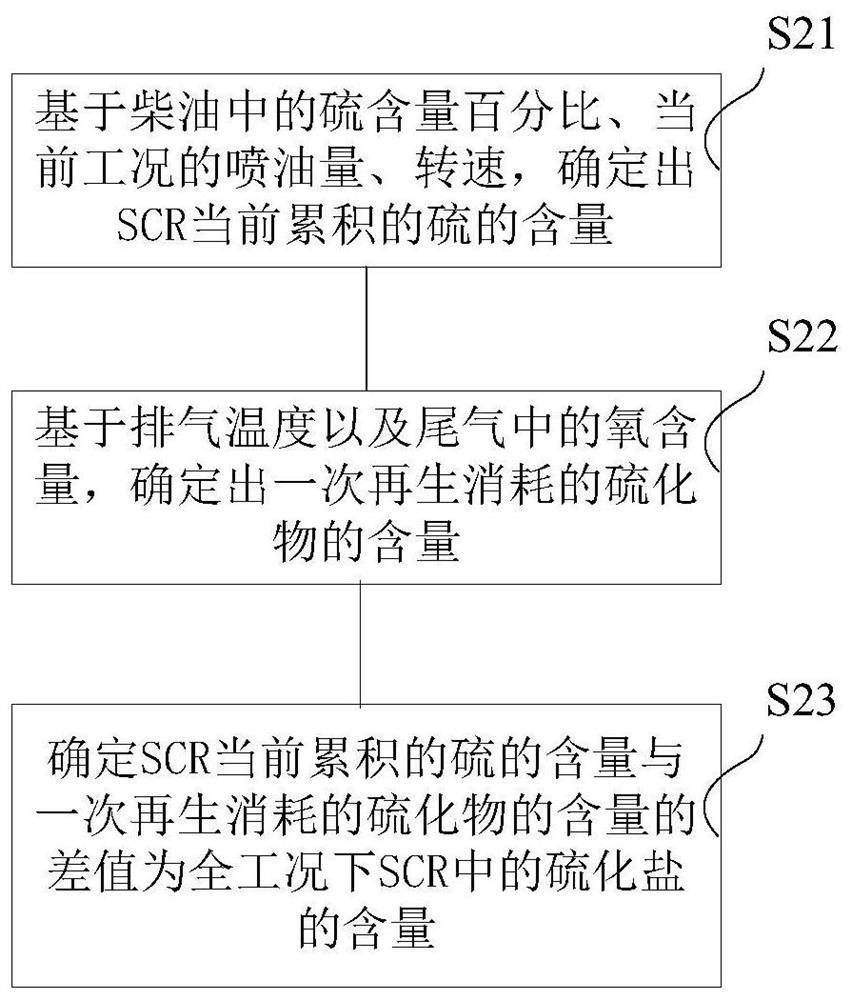

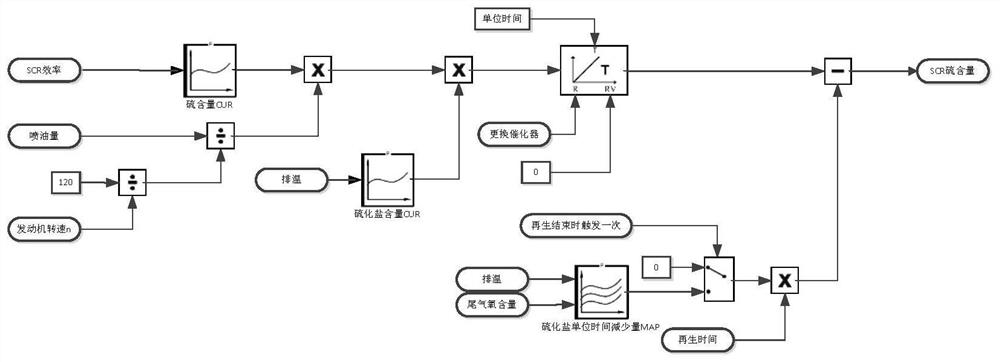

Desulfurization control method and device, storage medium and electronic equipment

ActiveCN111140319AExtend regeneration timeTo achieve the effect of desulfurization in advanceGas treatmentInternal combustion piston enginesSulfidationProcess engineering

The embodiment of the invention provides a desulfurization control method and device, a storage medium and electronic equipment. The method comprises the following steps that firstly, the content of sulfide salt in SCR is obtained under all working conditions; whether the content of the sulphide salt is greater than a first preset value or not is judged, if so, a desulfurization action is executed, if not, whether the content of the sulphide salt is greater than a second preset value or not is judged, if so, a regeneration state of DPF is obtained, and if the regeneration state is regeneration, the regeneration time is controlled to be a third preset value, wherein the first preset value is greater than the second preset value, the third preset value is greater than the control duration during the normal regeneration, therefore, according to the scheme, when the content of the sulfide salt is greater than the first preset value, the desulfurization action is executed, and when the content of the sulfide salt is less than the first preset value and greater than the second preset value, the regeneration time is prolonged, so that the accumulated degree of sulfur can be judged in advance, thereby achieving the effect of desulfurization in advance.

Owner:WEICHAI POWER CO LTD

Acid precipitation treatment system and treatment method

InactiveCN109045773AExtended service lifeExtend regeneration timeChlorine/hydrogen-chloride purificationSedimentation settling tanksSlagElectricity

Owner:JIANGSU YONGJIN METAL TECHNOLOGY CO LTD

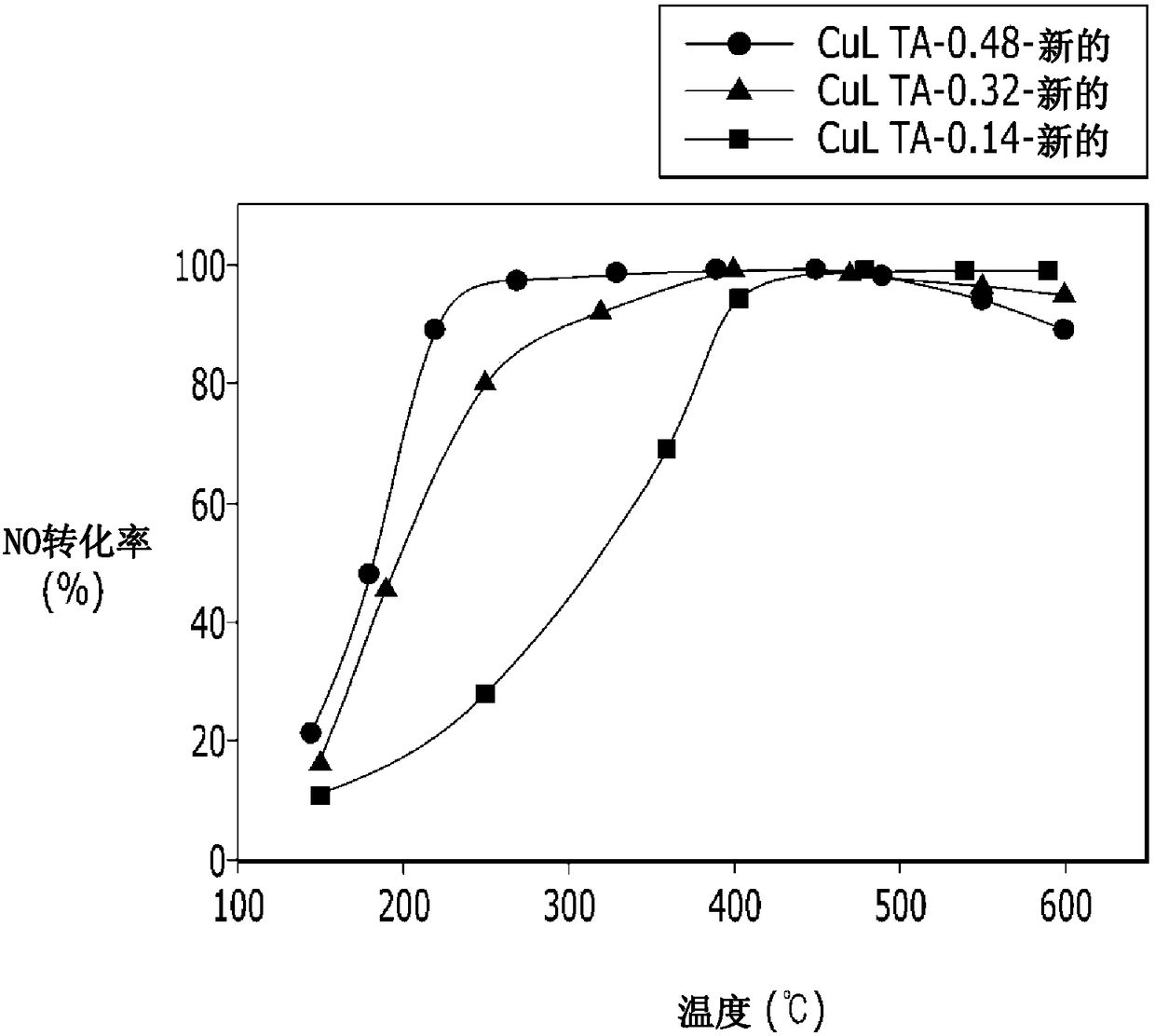

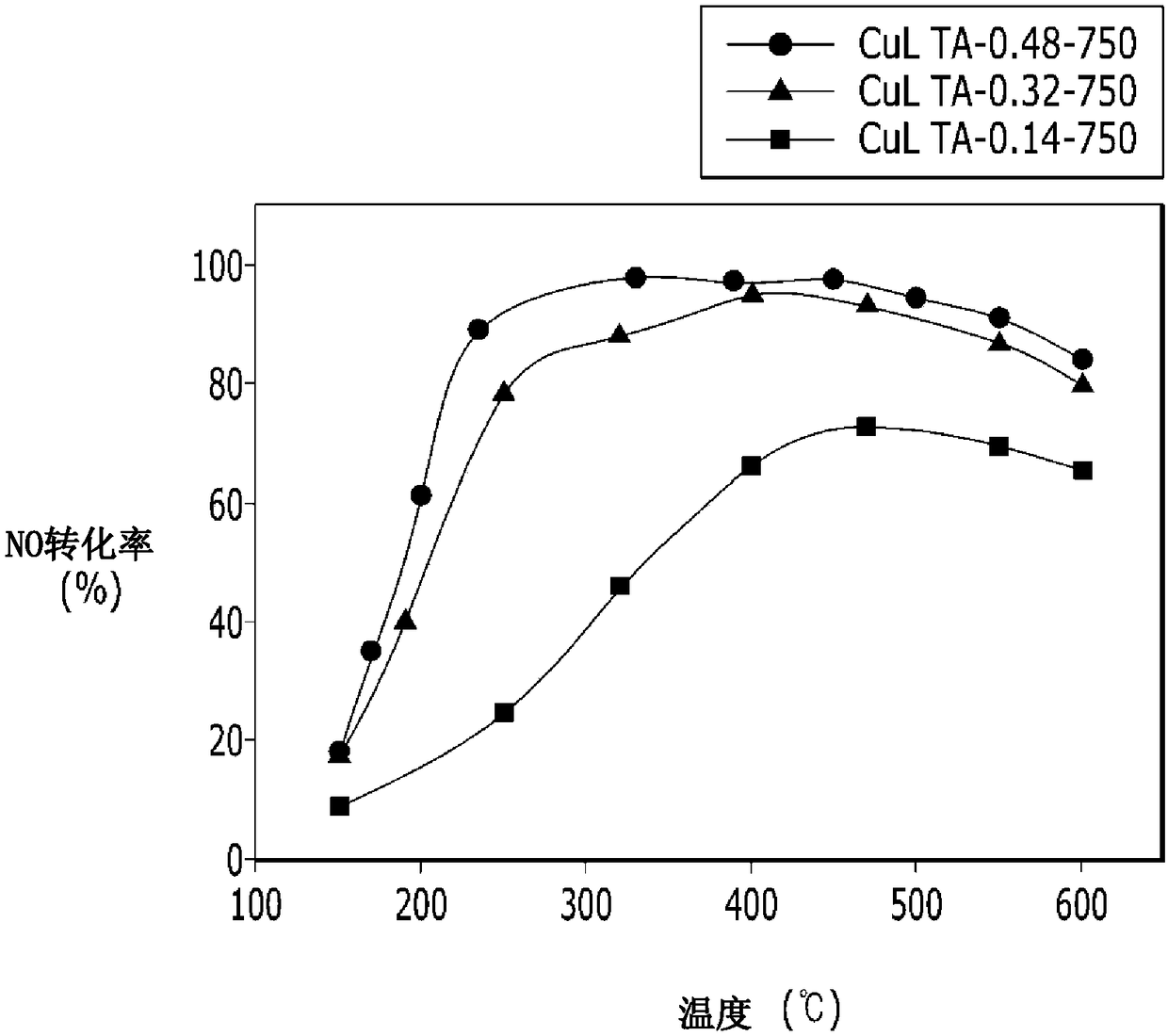

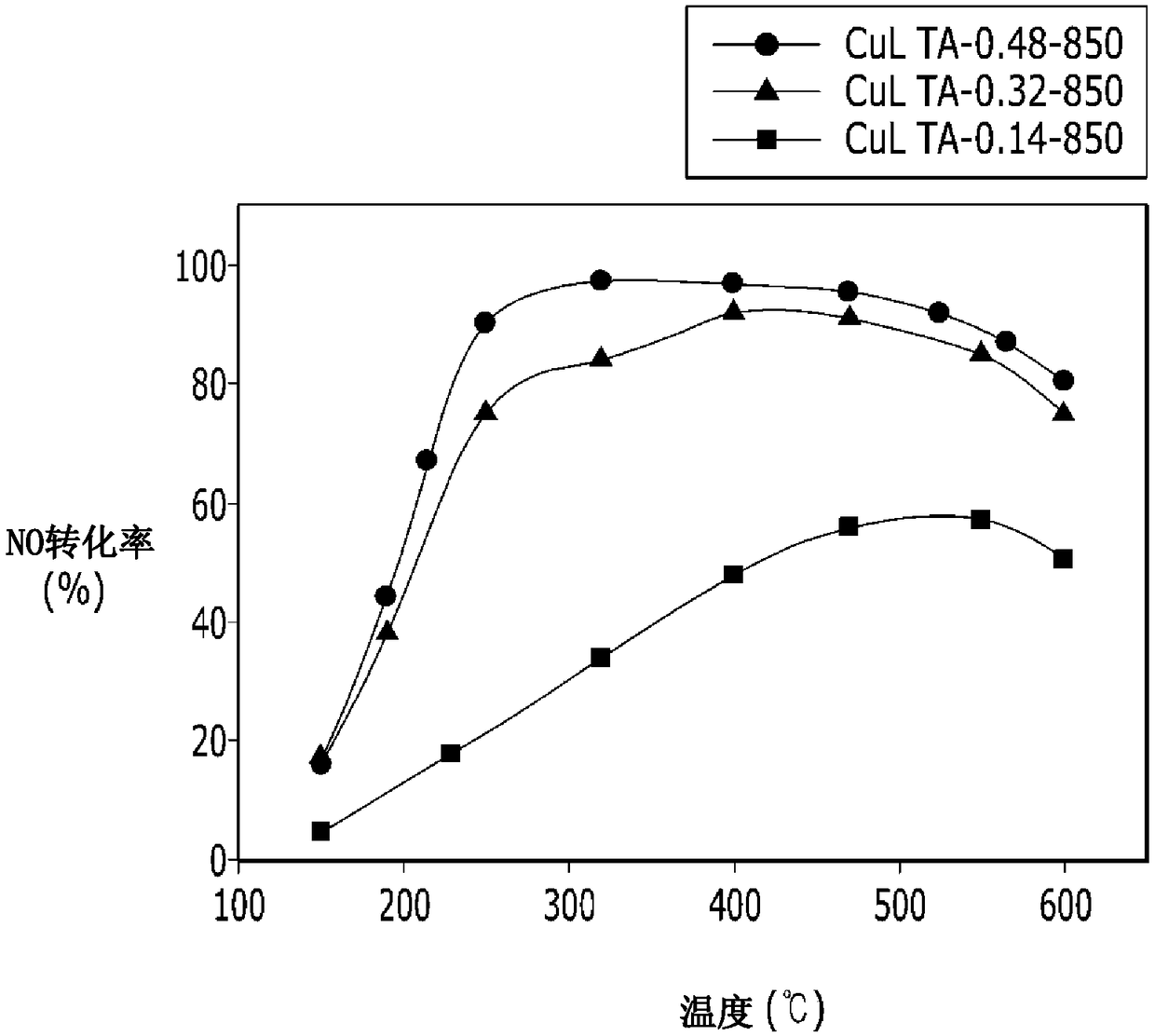

Cu/LTA catalyst and exhaust system, and manufacturing method of Cu/LTA catalyst

ActiveCN108071450AGood hydrothermal stabilityHeavy loadGas treatmentMolecular sieve catalystsCopperDiesel particulate filter

Provided herein is an exhaust system comprising a diesel particulate filter (SDPF) coated with a selective catalytic reduction wherein the SCR is coated with a Cu / LTA catalyst comprising a LTA zeolitethat includes copper ions and the SCR is coated on a high pore diesel particulate matter filter, wherein a ratio of copper and aluminum is from about 0.14 to about 0.48, and wherein the Si / Al ratio of the LTA zeolite is from about 8 to about 100.

Owner:HYUNDAI MOTOR CO LTD +1

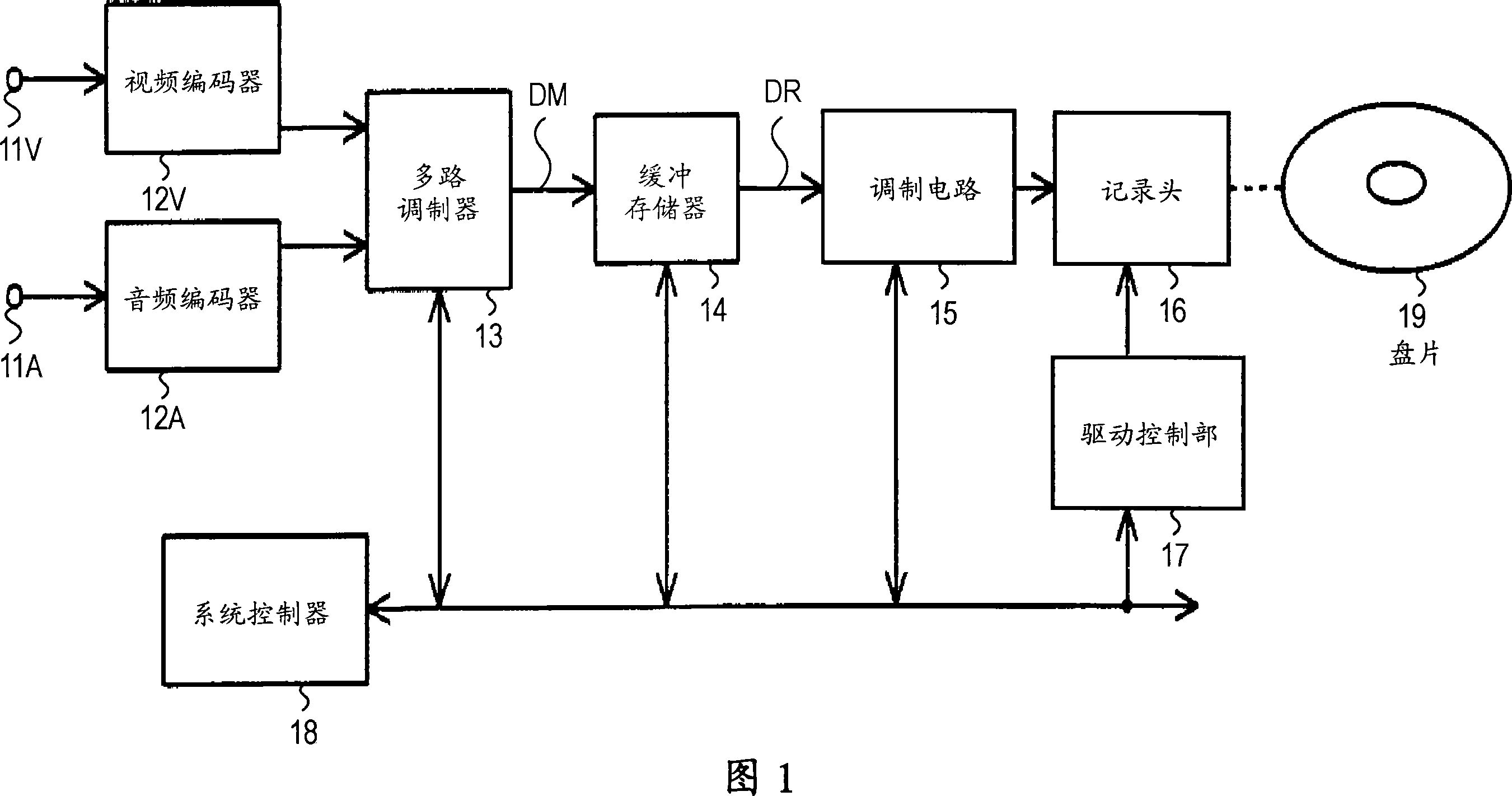

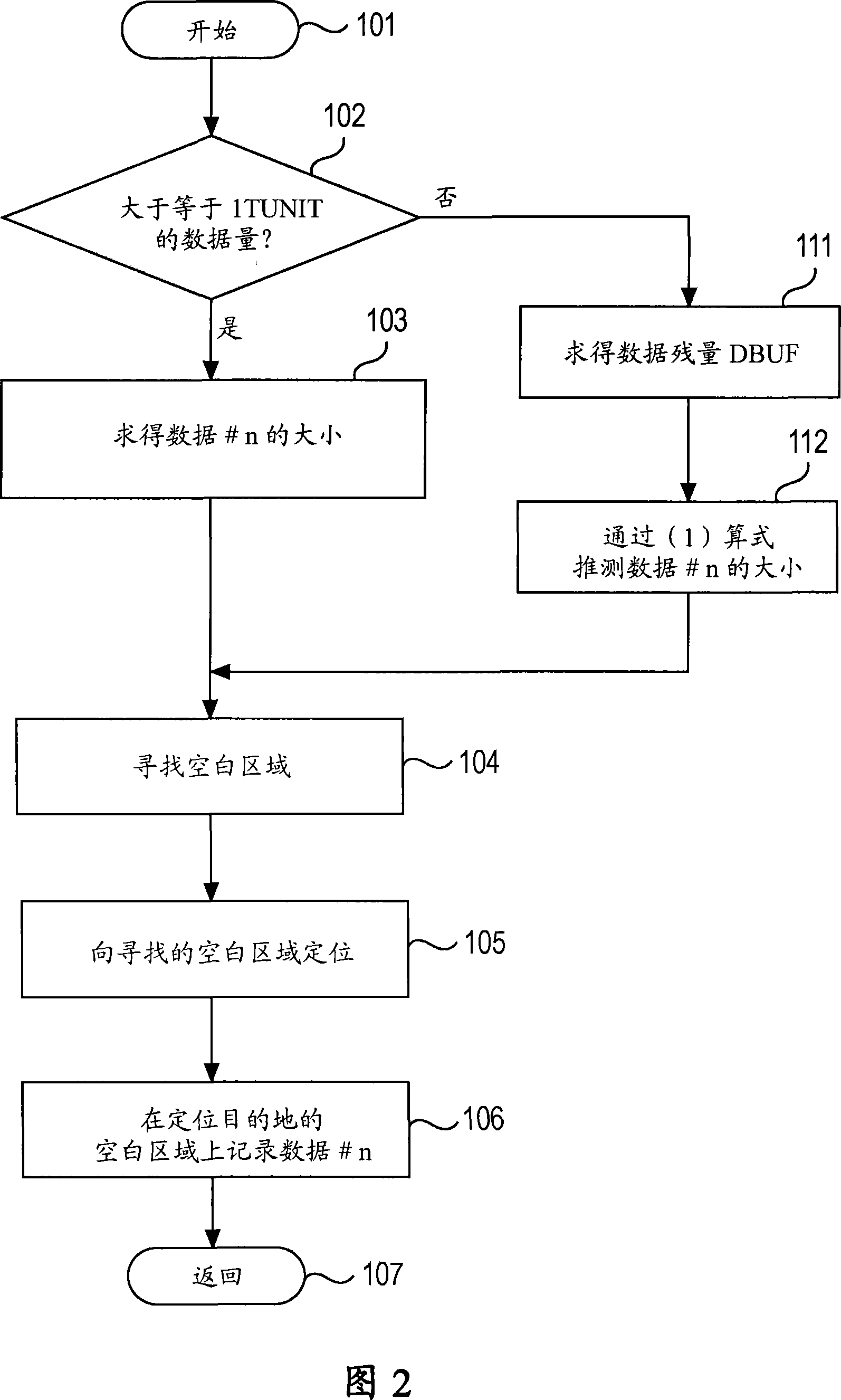

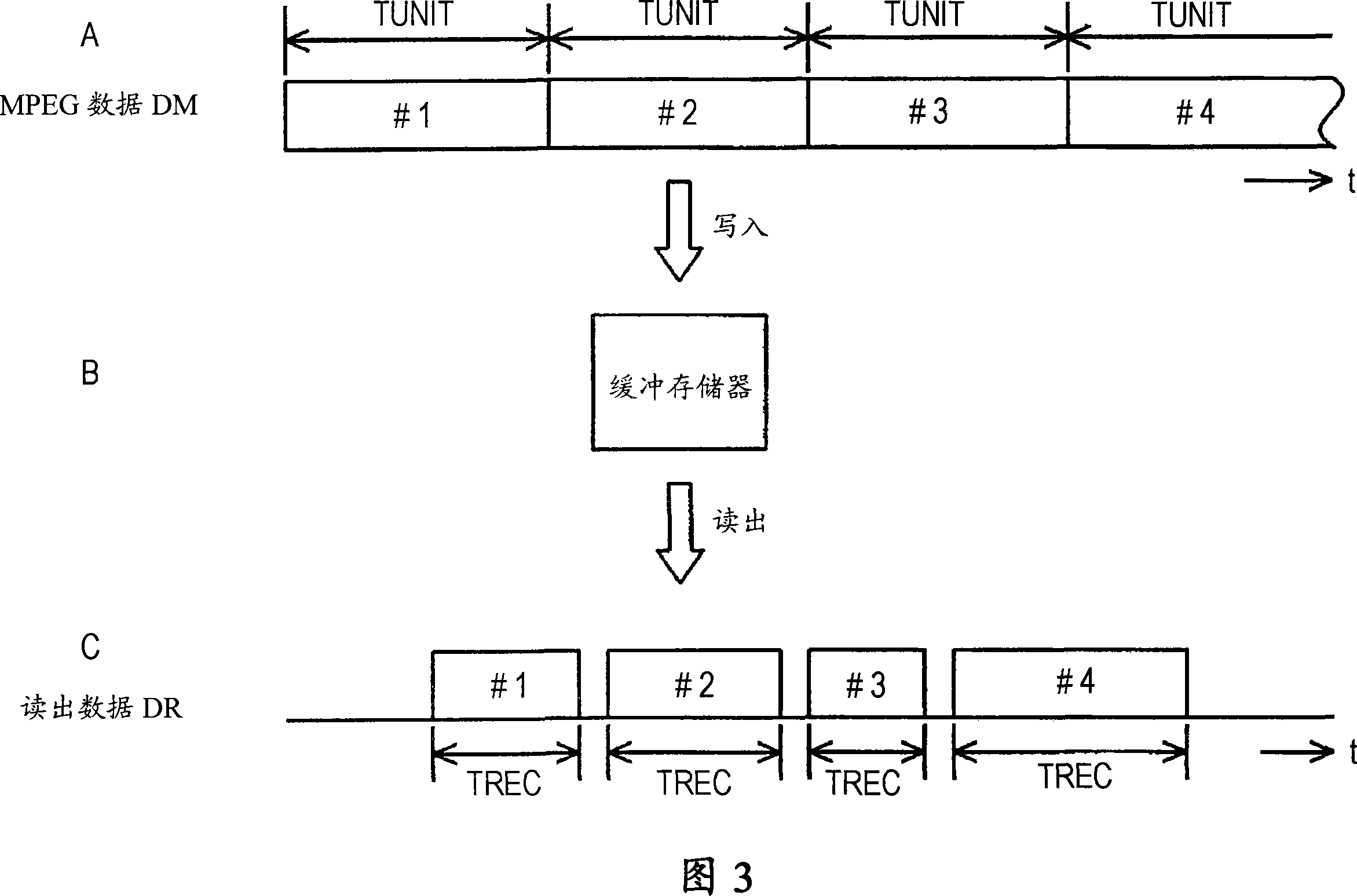

Digital data recording device and recording method

InactiveCN1989562AEasy to useEffective capacityData buffering arrangementsRecord information storageDigital dataBit rate

When dividing digital data of variable bit rate into continuous areas of unit periods, it is possible to suppress generation of fragmentation. When the data amount of the buffer memory is equal to or above the unit period, the digital data is read out from the buffer memory by the unit period and the digital data which has been read out is recorded as a continuous area (step 106). When the data amount of the buffer memory is smaller than the unit period, the data amount is predicted from the time corresponding to the digital data amount smaller than the unit period and from the length of the unit period (step 112). The digital data of the unit period is recorded in a recording-enabled area capable of continuously recording the digital data of the predicted data amount (step 106).

Owner:SONY CORP

Dedusting and decoking device and method for high-tar and high-dust high-temperature gas

ActiveCN105861077BEfficient removalExtended service lifeDispersed particle filtrationTransportation and packagingCombustionTar

The invention relates to a high-tar high-dust high-temperature gas dedusting and decoking device and method thereof, including a filtering device; a shell device for accommodating the filter; a blowback device for cleaning the dust on the filter; wherein , also includes a high-temperature gas circulation device, the high-temperature gas circulation device includes a circulating gas heating device for heating the purified gas coming out of the filter, the inlet port of the circulating gas heating device is connected with the outlet of the filter, and the circulating gas heating device The outlet end of the device communicates with the shell device, and the circulating gas heating device is provided with a gas supply device for supplementing oxygen-containing gas. The device of the present invention can effectively remove the dust and tar pollution on the filter by setting the combination of back blowing and combustion, effectively improve the service life of the filter and the filtering efficiency, and reduce the regeneration time of the filter from 60h To 10h, the service life of the filter has been increased by more than 50%.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

Fuel additive containing porphyrin metal complex as well as preparation method and application of fuel additive

PendingCN114317050AFix passive regeneration failureImprove solubilityOrganic chemistryLiquid carbonaceous fuelsPhysical chemistryOil additive

The invention discloses a fuel additive containing a porphyrin metal complex as well as a preparation method and application of the fuel additive. The fuel additive is prepared from components including solvent oil, an amine detergent and a porphyrin metal complex, and can effectively solve the problem of passive regeneration failure of a diesel engine particulate filter (DPF) and reduce the number of times of active regeneration, so that the effects of maintaining the DPF, saving oil and reducing the number of times and cost of maintenance are achieved.

Owner:天津悦泰石化科技有限公司

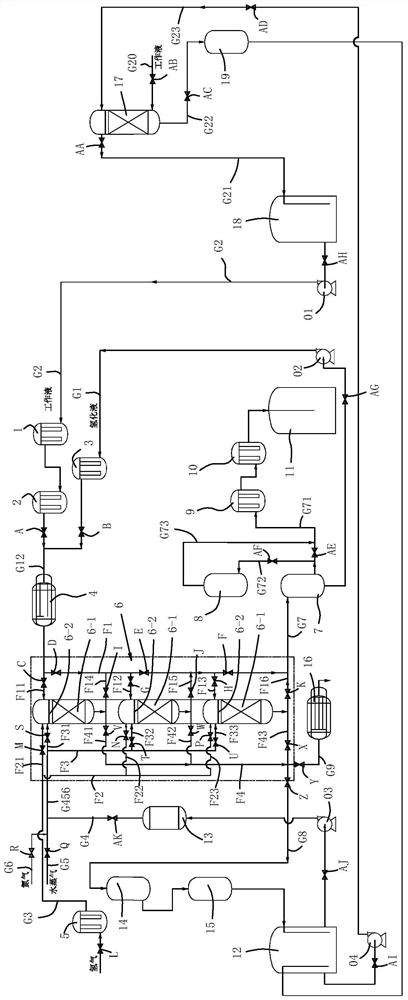

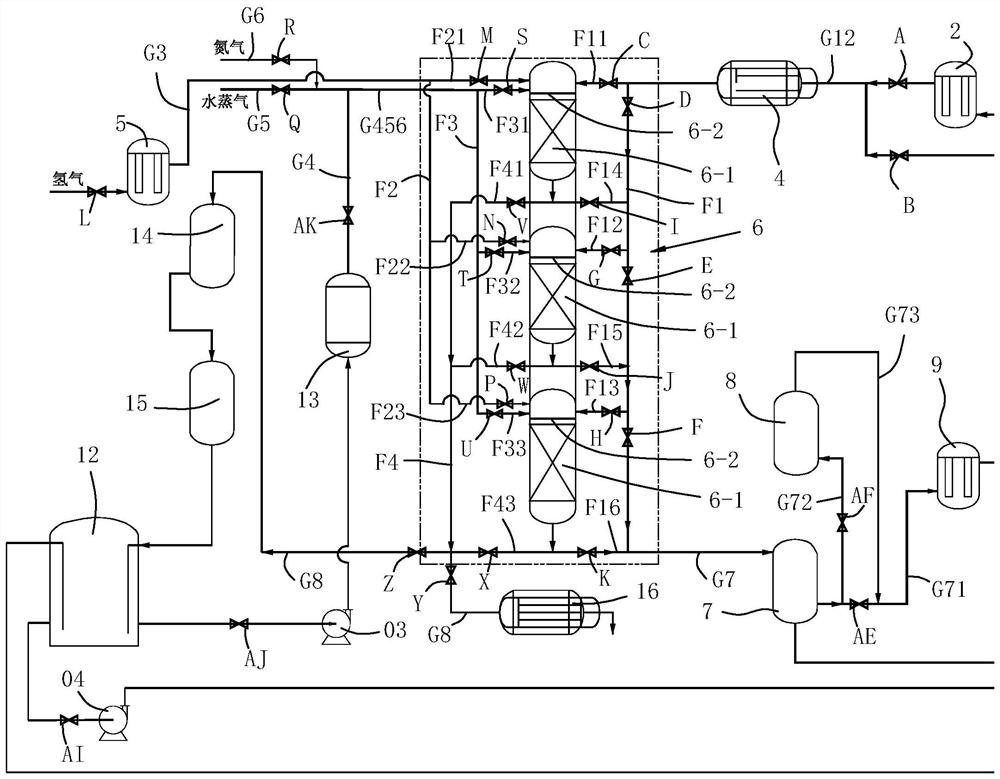

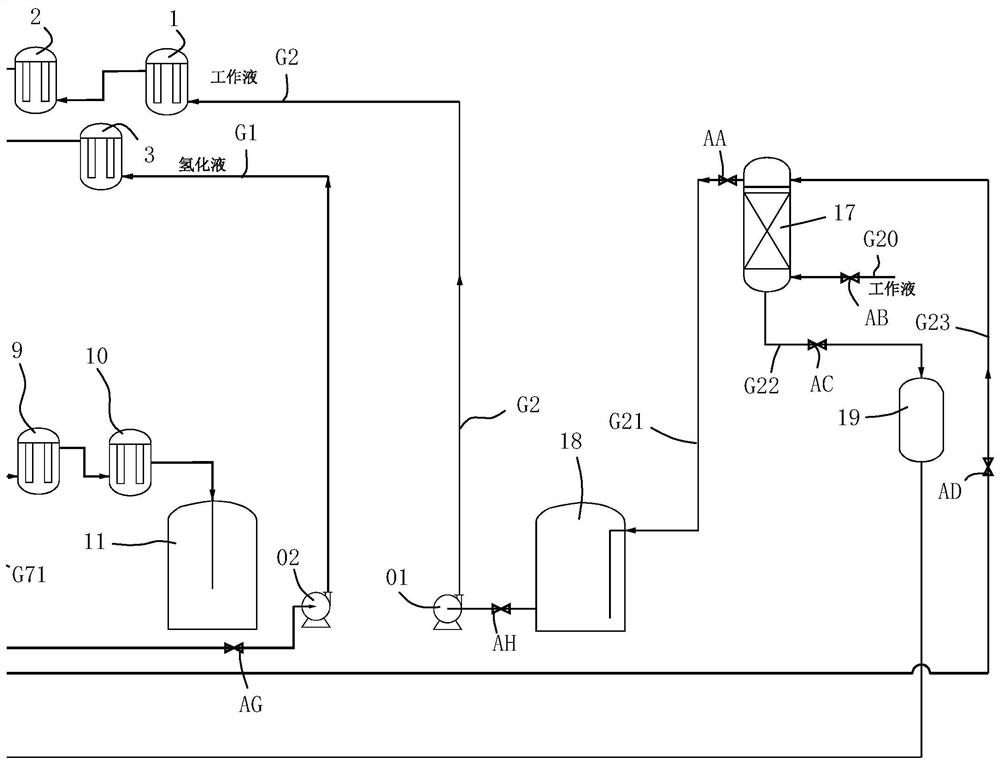

Method for prolonging service life of palladium catalyst of hydrogenation tower and hydrogenation tower system thereof

PendingCN113413834APrevents reduction of catalyst activityImprove regenerative abilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingPtru catalystVapor–liquid separator

The invention discloses a method for prolonging the service life of a palladium catalyst of a hydrogenation tower and a hydrogenation tower system thereof. The method for prolonging the service life of the palladium catalyst by using the hydrogenation tower system comprises the following steps: 1, filtering a working solution; 2, mixing with hydrogenation liquid, preheating by a working liquid preheater, and mixing with hydrogen; 3, inputting into a hydrogenation tower which consists of three sections of hydrogenation tower units, two sections of the three sections of hydrogenation tower units being in an up-and-down serial use state, and the other section being always in a regeneration state or a standby state after regeneration; 4, the working solution and hydrogen entering the hydrogenation tower sequentially enter two sections of hydrogenation tower units, then flowing out from the tower bottom of the hydrogenation tower units and entering a hydrogenation liquid gas-liquid separator; 5, hydrogenated liquid in the hydrogenated liquid gas-liquid separator being filtered and then entering a hydrogenated liquid storage tank; and 6, regenerating the palladium catalyst. The use cycle of the palladium catalyst can be prolonged, the production cost is reduced, the economic benefit and the social benefit are greatly improved, and sewage discharge is reduced.

Owner:HANGZHOU MINGXIN HYDROGEN PEROXIDE

Method for establishing hematopoietic stem cells bank by extracting hematopoietic cells from placenta tissues

InactiveCN1195055CIncrease the number ofSave livesMammal material medical ingredientsBlood/immune system cellsHematopoietic cellEnzyme digestion

A process for extracting hemopoietic stem cells from the placenta of healthy puerperant to create hemopoistic stem cell bank features that the mechanical, enzyme digestive and monoclonal antibody-magnetic bead method is used to extract blood stem cells from placenta, and concentrate and purify them. Its advantages are high activity and high concentration.

Owner:上海厚东生物科技有限公司

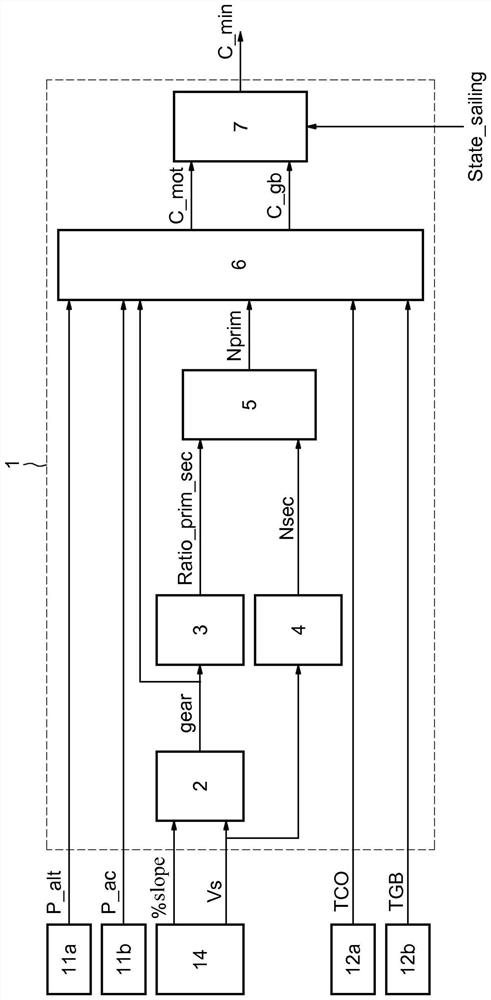

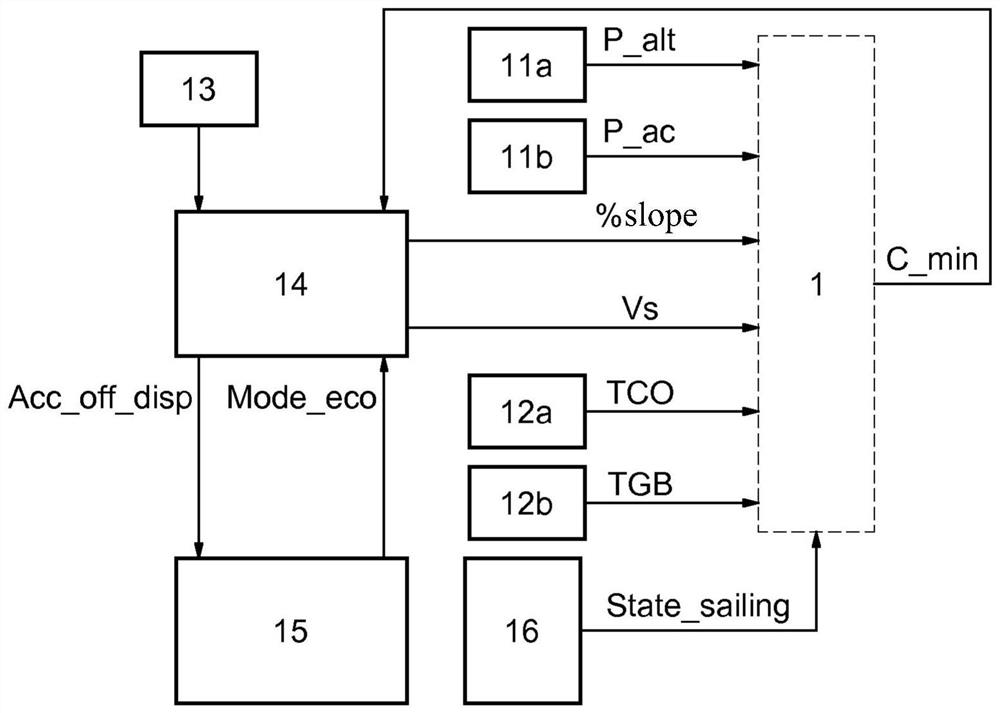

System for calculating the minimum torque at the wheel of a motor vehicle and system for determining the moment at which the foot is lifted from the accelerator using such a calculation system

PendingCN111801259AReduce consumptionExtend regeneration timeRoad transportVehicle sub-unit featuresPower sensorAlternator

The invention relates to a system for calculating the minimum torque at the wheel of a motor vehicle provided with at least one temperature sensor of the engine (12a) and of the transmission fluid (12b), at least one power sensor of the alternator (11a) and at least one the air-conditioning system (11b), and at least one driving assistance computer (14). A calculation system comprising: a determining means (2) for determining the gear engaged as a function of the slope on which the vehicle is driving and the speed of the vehicle coming from the driving assistance computer (14); a means for determining (3) a ratio between the speed of rotation of the input shaft and the speed of rotation of the output shaft of the drive train as a function of the gear engaged; a calculation means (4) for calculating a speed of rotation of the output shaft as a function of the speed of the vehicle; a calculation means (5) for calculating the speed of rotation of the input shaft as a function of the ratioand the speed of rotation of the output shaft; a calculation means (6) for calculating the resisting torque of the engine and the drag of the gearbox as a function of the power of the alternator, thepower of the air-conditioning air compressor, the engine temperature, the temperature of the transmission fluid, the gear engaged and the speed of rotation of the input shaft; and a calculation means(7) for calculating the minimum torque as a function of the resisting torque of the engine, the drag of the gearbox and the state of the sailing mode.

Owner:RENAULT SA

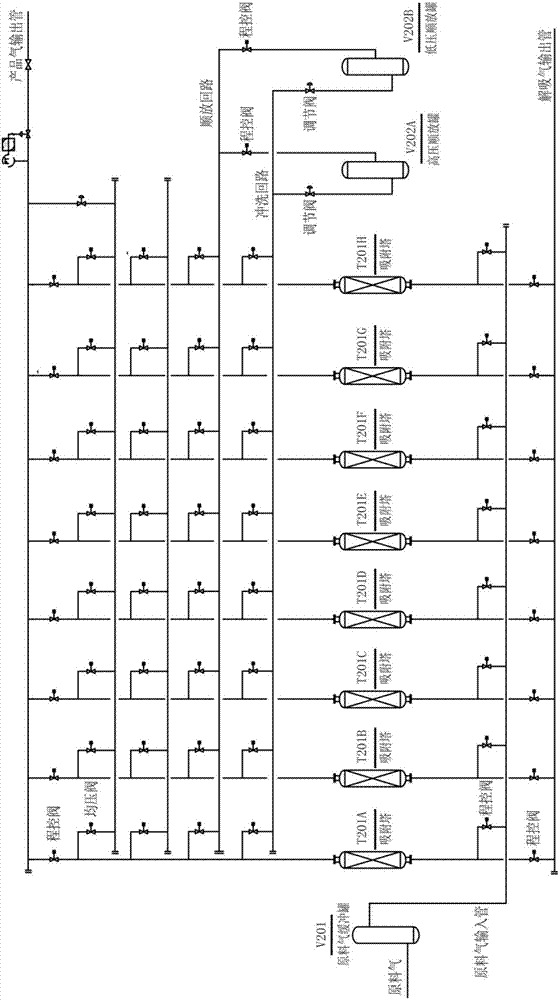

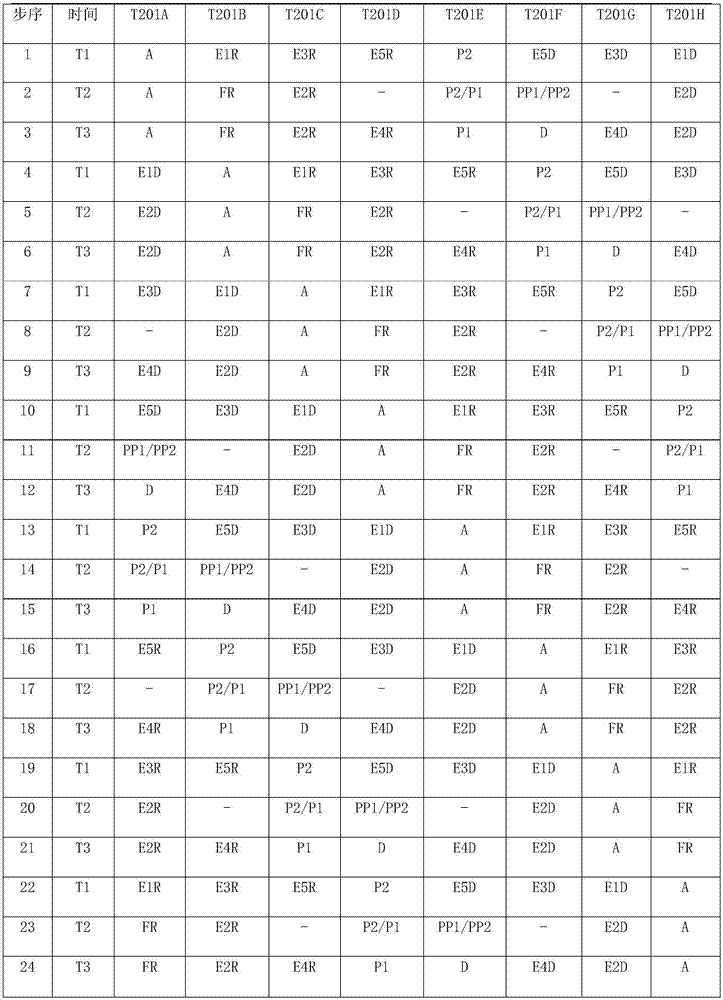

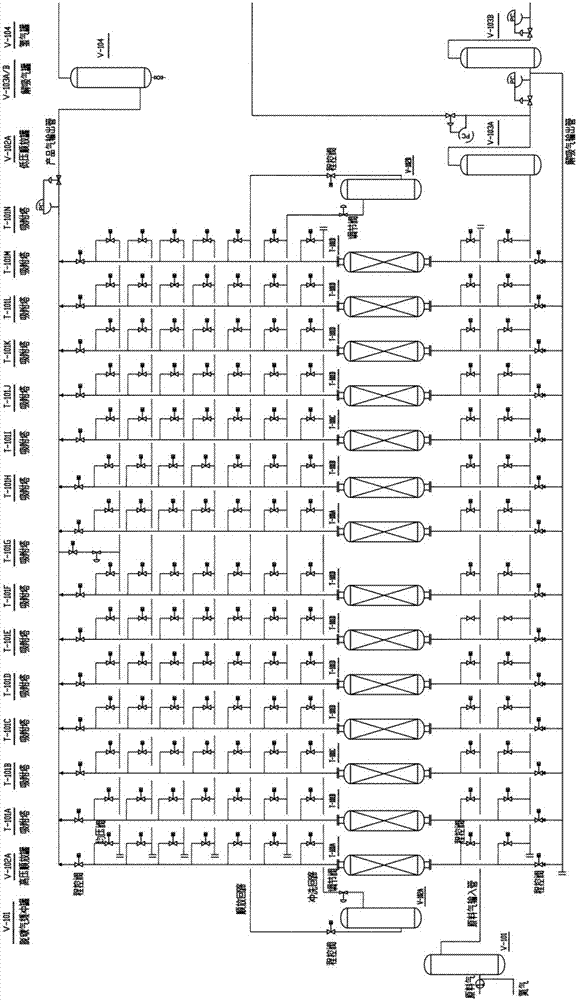

Multi-tower pressure swing adsorption grading flushing device and method

InactiveCN107511026AOvercoming defects in craftsmanshipExtend regeneration timeGas treatmentDispersed particle separationFlushing timeProduct gas

The invention discloses a multi-tower pressure swing adsorption grading flushing device and a method. Two concurrent discharge vessels are connected with an adsorption tower; one vessel is a high-pressure concurrent discharge vessel for storing product gas in higher purity and the other vessel is a low-pressure concurrent discharge vessel for storing product gas in lower purity; adjusting valves for adjusting the flushing flux are arranged at an outlet of the high-pressure concurrent discharge vessel and at the outlet of the low-pressure concurrent discharge vessel; the product gas in lower purity in the low-pressure concurrent discharge vessel is firstly used for flushing and then the product gas in higher purity in the high-pressure concurrent discharge vessel is used for later flushing in the flushing process; the flushing time is adjusted according to the pressure of the high-pressure concurrent discharge vessel and the low-pressure concurrent discharge vessel, so that the complete gas exhausting in the flushing process is guaranteed; the practical running regenerating effect is excellent; and the impurity content in the product gas can be effectively controlled.

Owner:CHENGDU JUTAO OIL ENG CO LTD +1

A device and method for regeneration of powdered activated carbon

ActiveCN103752296BImprove removal efficiencyImprove decolorization efficiencyOther chemical processesCombustible gas purificationActivated carbonCombustion

The invention discloses a device and a method for regeneration of powdered activated carbon. The device comprises a furnace body, wherein a retractable furnace door is arranged on the furnace body; an internal hollow hearth is arranged inside the furnace body; insulating layers are arranged at the four walls and the periphery of the top part of the hearth; heating wires are embedded in the insulating layers. The device is characterized by also comprising an exhaust and tail gas combustion treatment system, an intake valve, a bracket structure, more than one drawer-type box body and a gas outlet valve, wherein the bracket structure is fixedly arranged inside the hearth; the drawer-type box body is detachably arranged on the bracket structure; the exhaust and tail gas combustion treatment system is fixedly arranged at the top part of the furnace body; the intake valve is fixedly arranged at the top of the furnace body; the gas outlet valve is fixedly arranged at the bottom of the furnace body. Compared with the prior art, the regeneration treatment efficiency can be greatly improved, energy consumption and time are saved, and the operation is simple and feasible.

Owner:HUBEI JUNJI WATER TREATMENT

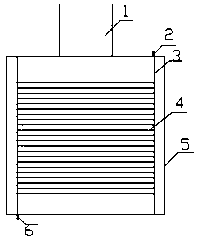

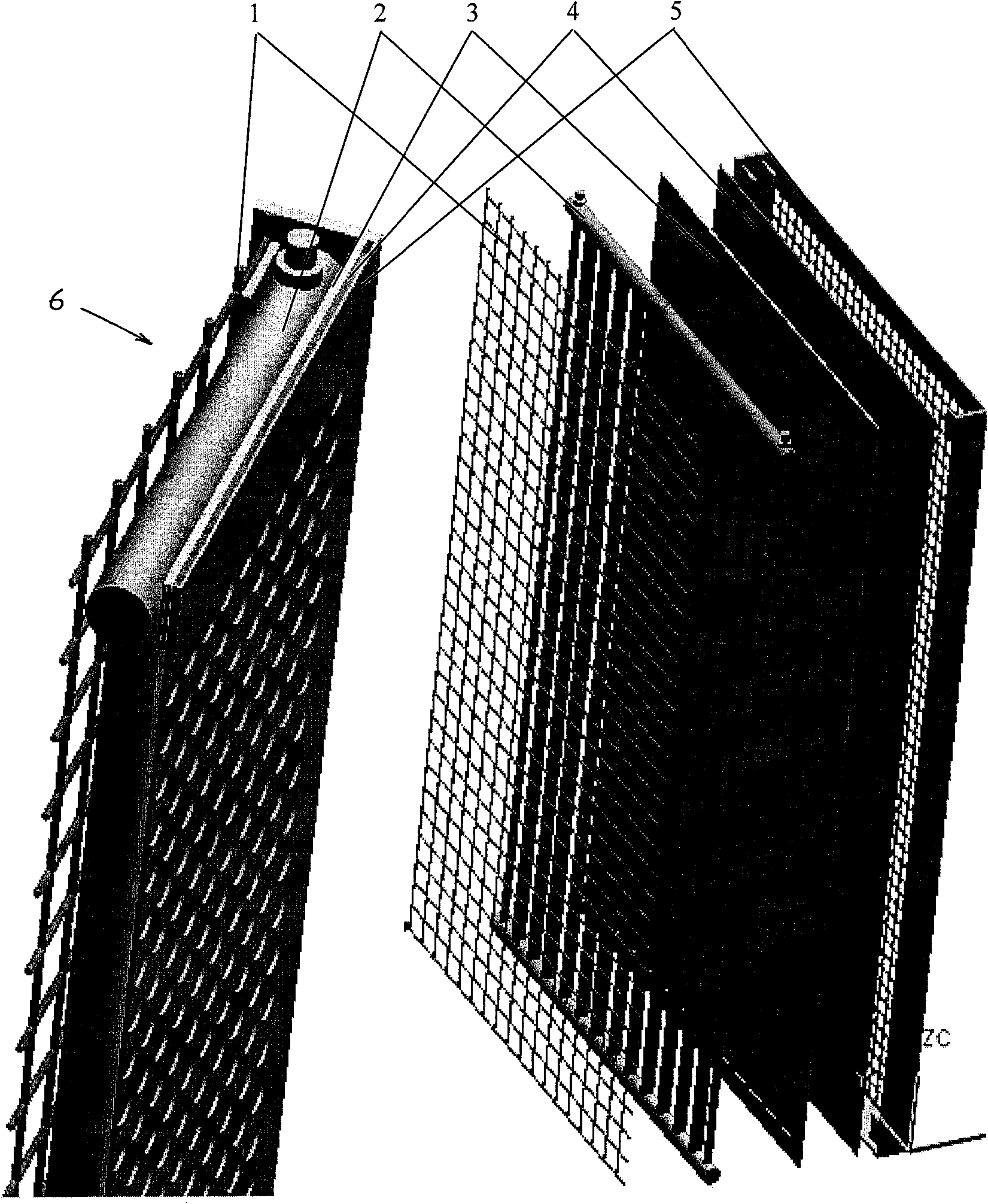

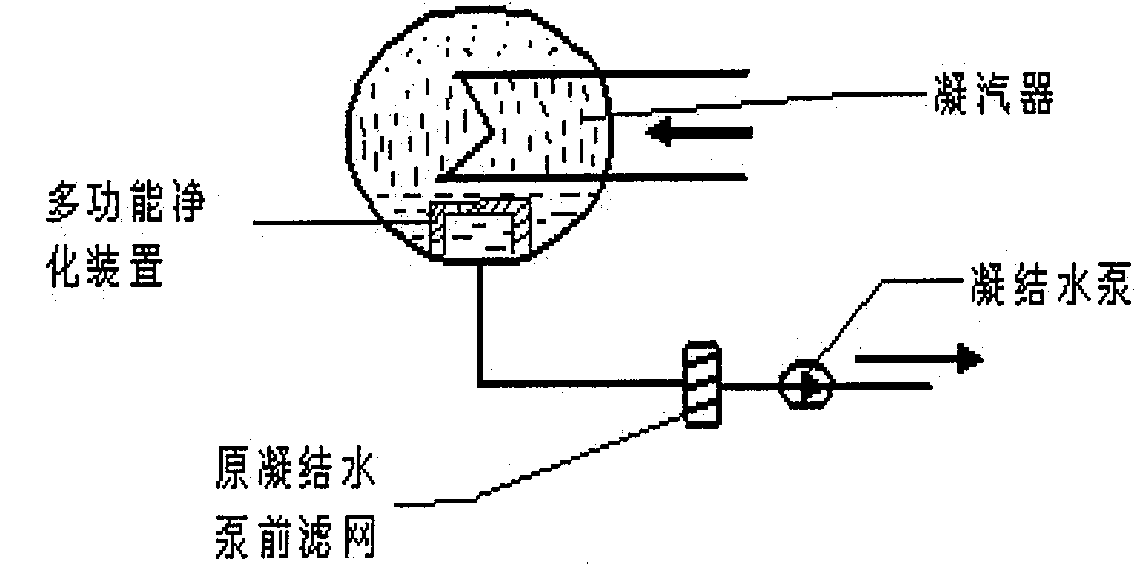

Multifunctional purification apparatus in condenser of power plant

ActiveCN101693156BSpeed up iron removal and purificationExtend regeneration timeFiltration separationPower stationEngineering

The invention relates to a multifunctional purification apparatus in a condenser of a power plant, which is mounted in the upper part of a water outlet in the condenser. The multifunctional purification apparatus is a hollow cubical purification apparatus assembled by a plurality of purification modules in the condenser. From the outer side to the inner side, the modules are divided into five layers: the first layer is an eddy current resisting apparatus made by stainless steel bars or steel discs; the second layer is a magnetic field screen which is made by permanent magnetic pipes and has the function of deferrization; the third layer is a stainless steel screen having the function of fine filtering; the fourth layer is a stainless steel orifice having the function of coarse filtering; and the fifth layer is an oblate cubical framework-framework orifice made by porous stainless steel plates with intervals in the middle, and the fifth layer has no top surface or front surface but other four surfaces. The five layers form the multifunctional purification modules which are assembled to form a sealed purification apparatus. The invention can accelerate deironing purification of condensed water in starting a steam turbine generator unit, reduce emission, save energy, and prolong the service life of resins.

Owner:北京圣朗玛磁选技术有限公司

A desulfurization control method, device, storage medium and electronic equipment

ActiveCN111140319BExtend regeneration timeTo achieve the effect of desulfurization in advanceGas treatmentInternal combustion piston enginesSulfidationProcess engineering

Owner:WEICHAI POWER CO LTD

Filtering method and filtering device with alternating electric field on filter element

ActiveCN102380250BReduce the rate of formationImprove stabilitySemi-permeable membranesStationary filtering element filtersEngineeringElectric field

The invention discloses a filtering method, which not only can prevent charged particles from polluting a filter element, but also can increase filtering stability. The method includes that alternating voltage of 10Hz to 50Hz is applied between the filter element and a shell of a filtering device when substances to be filtered realize gas-solid or liquid-solid separation via the filtering device. Under the action of the alternating electric field, the charged particles in the filtering device move repeatedly, as masses of the particles are different and flowing speeds of the particles under the action of the same force are different, the particles with different masses can be separated within a certain space, so that the particles with different masses are successively distributed between the filter element and the shell, and the integral filtering stability is increased. The invention further provides a filtering device comprising a shell and a filter element which are insulated from each other, and the shell and the filter element are respectively connected with two output poles of a power polarity converting circuit with the alternating frequency of 10Hz to 50Hz.

Owner:CHENGDU INTERMENT TECH

A system and method for oil and gas recovery with asymmetric double-tank adsorption and desorption

ActiveCN106310699BReduce the pumping volumeExtend regeneration timeGas treatmentDispersed particle separationActivated carbonRecovery method

The invention discloses a recovery system and a recovery method for an oil gas absorbed and desorbed by asymmetric double pots. The recovery system comprises a first stop valve, a first-level oil gas condenser, a second-level oil gas condenser, a second stop valve, a first-level big activated carbon canister and a third stop valve, wherein an oil gas inlet is connected with one end of the first stop valve; a positive input end of the first-level oil gas condenser is connected with the other end of the first stop valve; a positive output end of the first-level oil gas condenser is connected with an input end of the second-level oil gas condenser; an output end of the second-level oil gas condenser is connected with a negative input end of the first-level oil gas condenser; a negative output end of the first-level oil gas condenser is connected with one end of the second stop valve; the other end of the second stop valve is connected with one end of the first-level big activated carbon canister; one end of the third stop valve is connected with the other end of the first-level big activated carbon canister; the other end of the third stop valve is connected with a first oil gas outlet; the first stop valve, the first-level oil gas condenser, the second-level oil gas condenser, the first-level oil gas condenser, the second stop valve, the first-level big activated carbon canister and the third stop valve are successively connected and form an oil gas recycling subsystem.

Owner:上海聚宸新能源科技有限公司

Refining agent for refining primary brine in chlor-alkali industry and its application

ActiveCN105565342BAdaptableReduce operating loadAlkali metal halide purificationChemical industryPhosphate

The invention relates to the field of the chlorine alkali chemical industry, and in particular relates to a novel refining agent for replacing an existing refining agent in a refining process of primary brine in the chlorine alkali industry. The invention aims to solve the technical problem that in the chlorine alkali chemical industry process at present, the quality of brine entering a resin tower is still not high. The technical scheme for solving the technical problem is to provide the novel refining agent used in the refining process of the brine used in the chlorine alkali industry to replace the originally used 'two-alkali' refining agent. The refining agent takes phosphate as an active ingredient. The novel refining agent is strong in adaptability, and can reduce the total amount of calcium and magnesium in the primary brine by 10 times by replacing the original refining agent, so that the operating load of the resin tower is reduced, the regeneration time of the resin tower is prolonged, then the production cost is reduced, and the refining agent has a very good application prospect.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com