Biological treatment system of sludge odor and method for treating sludge odor by utilizing same

A biological treatment and odor technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problem of no odor treatment, etc., to prolong regeneration time, prevent filler deformation, and ensure the effect of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

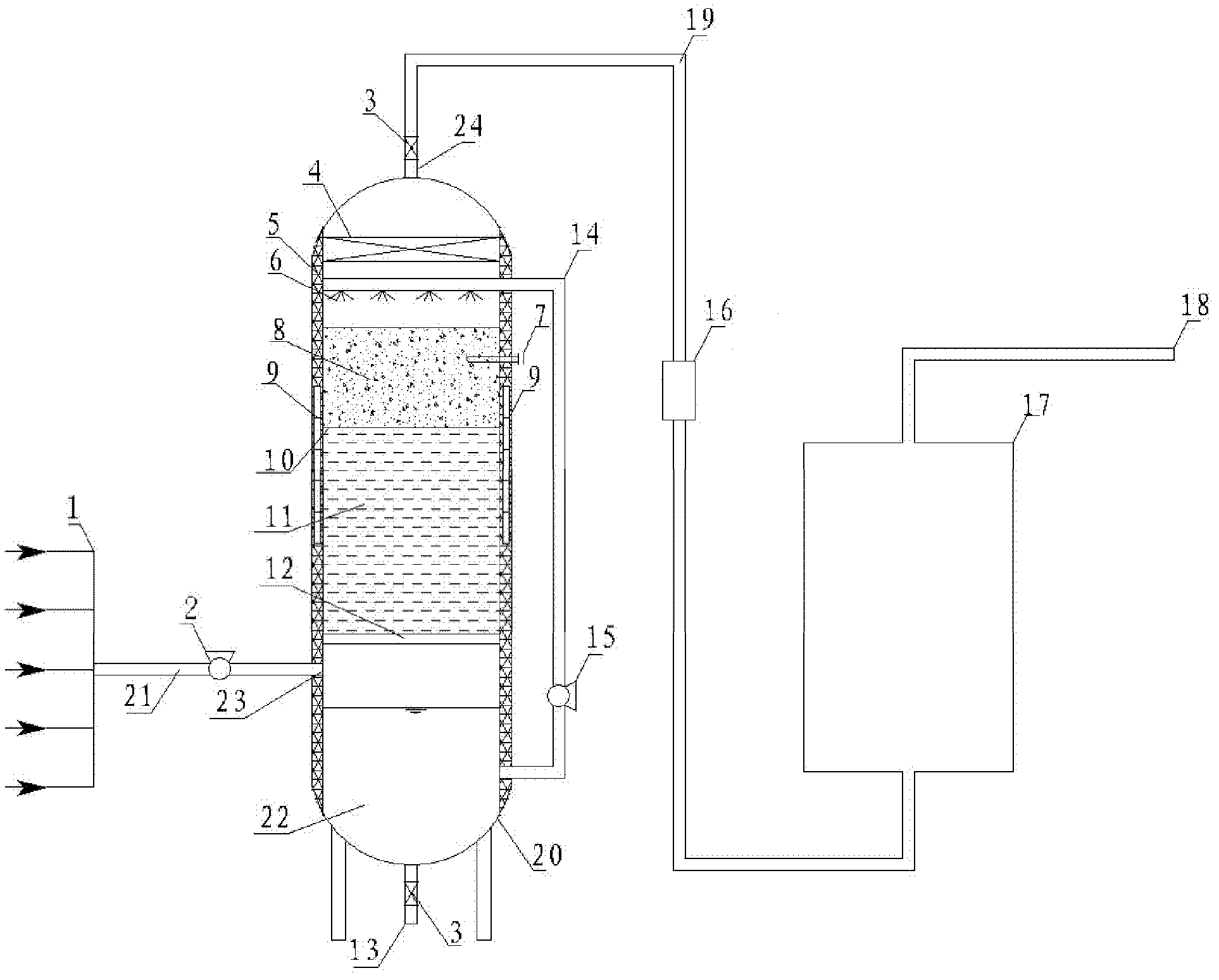

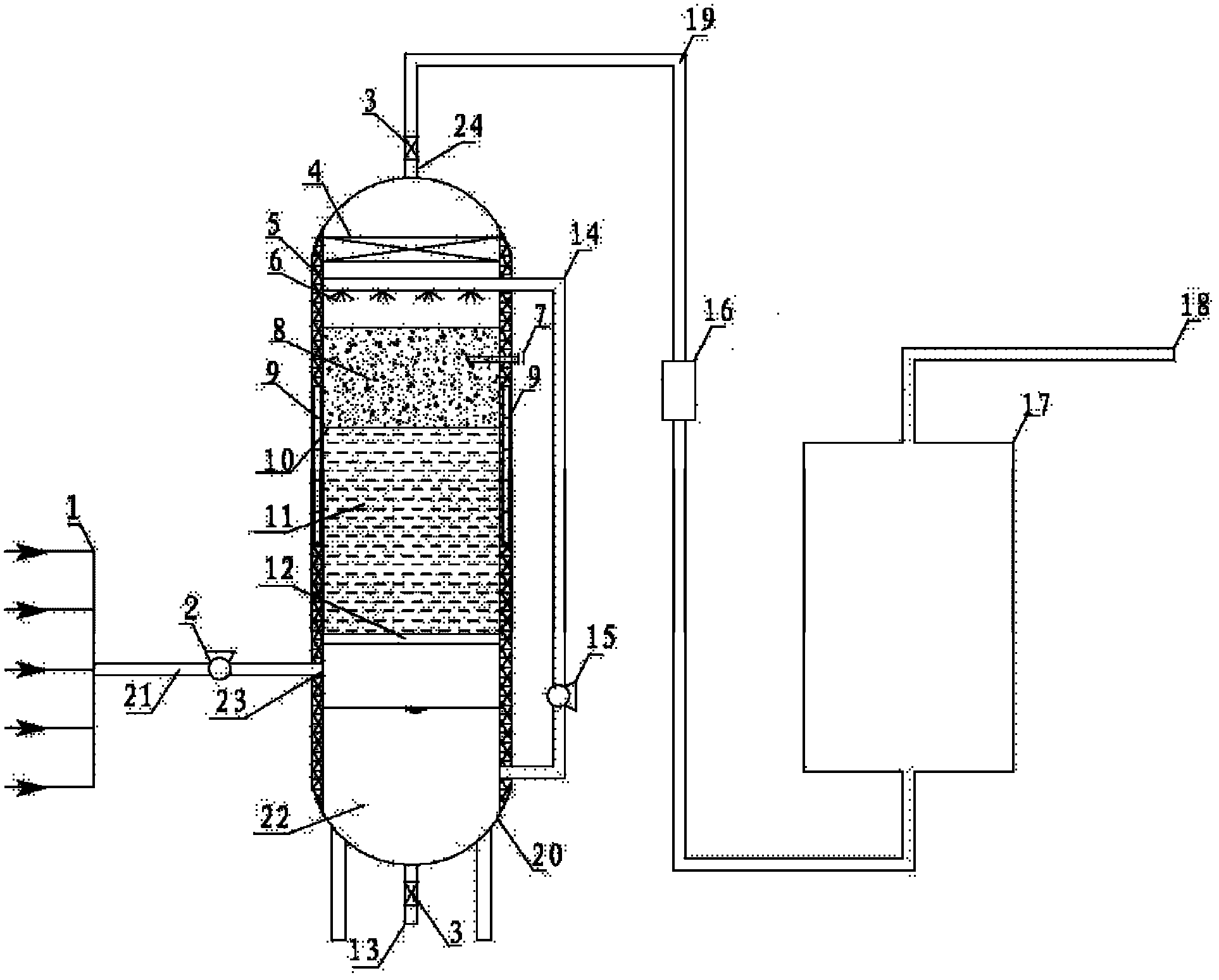

[0037]Embodiment 1: The biological treatment system for sludge odor in this embodiment includes an odor collection device 1, an odor fan 2, an air inlet pipe 21, a biological deodorization tower 20, an outlet pipe 19, an activated carbon adsorption device 17, and a gas monitor 16 and discharge pipe 18; Wherein odor collecting device 1 links to each other with biological deodorization tower 20 through inlet pipe 21, is provided with odor blower 2 on inlet pipe 21; Biological deodorization tower 20 is connected with activated carbon adsorption device 17 through outlet pipe 19 The inlet is connected, the discharge pipe 18 is arranged on the outlet of the activated carbon adsorption device 17, and the gas monitor 16 is arranged on the outlet pipe 19.

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the biological deodorization tower 20 is provided with an odor outlet 24, an insulation layer 5, a heating pipe 9, a delivery pipe 14, a nozzle 6, and a hard filler 8 , temperature measuring probe 7, support 10, soft filler 11, ventilating partition 12, odor inlet 23, nutrient solution section 22, discharge outlet 13; Wherein the tower wall of biological deodorization tower 20 is provided with insulation layer 5, in insulation The middle part of the layer 5 is provided with a heating pipe 9; the top of the tower is provided with an odor outlet 24, and a ball valve 3 is arranged on the odor outlet 24; the soft packing 11 is arranged on the breathable partition 12, and the hard packing 8 is arranged Above 11, a bracket 10 is set between the hard packing 8 and the soft packing 11; one end of the delivery pipe 14 passes through the tower wall of the biological deodorization tower 20 and communicate...

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the biological deodorization tower also includes a wire mesh demister 4, and the wire mesh demister 4 is arranged between the nozzle 6 and the odor outlet 24 between. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com