Multifunctional purification apparatus in condenser of power plant

A purification device and condenser technology, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of resin regeneration, mechanical impurities, high cost, reduce vacuum system links, prolong service life and The effect of regeneration time and speeding up the time to generate more power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

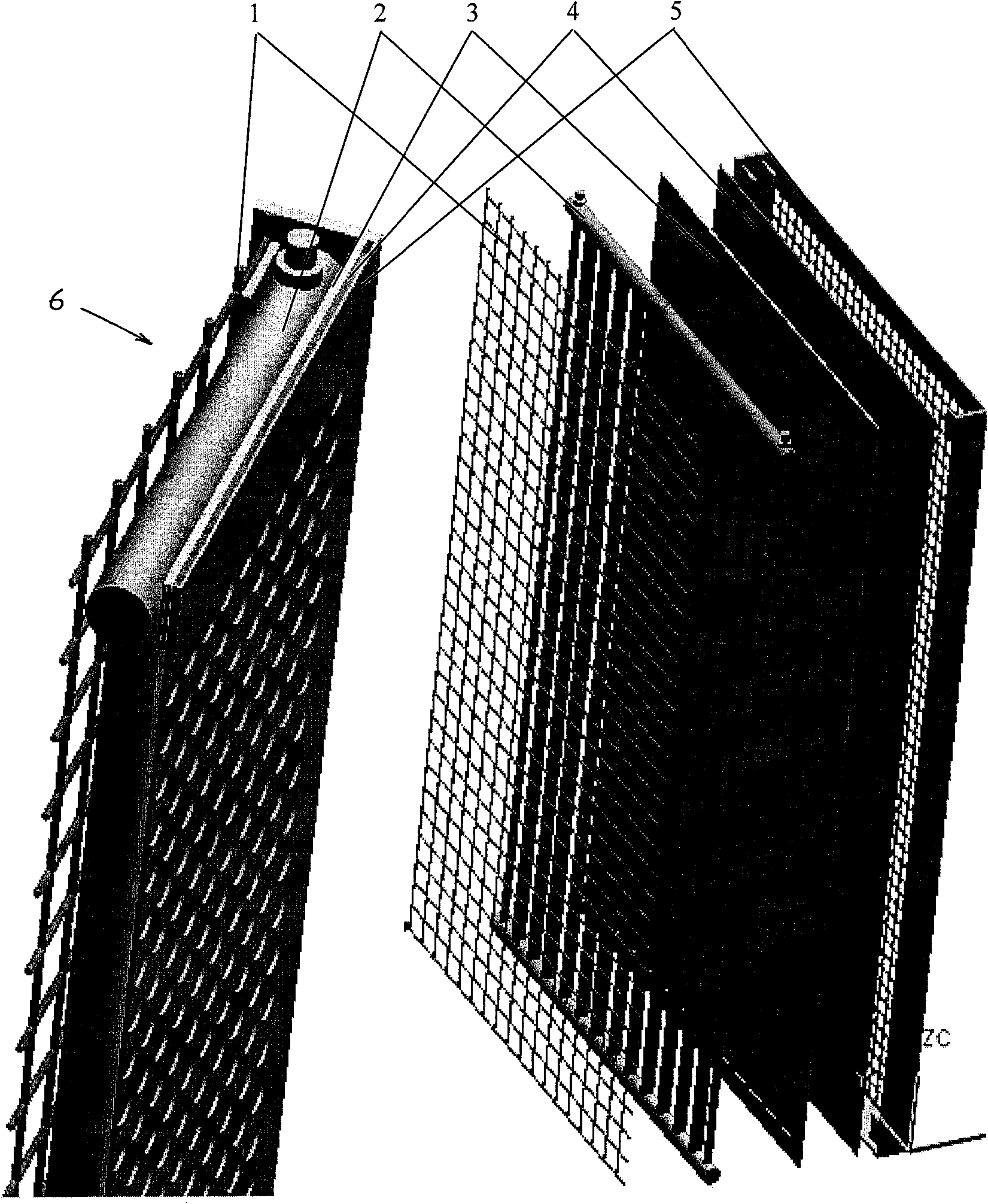

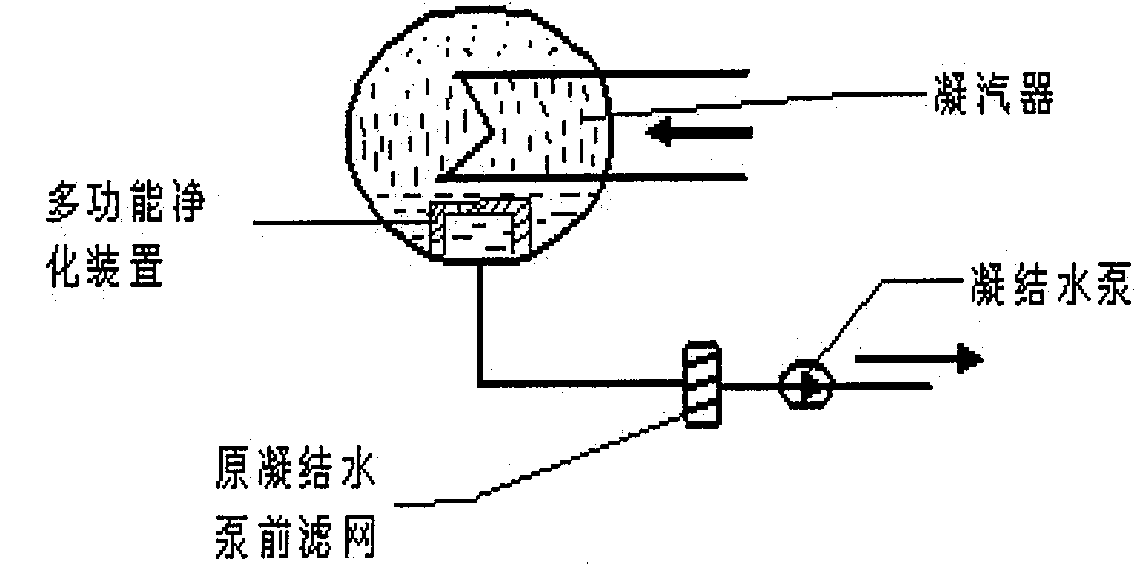

[0024] see Figure 10 , In order to solve the adverse effects of impurities, a multifunctional purification device is installed in the condenser, which can not only remove iron impurities generated during operation, but also remove other mechanical impurities left in the system during equipment installation and maintenance. For the convenience of the φ500mm manhole door for installation, maintenance and cleaning, it is designed as a module, and then assembled in the condenser. It can replace the traditional mechanical filter installed in the inlet pipe of the condensate pump, eliminating the resistance loss caused by this type of mechanical filter. Due to the large space in the condenser, the multi-functional purification device installed in this space can be made into a filtration and purification area 10 to 20 times larger than the area of the filter screen in front of the traditional condensate pump. The larger the purification area, the lower the resistance, which can ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com