A system and method for oil and gas recovery with asymmetric double-tank adsorption and desorption

An oil and gas recovery system and asymmetric technology, which are applied in the field of asymmetric double-tank adsorption and desorption oil and gas recovery systems, can solve the problems such as the inability to seal the tank mouth, the reduction of internal oil and gas, and the long interval, and achieve the equipment footprint. The effect of large, saving investment cost and long regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

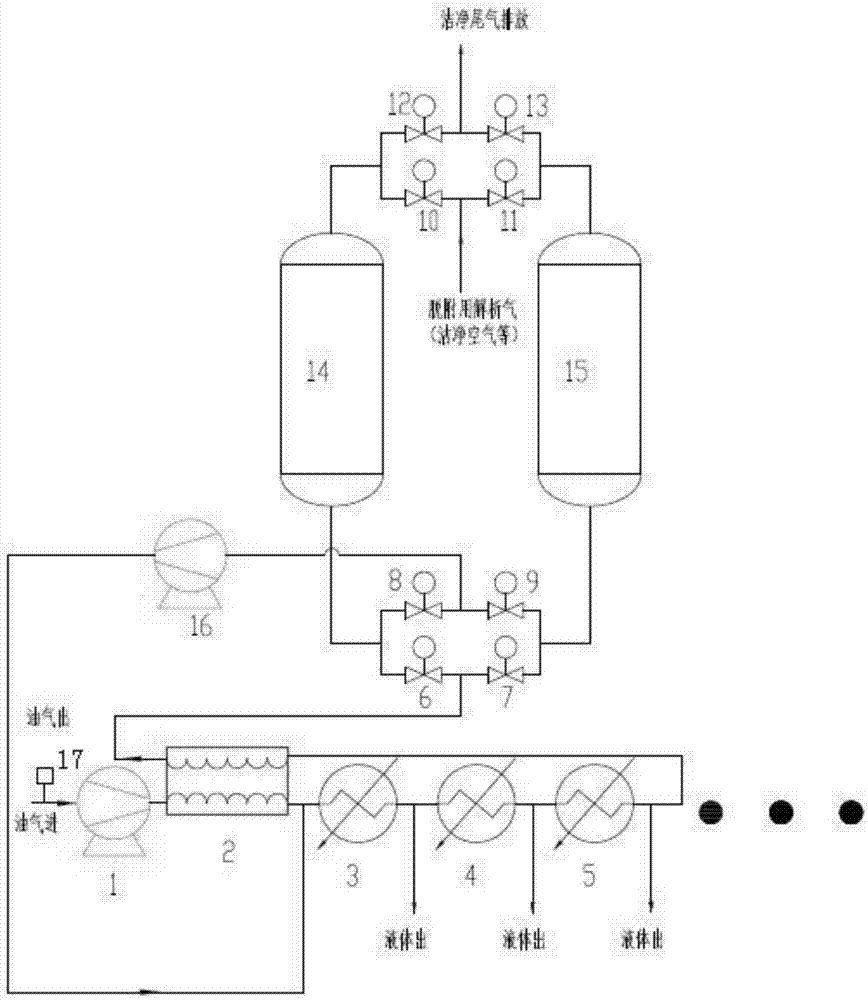

[0096] Such as Figure 4 As shown, the present invention discloses an asymmetric double tank absorption and desorption oil gas recovery system, which is used to recover the oil gas generated in the volatilization process and oil unloading process of buried tanks or storage tanks, including a first cut-off valve 1, a first-stage Oil-gas condenser 2, secondary oil-gas condenser 3, second shut-off valve 4, first-stage large activated carbon tank 5 and third shut-off valve 6, wherein:

[0097] One end of the first cut-off valve 1 is connected to the oil-gas inlet, and the other end is connected to the positive input end of the first-stage oil-gas condenser 2; the positive output end of the first-stage oil-gas condenser 2 is connected to the second-stage oil-gas condenser The input end of the device 3; the output end of the secondary oil-gas condenser 3 is connected to the reverse input end of the first-stage oil-gas condenser 2; the reverse output end of the first-stage oil-gas co...

Embodiment 2

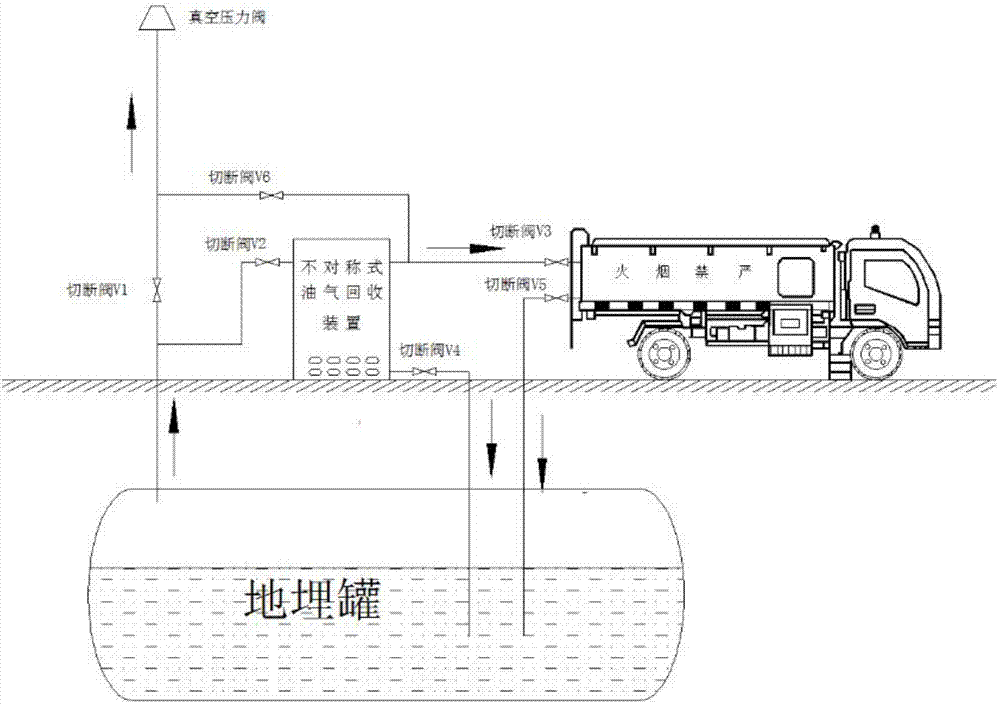

[0108] Such as Figure 5 As shown, the difference between this embodiment and the oil and gas recovery system described in Embodiment 1 is that, in addition to the vacuum pump 8, the pressure maintaining device 9, and the fourth shut-off valve 10, the system also includes a fifth shut-off valve 12 and a secondary Small activated carbon tank 13, wherein:

[0109] The inlet of the vacuum pump 8 is connected with an end of the first-stage large activated carbon tank 5, and the outlet of the vacuum pump 8 is connected with the positive input end of the first-stage oil-gas condenser 2;

[0110] One end of the pressure maintaining device 9 is simultaneously connected to the second cut-off valve 4 and the reverse output end of the primary oil-gas condenser 2, and the other end is connected to one end of the fourth cut-off valve 10;

[0111] One end of the fifth shut-off valve 12 is connected with the other end of the first-stage large activated carbon tank 5, and the other end is co...

Embodiment 3

[0116] Such as Figure 6 As shown, the present invention additionally discloses an asymmetric double tank adsorption and desorption method for oil and gas recovery, using the oil and gas recovery system described in Example 1 for oil and gas recovery, and the specific steps include:

[0117] Step 1: The oil and gas generated during unloading or tanking pass through the first cut-off valve and enter the first-stage oil and gas condenser to reduce the temperature to -10 to +10°C and remove most of the moisture in the oil and gas;

[0118] Step 2: The pre-cooled oil and gas enter the secondary oil and gas condenser, and the refrigeration device outputs cooling capacity to the secondary oil and gas condenser to reduce the temperature of the oil and gas to -10~-80°C, and part of the hydrocarbons in the oil and gas are condensed and recovered , the remaining low-temperature gas returns to the first-stage oil-gas condenser for heat exchange with the high-temperature oil-gas that ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com