No-shaft magnetic pump

A magnetic pump and shaftless technology, which is applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of complex shaft drive structure, inability to flexibly adjust, increase pump dissolution loss, etc., to meet the needs of high-power magnetic rotation, Cooling and lubricating direct and effective, widening the effect of technology development path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

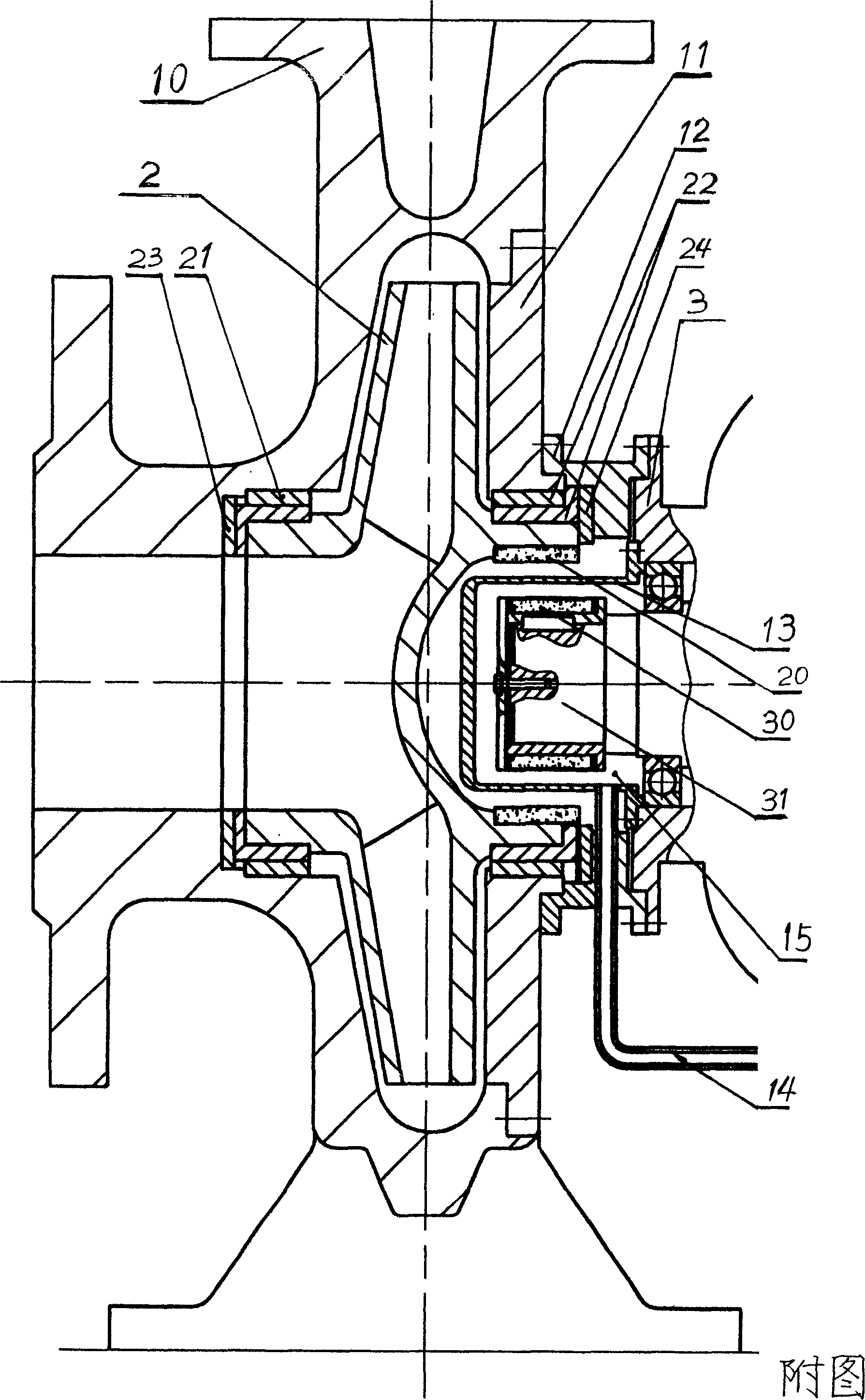

[0006] The structure of the shaftless magnetic pump of the present invention is shown in the figure, and its pump impeller 2 is assembled on the pump inlet of the pump body 10 and the side opposite to the pump inlet through the sliding bearings at both ends of the pump impeller 21, 22 and the thrust discs 23 and 24. On the pump cover 11, the drive matching end of the pump impeller 2 and the motor output shaft 31 is set as an outer magnetic rotor 20, and the motor output shaft 31 is fixedly equipped with an inner magnetic sleeve 30, so that it constitutes an inner magnet that is magnetically matched with the outer magnetic rotor 20 of the pump impeller. The magnetic rotor, the motor 3 is fixedly assembled on the pump cover 11 and the pump body 10 through the coupling frame 12, driven by the motor 3, the pump impeller 2 is driven to rotate at high speed under the action of magnetic force to realize pumping. The space between the two magnetic rotors is provided with a spacer 13, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com